Environment-friendly powder 3D printer

A 3D printer, an environmentally friendly technology, applied in the field of 3D printing, can solve the problems of difficult to deal with white garbage, ecological environment waste, etc., to solve the problem of mechanical movement interference, reduce the floor space, and solve the effect of insufficient powder space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments.

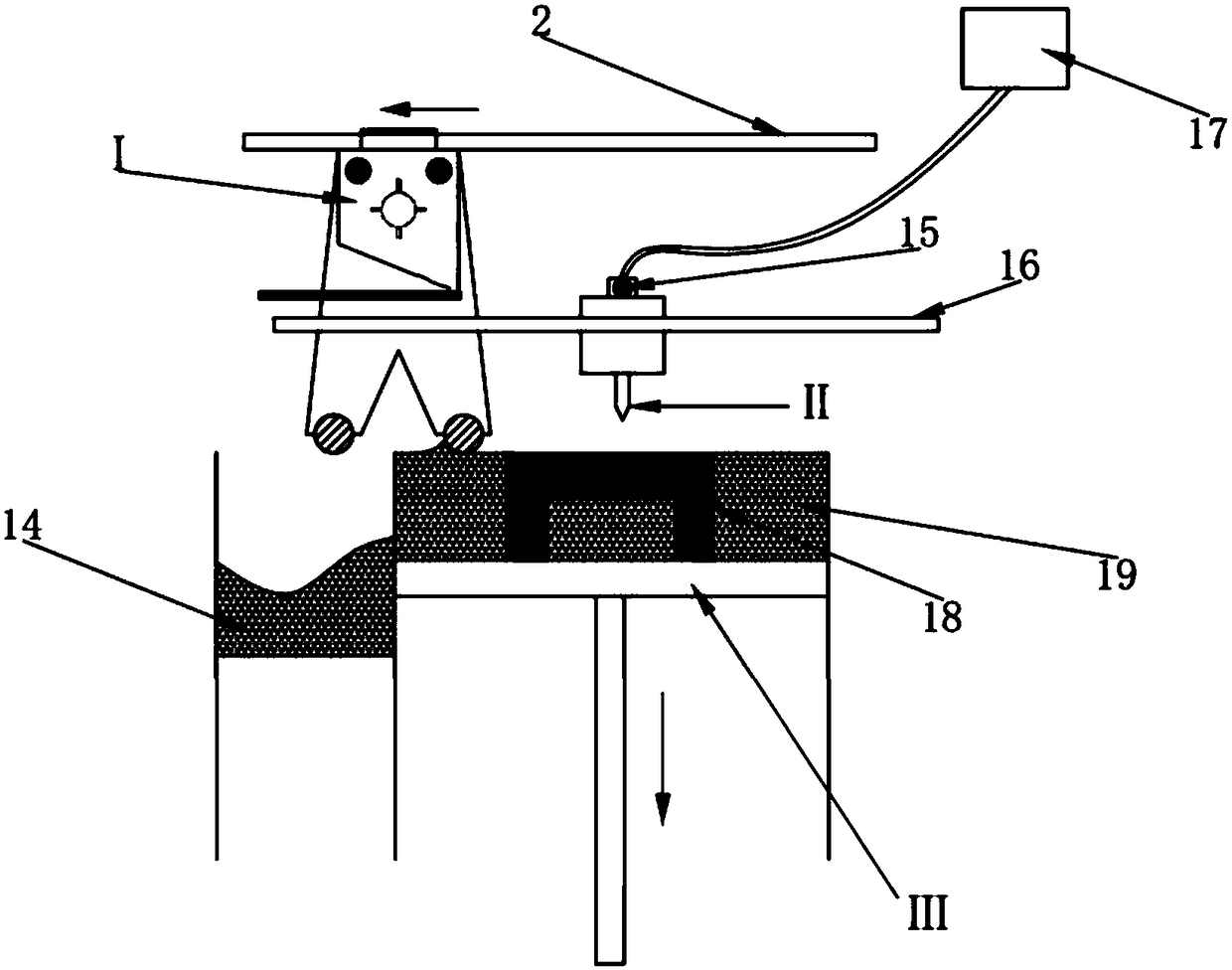

[0044] like figure 1 As shown, an environmentally friendly powder 3D printer, its main structure includes three parts: powder spreading mechanism Ⅰ, printing nozzle Ⅱ and lifting printing platform Ⅲ. The lifting printing platform III is used as a platform for carrying molded parts 18 and unbonded powder 19 in 3D printing, while the powder spreading mechanism I and printing nozzle II are used to add leaf powder and binder to the platform respectively.

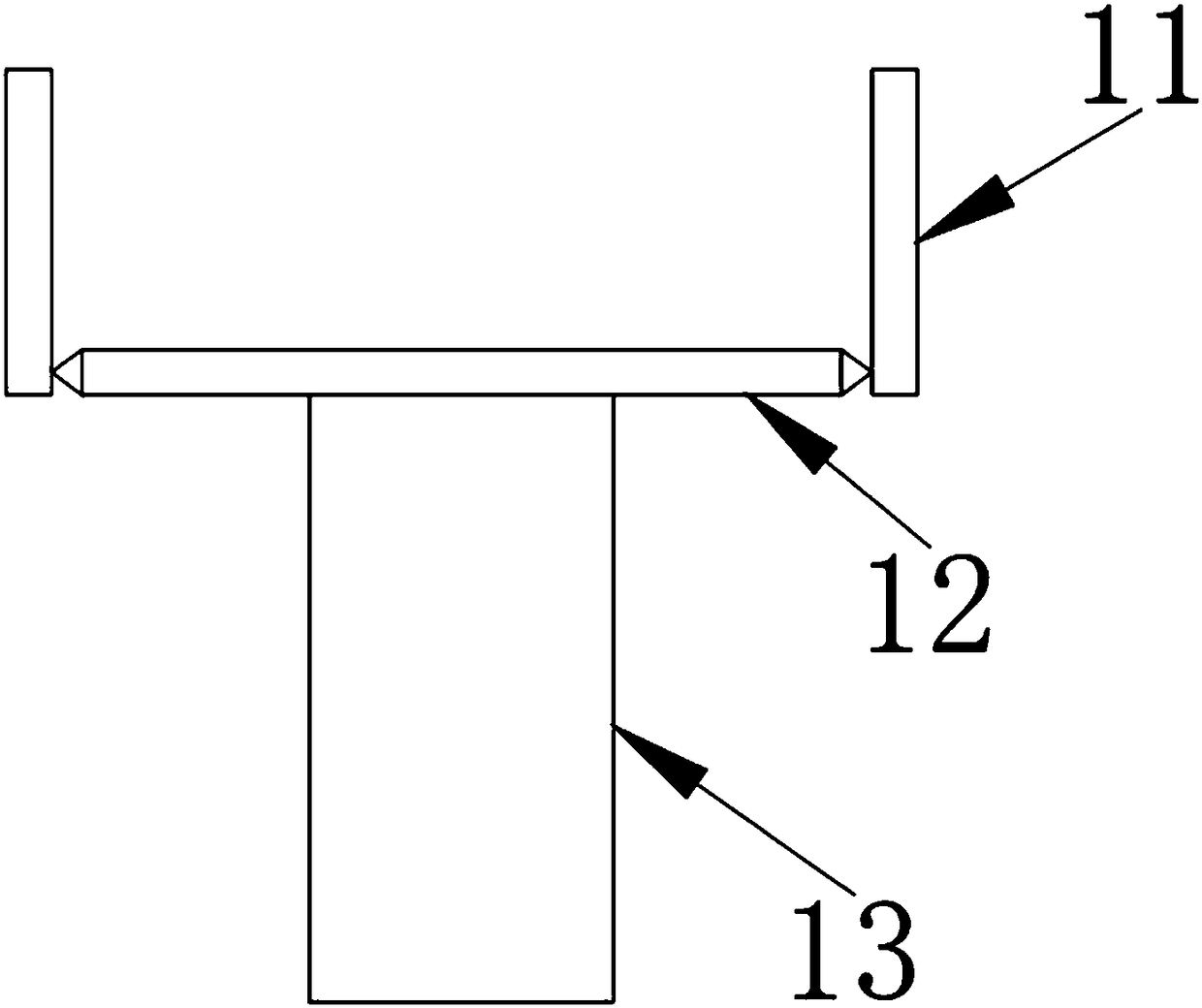

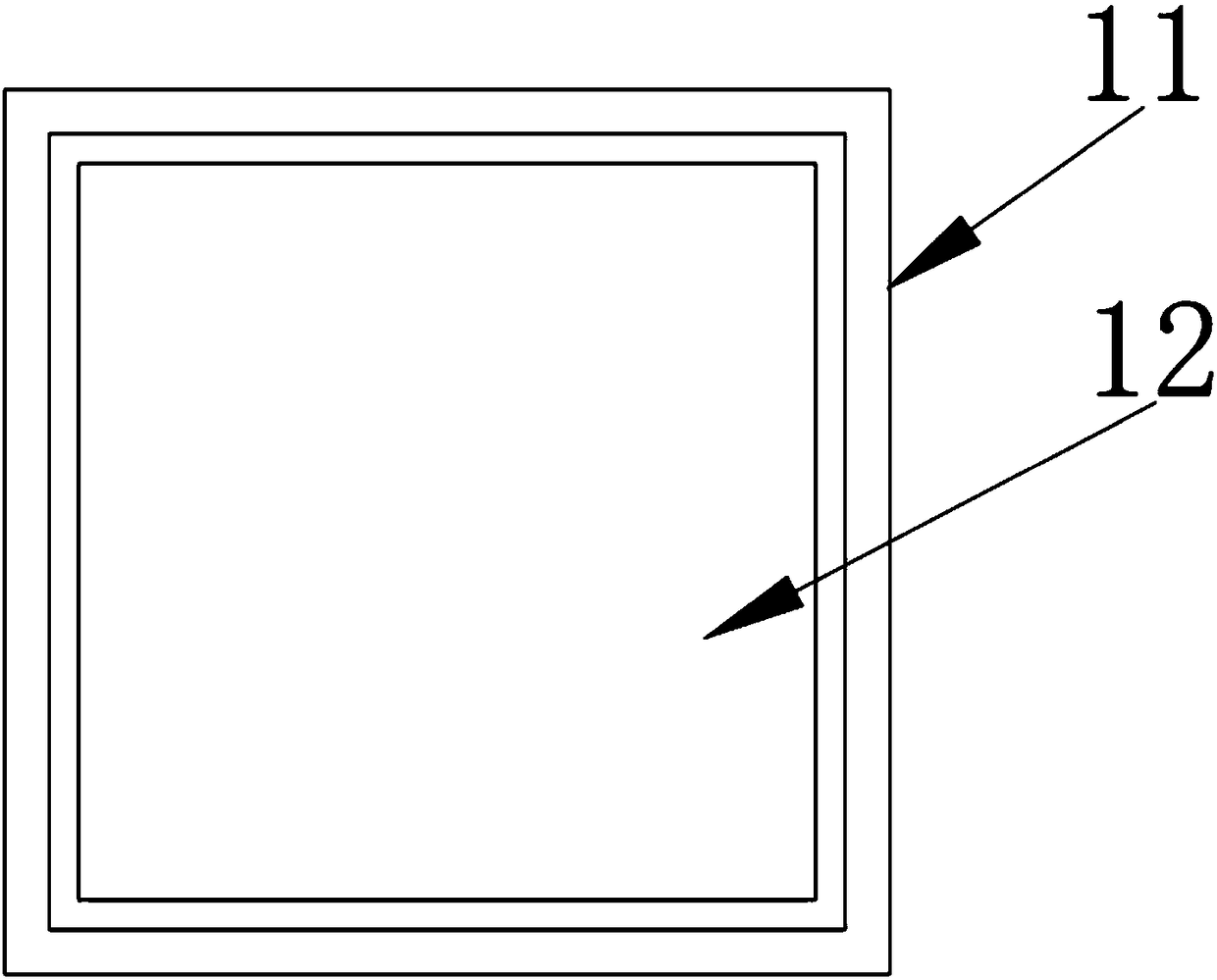

[0045] like figure 2 and 3 As shown, the lifting printing platform III includes a powder spreading baffle 11 , a printing platform 12 and a support column 13 . The powder-spreading baffle 11 is a ring-shaped and closed plate, which is surrounded by a square tube without a cover and bottom. The printing platform 12 is horizontally arranged inside the powder-spreading baffle 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com