Stretchable microelectronic device taking hydrogel as substrate and preparation method

An electronic device and hydrogel technology, applied in the field of stretchable microelectronic devices, can solve problems such as insufficient mechanical strength and flexibility, difficulty in miniaturization of electrodes, and limitations on the application of flexible devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

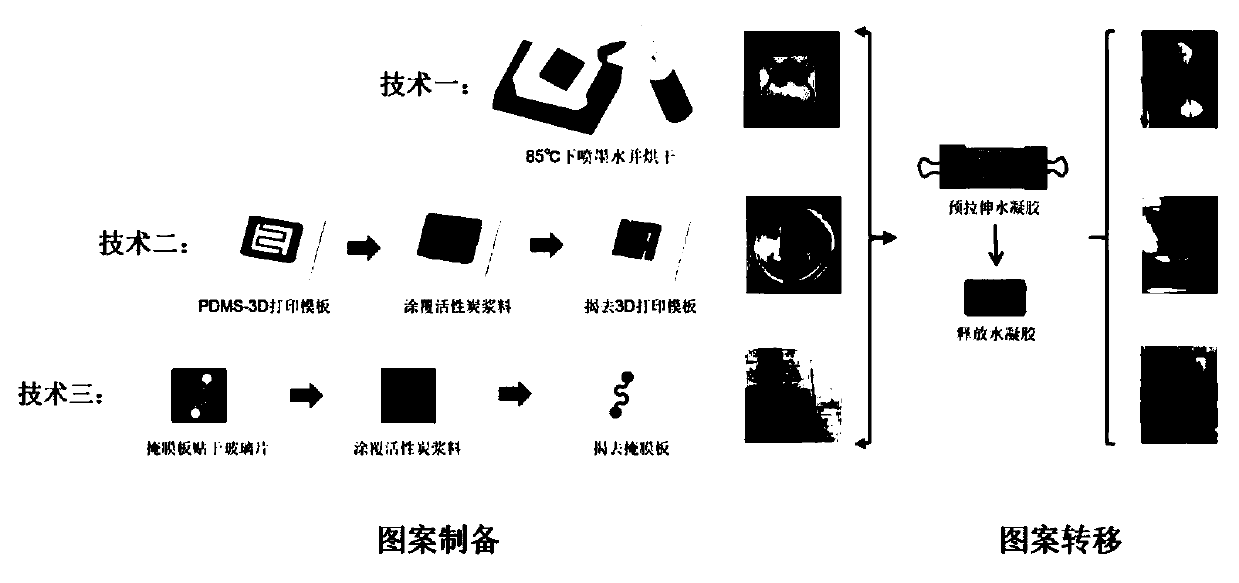

Method used

Image

Examples

Embodiment 1

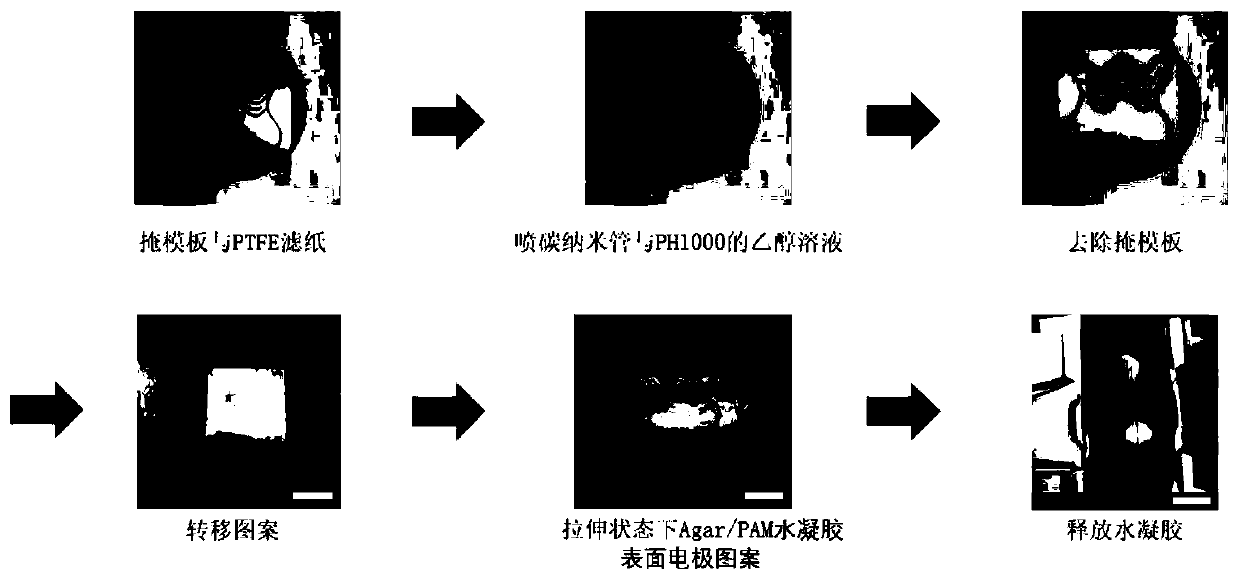

[0031] Transfer-printed carbon nanotube / conducting polymer composite electrode using PTFE filter paper substrate. The method follows image 3 The following steps are shown:

[0032] (1) Customize a stainless steel mask with a specific pattern, and the shape of the electrode ink leaked from the hollow part is the shape of the final micro-electrode.

[0033] (2) Attach the stainless steel mask plate to the PTFE filter paper and place it on a hot stage at 80°C.

[0034] (3) Prepare 0.2-2mg / mL carboxylated multi-walled carbon nanotubes (MWCNT) and 0.2-2mg / mL poly(3,4□ethylenedioxythiophene):polybenzenesulfonate (PEDOT:PSS) in ethanol solution. By diluting PH1000 (1.3-1.5%wt PEDOT:PSS aqueous solution), control the mass ratio of MWCNT and PEDOT:PSS between 1:5 and 5:1, and sonicate for 1h.

[0035] (4) Spray the prepared solution on the PTFE filter paper with a spray can, quickly remove the mask plate, and dry the electrode pattern on the filter paper at 80°C.

[0036] (5) Pre...

Embodiment 2

[0040] Activated carbon microelectrodes were transferred and printed using 3D printing templates and PDMS substrates. The method follows figure 2 The following steps are shown:

[0041] (1) Use 3D drawing software to establish the required electrode digital model with a certain shape, print out a single-layer polylactic acid (PLA) micro-pattern template with a precision of 500 microns, and the shape of the electrode slurry leaked from the hollow part is the final The shape of the microelectrodes.

[0042] (2) Mix PDMS (sylgard 184) prepolymer and cross-linking agent at a mass ratio of 10:1 to 5:1, fully mix for 10 minutes, and perform air extraction treatment, and the viscous liquid to be mixed does not contain air bubbles at all Then, slowly pour it into the Petri dish.

[0043] (3) Place the printed 3D printing template flat on the surface of the PDMS prepolymer viscous liquid. Then the petri dish was placed in an oven at 80°C for 1 hour to solidify the PDMS, and it was t...

Embodiment 3

[0047] Microelectrodes were transfer printed using a glass substrate. The method follows Figure 4 The following steps are shown:

[0048] (1) Customize a stainless steel mask with a specific pattern, and the shape of the electrode paste leaked from the hollow part is the shape of the final micro-electrode.

[0049] (2) Stick the wetted stainless steel mask to the glass surface by capillary action.

[0050] (3) Spray the ethanol solution of MWCNT / PEDOT:PSS composite electrode on the glass surface, or prepare electrode slurry with activated carbon, acetylene black and polytetrafluoroethylene (PTFE) binder, and use isopropanol as solvent, and evenly coat Apply on the mask plate, remove the mask plate, and the remaining pattern is the required electrode pattern.

[0051] (4) Dry the glass sheet printed with the micropattern on a hot table at 120° C. for 30 minutes.

[0052] (5) Transfer the electrode pattern to the surface of the hydrogel according to the aforementioned metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire resistance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com