Continuous carbon fiber 3D printing device

A 3D printing and carbon fiber technology, which is applied in the field of additive manufacturing, can solve the problems that the fibers cannot produce silk resin, affect the molding speed, and cannot bond the fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

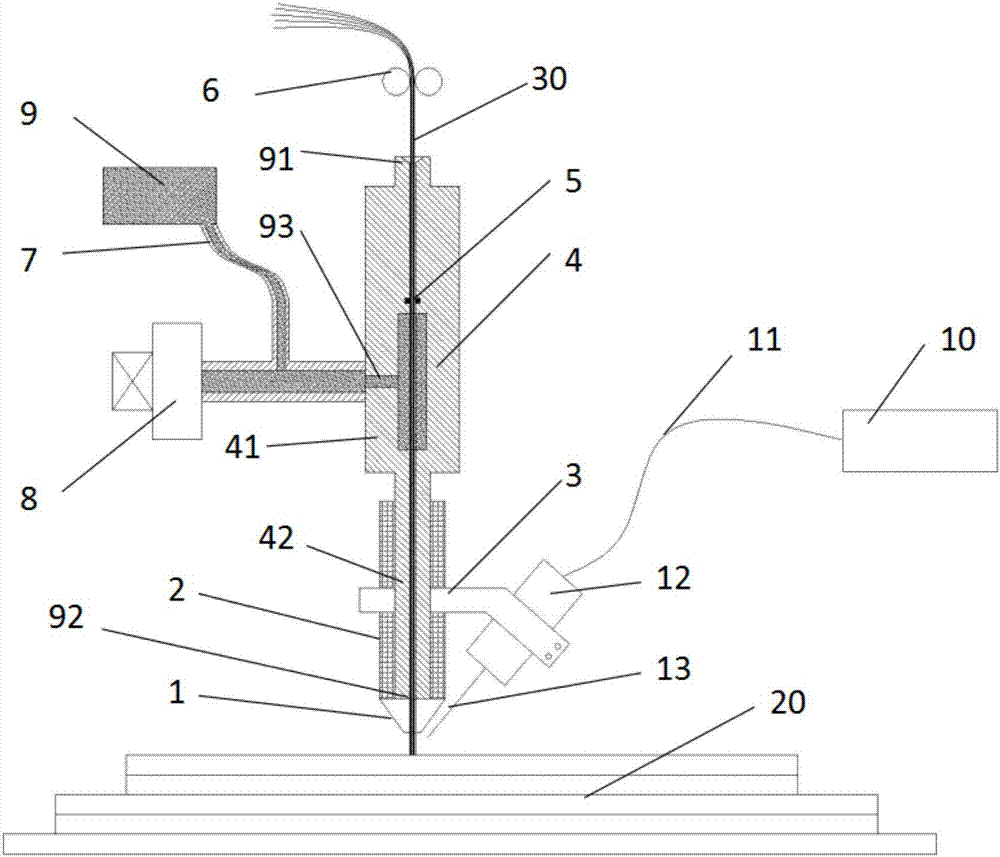

[0040] Such as figure 1 As shown, a schematic structural diagram of a typical carbon fiber 3D printing device of the present invention. The device includes a nozzle 1, a heating coil 2, a support 3, a spray cavity 4, a liquid supply pump 8, a resin tank 9, a laser 10, and a collimator 12.

[0041] The spray chamber 4 includes a first end 41 and a second end 42, and the diameter of the first end 41 is larger than the diameter of the second end 42; the spray chamber is similar to a three-way structure, and the spray chamber 4 has two inlets (the first inlet 91, the second inlet 93), a spray cavity outlet 92, the second inlet 93 is arranged on the side of the first end 41, and the first inlet 91 of the spray cavity 4 is provided with a sealing ring 5. A guide wheel 6 is also provided before the first entrance 91 of the spray chamber 4. The outlet of the liquid supply pump 8 is connected to the second inlet 93 of the spray chamber 4, the inlet of the liquid supply pump 8 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com