Photocurable material for 3D inkjet printing, and preparation method thereof, and printing method

A light-curing material and inkjet printing technology, applied in the chemical industry, additive processing, sustainable manufacturing/processing, etc., can solve the problems of affecting eyesight, difficult to print target 3D objects, uneven curing, etc., to achieve the best 3D The effect of inkjet printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

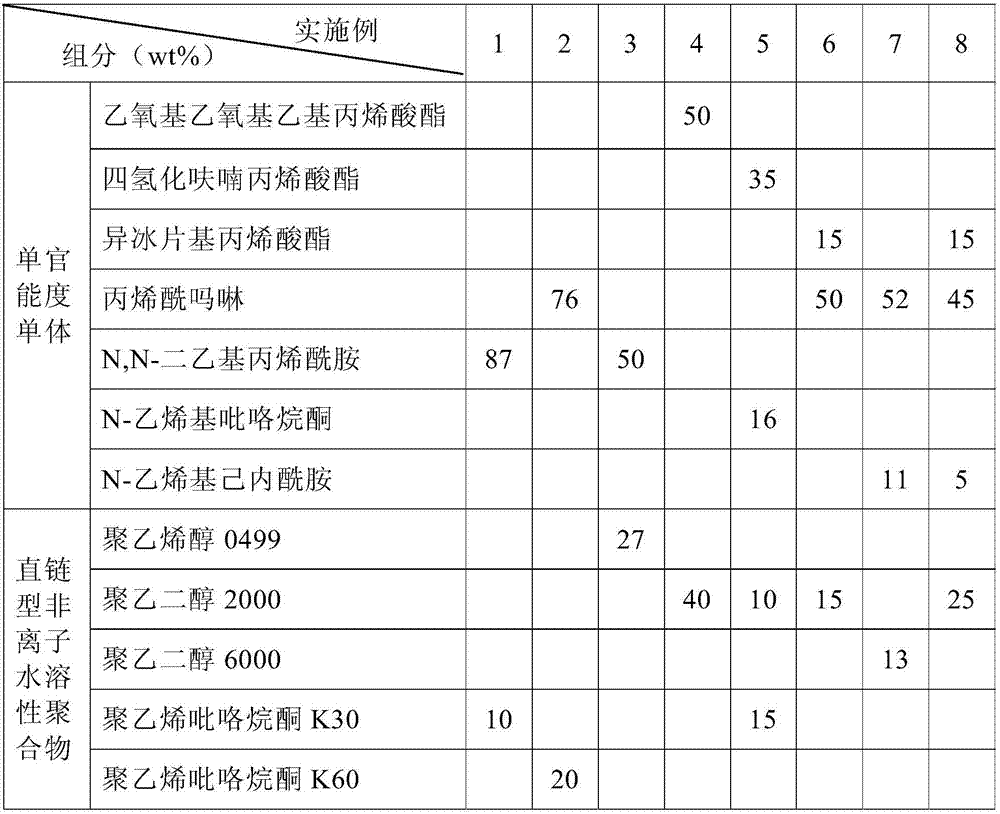

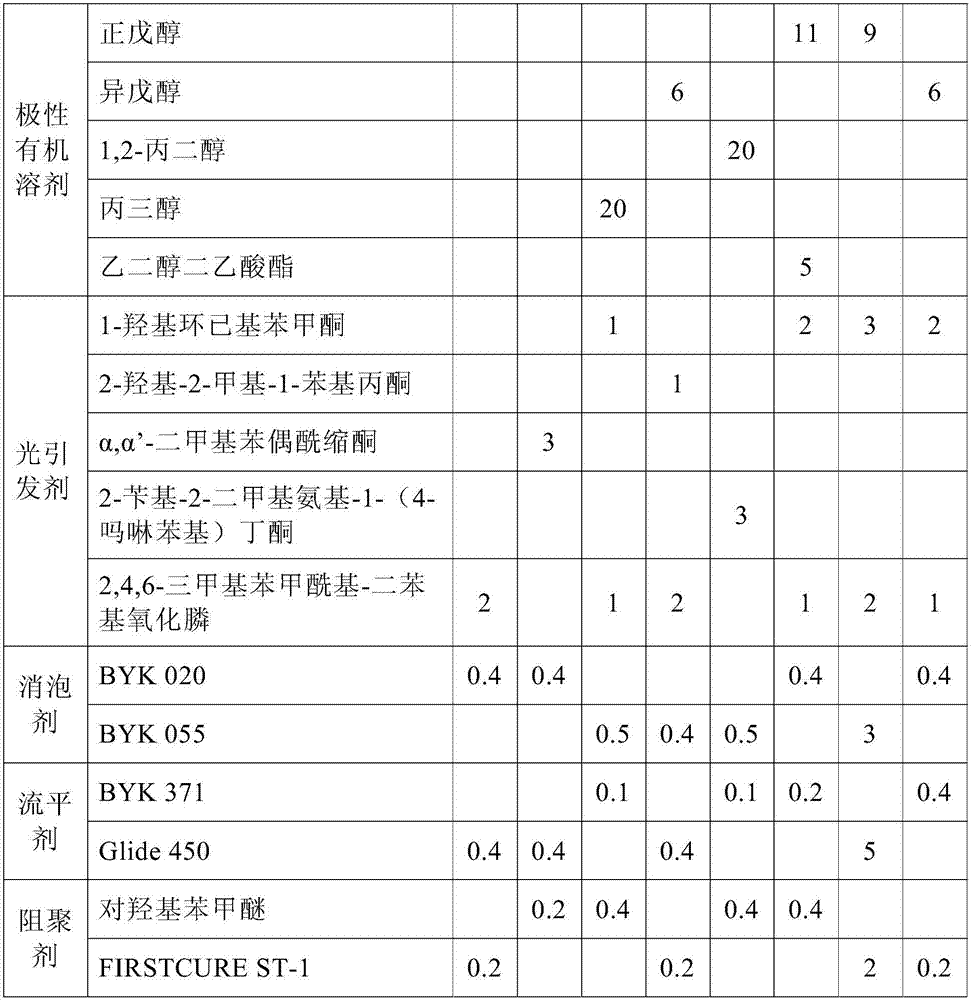

[0056] See Table 1 for the composition and mass percentage of light-curing materials.

[0057] Preparation method of light curing material:

[0058] (1) Mixing monofunctional monomers, linear non-ionic water-soluble polymers, polar organic solvents, defoamers, leveling agents, and polymerization inhibitors to obtain a first mixture;

[0059] (2) Add a photoinitiator to the first mixture and mix to obtain a second mixture;

[0060] (3) The second mixture is subjected to two-stage filtration; wherein the first-stage filtration adopts a 0.45μm glass fiber membrane of Shanghai Haoqing Environmental Protection Technology Co., Ltd., and the second-stage filtration adopts Shanghai Yiling Filter Equipment Co., Ltd. A polypropylene membrane with a pore size of 0.2 μm, collect the filtrate to obtain the third mixture;

[0061] (4) The third mixture is first degassed at normal pressure for about 1 hour, and then degassed under reduced pressure at -0.05 to -0.1 atmospheres for about 1 hour to obta...

Embodiment 9

[0074] The composition and mass percentage of the light-curing material are the same as in Example 3, see Table 1.

[0075] Preparation method of light curing material:

[0076] (1) Mix the monofunctional monomer and the linear non-ionic water-soluble polymer, heat to about 60°C, stir, and place the linear non-ionic water-soluble polymer completely dispersed in the monofunctional monomer. To room temperature about 25°C, then add polar organic solvent, defoamer, leveling agent, polymerization inhibitor, use a stirrer to stir for about 3 hours, until the components are uniformly mixed to obtain the first mixture;

[0077] (2) Add a photoinitiator to the first mixture and continue to stir for about 2 hours until the components are evenly mixed to obtain a second mixture;

[0078] (3) Perform secondary filtration on the second mixture; wherein, the first stage filtration uses a glass fiber membrane with a pore size of 0.45 μm, and the second stage filtration uses a polypropylene membrane ...

Embodiment 10

[0082] A 3D inkjet printing method, wherein the supporting material used for 3D inkjet printing is the photocurable material described in any one of the above embodiments 1-8.

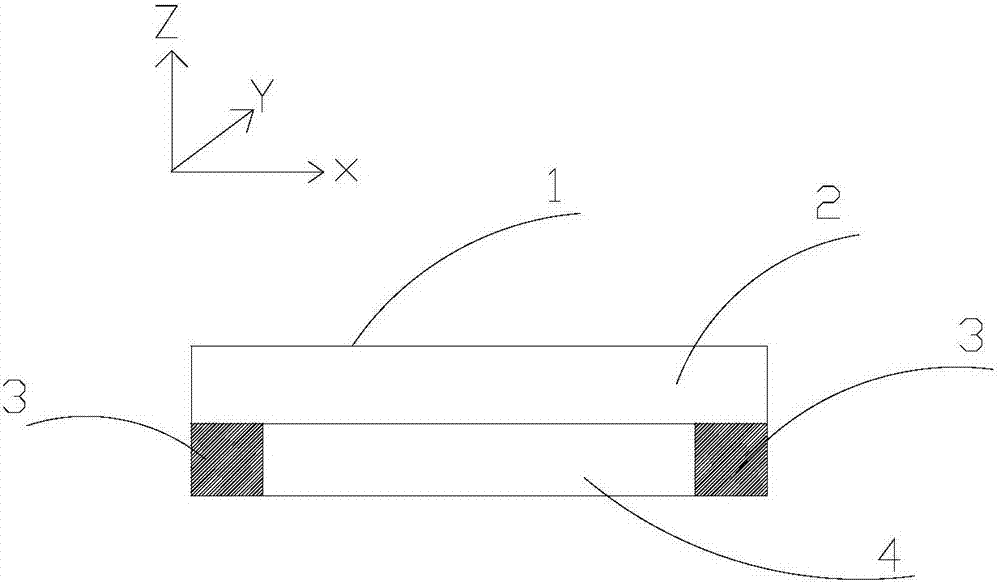

[0083] Inkjet printing is performed using a 3D printing device equipped with the above 3D inkjet printing material. reference figure 1 , The printed intermediate 3D object 1 is composed of a supporting part 3, a first physical part 2 and a second physical part 4, wherein the supporting part 3 is printed by the above light-curing material, the first physical part 2 and the second physical part 4The two parts of the target 3D object are integrated.

[0084] After the printing is completed, the intermediate 3D object 1 is placed in water, and the supporting part 3 is dispersed in the water and completely separated from the target 3D object (combination of the first physical part 2 and the second physical part 4), and finally the target 3D object is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com