Shaft-like rotary workpiece static external round machining machine tool

A technology for rotating workpieces and shafts, which is applied to the field of machine tools for machining external circles without rotating workpieces with shafts, can solve the problems of inability to meet the requirements of machining the external circle of the workpiece, and the workpiece cannot be rotated, and achieves good processing quality, high processing efficiency, and high processing efficiency. The effect of improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

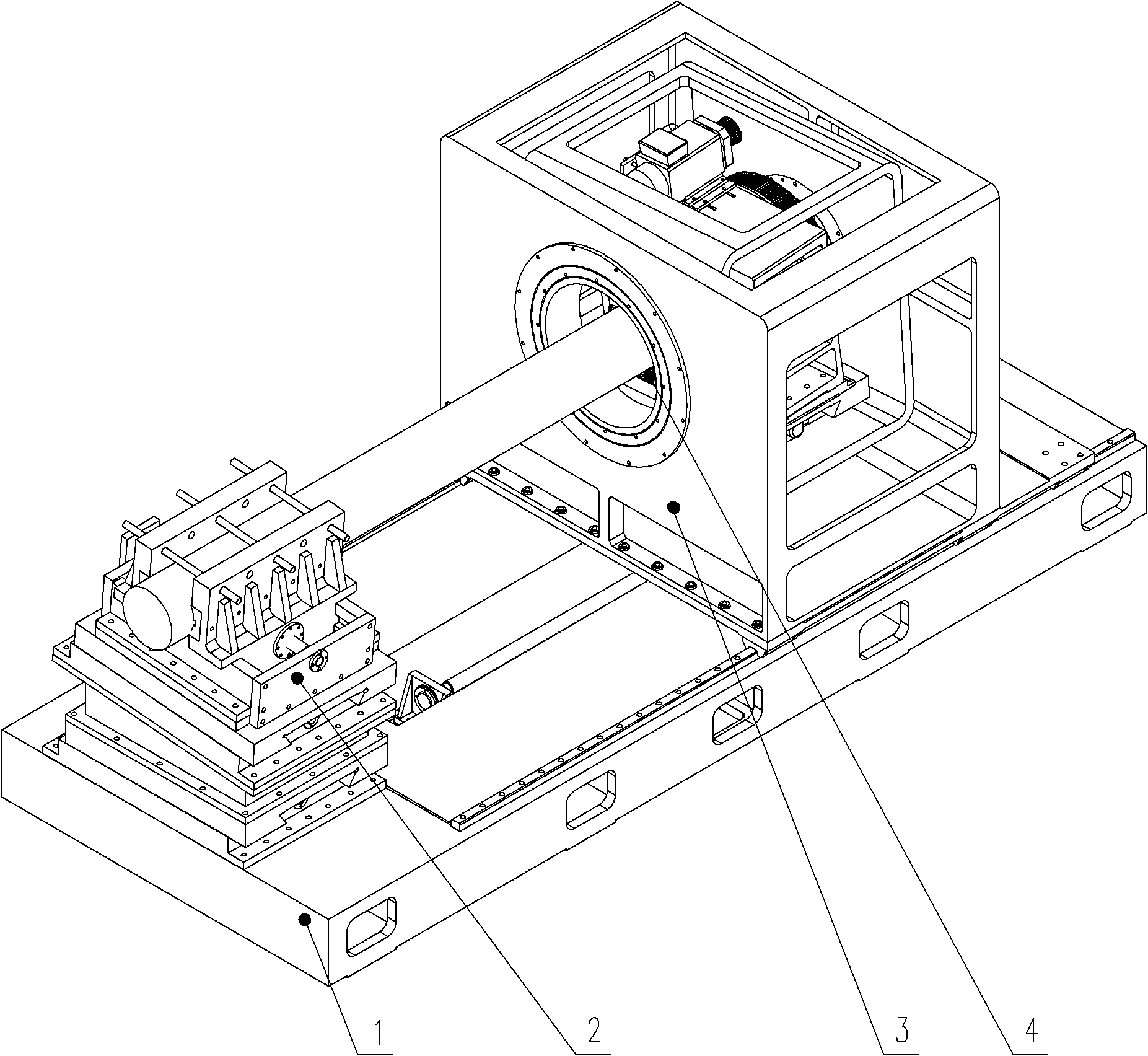

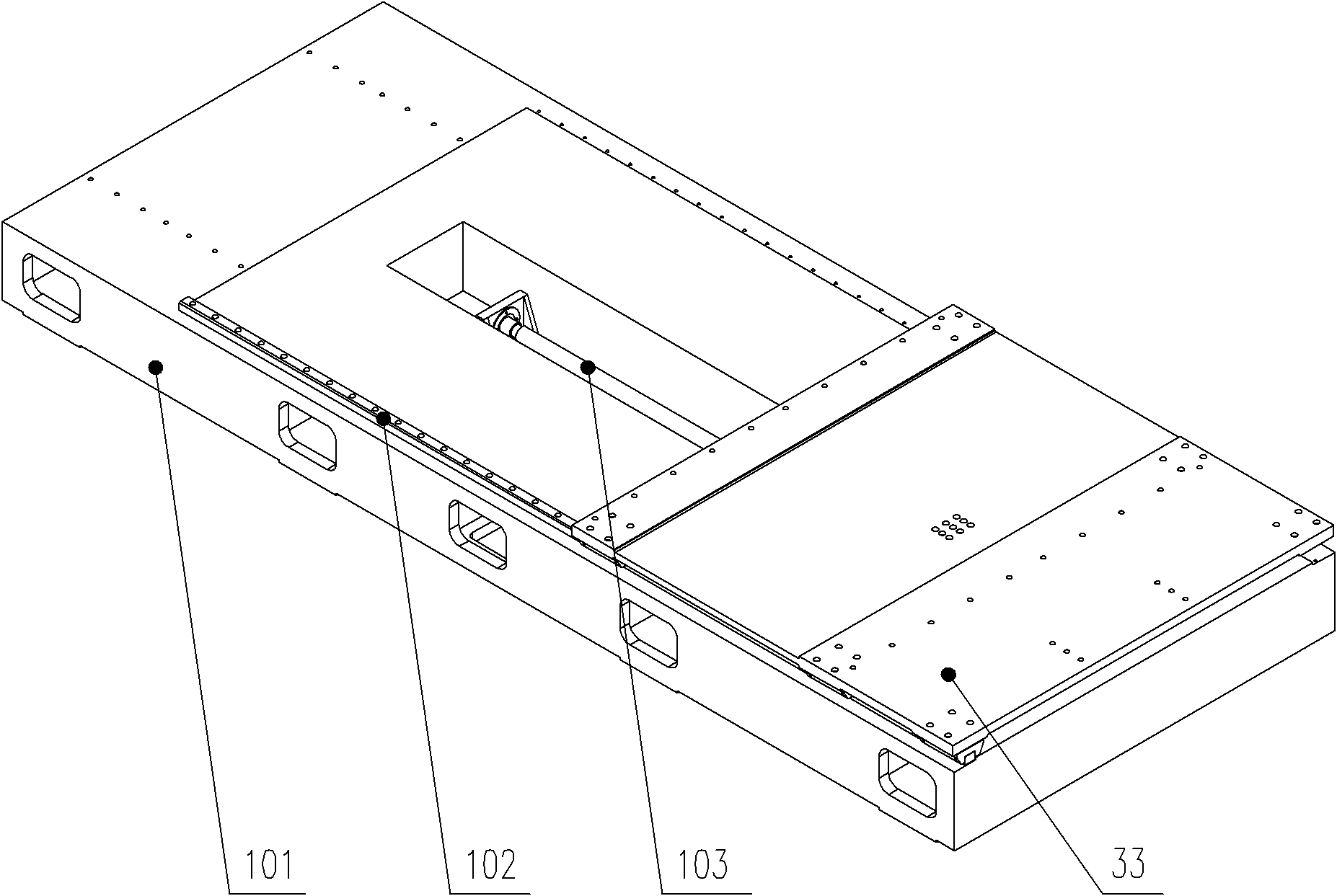

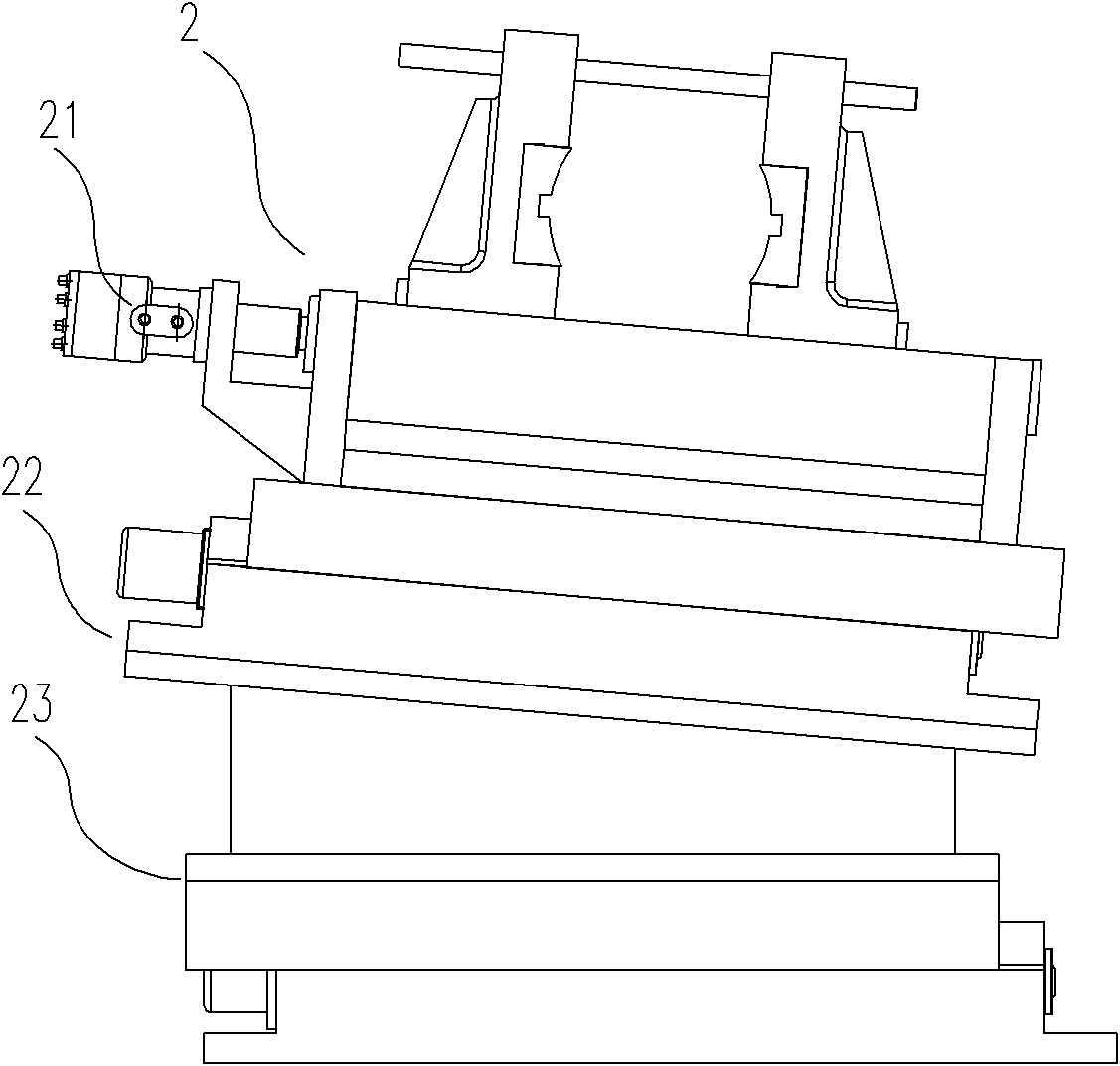

[0061] figure 1 Disclosed in is a non-rotating shaft-type rotary workpiece processing machine tool, which includes a bed component 1, a workpiece clamping device 2, a cutter head rotation device 3, a cutter head device 4, a hydraulic system, a cooling system and a numerical control system; The bed component 1 includes a bed 101, a linear guide rail 102 installed on the bed and an axial feed screw assembly 103, and the axial feed screw assembly 103 is composed of an axial feed screw and a screw nut (see figure 2 ); the workpiece clamping device 2 is composed of a clamping assembly 21, an oblique adjustment assembly 22 and a horizontal adjustment assembly 23 stacked together in sequence (see Figure 3 ~ Figure 6 ), the clamping assembly 21 is composed of a clamping power device 211, a guide support 213, a left V-shaped block 214, a two-way screw 215, a two-way screw nut 216 and a right V-shaped block 217 (see Figure 7 ), the clamping power device 211 is connected to the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com