Horizontal lathe for machining cylindrical eccentric part and method adopted by same

A horizontal lathe, eccentric technology, applied in the direction of metal processing machinery parts, cutting tools for lathes, metal processing equipment, etc., can solve the problem that it is difficult to ensure the processing quality of parts in the complex processing process of products, and the processing control of eccentric holes is difficult to determine by cutting tool design Difficult to implement, low processing accuracy and processing efficiency, etc., to achieve the effect of improving stability and processing accuracy, improving cutting efficiency, and reducing tool weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

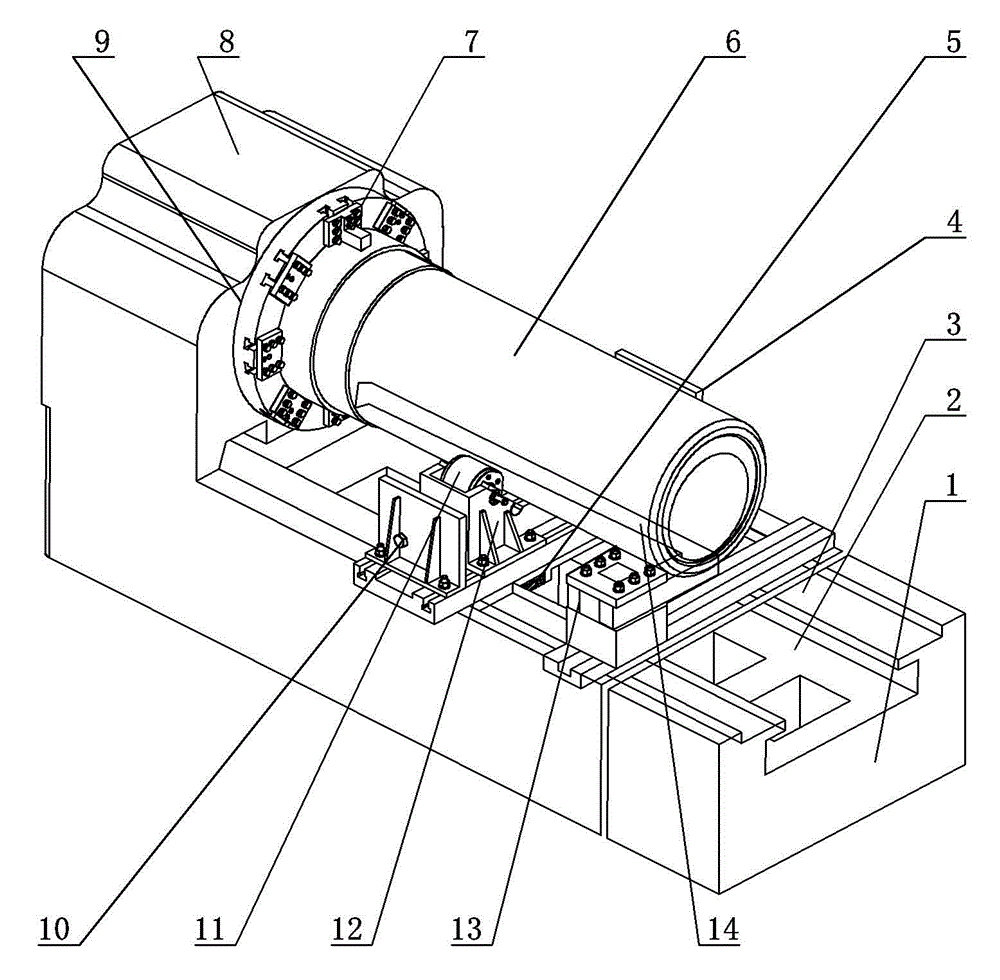

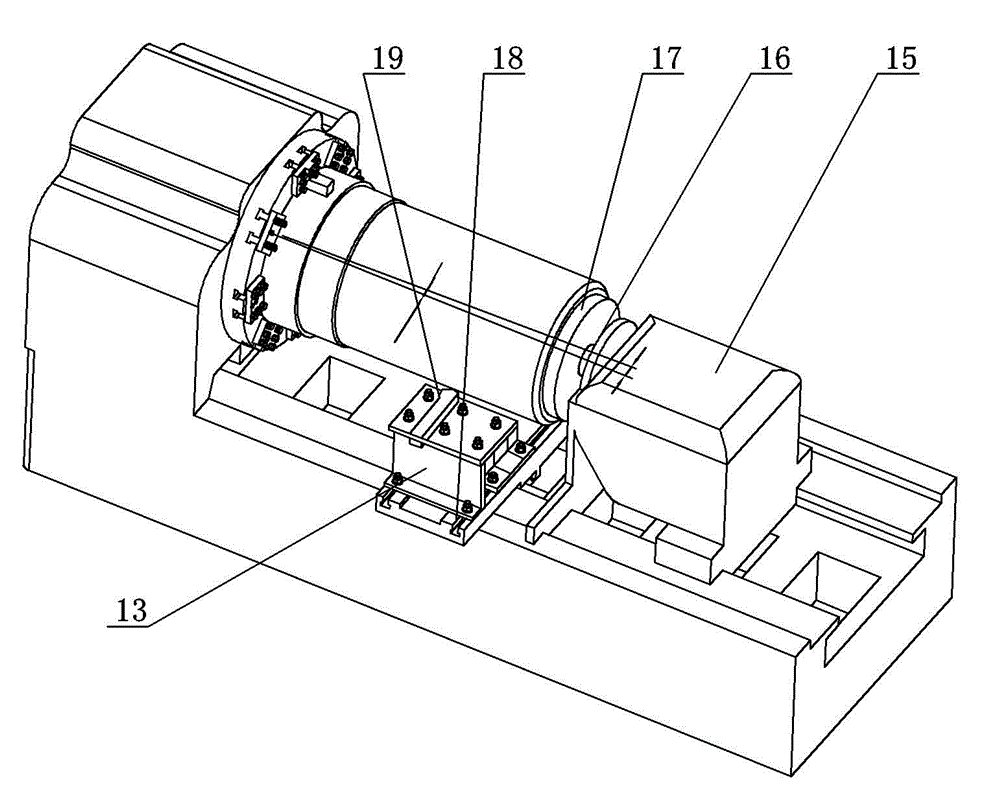

[0036] Such as figure 1 Shown is a schematic diagram of the structure of the horizontal lathe 1 of the present invention when machining the inner hole; in the figure, the axis of the main shaft of the horizontal lathe 1 is the X direction, and the direction perpendicular to the bed 2 of the horizontal lathe 1 is the Z direction and the Y direction Perpendicular to the X and Z directions. The left side of horizontal lathe 1 is bed head 8, and the right side is bed tail 15 (in figure 1 Not shown in the figure), between the head of the bed 8 and the end of the bed 15 is a horizontal bed 2. The inboard of head of bed 8 is provided with chuck 9, and jaw 7 is arranged on chuck 9, and among the figures, jaw 7 is eight, and chuck 9 is equally divided, and the effect of chuck 9, jaw 7 is to make cylinder class The eccentric sleeve part 6 is clamped and fixed on the head of the bed 8, so that it rotates with the chuck 9 under the drive of the main shaft of the horizontal lathe 1;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com