Machining method of silver target material

A processing method and silver target technology, which is applied in metal processing equipment, workpieces, manufacturing tools, etc., can solve the problems of silver target easy to produce lines, silver target performance degradation, and high roughness, so as to improve the quality of the processed surface and Effects of tool life, friction reduction, and surface roughness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

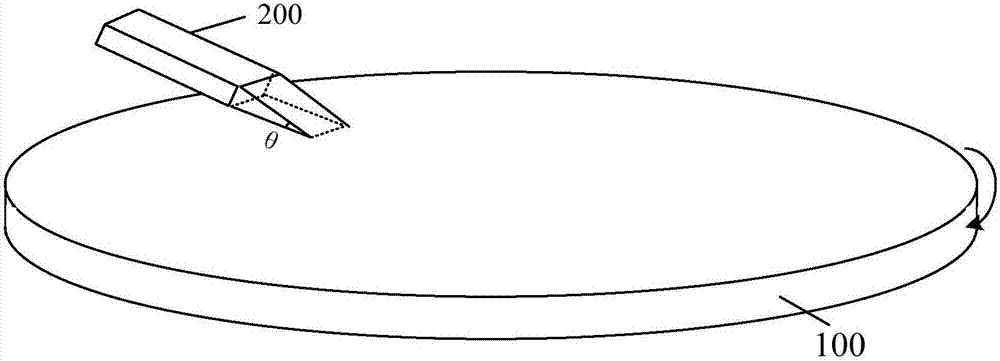

[0030] As mentioned in the background art, there are many problems in the current method of forming the silver target, for example, the surface roughness of the formed silver target is relatively high, which reduces the performance of the silver target.

[0031] Now in combination with a method of forming a silver target, the reason why the performance of the silver target is reduced due to the high surface roughness of the silver target formed by the formation method is analyzed:

[0032] The hardness of the silver target is low, and the parameter selection is unreasonable in the turning process, which will easily lead to the deformation of the silver target and the surface of the silver target is easy to produce lines, so that the surface roughness of the silver target is high, making the silver target Reduced performance. In addition, the hardness of the silver target is low. During the turning process, more chips are generated. The chips are easy to cause the tool to gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com