Interior and exterior incremental forming device for metal corrugated pipe

A metal bellows and incremental forming technology, applied in the field of inside and outside incremental forming devices for metal bellows, can solve the problems of inability to guarantee the quality of final formed products, output stability, quality defects, unqualified, etc. Simple structure and the effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

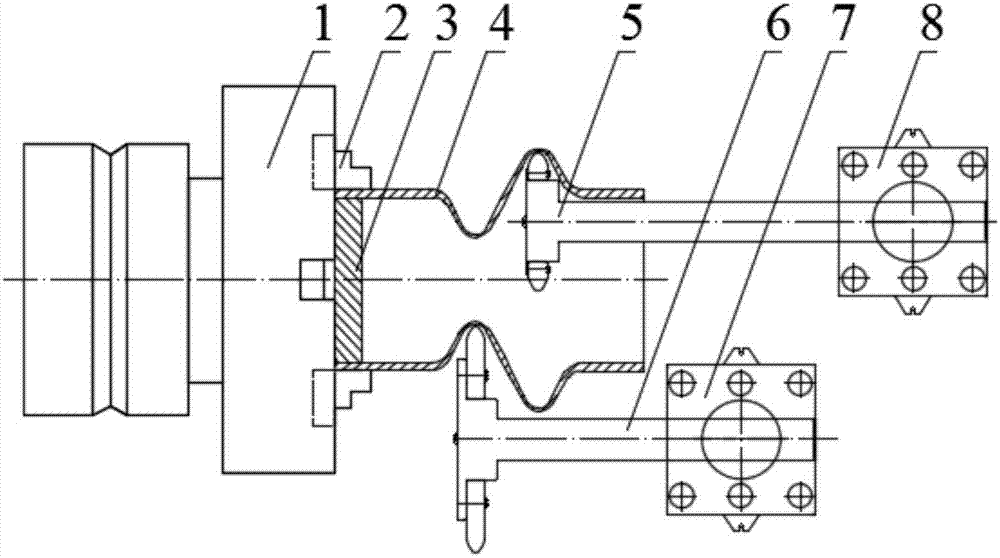

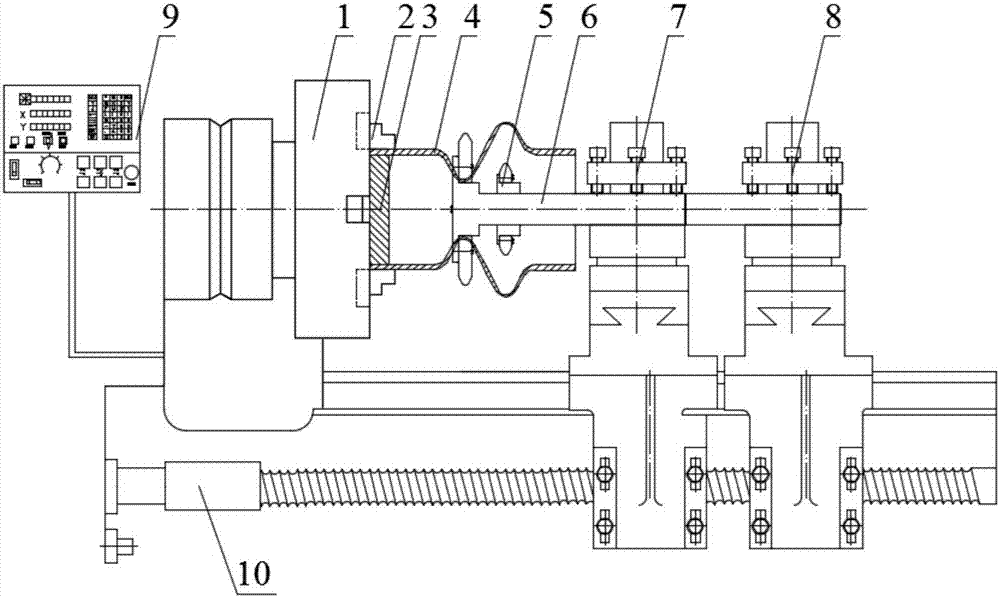

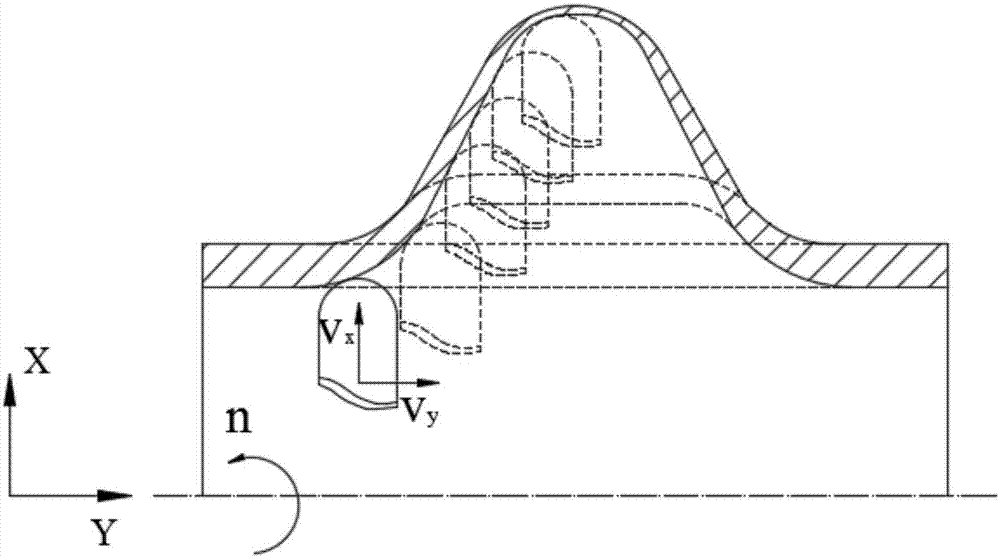

[0024] The present invention is a metal bellows internal and external incremental forming device, such as figure 1 and figure 2 As shown, it includes a forming system and a digital control device 9 connected to the machine tool 10; the forming system includes a centering chuck 1, and the centering chuck 1 is connected with the main shaft of the machine tool 10, and the center of the centering chuck 1 The mandrel 3 is vertically connected, and the center of the centering chuck 1 is also provided with a jaw 2; the forming system also includes an incremental forming tool wheel 5 inside the crest and an incremental forming tool wheel 6 outside the trough, and an incremental forming tool inside the crest The tool bar of the wheel 5 is connected to the wave crest forming tool rest 8, and the tool bar of the incremental forming tool wheel 6 outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com