A Method for Cutting Squared Monocrystalline Silicon Rods Using Diamond Wire

A technology of diamond cutting wire and monocrystalline silicon, which is applied in metal processing equipment, fine working devices, grinding machines, etc., can solve the problems of large head margin, poor verticality, and great influence on finished products, so as to achieve easy operation, The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In an exemplary embodiment of the present invention, a method for squaring a monocrystalline silicon round rod by using a diamond wire is provided. Using high-speed feeding of diamond wires to cut monocrystalline silicon round rods;

[0042] Among them, the specification and size of the monocrystalline silicon round rod: the diameter is 216±3mm, and the length is determined according to the requirements of the rod.

[0043] The diamond cutting wire is: the substrate is a high-carbon steel wire with a diameter of 0.39mm-0.42mm, and the substrate is embedded with diamond particles with a particle size of 40um-50um;

[0044] The specific steps of the prescribing method are as follows:

[0045] (1) Winding: The diamond cutting wire protrudes from the winding drum, winds on the tensioning wheel arranged in a staggered manner, and then winds on the guide wheel, and puts the diamond cutting wire horizontally above the workbench; through the cutting wheel and The guide wheel ...

Embodiment 2

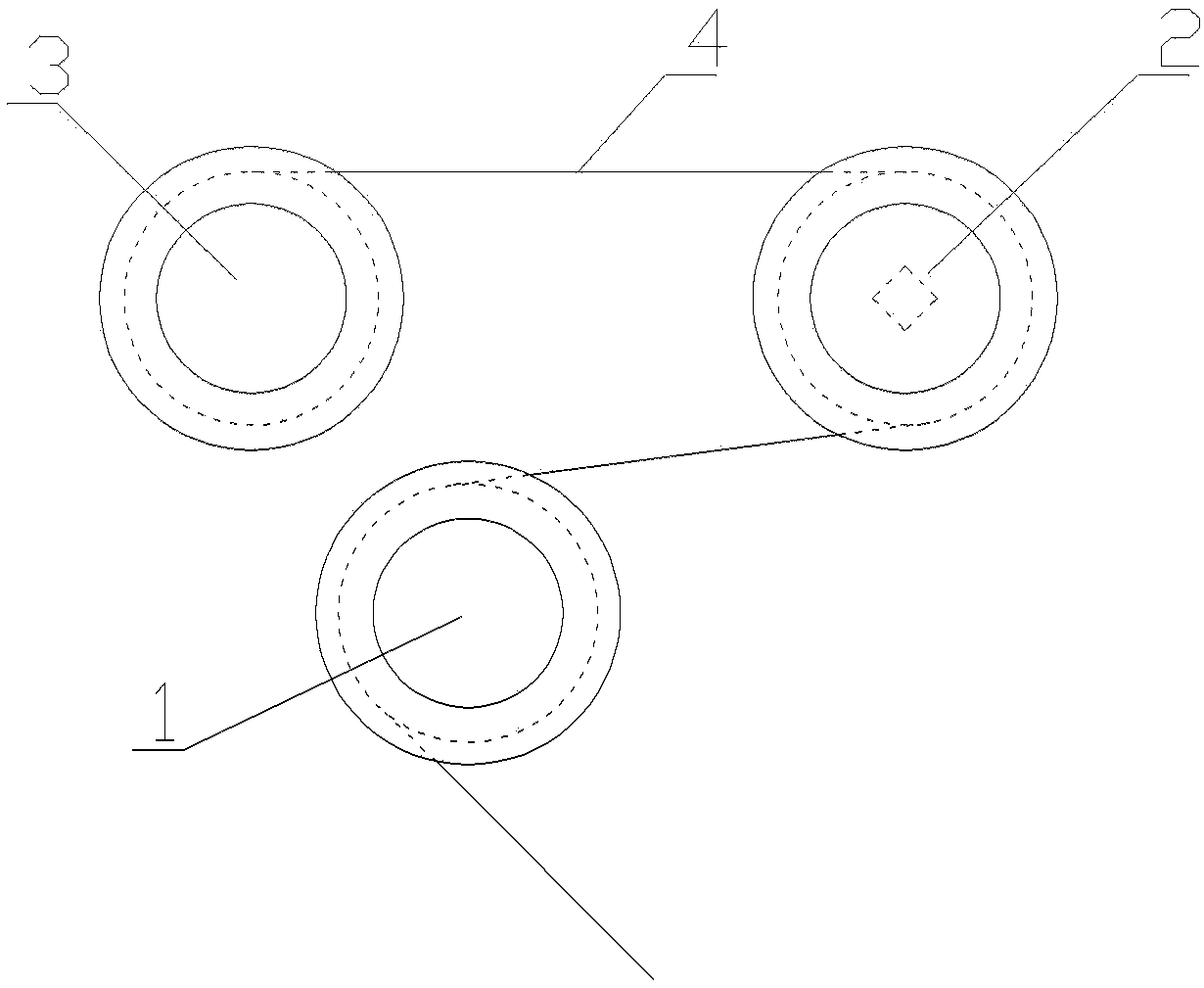

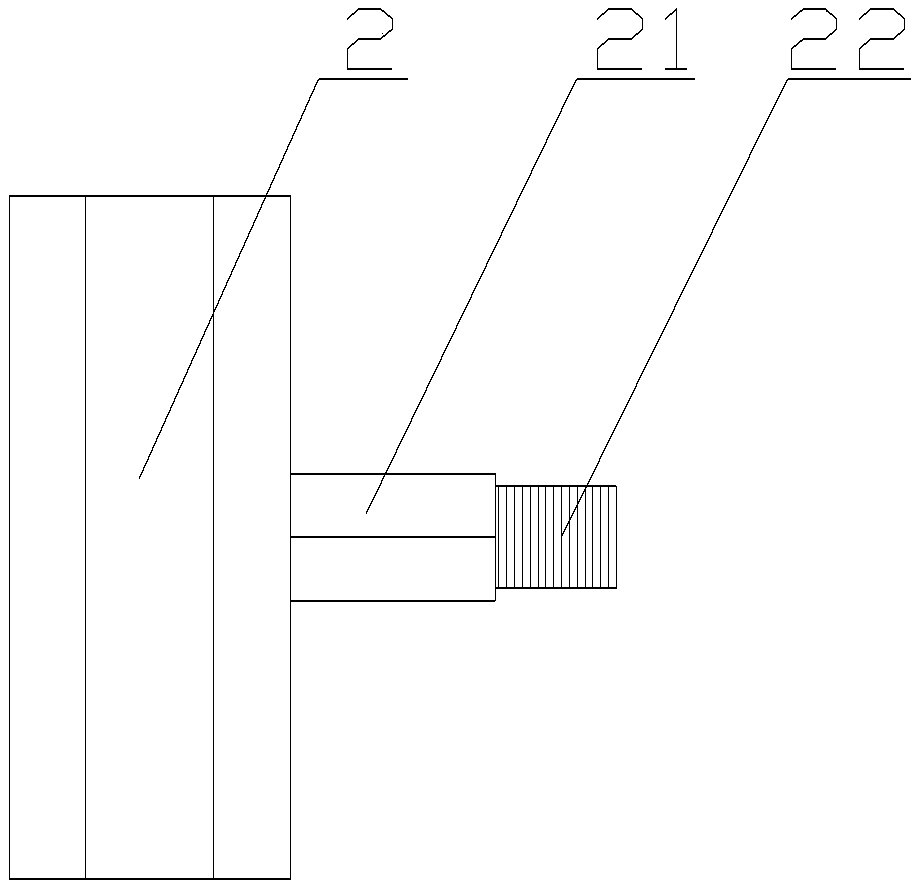

[0051] Under the same situation as the first embodiment, the feed speed is increased to 1.0mm / min, and the feed rate of the new line is reduced from 10m / min to 8m / min. Such as figure 1 , figure 2 As shown, since there are three tension pulleys, including the first tension pulley 1, the second tension pulley 2 and the third tension pulley 3 which are sequentially staggered from bottom to top. A section of square head mounting column 21 is vertically installed at the wheel center of the second tensioning wheel 2, and the end of the square head mounting column 21 has a section of fastening column 22 with external threads. At this time, replace the second tensioning wheel 2 to ensure the tension Validity and accuracy of testing.

Embodiment 3

[0053]When the other solutions are the same as in Embodiment 1, the feed speed is increased to 1.1mm / min, and the feed of the new line is 8m / min. Change the size of the second tensioning wheel accordingly to ensure the thread tension.

[0054] Generally, the surface roughness of the processed monocrystalline silicon square rod is about 0.8-1.0um, and the verticality of the cut surface is 90±0.2° or 90±0.3°. For the crystalline silicon square bar sample, the verticality of adjacent surfaces, surface roughness and cutting time are tested respectively, and Table 1 is obtained, as follows:

[0055] Table 1

[0056]

[0057] It can be seen from the above table that the verticality of the cutting surface is stable and the verticality is good; the surface roughness has been greatly improved, and the cutting time has not been extended.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com