Winding method of edgewise coil and bobbin winder

A winding method and a technology of a winding device, which are applied in the field of a flat coil winding method and a winding device, and can solve problems such as reducing the winding speed, inability to carry out winding, large swing or shaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

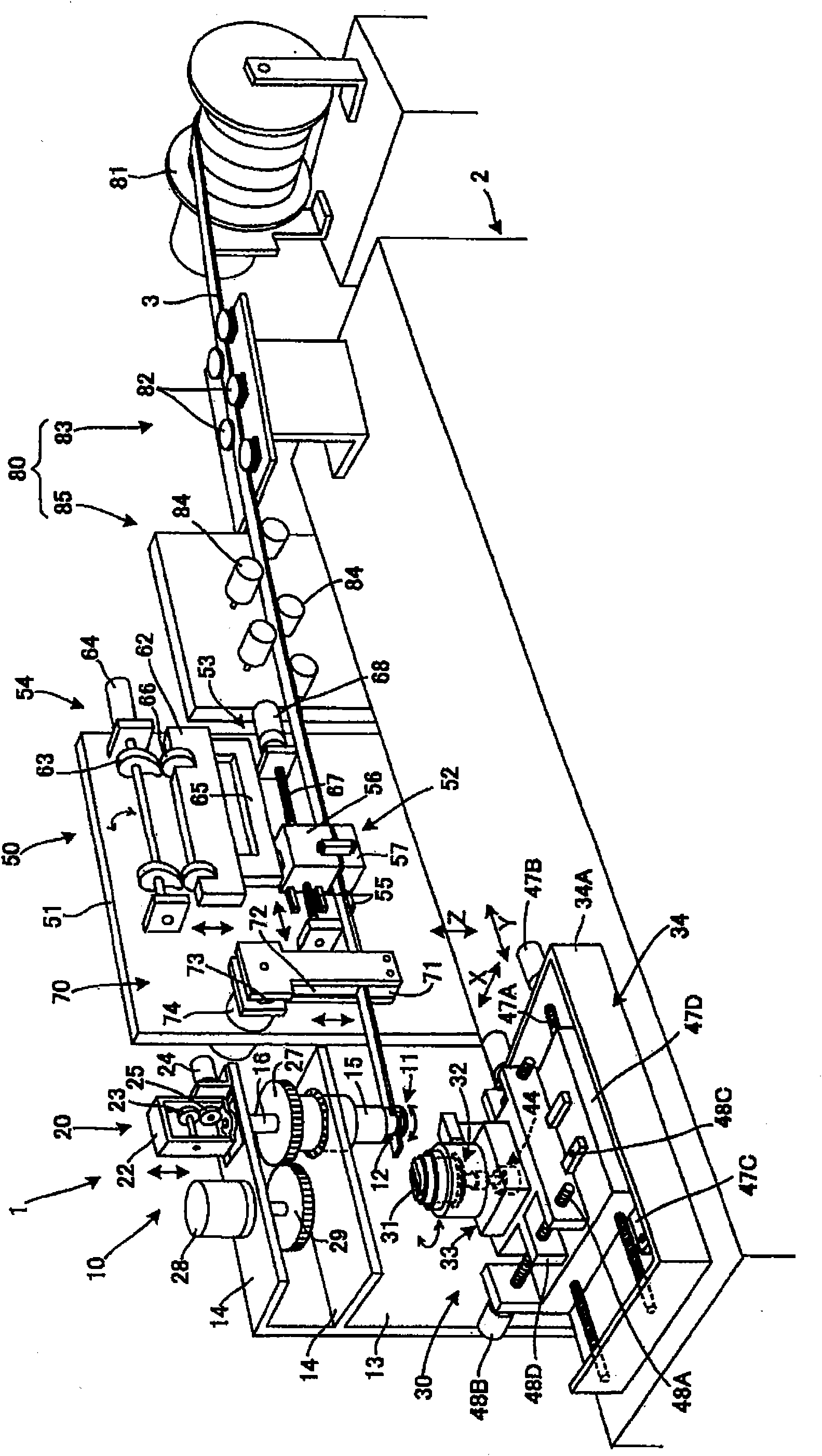

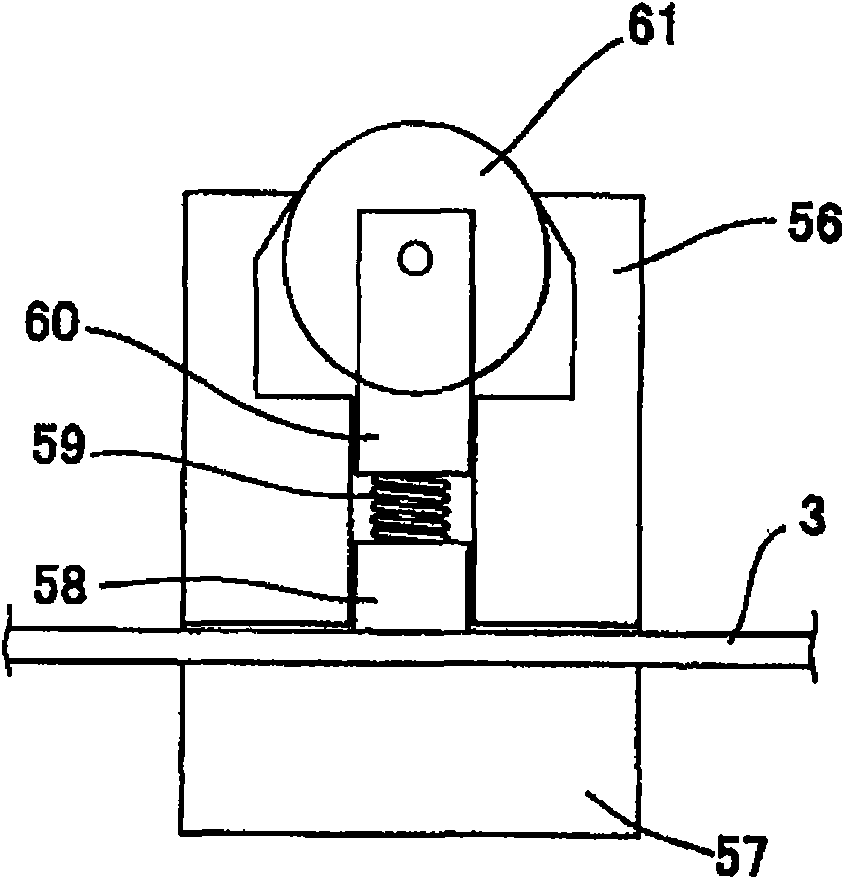

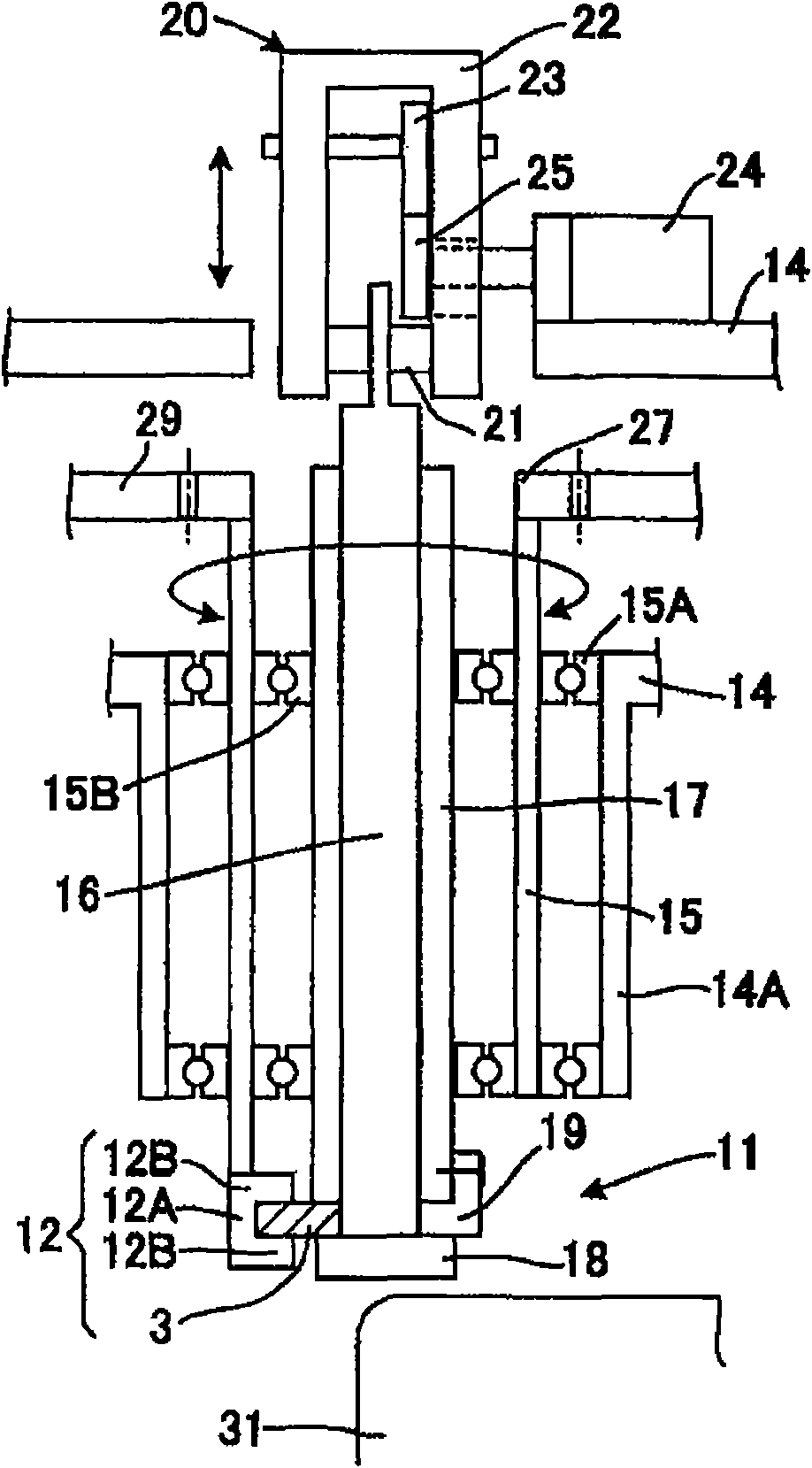

[0032] Hereinafter, an edgewise coil winding method and a winding device for forming an edgewise coil (hereinafter, may be simply referred to as a "coil") in the present invention will be described based on one embodiment. figure 1 It is a perspective view of an edgewise coil winding device to which the present invention is applied.

[0033] figure 1 Among them, the prolate coil winding device 1 has: a bending unit 10, which uses a main clamp 11 and a bending mechanism 12 to hold the flat wire 3, and bend it into a predetermined angle such as 90 degrees; The unit 30, wherein the frame-shaped flat wire 3 is sequentially bent by the bending unit 10 to be rolled into a frame shape, and changes shape in a plane along with the bending action of the bending unit 10 .

[0034] In addition, a pressing unit 70 is provided, which clamps the flat wire 3 sent out to the bending unit 10 on the upstream side of sending out the flat wire 3 to the bending unit 10, thereby preventing the flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com