Twice-molded type reversible-plug USB connector and manufacturing method thereof

A manufacturing method and forward and reverse insertion technology, applied in the direction of connection, connecting device parts, contact parts, etc., can solve the problems of incompatibility, product yield impact, occupation, etc., and achieve the effect of preventing terminals from being scattered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The manufacturing method of this application's two-time molded positive and negative USB connector is a USB3.1TypeC socket connector. A new type of interface that can greatly increase the transmission rate at the same time.

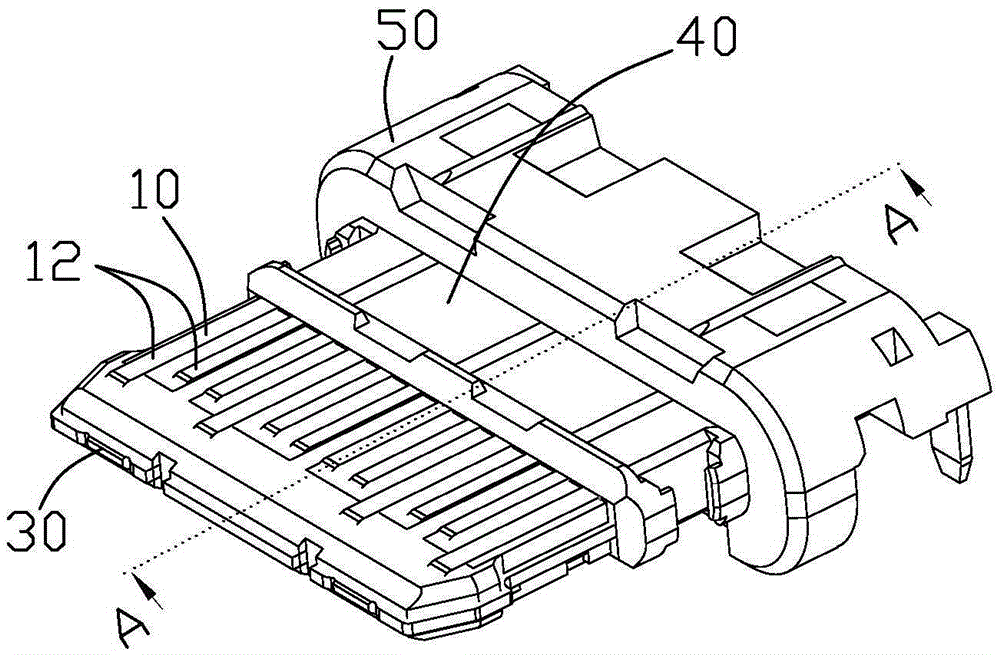

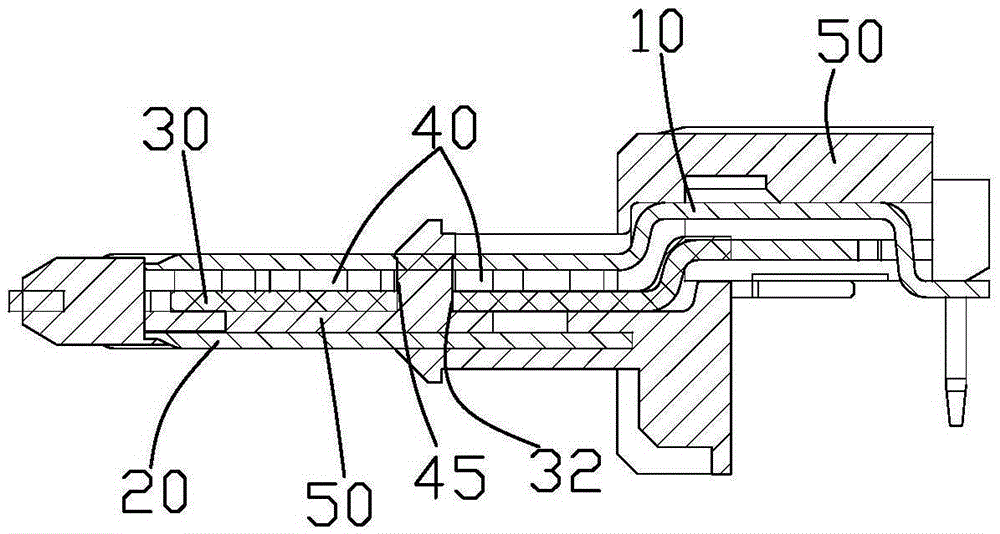

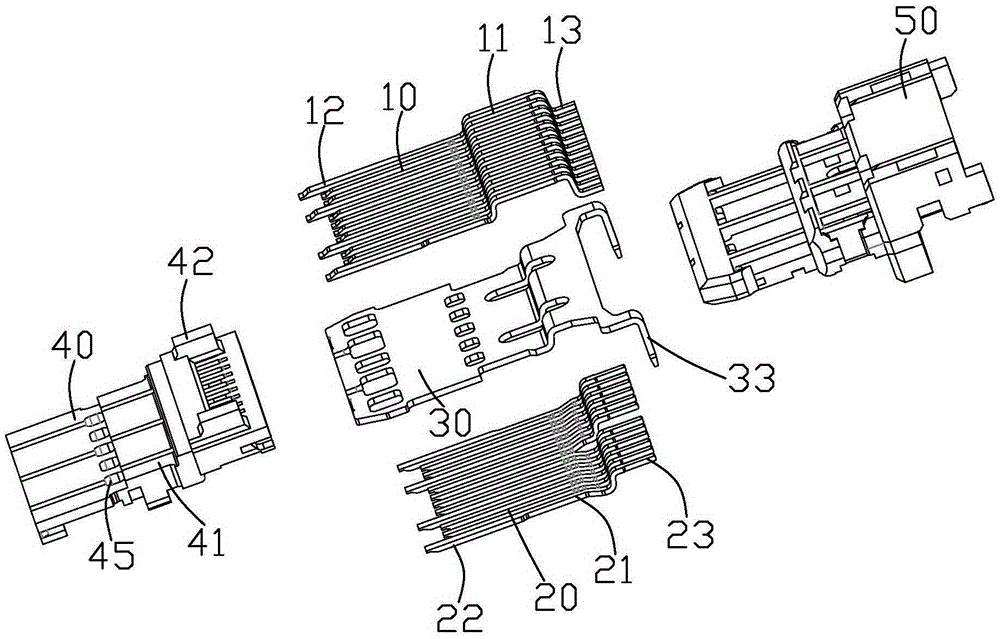

[0022] see Figure 1 to Figure 5 As shown, the secondary molding type positive and negative plug-in USB connector of the present application includes a first terminal group 10, an isolation middle plate 30, a first insulator 40 that molds the first terminal group 10 and the isolation middle plate 30 together, The second terminal group 20 and the second insulator 50 integrally formed with the first insulator 40 and the second terminal group 20 .

[0023] The first terminal group 10 includes a first holding portion 11 , a first contact portion 12 and a first welding portion 13 respectively extending from two ends of the first holding portion 11 . After the first terminal group 10 is stamped and formed, the ends of the first contact portion 12 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com