Method of forming light doped drain electrode using inverse taper grid structure

A lightly doped drain and gate structure technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as shortening channels, making it difficult to manufacture, reducing component yield and electrical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

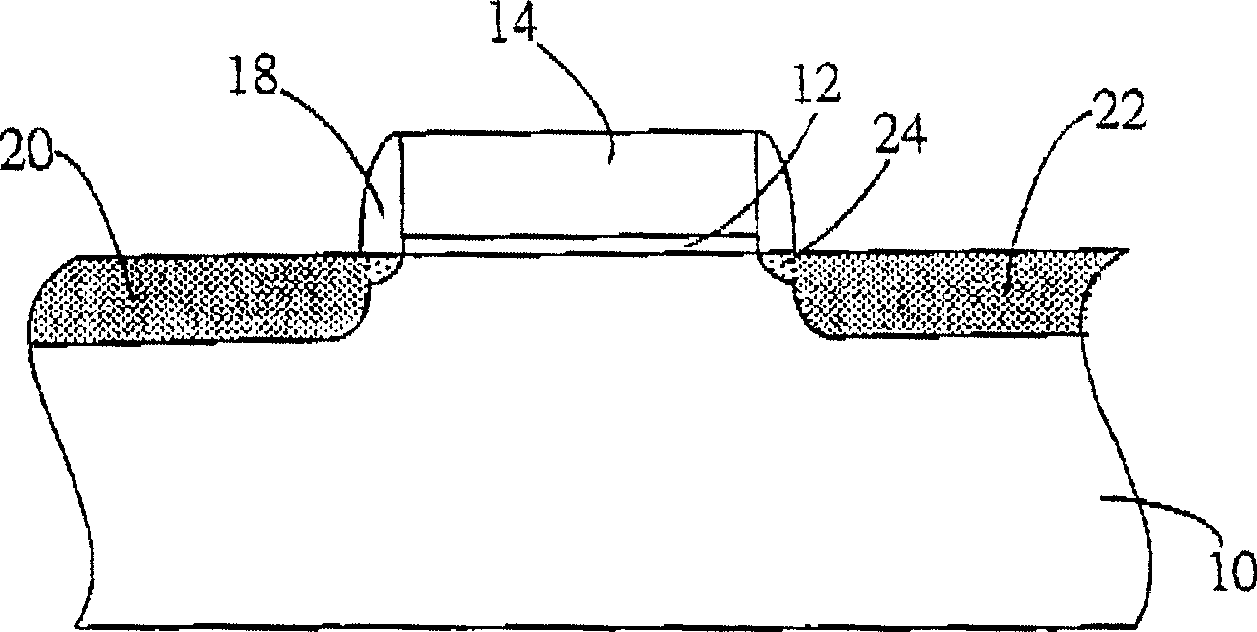

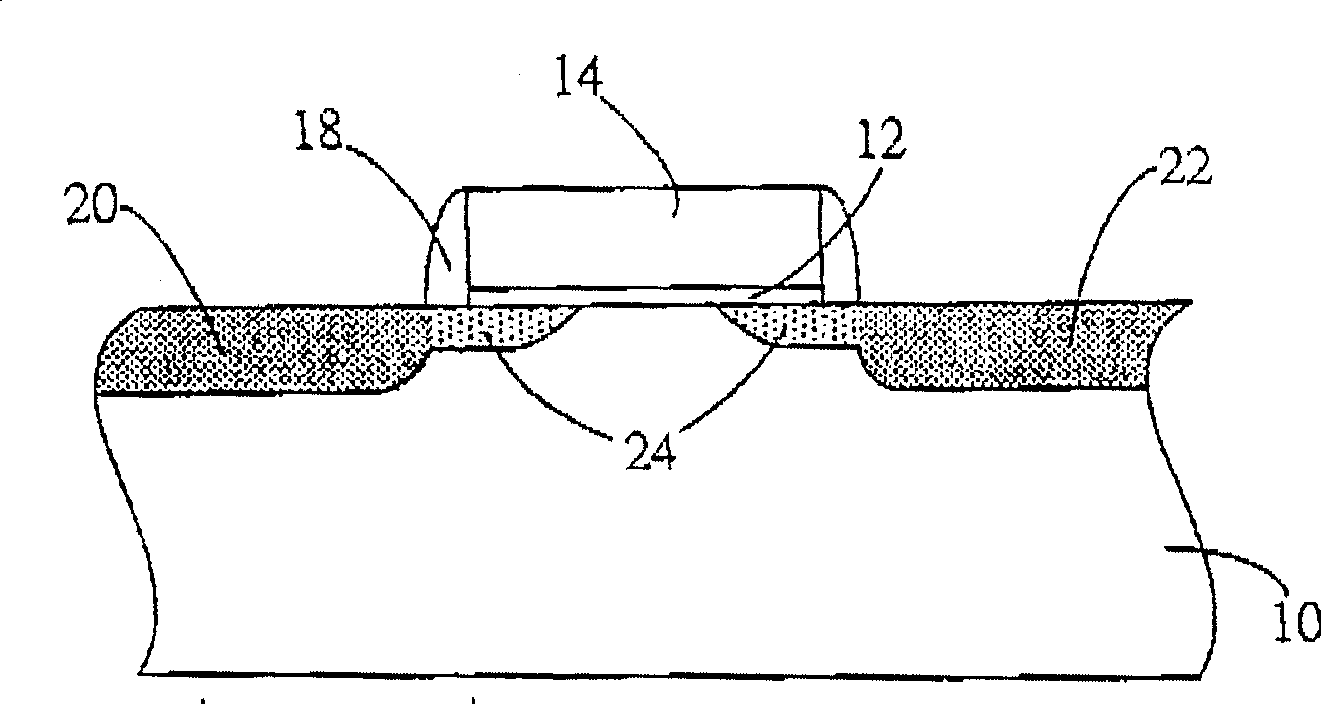

[0013] In the present invention, a gate stack structure is preformed on the substrate, and the gate stack structure is etched into a reverse trapezoidal shape, so that after the shallow ion doped region is formed, the shallow ion doped region is only laterally Diffusion to the substrate below the bottom edge of the gate stack structure, when heavy ion doping is performed to form an LDD structure, the length of the channel can be ensured, and the short channel effect commonly seen in sub-micron semiconductor manufacturing processes can be effectively solved.

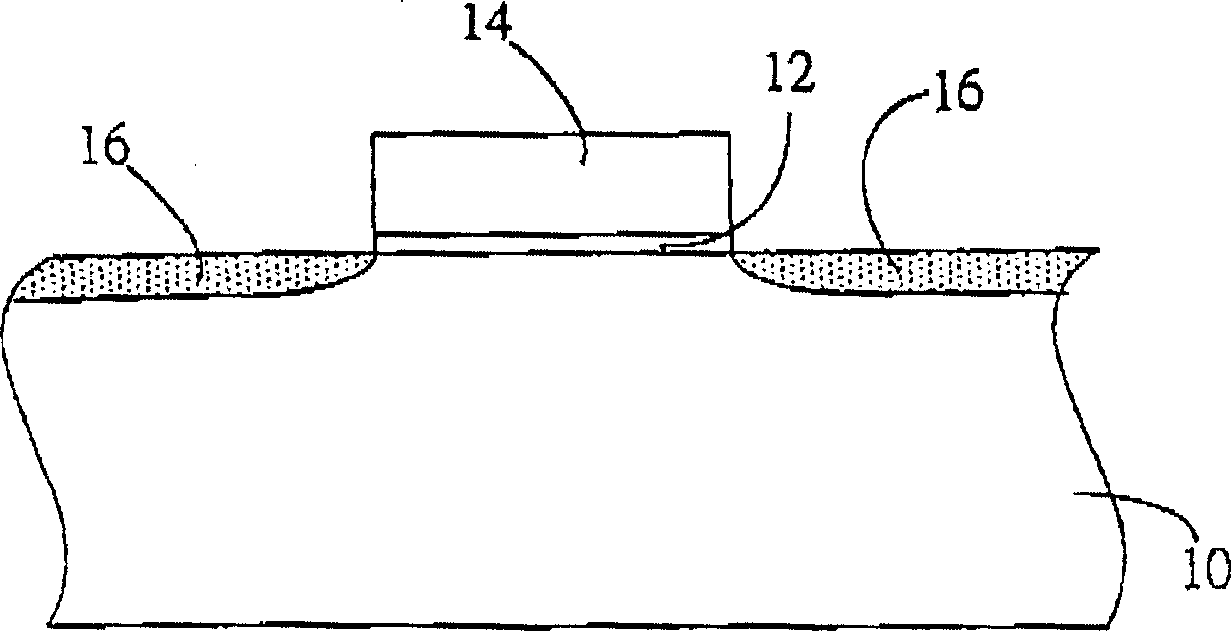

[0014] Figure 2A to Figure 2E The schematic cross-sectional views of each step of making the LDD for a preferred embodiment of the present invention are respectively; as shown in the figure, the manufacturing method of the present invention includes the following steps:

[0015] see Figure 2A First, a gate oxide layer 22 is formed on the substrate 20; then a polysilicon layer 24 is deposited on the gate oxide layer 22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com