Multiphase submarine cable transversal arrangement circularly laying construction method

A submarine cable laying and submarine cable technology, which is applied in the construction field of multi-phase submarine cable horizontal arrangement and circular laying, can solve the problems that are not suitable for large-diameter submarine cable laying construction, submarine cable laying process description, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

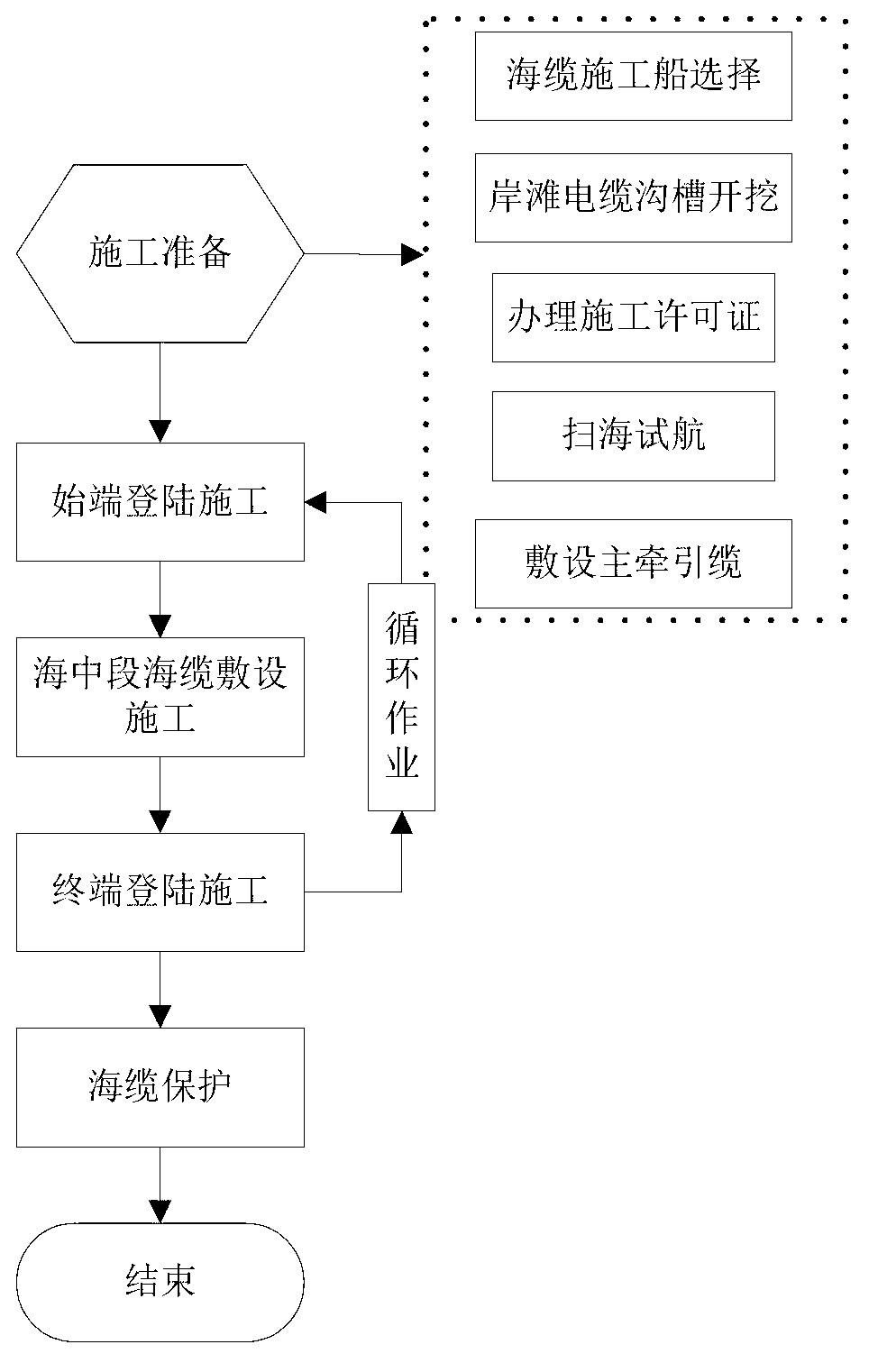

[0072] Such as figure 1 As shown, a brief introduction to the technological process: construction preparation (selection of submarine cable laying ship, submarine cable transfer, excavation of shore beach submarine cable trenches, certification, sea sweeping trial and laying of the main traction cable, etc.) → landing construction at the beginning → mid-sea section Cable laying construction → terminal landing construction (including circular laying construction) → submarine cable protection.

[0073] 1. On-site construction preparation

[0074] 1. Selection of submarine cable laying vessel

[0075] The construction and laying vessel is selected according to parameters such as the outer diameter R of the submarine cable drum, the maximum allowable height h of the submarine cable drum, the minimum back-twisting height and the total weight of the submari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com