Variable frequency steel strand cable penetrating machine

A steel strand and cable threading technology, which is applied in the field of steel strand threading machines, can solve the problems of human fatigue, difficulty in accurately controlling the length of steel strands, and high labor intensity, and achieve the effect of solving long-distance cable threading problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

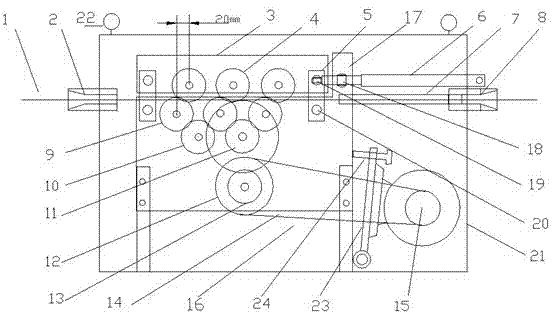

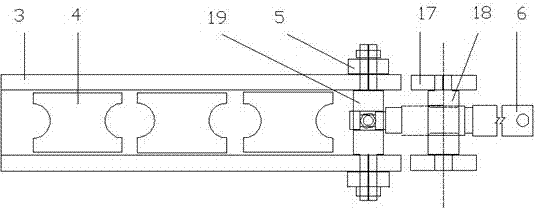

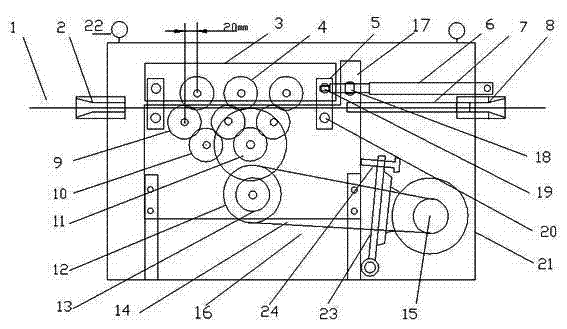

[0018] Such as figure 1 , 2 As shown, the present invention includes a machine casing 21, which adopts a cuboid structure, and a lifting ear 22 is arranged above the machine casing 21. A steel strand inlet pipe 8 and a steel strand outlet pipe 2 are arranged on both side plates of the machine housing 21, the inlet and outlet of the two are bell-shaped, and the steel strand guide is set at the front end of the steel strand inlet pipe 8. Tube 7.

[0019] A driving mechanism, a clamping mechanism and an adjusting screw 6 are arranged inside the machine housing 21 . The driving mechanism is composed of a bridge gear 10, a speed reduction gear set 11, a belt pulley 12, a transmission gear 13, a V-belt 14, a motor 15 and a tensioning device, wherein the speed reduction gear set 11 is composed of two large and small gears. Coaxial, the diameter ratio of the two gears can be determined according to the design requirements; the tensioning device includes a tensioning frame 23, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com