Full-automatic circular sawing machine

A fully automated, circular sawing machine technology, applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc., can solve the problems of unguaranteed cutting accuracy and low efficiency, so as to save labor costs, improve production efficiency, Precisely control the effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make those skilled in the art better understand the technical scheme of the present invention, the present invention will be further described below:

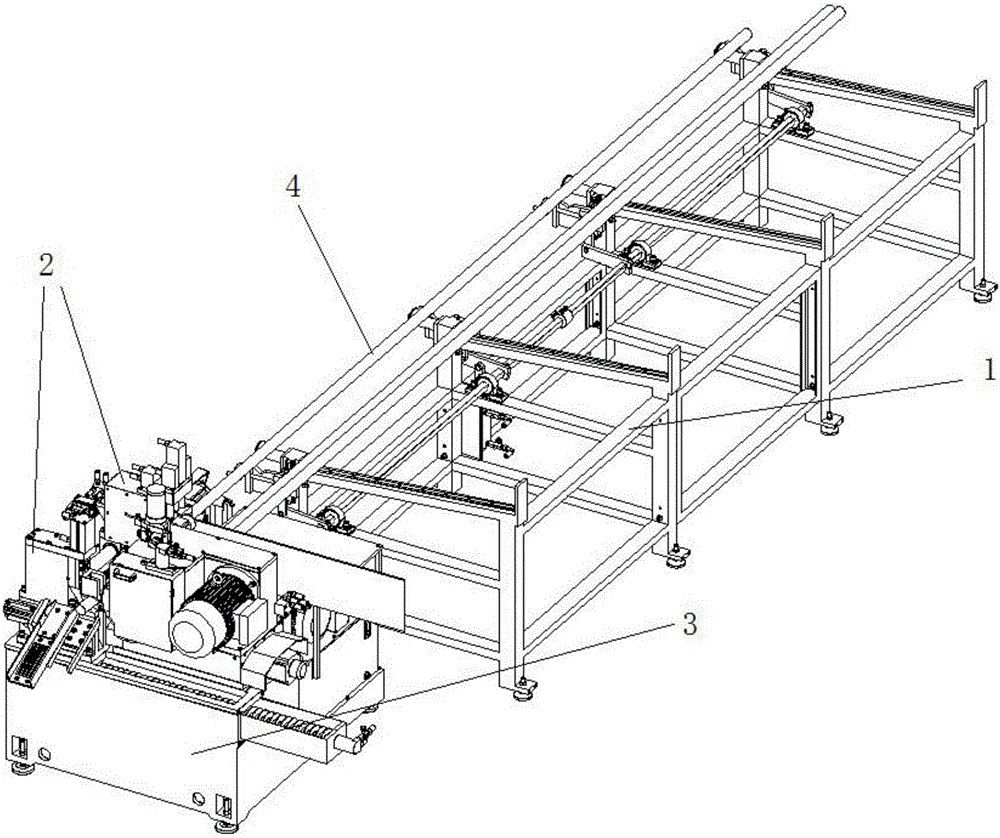

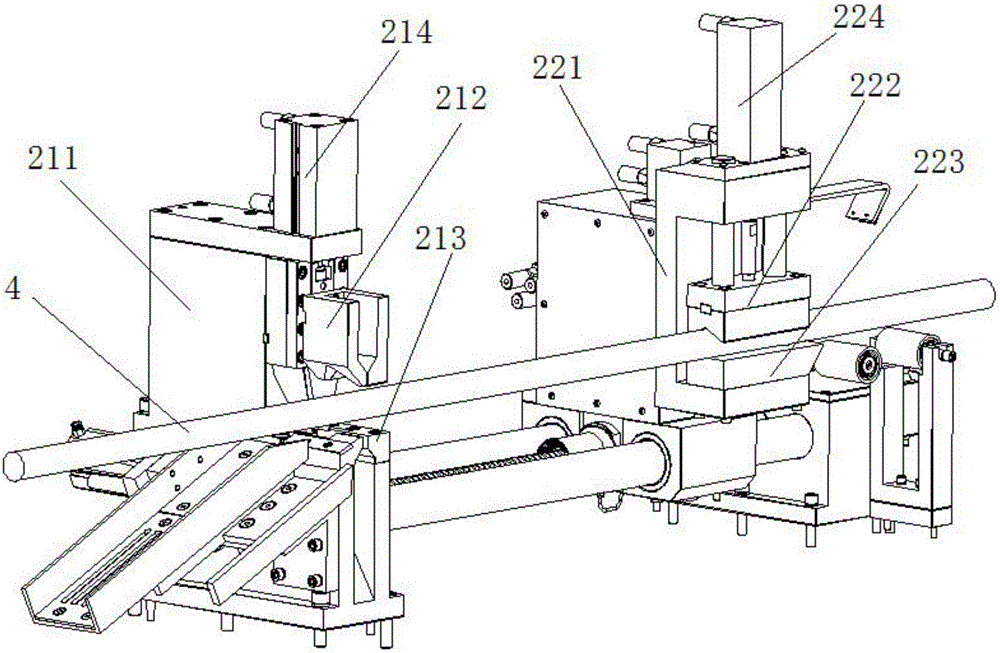

[0015] Such as figure 1 As shown, a fully automatic circular saw machine includes a circular saw machine 3, a feeding mechanism 2, and a feeding mechanism 1.

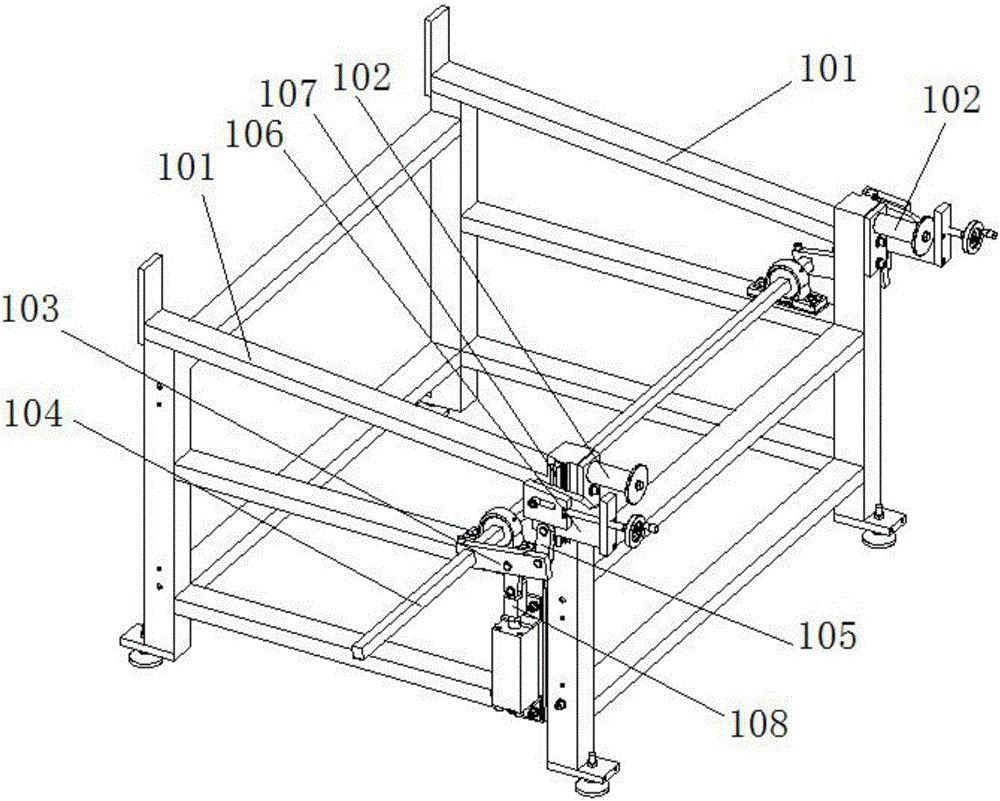

[0016] Feeding mechanism such as figure 2 As shown, it includes a feeding rack arranged on the frame and a storage rack located on one side of the feeding rack. The storage rack is composed of several parallel inclined bars 101, and the feeding rack is composed of several rollers 102. The workpiece 4 on the storage rack is transferred to the feeding rack by at least two sets of jacking mechanisms working together.

[0017] The jacking mechanism 1 includes a connecting piece 103, one end of the connecting piece 103 is connected with the transmission rod 104, and one end is hinged with the bottom end of the jacking piece 105, and the top of the jackin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com