Method for manufacturing fine straight PZT piezoelectric fiber array

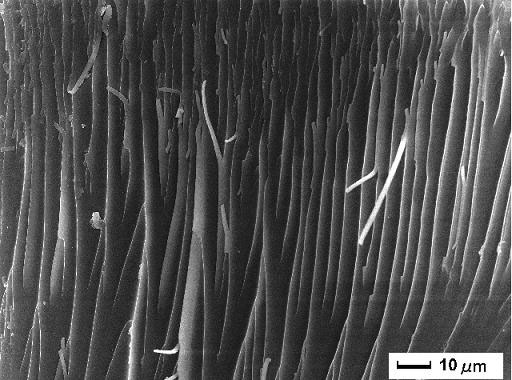

A piezoelectric fiber, flat technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, fiber chemical characteristics, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem of fiber uniformity decline, Disorder, fiber thickness limitation and other problems, to achieve the effect of neat and orderly arrangement of fibers, less damage, and high-voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

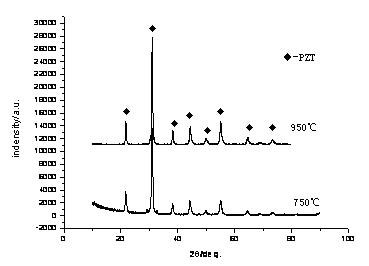

[0025] The preparation method of PZT piezoelectric fiber of the present invention is to carry out by following process:

[0026] 1. Preparation of PZT sol: After treating the above proportion of lead acetate, zirconium nitrate and tetrabutyl titanate in a solvent and stabilizer, mix it with the above proportion of water and acetic acid, and heat it at 80°C under the conditions of low temperature heating and ultrasonic vibration Mix the mixture evenly, stir evenly on a magnetic stirrer and completely generate the hydrolysis reaction to obtain the sol;

[0027] 2. Preparation of sol-powder mixing system: Mix sol and nano-PZT powder according to the above-mentioned ratio, add PEG as a dispersant, heat and stir evenly at a low temperature of 80°C, and disperse ultrasonically so that the mixture and sol are fully mixed evenly;

[0028] 3. Preparation of PZT piezoelectric fiber: Cut the plastic capillary into an appropriate length, fill the gap between the capillary with glue or par...

Embodiment 1

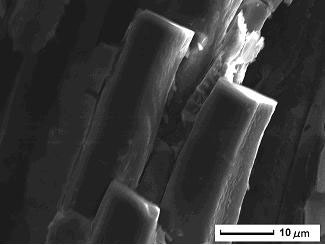

[0039] Weigh the four raw materials of lead acetate, zirconium nitrate and tetrabutyl titanate at a molar ratio of 100:56:44, dissolve and mix them uniformly with ethylene glycol monomethyl ether, add 1:1 water and acetic acid, and stir under magnetic force Adjust the solution concentration to 0.3mol / l to obtain a sol, take 10 parts of the sol, weigh 1 part of PZT nano powder according to the weight ratio of sol: PZT powder of 1:0.1, and then add PEG1000, the amount added is 0.5% of the PZT nano powder , disperse for half an hour under the action of magnetic stirring, and disperse in an ultrasonic disperser for 2 hours to prepare a sol powder system. Cut thin-walled plastic capillaries with an inner diameter of 0.25mm into 2cm lengths, and arrange 50 capillaries in a circular cross-section array shape. Fill the gap between the capillary tubes with paraffin wax and place it in a quartz tube with an inner diameter of 1 cm, solidify at room temperature for 30 minutes, then sea...

Embodiment 2

[0041] Weigh the four raw materials of lead acetate, zirconium nitrate and tetrabutyl titanate at a molar ratio of 100:56:44, dissolve and mix them uniformly with ethylene glycol monomethyl ether, add 1:1 water and acetic acid, and stir under magnetic force Adjust the concentration of the solution to be 0.5mol / l to obtain the sol, take 100 parts of the sol, weigh 6 parts of PZT nano-powder according to the sol: PZT powder weight ratio of 1:0.06, then add PEG400 and PEG2000, the addition is 1% of the PZT nano-powder 0.6%, disperse for half an hour under the action of magnetic stirring, and then disperse in an ultrasonic disperser for 2 hours to prepare a sol powder system. Cut thin-walled plastic capillaries with an inner diameter of 0.3mm into 4cm lengths, and take 100 tubes and arrange them in a circular cross-section array Shape, fill the gap between the capillary with 501 universal glue, place it in a quartz tube with an inner diameter of 2 cm, cure at room temperature for 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com