Full-automatic inductor tin dipping device and control method

A fully automatic, mobile device technology, applied in the directions of tin feeding devices, auxiliary devices, manufacturing tools, etc., can solve the problems of increasing production costs of enterprises, wire burnt or virtual welding, burns of production personnel, etc., to improve production efficiency and ensure Quality, the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

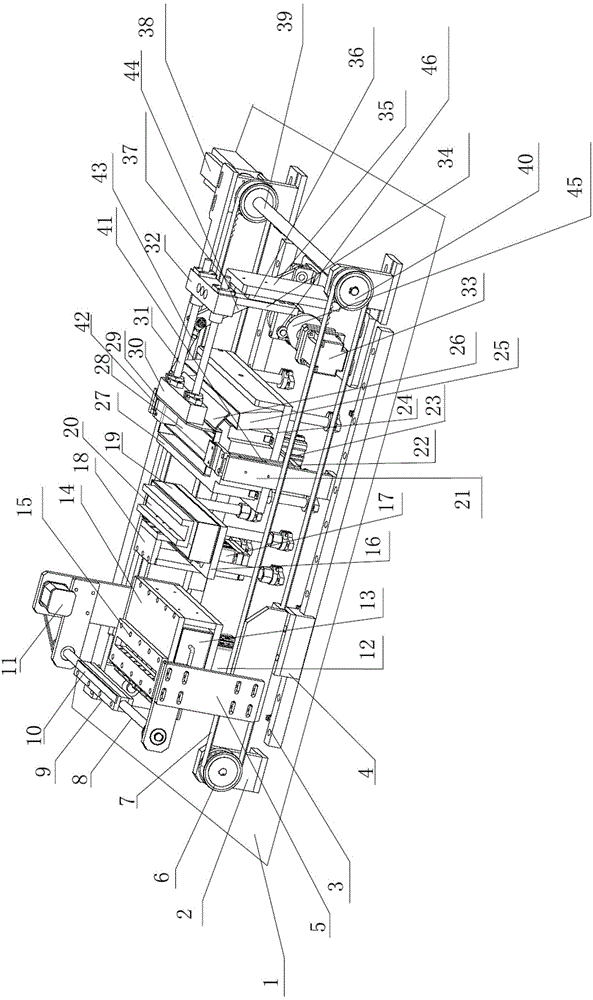

[0035] Such as figure 1 As shown, the fully automatic inductive tin immersion device of this embodiment includes an operating platform 1, a material suction device, a blanking device, a turning device, a moving device, a flux device, a tin immersion device and a tin scraping device, and the suction device is set On the unloading device, the unloading device is set on the left side of the operating platform, one end of the turning device is connected to the suction device, and the other end is set on the moving device, the moving device is set on the operating platform, the flux The device is located on the right side of the unloading device, the immersion tin device is located on the right side of the flux device, and the moving device can move from the loading position to the immersion tin device; the tin scraping device is set on the right side of the immersion tin device .

[0036] The material suction device includes a material rod 9 and a material rod connecting shaft 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com