Hollow and smooth titanium-mass forging golf iron head

A technology of golf and golf, which is applied to golf balls, golf clubs, rackets, etc., can solve problems such as limited effects, and achieve the effects of improving stability, improving experience, and stabilizing the center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

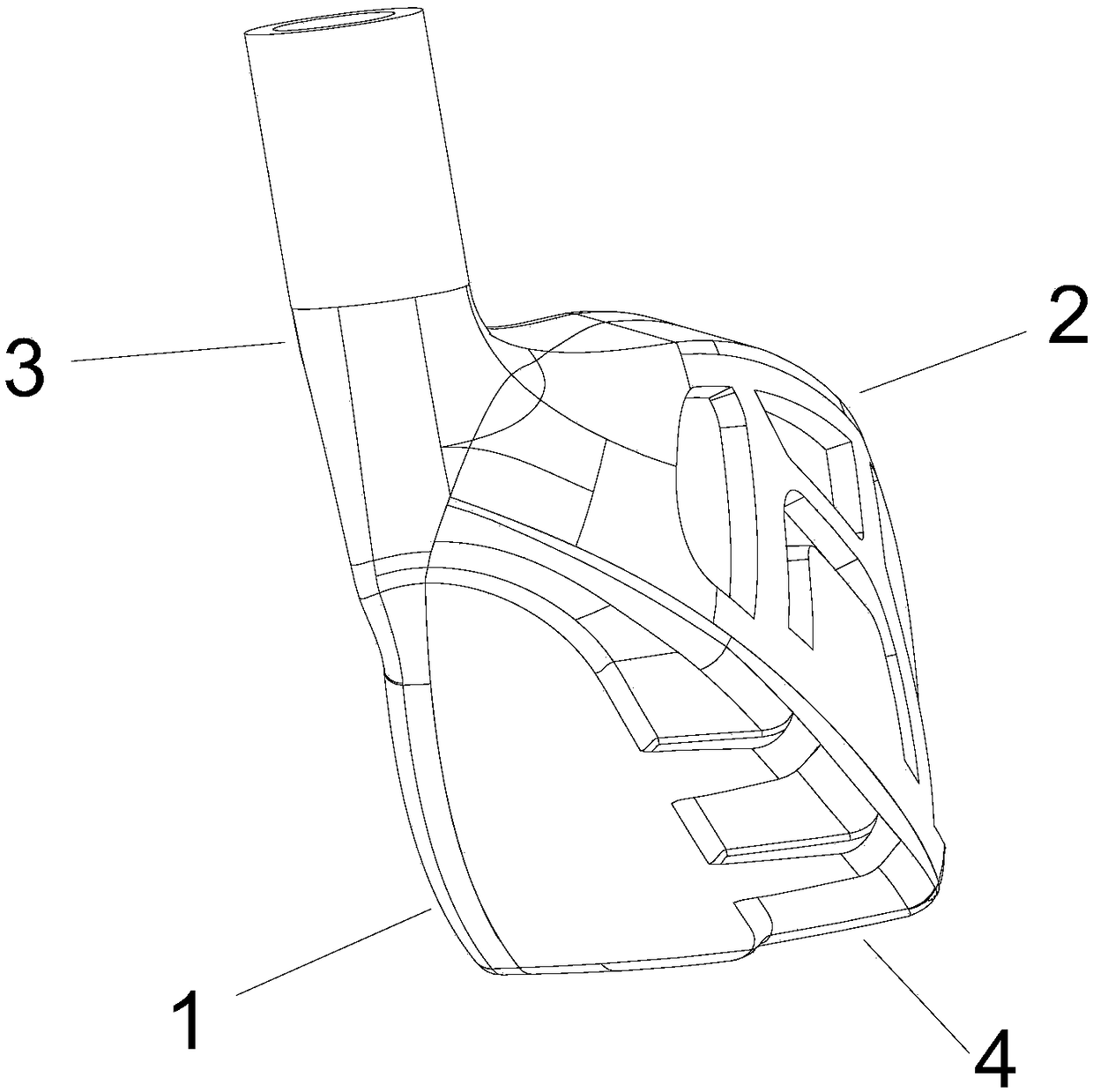

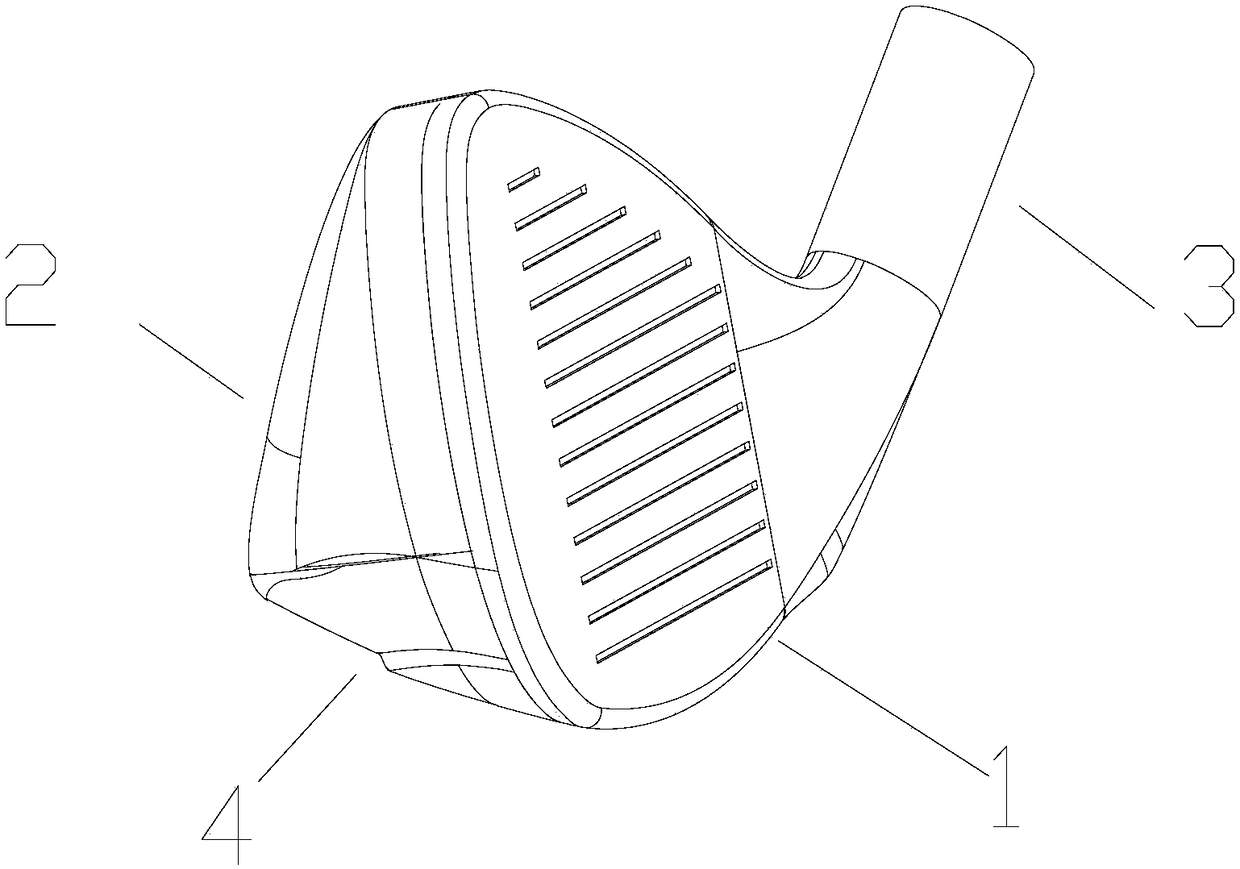

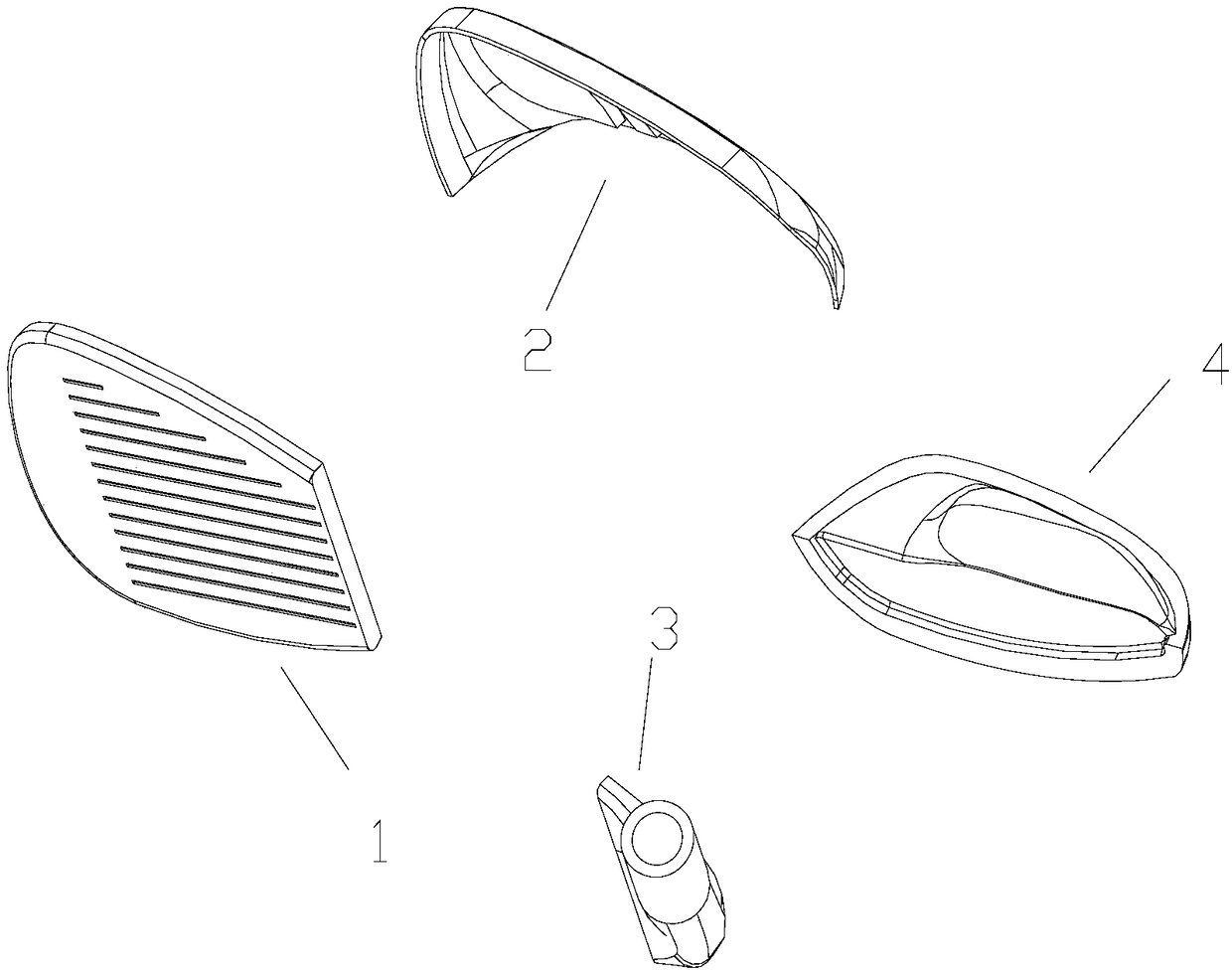

[0037] A hollow smooth titanium forged golf iron head, such as Figures 1 to 9 As shown, a striking surface body 1 , an upper cover body 2 , a club head 3 and a counterweight 4 that directly contact the golf ball are provided. The side that contacts the golf ball when striking the golf ball is defined as the front and the ground as the bottom, and the density of the counterweight 4 is greater than that of the striking surface body 1 or the upper cover body 2 .

[0038] The upper cover body 2 and the weight block 4 are set up and down and welded seamlessly. The club head 3 is first welded to the striking surface body 1. After welding, the upper cover body 2 and the counterweight block 4 are integrally seamless with the striking surface body 1 and the club head 3 Welding, the weight block 4, the upper cover body 2, the club head 3 and the striking surface body 1 form a closed body.

[0039] In the closed body, a cavity is formed between the upper cover body 2 , the striking sur...

Embodiment 2

[0045] A hollow smooth titanium forged iron golf club head, other features are the same as in Embodiment 1, the difference is that the inner surface of the striking surface body 1 of this embodiment is a concave surface, such as Figure 10 shown.

[0046] Compared with Embodiment 1, the part of the striking face body 1 in this embodiment that contacts the golf ball is thinner, which is more conducive to deformation so that the golf ball can fly farther.

Embodiment 3

[0048] A hollow smooth titanium forged iron golf club head, the other features are the same as those in Embodiment 1, the difference is that there are protruding outer eaves around the striking surface body 1, the upper cover body 2, the club head 3 and the counterweight 4 Correspondingly welded to the outer eaves 11 to realize welding and fixing with the upper cover body 2, such as Figure 11 shown.

[0049] Compared with Embodiment 1, the counterweight 4 of this embodiment is far away from the hitting surface, because the density of the striking surface body 1 is smaller than that of the counterweight 4, and the structure of the outer eaves 11 makes the counterweight 4 farther away from the striking surface than in Embodiment 1. surface body 1, so the overall center of gravity of the golf iron head is farther away from the striking surface body 1, which is more conducive to deformation so that the golf ball can fly farther.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com