Hockey goalie club and manufacturing method thereof

A production method and goalkeeper technology, applied to rackets, sports accessories, etc., can solve the problems of slow hitting speed, heavy weight, slow hitting response, etc., to improve hitting flexibility, improve hitting flexibility, and good strength. and rebound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

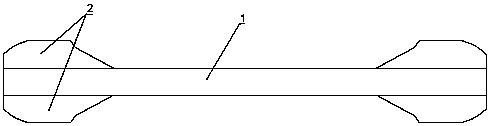

[0030] A hockey goalkeeper club described in this embodiment includes a handle and a goalkeeper board. The goalkeeper board is composed of a front section and a middle section. The front section of the goalkeeper board includes a front section made of epoxy resin foam material The filling board and the carbon fiber yarn or glass fiber yarn covered on the front filling board; the middle part of the goalkeeper board includes a support rod supported by carbon fiber yarn or glass fiber yarn and epoxy resin hair at both ends of the support rod. The mid-section filler plate supported by foam material, wrap carbon fiber yarn or glass fiber yarn material on the support rod and the middle section filler panel, and paste multi-layer carbon fiber yarn material or glass fiber yarn material on the front of the middle section; the front part of the goalkeeper board And the middle section is covered with a layer of veil, the veil is carbon fiber yarn or glass fiber yarn; the handle and the go...

Embodiment 2

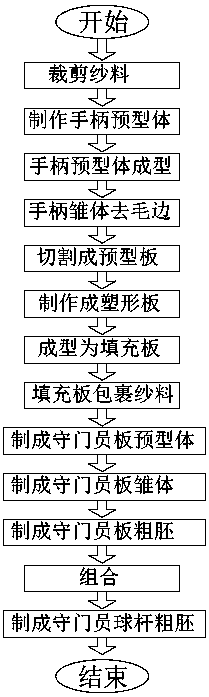

[0033] Such as figure 2 As shown, a method for making a hockey goalkeeper club described in this embodiment includes the following steps:

[0034] (1) Cut the required carbon fiber yarn or glass fiber yarn according to the structure;

[0035] (2) Put the preform tool used to make the goalkeeper's handle on a nylon membrane tube with one end sealed, and then vacuumize; wrap several layers of carbon fiber on the handle tool with the nylon membrane tube, remove the vacuum tube, and preform the handle. The mold tool is taken out to obtain the handle preform;

[0036] (3) Put the handle preform into the handle forming mold, and obtain the handle prototype after molding;

[0037] (4) Cut off the excess burr from the handle embryo to obtain the rough embryo of the handle;

[0038] (5) Cut the epoxy resin foam material into preforms for the front section and the middle section of the goalkeeper board;

[0039] (6) Put the preformed plates of the front section and the middle secti...

Embodiment 3

[0052] Such as figure 2 As shown, a method for making a hockey goalkeeper club described in this embodiment includes the following steps:

[0053] (1) Cut the required carbon fiber yarn or glass fiber yarn according to the structure;

[0054] (2) Put the preform tool used to make the goalkeeper's handle on the nylon film tube with one end sealed, and then vacuum; wrap several layers of glass fiber yarn on the handle tool with the nylon film tube, and remove the vacuum tube. The handle preform is taken out to obtain the handle preform;

[0055] (3) Put the handle preform into the handle forming mold, and obtain the handle prototype after molding;

[0056] (4) Cut off the excess burr from the handle embryo to obtain the rough embryo of the handle;

[0057] (5) Cut the epoxy resin foam material into preforms for the front section and the middle section of the goalkeeper board;

[0058] (6) Put the preformed plates of the front section and the middle section of the goalkeeper b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com