A kind of production equipment and production method of fatty acid methyl ester soap

A fatty acid methyl ester and production equipment technology, which is applied in the direction of carboxylate/lactone preparation, separation method, and recovery of fatty substances. It can solve problems such as insufficient reaction, incomplete separation of methanol, and large equipment footprint. Strong foam, low solubility, and the effect of reducing equipment footprint and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and advantages of the technical solution more clear, the technical solution will be further described in detail below with reference to the specific embodiments. It should be understood that these descriptions are only exemplary and are not intended to limit the scope of the technical solution.

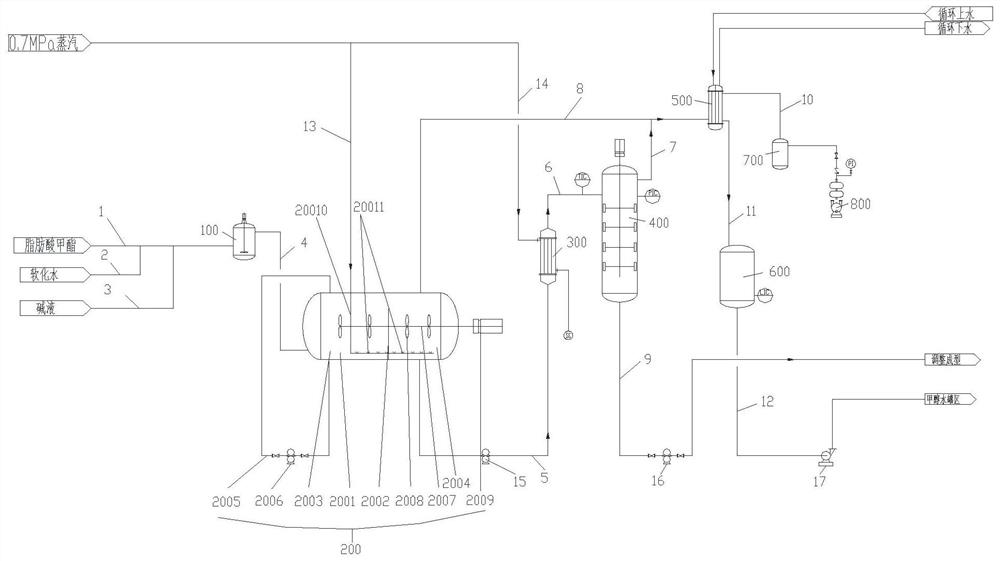

[0023] like figure 1 As shown, a production equipment for fatty acid methyl ester soap making, the production equipment comprises a feed mixer 100, a saponification reactor 200, a heater 300, a wiper dryer 400, a methanol condenser 500, a methanol water tank 600, a Foamer 700, vacuum pump 800;

[0024] The feed end of the feed mixer 100 is connected with the fatty acid methyl ester feed line 1, the softened water feed line 2 and the lye feed line 3, and the discharge end of the feed mixer 100 passes through the first output The pipeline 4 is connected to the feed end of the saponification reactor 200, and the discharge end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com