Powder material ton bag quantitative packing scale and packing method

A quantitative packaging and powder technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc., can solve the problems of hidden safety hazards, dangers, low work efficiency, etc., and achieve low labor intensity and operating costs, high degree of automation, The effect of increasing packaging output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

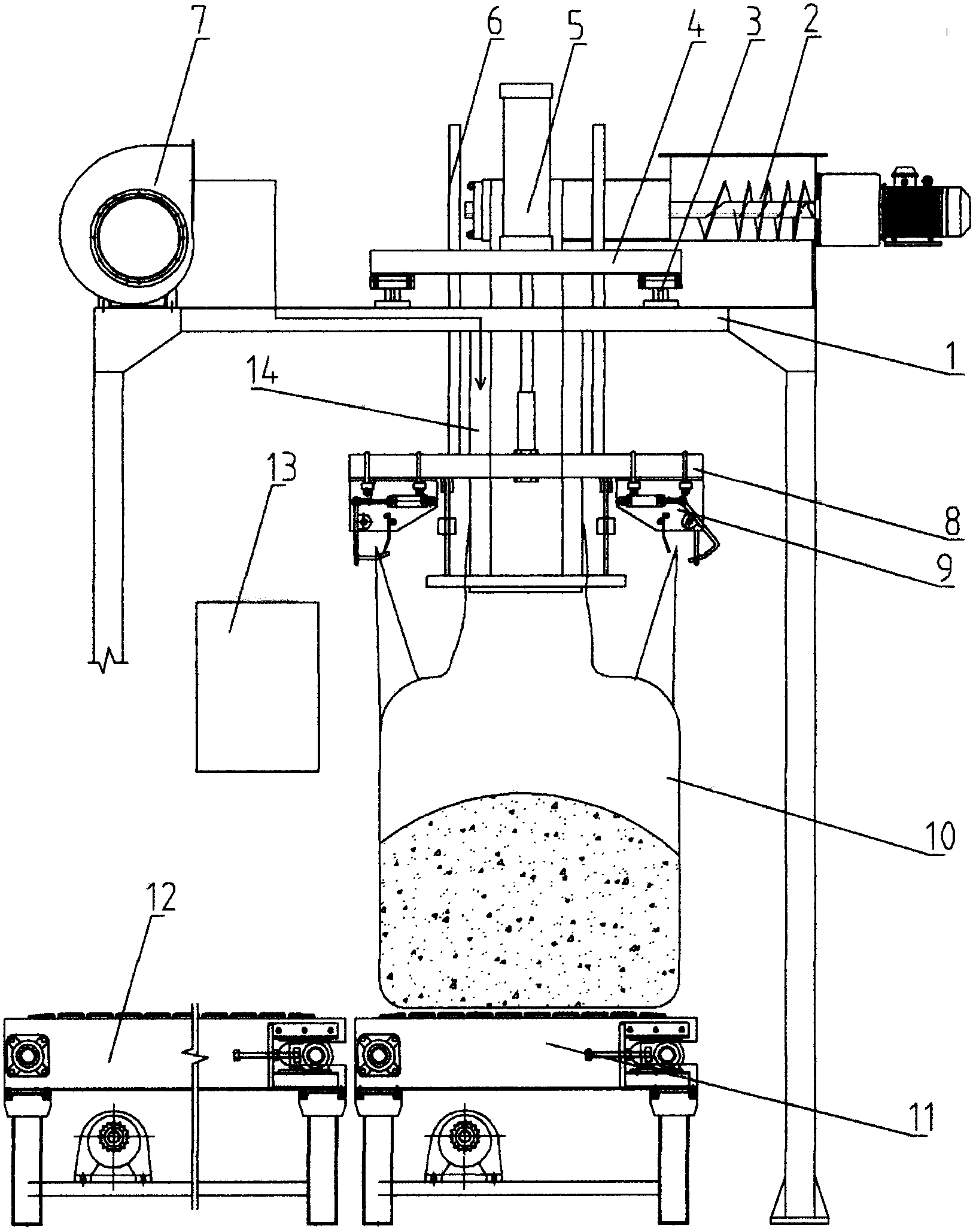

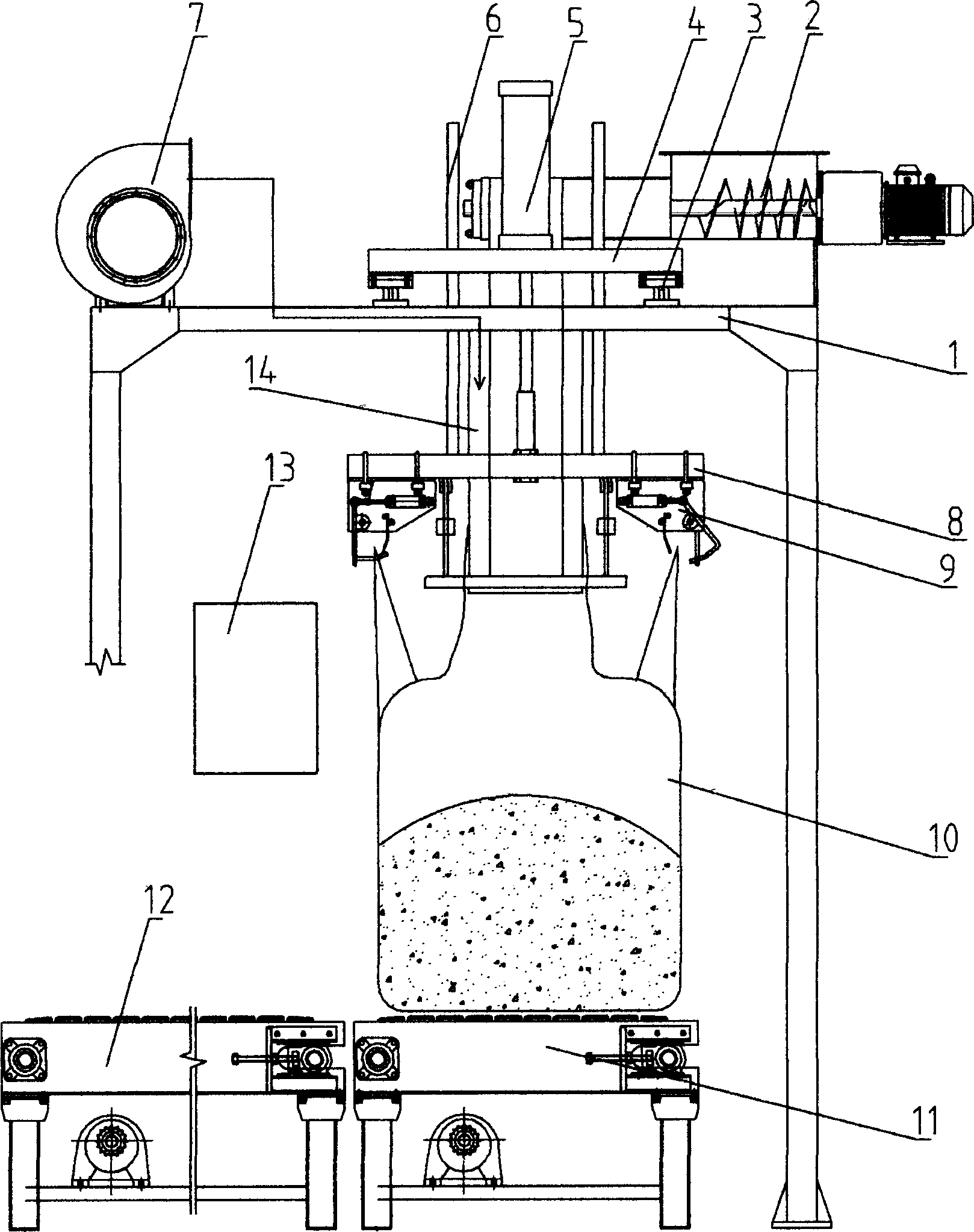

[0022] Such as figure 1 Shown is a schematic diagram of the composition and structure of the powder ton-bag quantitative packaging scale of the present invention. The powder ton-bag quantitative packaging scale of the present invention includes: a platform 1, a frequency conversion screw mechanism 2 for controlling the feeding speed, a weighing module 3, and a weighing module. Frame 4, cylinder 5, fan 7, lifting and clamping bag mechanism 8, automatic bag removing mechanism 9, chain plate conveyor 11 and chain plate conveyor 12, weighing control system 13 and air duct 14; wherein the weighing module 3 The platform 1 is connected with the weighing frame 4, the weighing frame 4 is used to transmit the weighing weight, and the cylinder 5 is installed on the weighing frame 4 and drives the lifting and clamping bag mechanism 8.

[0023] The working principle of the powder ton bag quantitative packaging scale of the present invention is described in detail as follows:

[0024] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com