Polyester film, and a preparation method and applications thereof

A polyester film and film technology, applied in the field of materials, can solve the problems of not being able to meet the high-temperature cooking performance of bonded products, not being able to meet the requirements for deep processing of laminated metal plates, and not being able to meet the needs of deep processing of coated metal plates, etc., to achieve Low depreciation cost of fixed equipment, low equipment price, energy saving and processing cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

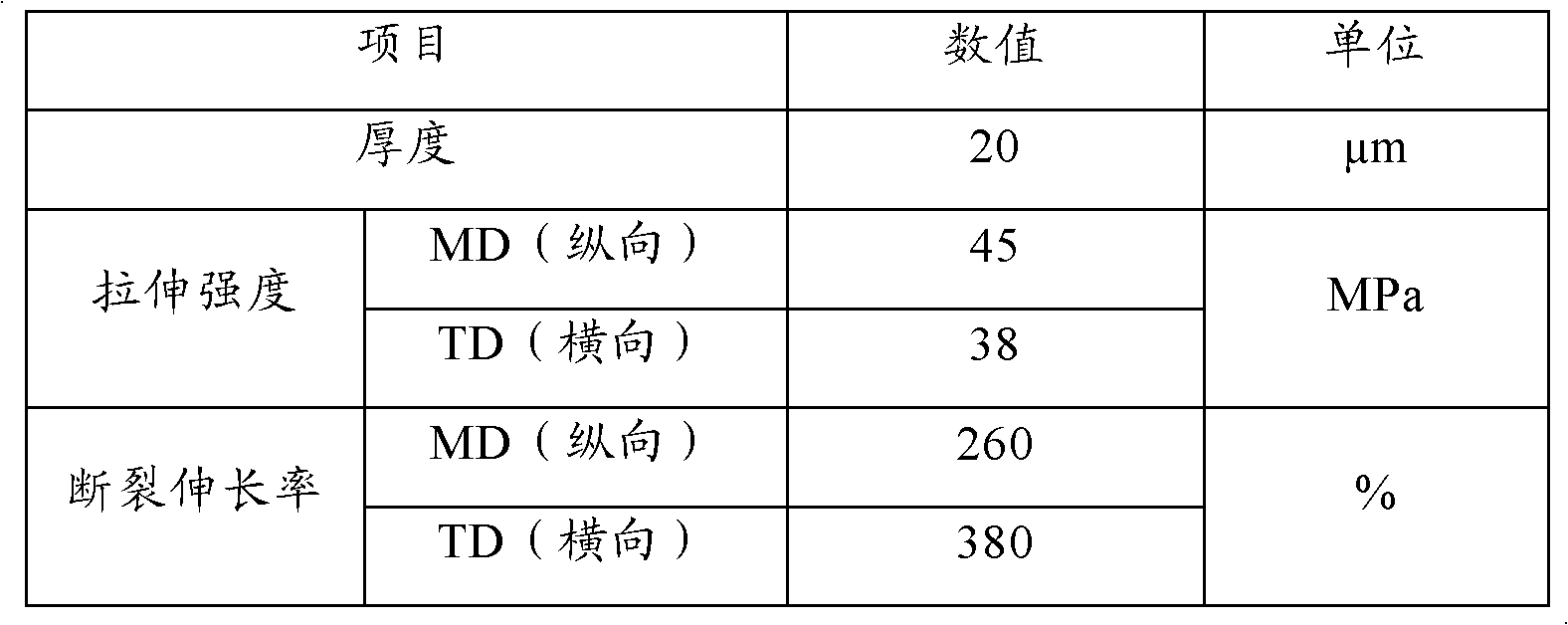

Embodiment 1

[0032] This embodiment discloses a kind of polyester film, and its raw material formula is:

[0033] Bottle-grade polyester chips: isophthalic acid-modified polyethylene terephthalate with an intrinsic viscosity of 0.78dl / g and a melting point of 240°C, and the molar content of the modified monomer isophthalic acid is 5%; Diformic acid modified polyethylene terephthalate is formed by adding isophthalic acid during the polymerization process of terephthalic acid and ethylene glycol through esterification and polycondensation.

[0034] Additive slice: SiO 2 The mass fraction of is 4000ppm, and the balance is the above-mentioned isophthalic acid-modified polyethylene terephthalate.

[0035] Production process: The above raw materials are fully mixed according to the weight ratio of bottle-grade polyester chips and additive chips at a weight ratio of 5:1, and dried on a fluidized bed at a drying temperature of 130°C for 4 hours. The dried mixture is extruded through a twin-screw...

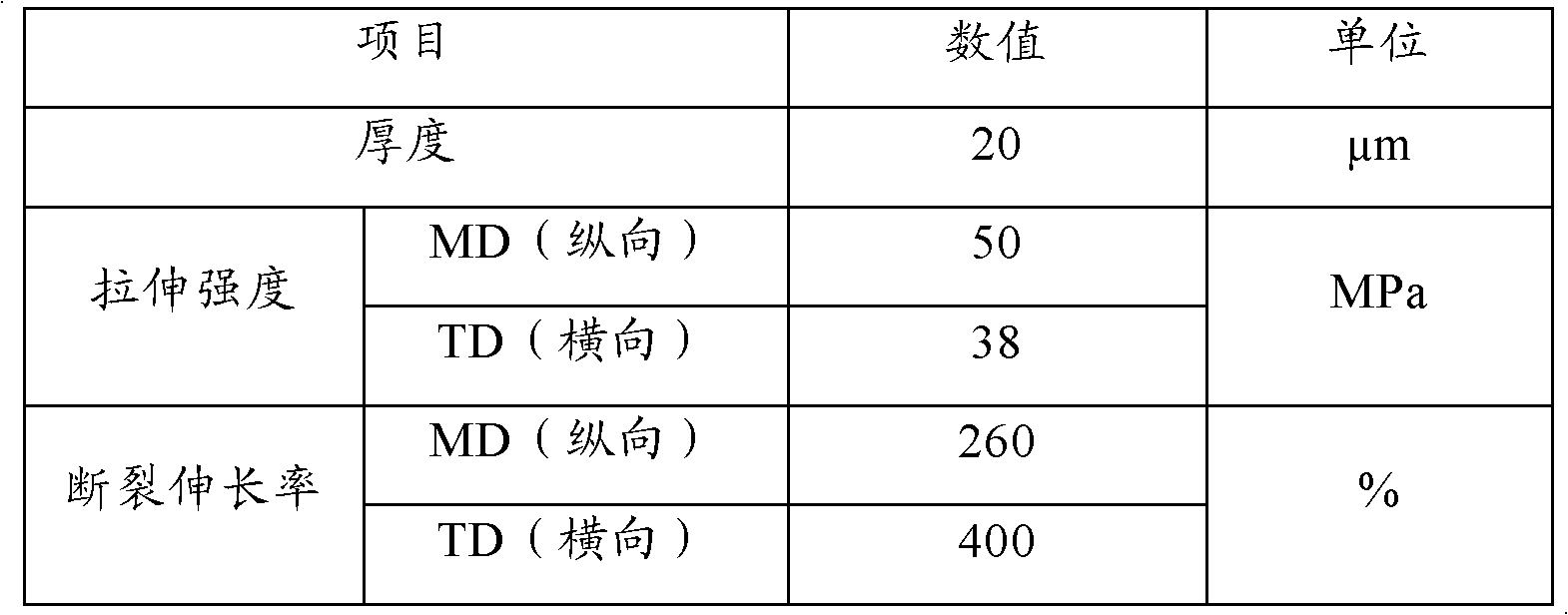

Embodiment 2

[0039] This embodiment discloses a kind of polyester film, and its raw material formula is:

[0040] Bottle-grade polyester chips: intrinsic viscosity 0.84dl / g, melting point 248°C, isophthalic acid modified polyethylene terephthalate, molar content of isophthalic acid 2%;

[0041] Additive slice: SiO 2 The mass fraction of is 3000ppm, and the balance is the above-mentioned isophthalic acid-modified polyethylene terephthalate.

[0042] Production process: The above raw materials are fully mixed with bottle-grade polyester chips and additive chips at a ratio of 5:1, and dried on a fluidized bed at a drying temperature of 140°C for 4 hours. The dried mixture is extruded through a twin-screw extruder. The temperature of each zone of the extruder is between 250°C and 265°C. It is extruded through a single-layer die with a melt thickness of 0.20mm. For film formation, the temperature of the casting roll is 60-75°C, the linear speed of the casting roll is 10 times of the melt outf...

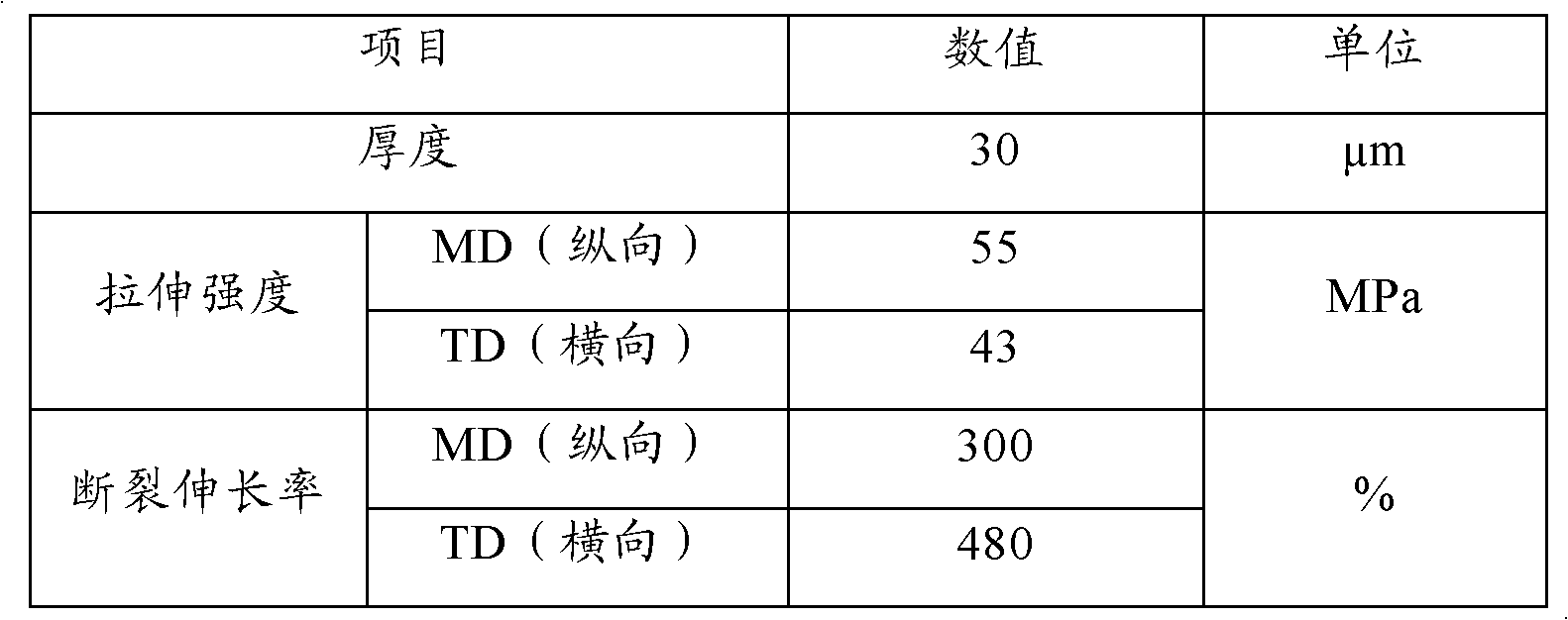

Embodiment 3

[0046] This embodiment discloses a kind of polyester film, and its raw material formula is:

[0047] Bottle-grade polyester chips: intrinsic viscosity 0.90dl / g, melting point 251°C, isophthalic acid-modified polyethylene terephthalate, molar content of isophthalic acid 1.2%;

[0048] Additive slice: SiO 2 The mass fraction of is 2000ppm, and the balance is the above-mentioned isophthalic acid-modified polyethylene terephthalate.

[0049] Production process: The above-mentioned raw materials are fully mixed with bottle-grade polyester chips and additive chips in a ratio of 4:1, and dried on a fluidized bed at a temperature of 150°C for 4 hours. The dried mixture is extruded through a twin-screw extruder. The temperature of each zone of the extruder is between 255°C and 270°C. It is extruded through a single-layer die with a melt thickness of 0.30mm. For film formation, the temperature of the casting roll is 60-75°C, the linear speed of the casting roll is 10 times of the melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com