Full-degradable thermoplastic composite material and sheet thereof

A composite material, fully degradable technology, applied in the field of fully degradable thermoplastic composite materials, can solve the problems of incomplete biodegradation, low glass softening temperature, unsuitable processing, etc., and achieve the effect of strong promotion significance, low cost and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

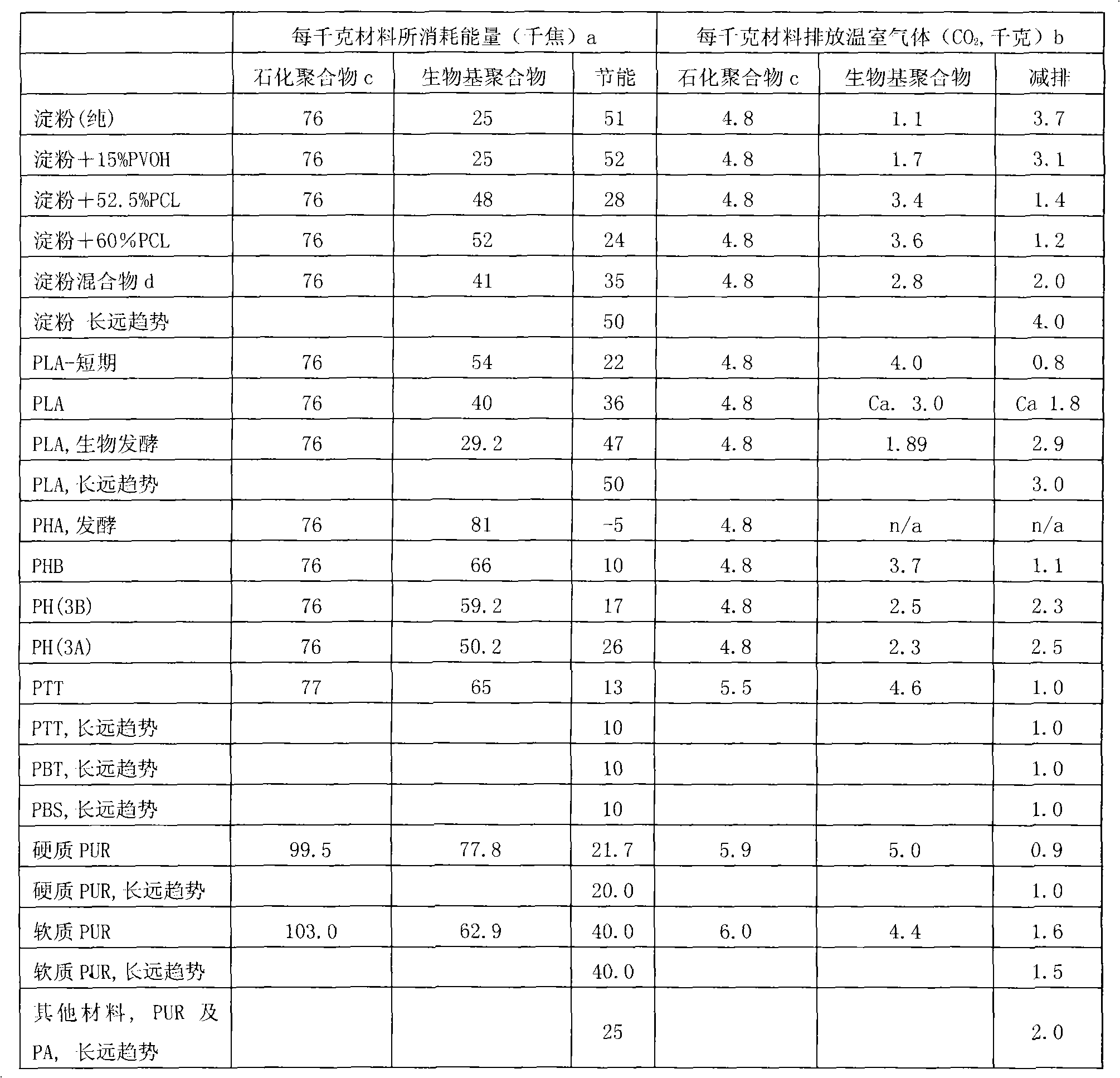

Method used

Image

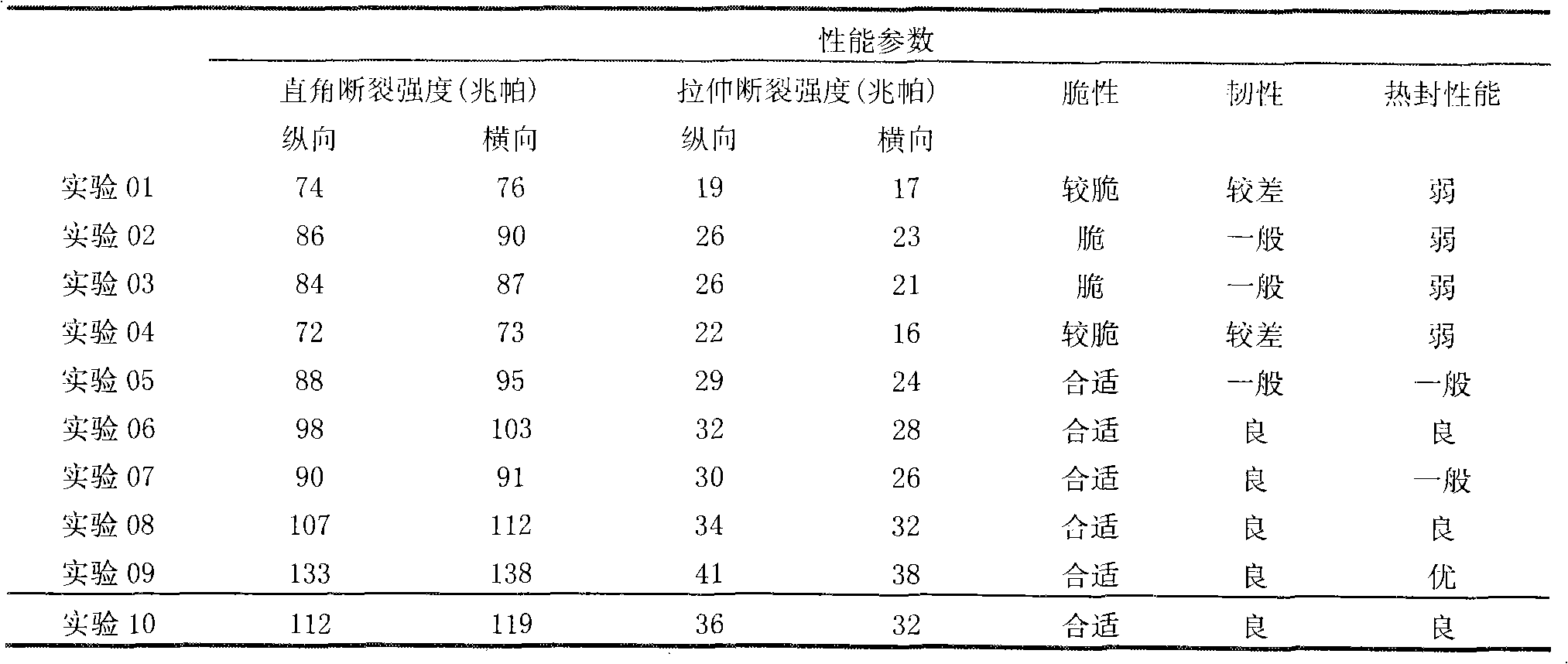

Examples

Embodiment 1

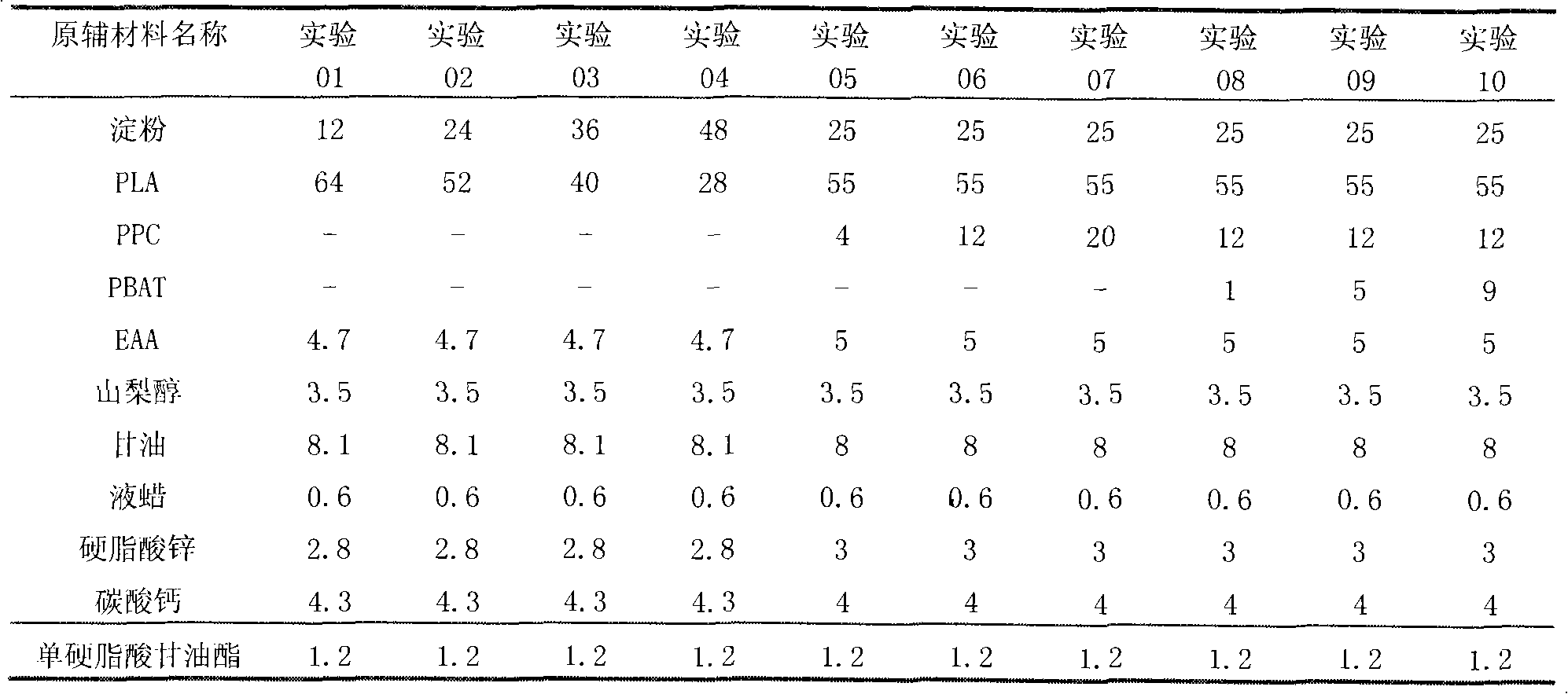

[0106] Embodiment 1: Preparation of fully degradable thermoplastic composite material and sheet of the present invention

[0107] Starch 25 kg PLA 55 kg PPC 12 kg

[0108] PBAT 5kg EAA 5kg Sorbitol 3.5kg

[0109] 8 kg of glycerin, 0.6 kg of liquid wax, 3 kg of zinc stearate

[0110] 4 kg calcium carbonate 1.2 kg monostearic acid

[0111] Put starch, PLA, PBAT, PPC and EAA into the mixer, pre-mix at room temperature for 6 minutes, and set the speed at 75 rpm; add the rest of the reaction aids, increase the temperature to 50 ° C, and increase the speed to 160 rpm, Mix at high speed for 8 minutes, discharge; mix and stir the materials evenly, put them into the twin-screw extruder, set the screw speed of each section at 120-800 rpm, set the temperature at 150-170°C, and control the vacuum degree of each section At 0.06-0.08Mpa, after melting, shearing, dispersing, rearranging, venting, plasticizing, extruding and cooling, the pellets of the fully degradable thermoplastic compos...

Embodiment 2

[0112] Put the prepared pellets into the tape casting machine, adjust the parameters of the die head and air knife, and go through melting, plasticizing, calendering, pulling, cooling and winding to obtain a fully degradable sheet with a thickness of 0.35mm. Embodiment 2: Preparation of fully degradable thermoplastic composite material and sheet of the present invention

[0113] Starch 25 kg PLA 45 kg PPC 9 kg

[0114] PBAT 6 kg EAA 4 kg Sorbitol 4 kg

[0115] Glycerin 8 kg Liquid wax 0.6 catties Zinc stearate 2.5 kg

[0116] Calcium Carbonate 5kg Glyceryl Monostearate 1.2kg

[0117] Put starch, PLA, PBAT, PPC and EAA into the mixer, pre-mix for 7 minutes at room temperature, and set the speed at 80 rpm; add the rest of the reaction aids, increase the temperature to 50 ° C, and increase the speed to 155 rpm, Mix at high speed for 10 minutes, discharge; mix and stir the materials evenly, put them into the twin-screw extruder, set the screw speed of each section at 120-800 rp...

Embodiment 3

[0119] Embodiment 3: Preparation of fully degradable thermoplastic composite material and sheet of the present invention

[0120] Starch 20 kg PLA 50 kg PPC 13 kg

[0121] PBAT 5kg EAA 5kg Sorbitol 3kg

[0122] 6 kg of glycerin, 0.8 kg of liquid wax, 3.5 kg of zinc stearate

[0123] Calcium carbonate 4 kg Glyceryl monostearate 0.8 kg

[0124] Put starch, PLA, PBAT, PPC and EAA into the mixer, pre-mix at room temperature for 6 minutes, and set the speed at 75 rpm; add the rest of the reaction aids, increase the temperature to 55 ° C, and increase the speed to 160 rpm, Mix at high speed for 9 minutes, discharge; mix and stir the materials evenly, put them into the twin-screw extruder, set the screw speed of each section at 120-800 rpm, set the temperature at 150-170°C, and control the vacuum degree of each section At 0.06-0.08Mpa, after melting, shearing, dispersing, rearranging, venting, plasticizing, extruding and cooling, the pellets of the fully degradable thermoplastic c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com