Formula and production process of antibacterial material applied to swimming goggles and swimming cap

An antibacterial material and production process technology, which is applied in the field of swimming goggle and swimming cap material preparation, can solve the problems of lack of antibacterial cleaning and sanitation, achieve excellent comprehensive physical and chemical properties, improve protection ability, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

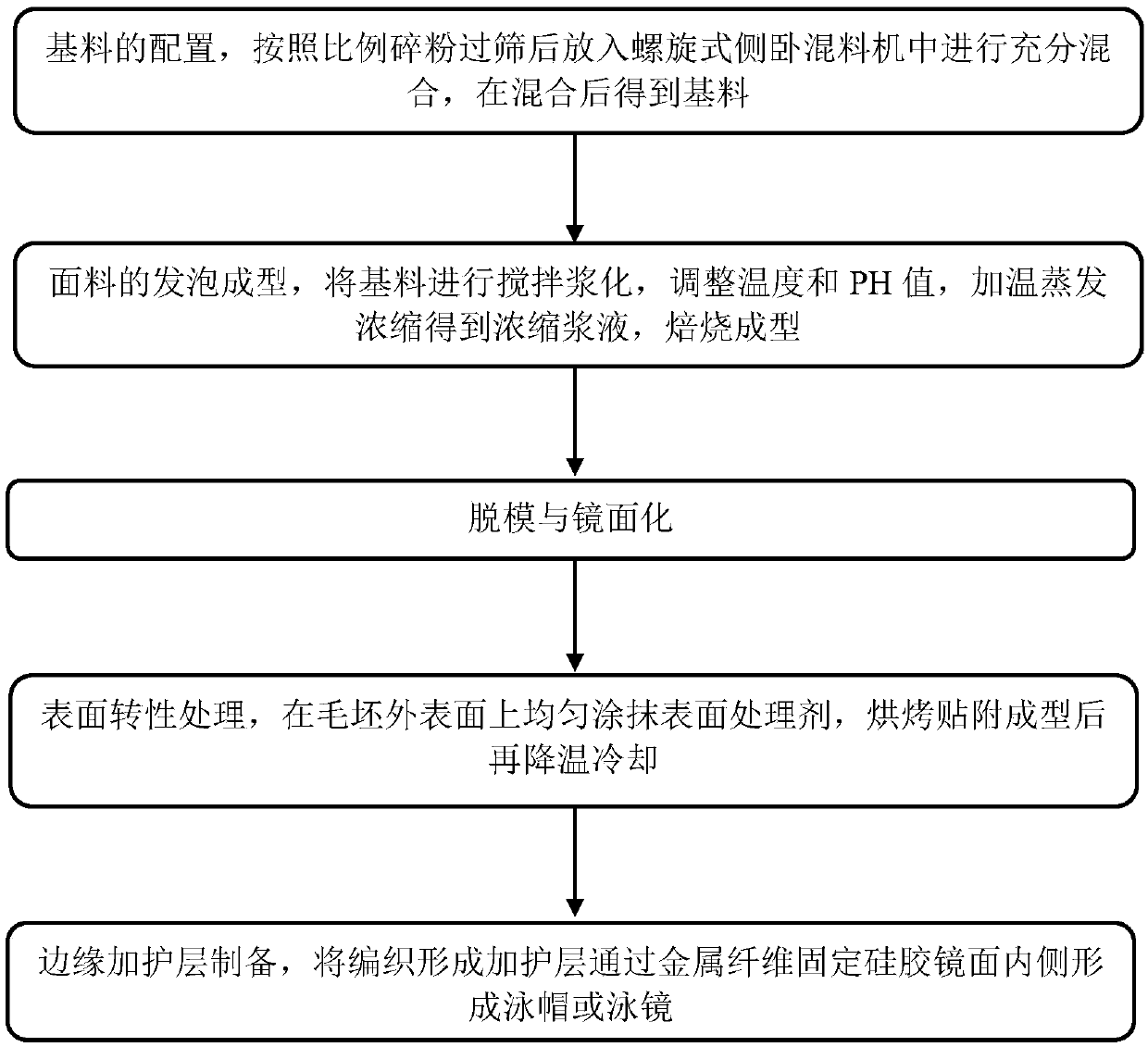

[0026] Such as figure 1 As shown, the present invention provides a kind of technical scheme: a kind of antibacterial material formula that is applied to swimming goggles and swimming cap, is made up of following raw materials according to parts by weight:

[0027] 40 parts of silica gel, 10 parts of bisphenol, 15 parts of polyethylene, 6 parts of nano silicon, 8 parts of antibacterial agent, 10 parts of foaming agent, 4 parts of lubricant, 2 parts of antioxidant, 2 parts of ultraviolet absorber, 8 parts of spandex fiber , 6 parts of metal fiber, 10 parts of waterproof coating.

[0028] Preferably, the antibacterial agent is formed by mixing Shiba Gonggong, Sophora flavescens and rhubarb evenly according to an equal mass ratio; the lubricant adopts any one or two of lanthanum chloride or carbonamide according to an equal mass ratio. Mixing; the ultraviolet absorber adopts phenyl salicylate; the foaming agent adopts any one or both of sodium carbonate or sodium bicarbonate acco...

Embodiment 2

[0036] Such as figure 1 As shown, the present invention provides a kind of technical scheme: a kind of antibacterial material formula that is applied to swimming goggles and swimming cap, is made up of following raw materials according to parts by weight:

[0037]50 parts of silica gel, 15 parts of bisphenol, 17 parts of polyethylene, 7 parts of nano silicon, 9 parts of antibacterial agent, 13 parts of foaming agent, 4 parts of lubricant, 2 parts of antioxidant, 2 parts of ultraviolet absorber, 9 parts of spandex fiber , 7 parts of metal fiber, 11 parts of waterproof coating.

[0038] Preferably, the antibacterial agent is formed by mixing Shiba Gonggong, Sophora flavescens and rhubarb evenly according to an equal mass ratio; the lubricant adopts any one or two of lanthanum chloride or carbonamide according to an equal mass ratio. Mixing; the ultraviolet absorber adopts phenyl salicylate; the foaming agent adopts any one or both of sodium carbonate or sodium bicarbonate accor...

Embodiment 3

[0046] Such as figure 1 As shown, the present invention provides a kind of technical scheme: a kind of antibacterial material formula that is applied to swimming goggles and swimming cap, is made up of following raw materials according to parts by weight:

[0047] 60 parts of silica gel, 20 parts of bisphenol, 20 parts of polyethylene, 8 parts of nano silicon, 10 parts of antibacterial agent, 15 parts of foaming agent, 5 parts of lubricant, 3 parts of antioxidant, 3 parts of ultraviolet absorber, 10 parts of spandex fiber , 8 parts of metal fiber, 12 parts of waterproof coating.

[0048] Preferably, the antibacterial agent is formed by mixing Shiba Gonggong, Sophora flavescens and rhubarb evenly according to an equal mass ratio; the lubricant adopts any one or two of lanthanum chloride or carbonamide according to an equal mass ratio. Mixing; the ultraviolet absorber adopts phenyl salicylate; the foaming agent adopts any one or both of sodium carbonate or sodium bicarbonate ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com