Active metal cutting chip breaking method and active metal cutting chip breaking device for unmanned workshop

A metal cutting, active technology, applied in metal processing equipment, turning equipment, auxiliary devices, etc., can solve the problems of increasing pretreatment machining allowance, chip breaking, tool impact, etc., and achieve the effect of stable chip breaking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment one is a method embodiment.

[0039] The parts processed in this embodiment have three different diameter variations, which are 30 mm, 26 mm and 24 mm respectively from left to right.

[0040] Step (a).

[0041] To turn the part, three cutting passes are performed. The depth of cut and workpiece diameter variation for each pass is shown in the table below. The three tool passes maintain the same spindle speed of 300r / min and feed rate of 0.02mm / rev.

[0042]

[0043] Step (b).

[0044] According to the cutting elements and conditions obtained in step (a), the trajectory of each cutting tool of the turning tool is determined.

[0045] Step (c).

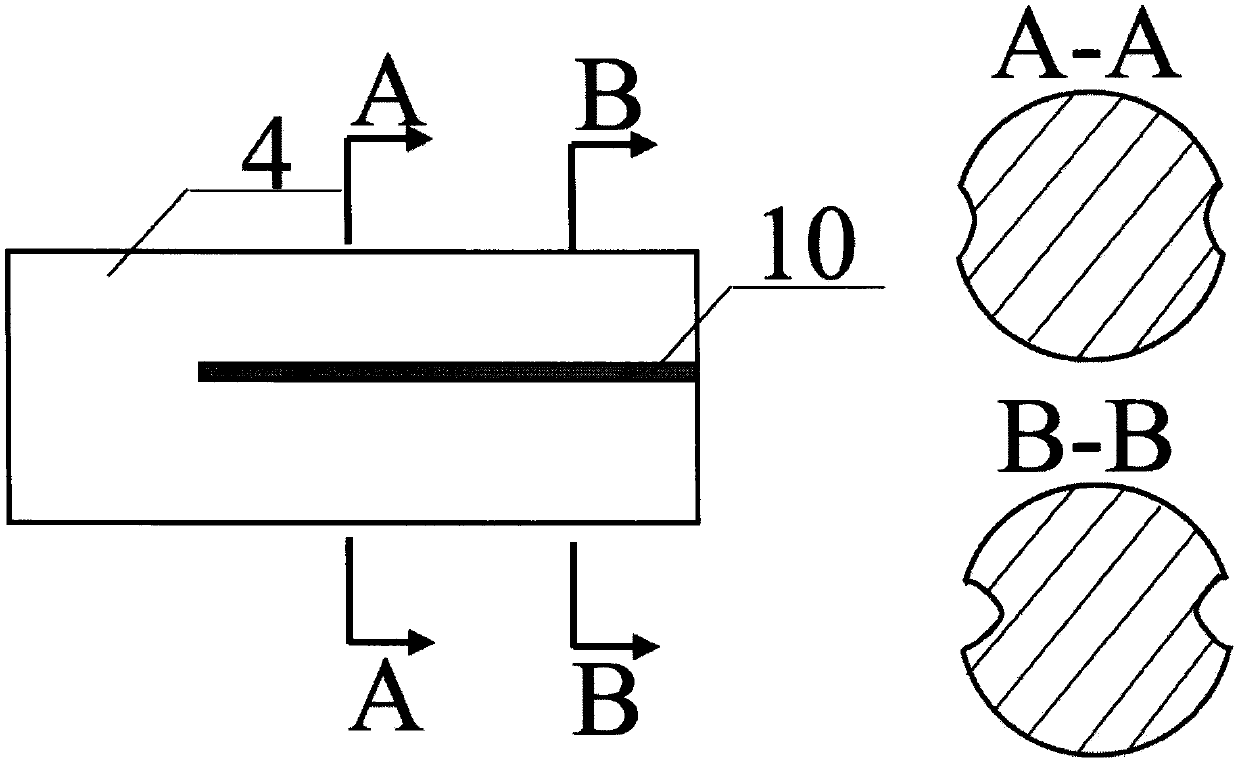

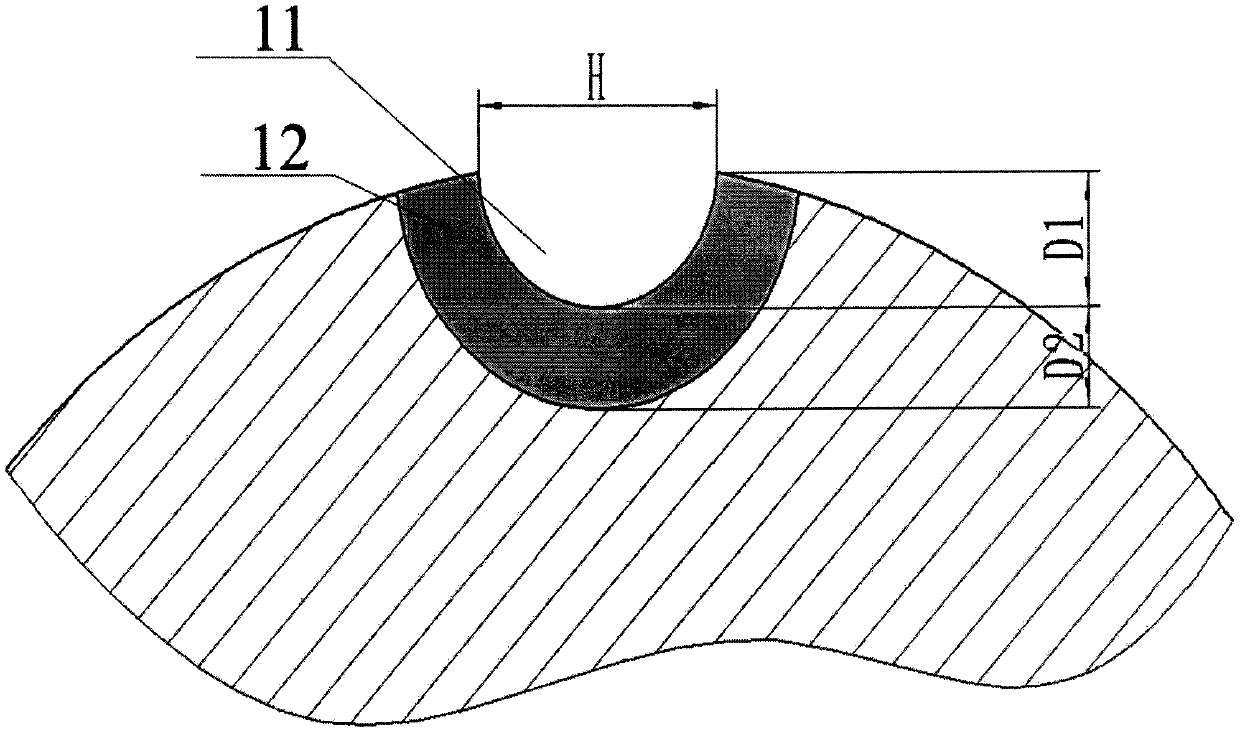

[0046] Before the first tool pass, the surface pretreatment topography is processed on the surface of the workpiece. The appearance of the topography is a groove shape, and the direction is parallel to the axial direction of the workpiece, such as Figure 1 shown. Depending on the depth of cut, the grooves h...

Embodiment 2

[0055] The second embodiment is a device embodiment.

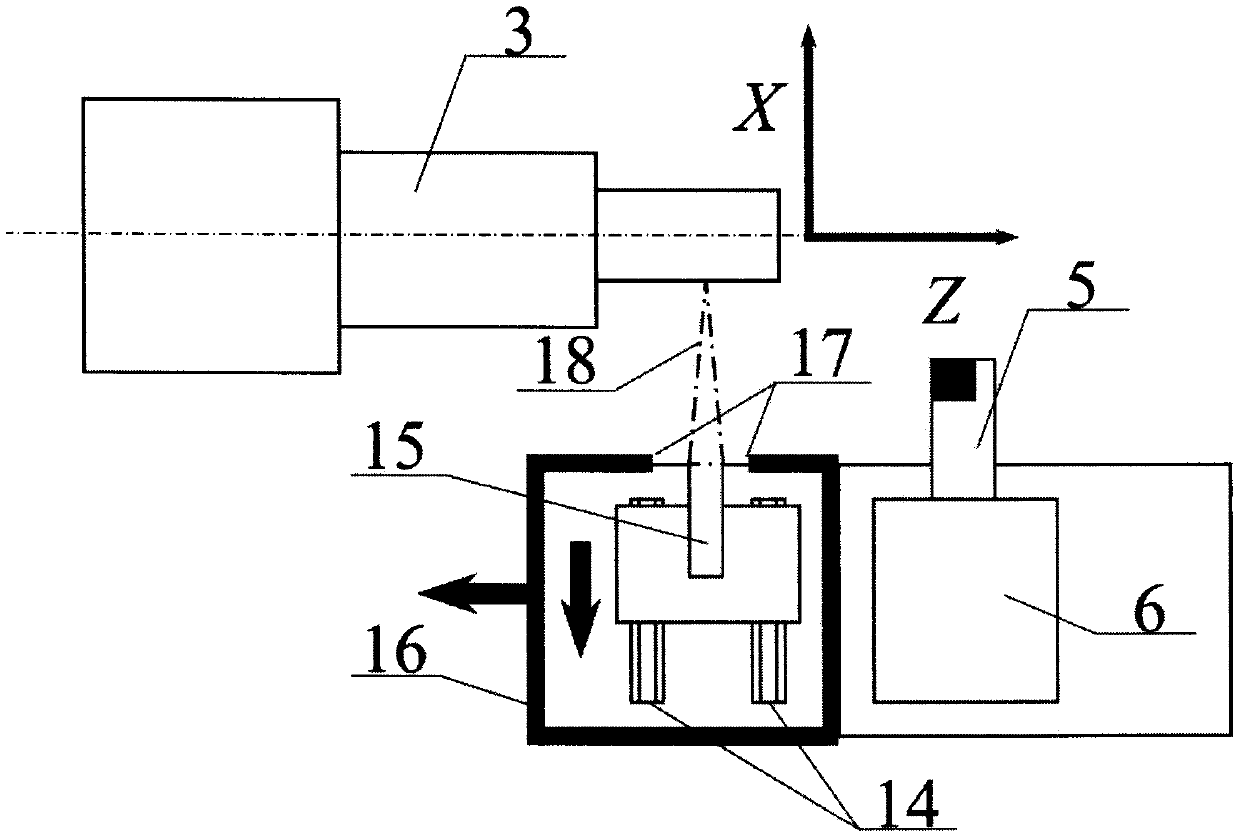

[0056] The parts processed in this embodiment have three different diameter variations, which are 30 mm, 26 mm and 24 mm respectively from left to right. The working principle of the device is as image 3 and Figure 4 shown.

[0057] The device in this embodiment includes a laser module 15 , a mechanical module, an air blowing module and a protective cover 16 .

[0058] The high-energy beam module modifies and pre-treats the workpiece surface by outputting high-energy beams.

[0059] The mechanical module realizes the motion function of the device. The output end of the high-energy beam module is fixed on the X-direction slide rail 14, which has a sliding function in the X-axis direction of the lathe; the horizontal guide rail is fixed on the tool rest. With the above structure, the distance between the output end of the high-energy beam module and the surface of the workpiece is kept constant.

[0060] A protective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com