Method for fatigue assessment of rolling bearing

一种滚动轴承、疲劳的技术,应用在测试滚动轴承的装配配置领域,达到加速开始和发展、快速预测和相关对比、高接触应力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

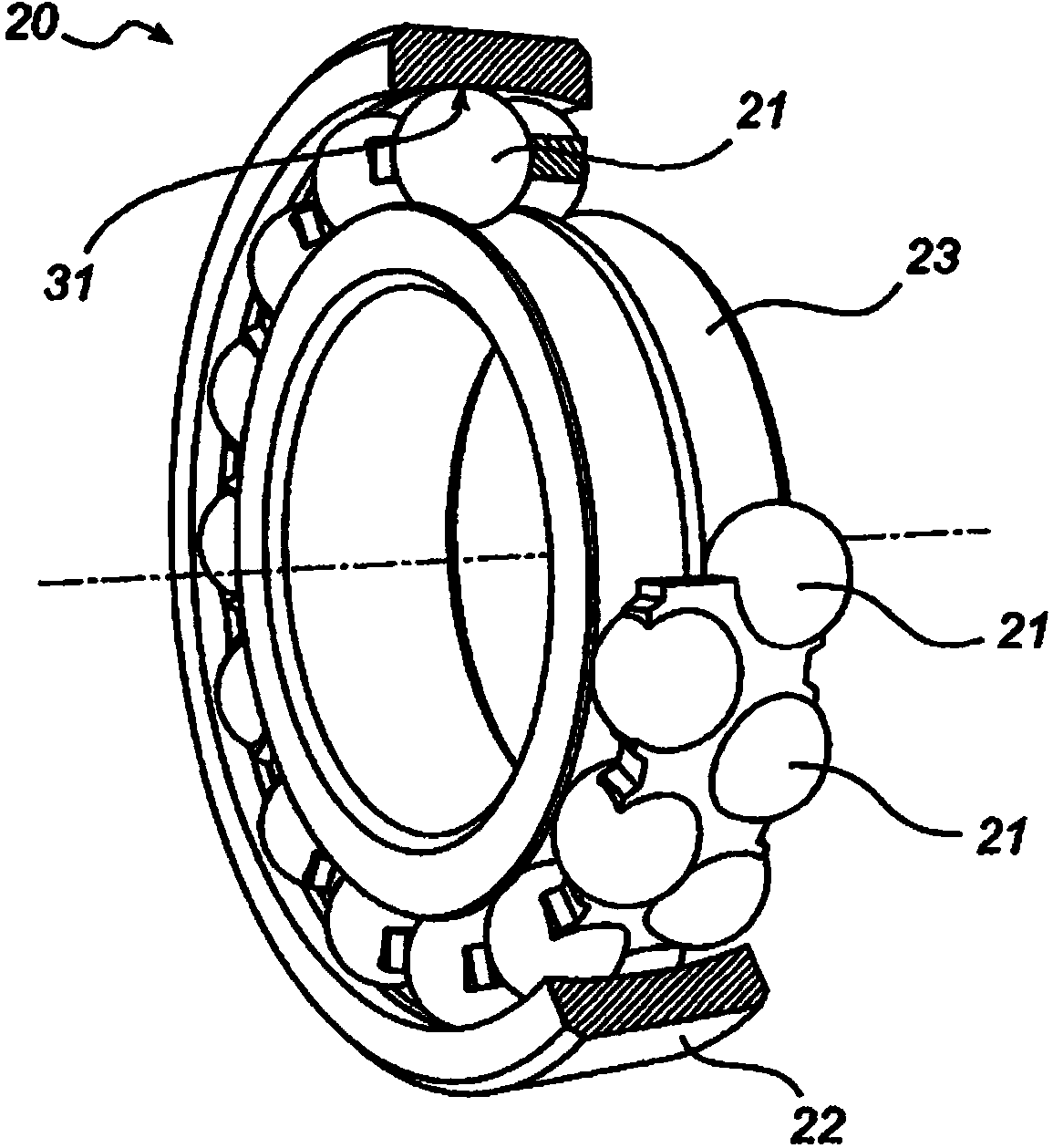

[0038] In the figures, similar or identical elements are denoted by the same reference numerals. The drawings are merely schematic representations, not true to scale and should not be considered as limiting the scope of the invention.

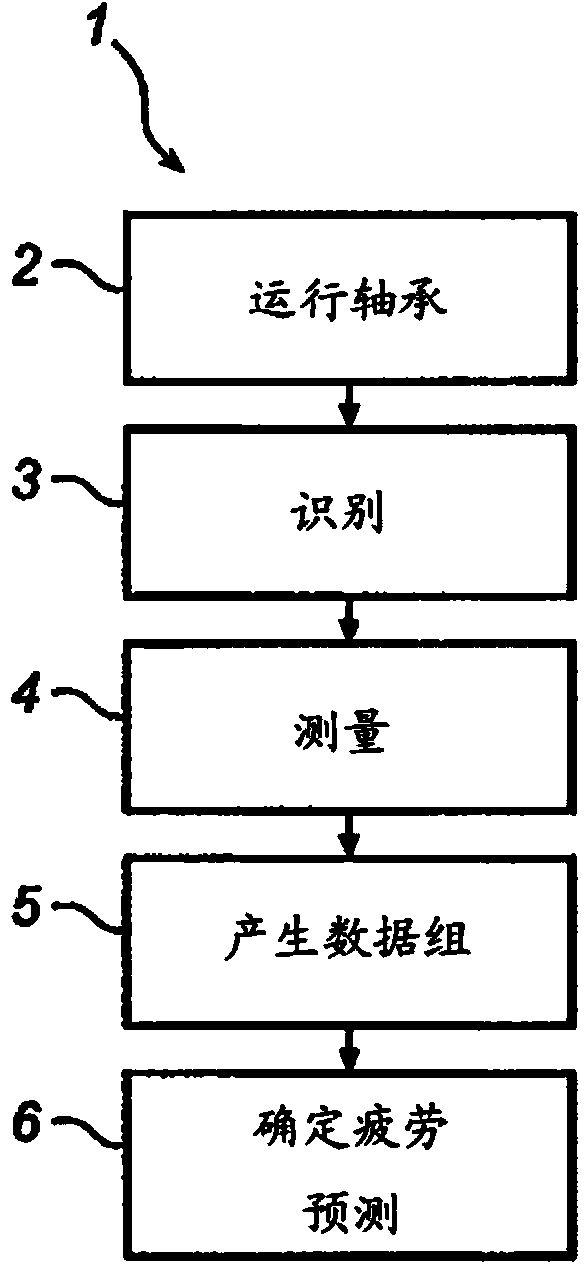

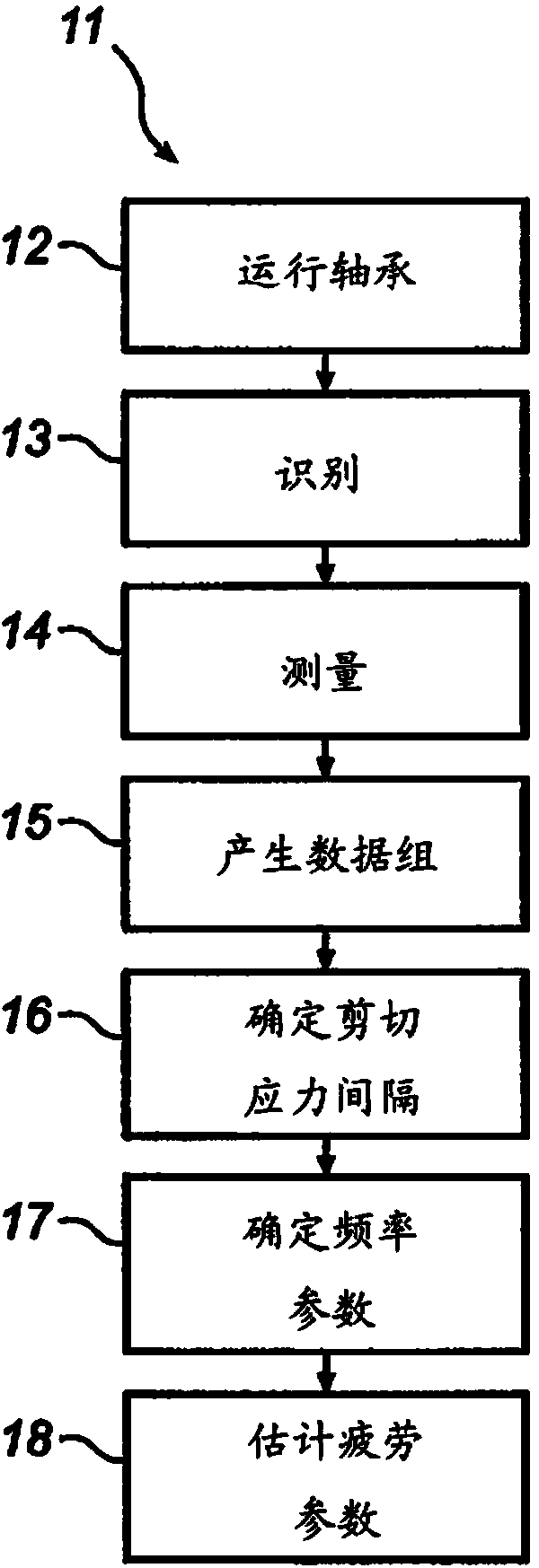

[0039] exist Figure 1a In to b, the schematic flow chart represents two different method embodiments 1 and 11 according to the invention. refer to Figure 1a , in Initial Running Bearing Step 2, the test bearing is run in a test rig, such as the SKF R-2 testing machine, where the test bearing is subjected to mechanical loads that produce subsurface changes in the raceway contact zone. The contact zone is formed by a three-dimensional volume of raceway material, which is subjected to internal and shear stress conditions that are created and initiated at, for example, point-like rolling contact surfaces between spherical rolling elements and raceways. Typically, test bearings are run until fracture or subsurface initiation fatigue failure occur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com