Ultrafast laser differential micro-nano texturing method for metal welding joint

An ultra-fast laser and metal welding technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of weak corrosion resistance and wear resistance, and achieve the effect of improving corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the implementation of the present invention is not limited to the following embodiments.

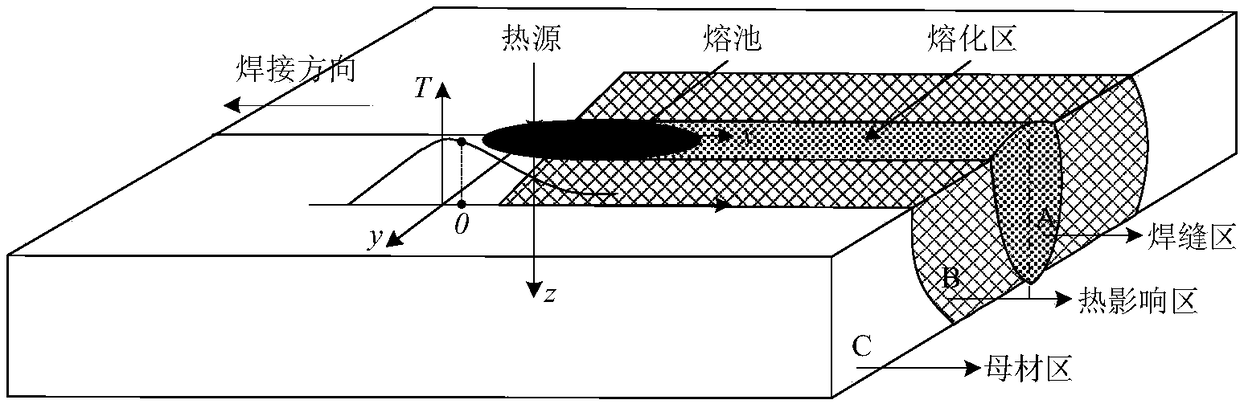

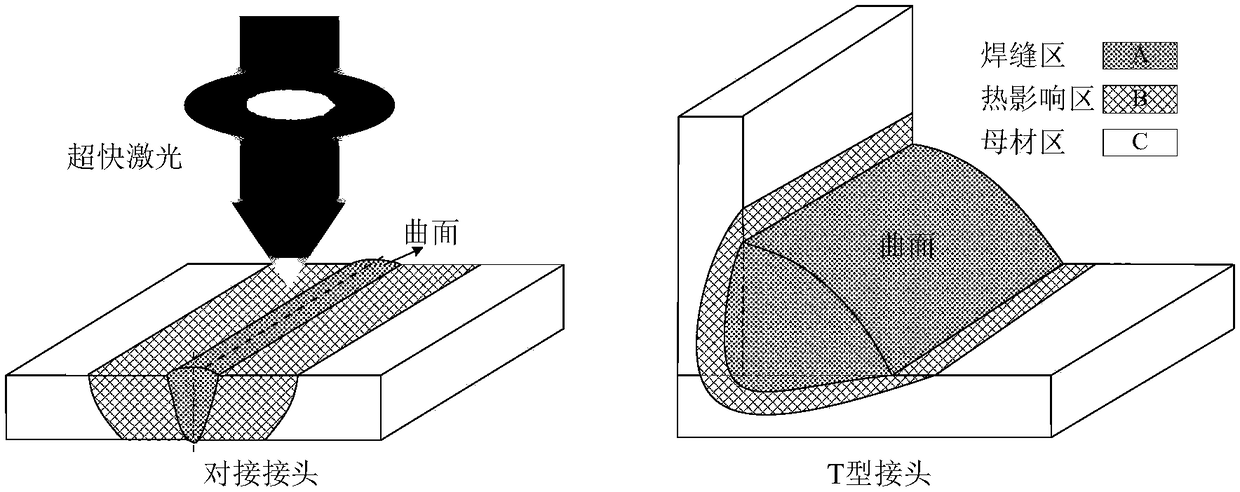

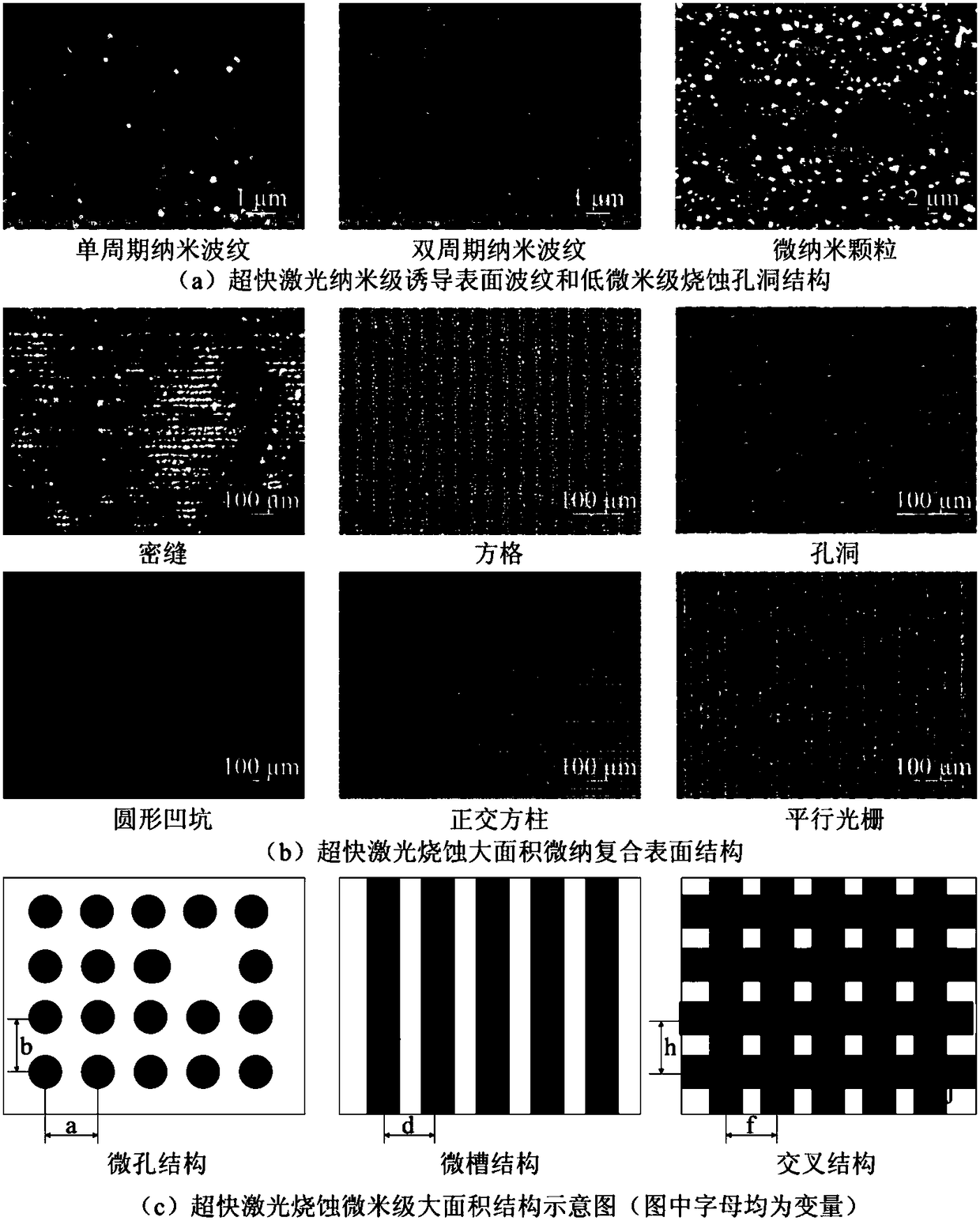

[0022] Such as figure 1 and figure 2 As shown, according to the differences in phase composition and microstructure in different regions of the metal welded joint, the metal welded joint is divided into weld zone (A), heat-affected zone (B) and base metal zone (C), and the weld zone The surface of (A) is generally a curved surface, and the surfaces of the heat-affected zone (B) and the base metal zone (C) are flat or curved. During the welding process, the physical and chemical changes in the weld zone, heat-affected zone and base metal zone of the metal welding joint are different. Even in their respective areas, the physical and chemical changes are also different. There are also differences in phase composition and microstructure in the respective areas of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com