Capacitor having features of heat dissipation and of energy conservation

a technology of heat dissipation and energy conservation, applied in the field of capacitors, can solve the problems of low capacitor working efficiency, large impact on the service life of the capacitor, and separation of the different capacitors, so as to improve the heat dissipation effect, reduce the impact of environmental pollution, and be friendly to the environmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

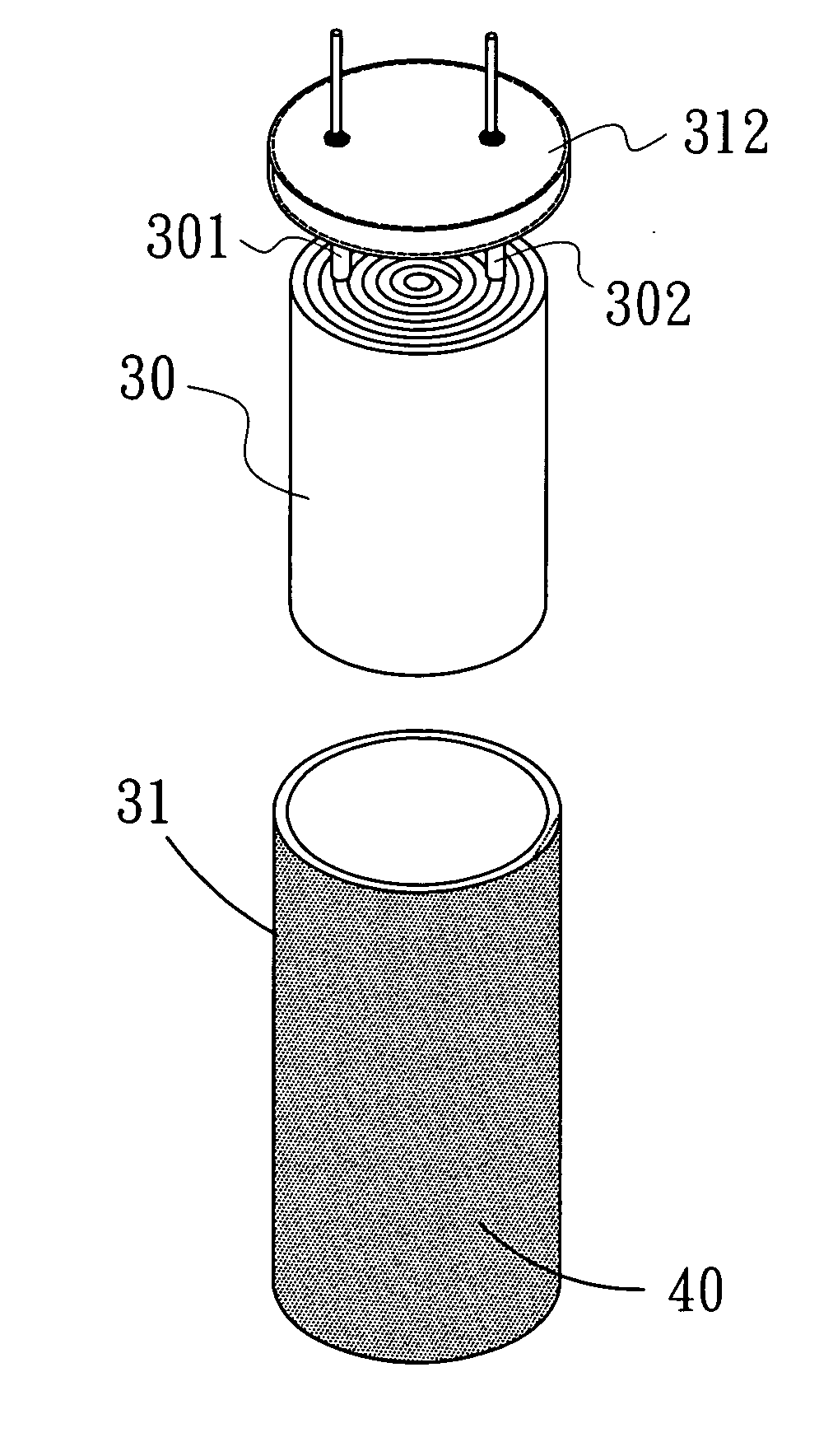

[0021]Present invention relates to a capacitor that has the features of heat dissipation and of energy conservation. Referring to FIGS. 4, 5A, 5B, and 5C, the capacitor of present invention comprises of a capacitor core 30, surrounding the capacitor core 30 is an aluminum shell 31, the aluminum shell 31 is filled up with rubber 312 which completely covers the top of the capacitor core 30, then with the use of an extruding machine, the upper orifice of the aluminum shell 31 is extruded and sealed up around the rubber 312 completely; the anode lead 301 and the cathode lead 302 of the capacitor core 30 are made to extend outward for electrical connection.

[0022]The outer surface of the aluminum shell 31 has an aluminum oxidized insulating layer 310 after the shell is processed through an aluminum metal surface transformation treatment, as shown in FIGS. 5A, 5B, and 5C, since the aluminum shell 31 is not covered with plastic film (or sleeve), heat dissipation is enhanced; also, since hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com