Method of producing photographic prints

a technology of photographic prints and methods, applied in the field of methodological handling of photographic films, can solve problems such as considerable errors, and achieve the effect of facilitating analysis of each fram

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

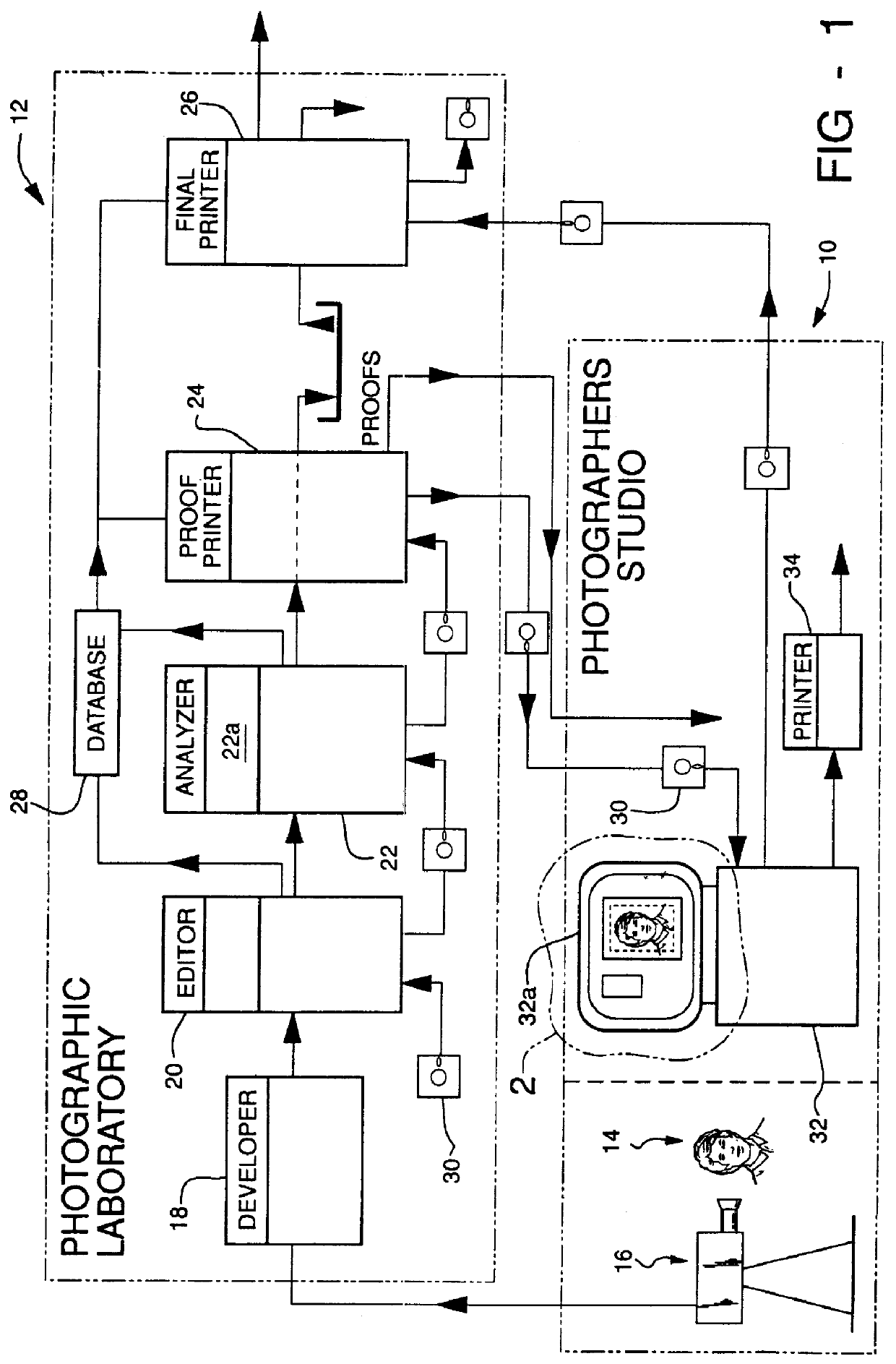

The invention methodology is illustrated in FIG. 1 in association with a photographic process involving a photographer's studio 10 and a photographic laboratory 12.

More specifically, the invention is illustrated in FIG. 1 in association with a photographic process (for example, portrait, wedding, or commercial) wherein a subject or subjects 14 are posed in the photographer's studio 10, a series of pictures is taken of each subject utilizing a camera 16, the exposed film is sent to the photographic laboratory 12 where the film is developed, edited and analyzed, a series of proof prints are made at the photographic laboratory, the proof prints are sent to the photographer's studio where they are reviewed by the photographer, typically with the assistance of the subject to select the desired proofs as well as order information with respect to each proof, and the proofs are returned to the photographic laboratory for use in producing the final photographic prints.

The photographic labora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com