Apparatus and method of operating an injector for an exhaust gas aftertreatment apparatus

an exhaust gas aftertreatment and injector technology, which is applied in the direction of mechanical equipment, engines, machines/engines, etc., can solve the problems of high temperature, inability to operate the device consistently, and inability to meet the needs of exhaust gas aftertreatment,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

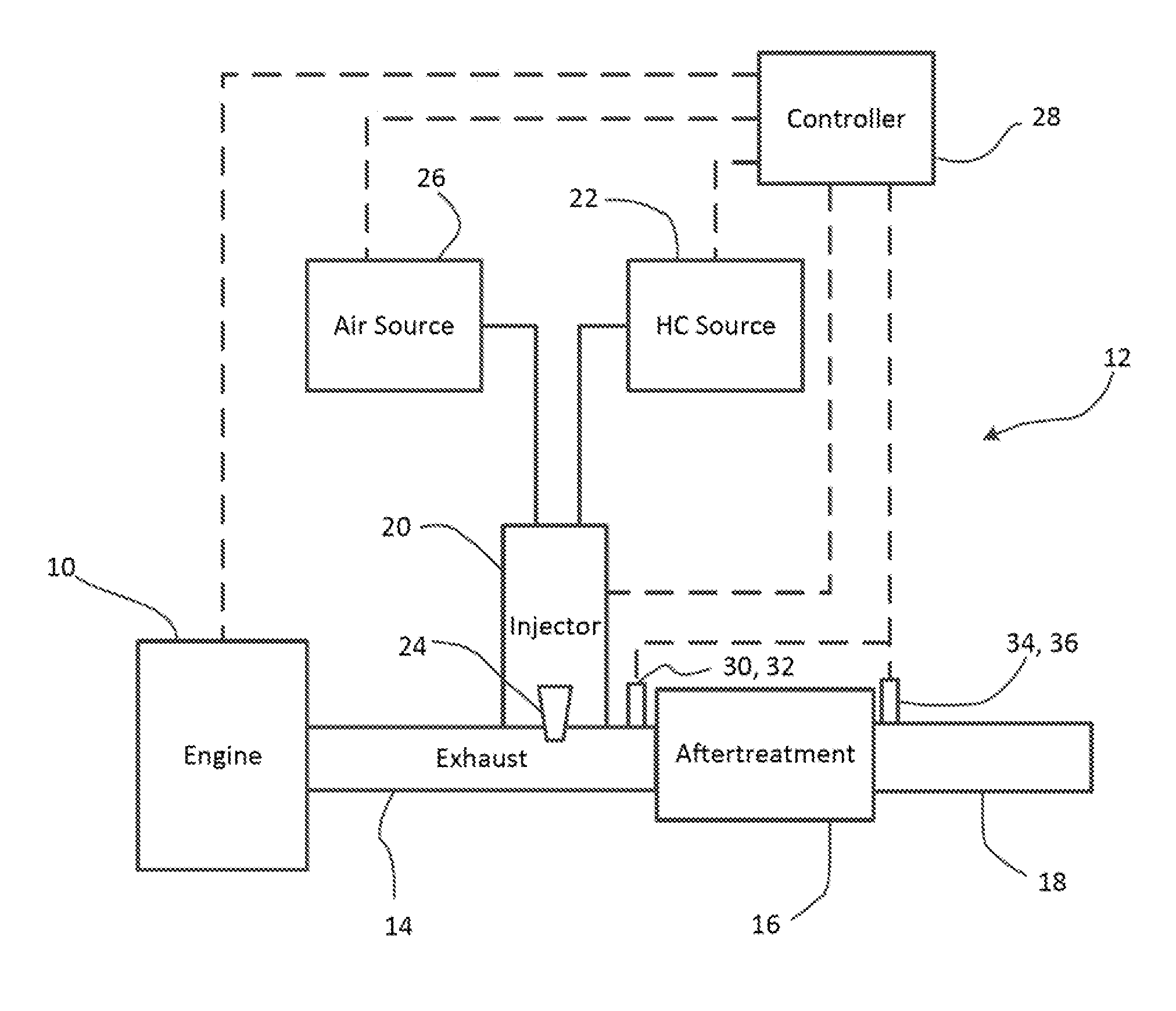

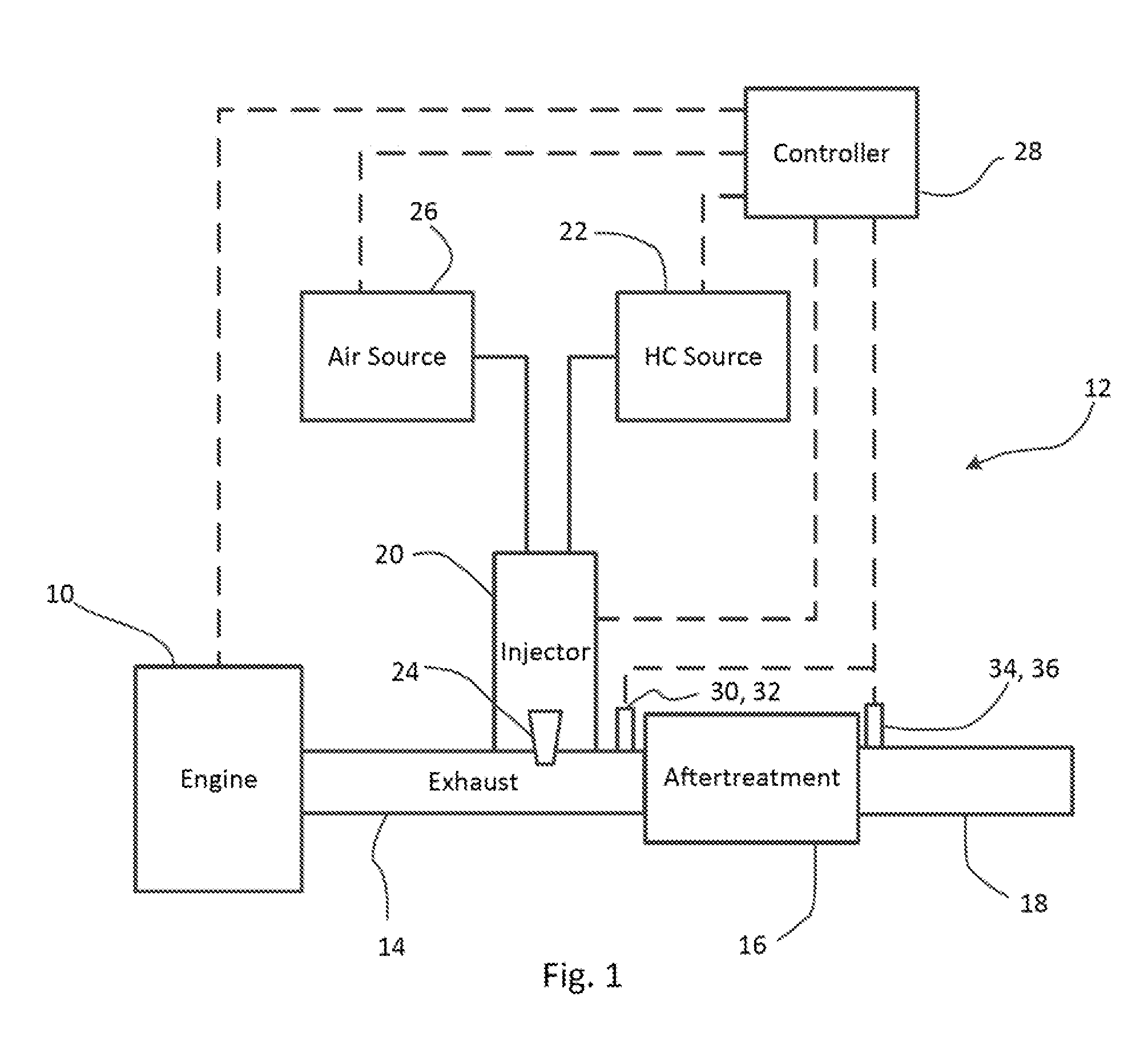

[0016]FIG. 1 illustrates an apparatus including an internal combustion engine 10 with an exhaust gas aftertreatment system 12 according to the invention. The engine 10 is connected to an exhaust gas conduit 14 that receives exhaust gas from the engine. Exhaust gas is carried by the conduit to an aftertreatment system 16, which may include a Diesel Oxidation Catalyst (DOC), a Diesel Particulate Filter (DPF), and a device for treating Nitrogen Oxides, such as a selective catalytic reaction device (SCR) or Lean NOx Catalyst (LNC). After the exhaust gas is treated, it is released to the environment through an exhaust stack or pipe 18.

[0017]The DPF filters the exhaust gas and collects soot and other particulate matter, which must be removed at intervals or the DPF becomes clogged. One common method for removing particulate matter, which is mainly carbon based, is to raise the temperature of the DPF filter body to a temperature sufficient to oxidize the particulate matter. The temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com