Gutter cover with passive ice and snow melt

a technology of passive applied in the field of gutter covers, gutter covers, ice and snow melting systems, can solve the problems of limiting the ability of gutter covers to collect water, roofs and other sloped surfaces are also subject to snow and ice accumulation, and other problems, to achieve the effect of effectively and efficiently preventing the clogging of gutters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

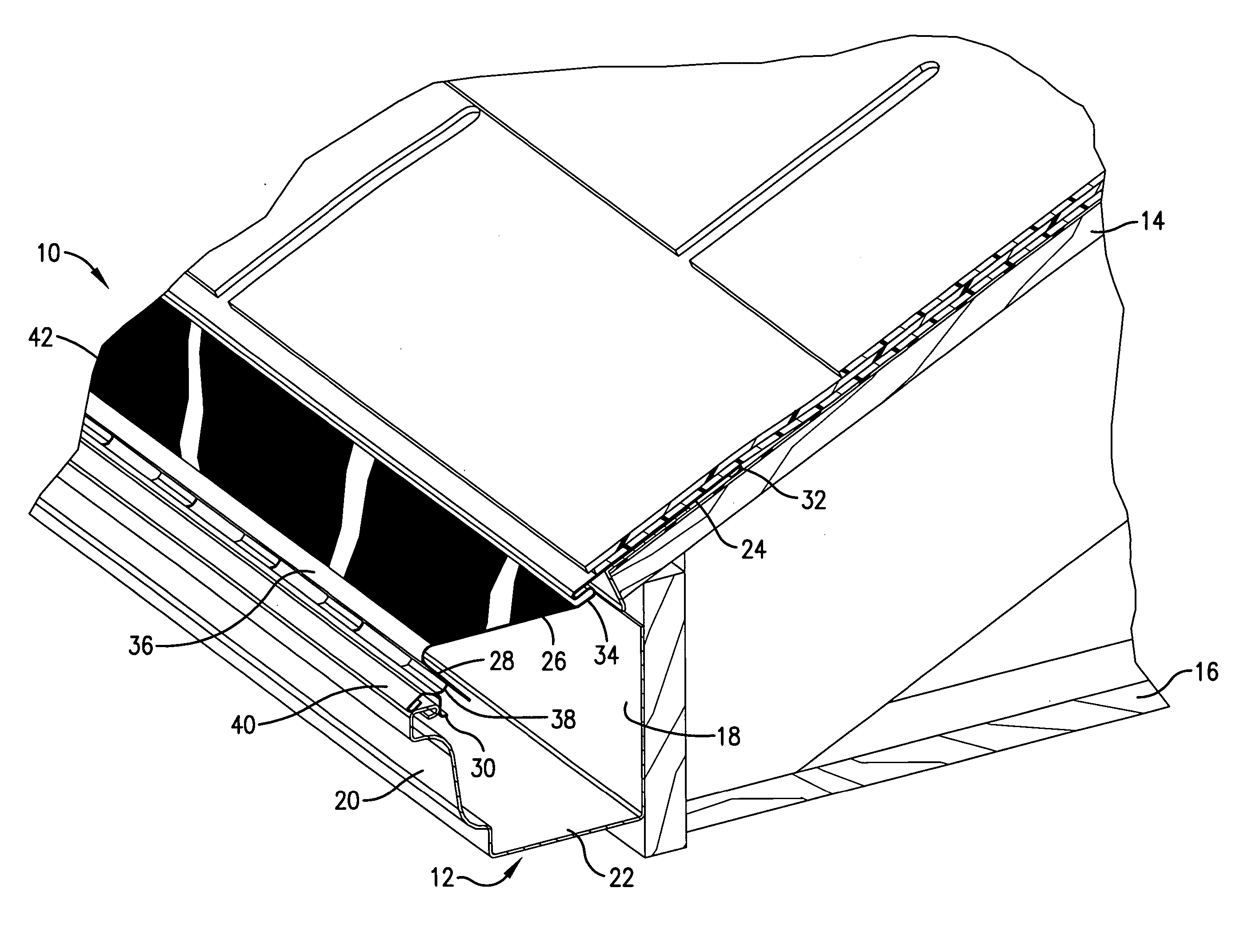

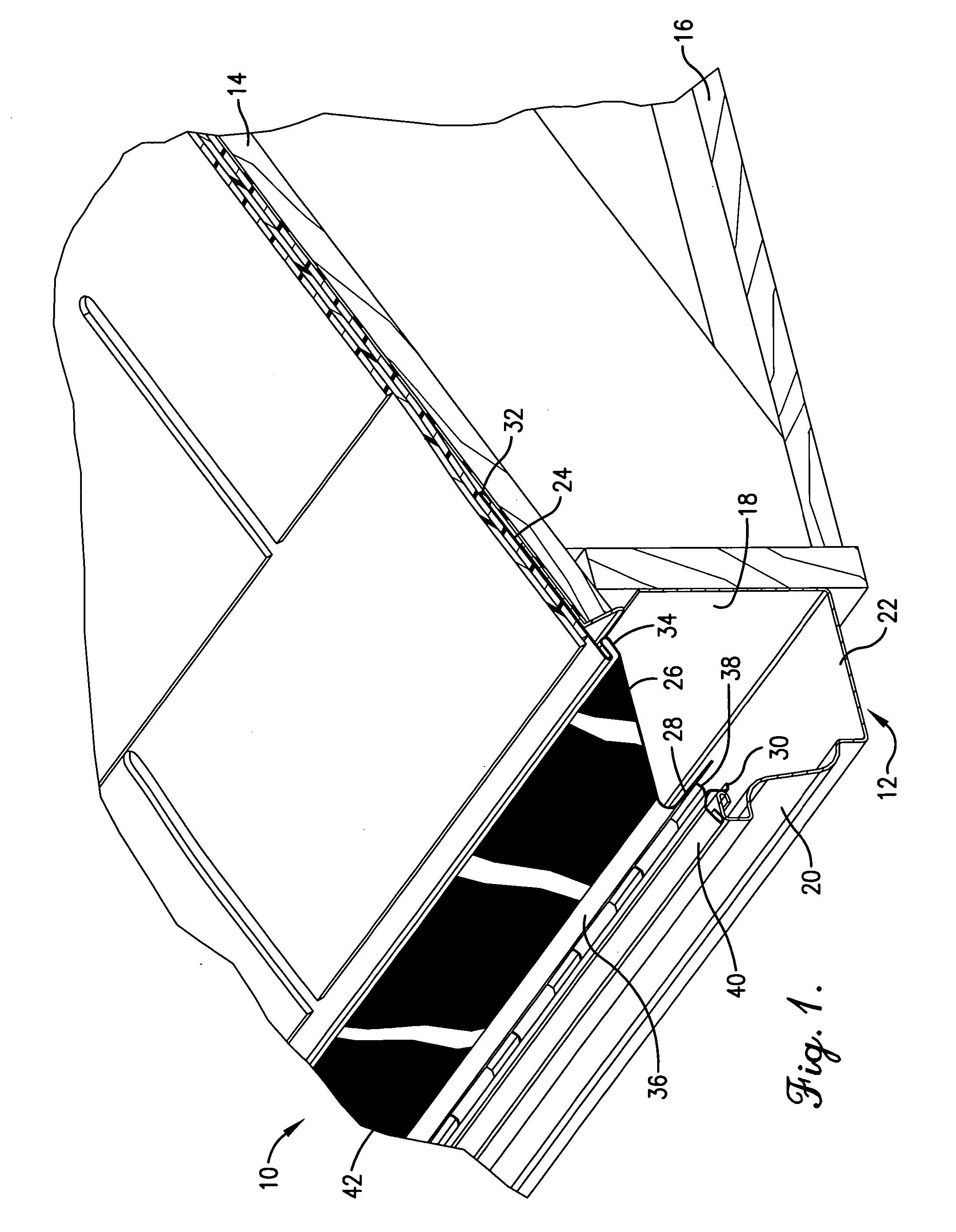

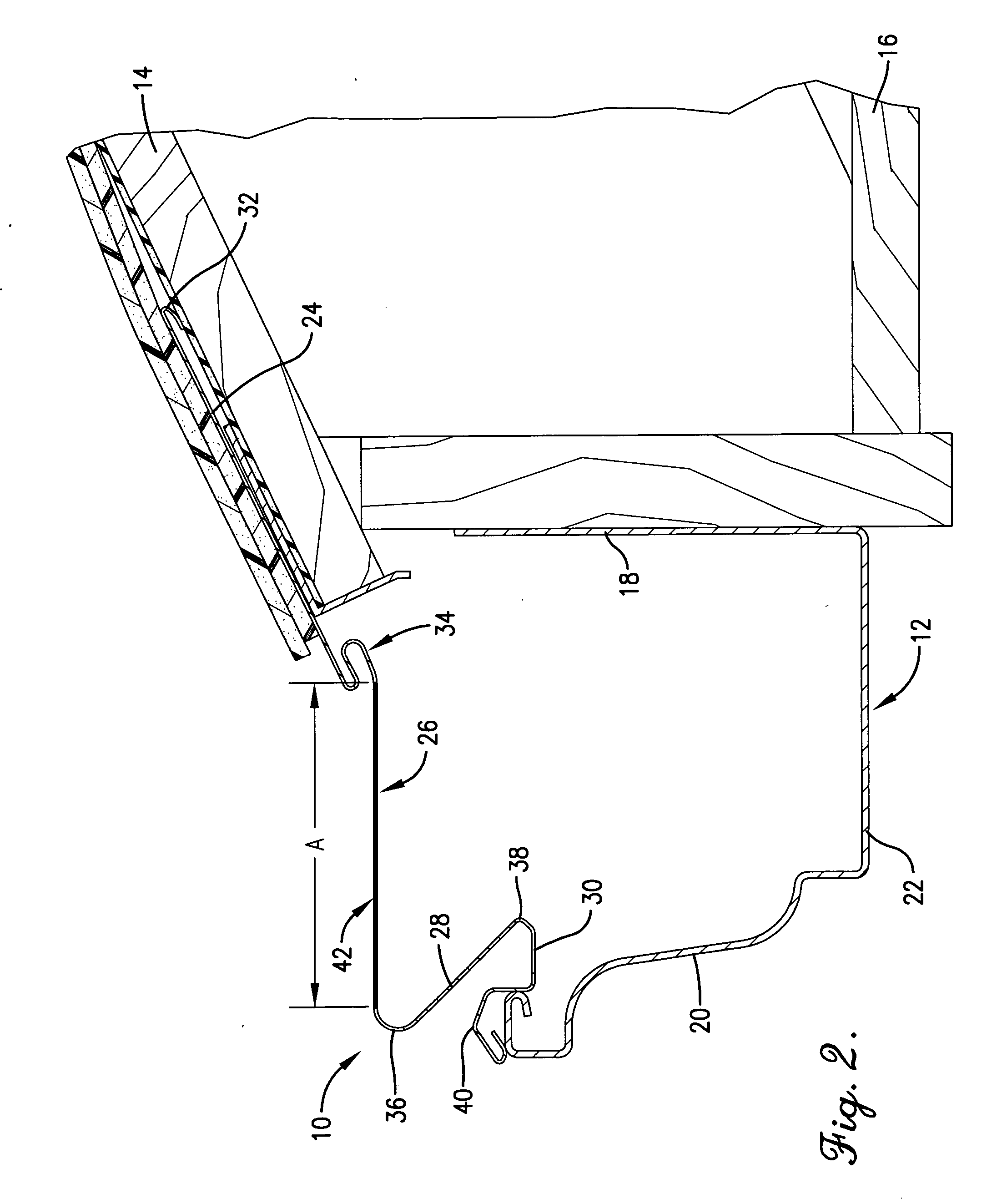

[0020]FIGS. 1-2 illustrate a gutter cover 10 constructed in accordance with a preferred embodiment of the present invention. The gutter cover 10 is adapted to be installed over a gutter 12 affixed below a lower surface of a roof 14 of a building 16.

[0021] The particular gutter cover 10 shown and illustrated herein is provided for purposes of disclosing a preferred embodiment of the present invention. Many aspects of the gutter cover 10, such as its size and construction material, may be selected as a matter of design choice. For example, the gutter cover may be formed of any suitable material such as aluminum, vinyl, galvanized steel, or stainless steel and may be sectional or seamless. The gutter 12 to which the gutter cover 10 is attached may have a K-shape, U-shape, or any other profile and may be of any diameter, such as 4, 5, or 6 inches.

[0022] Similarly, the particular size, shape and style of the roof 14 and the building 16 are not important to the present invention. The gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com