Adhesive heating and temperature control device used in accelerometer assembling process

An assembly process, accelerometer technology, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of uneven stress of bonding parts, difference in curing degree of adhesive, acceleration measurement error, etc., to achieve uniform heating , Improve the service life and avoid the effect of difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be described below with reference to the drawings. Elements and features described in one drawing or one embodiment of the present invention may be combined with elements and features shown in one or more other drawings or embodiments. It should be noted that representation and description of components and processes that are not relevant to the present invention and known to those of ordinary skill in the art are omitted from the drawings and descriptions for the purpose of clarity.

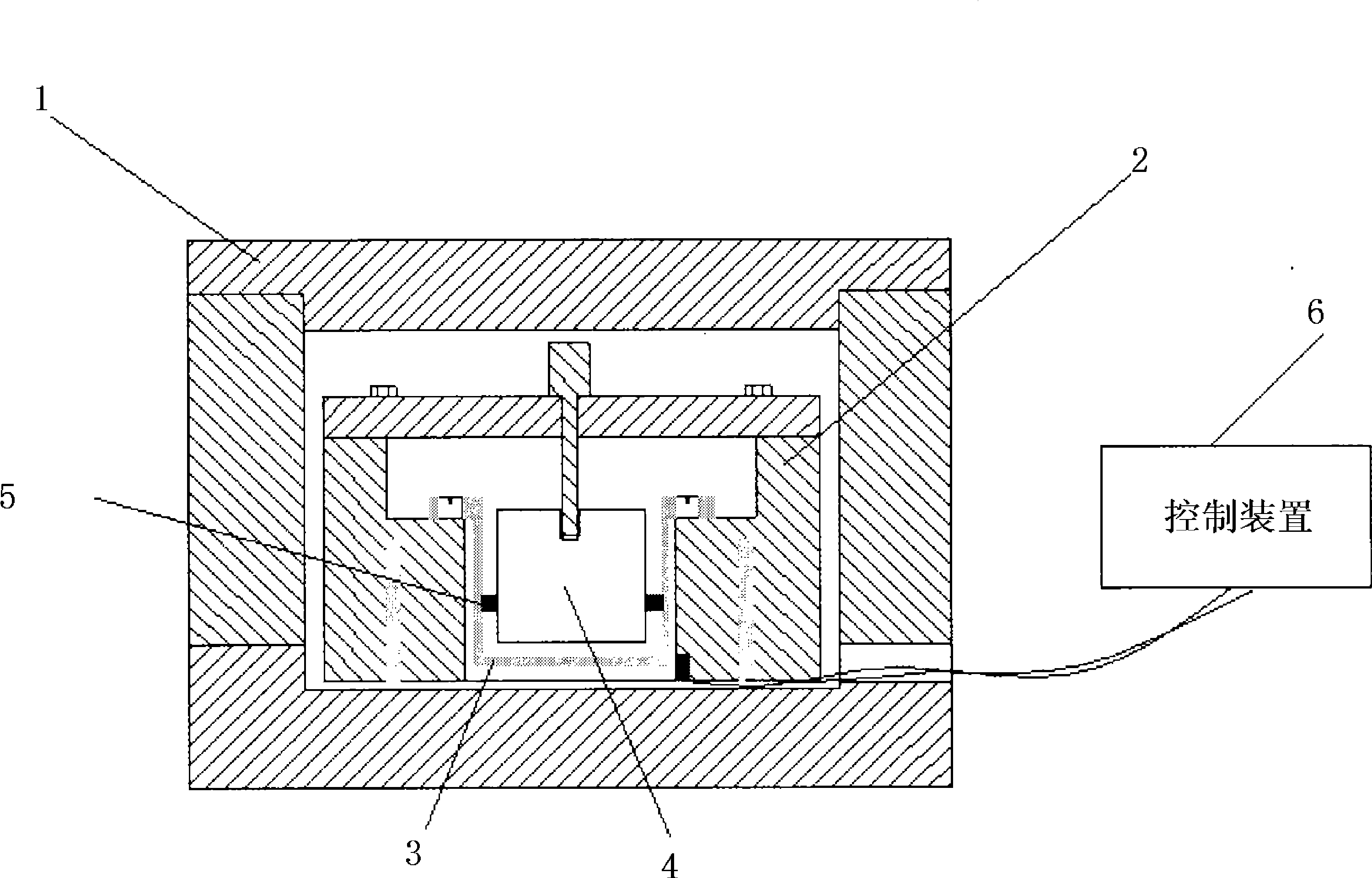

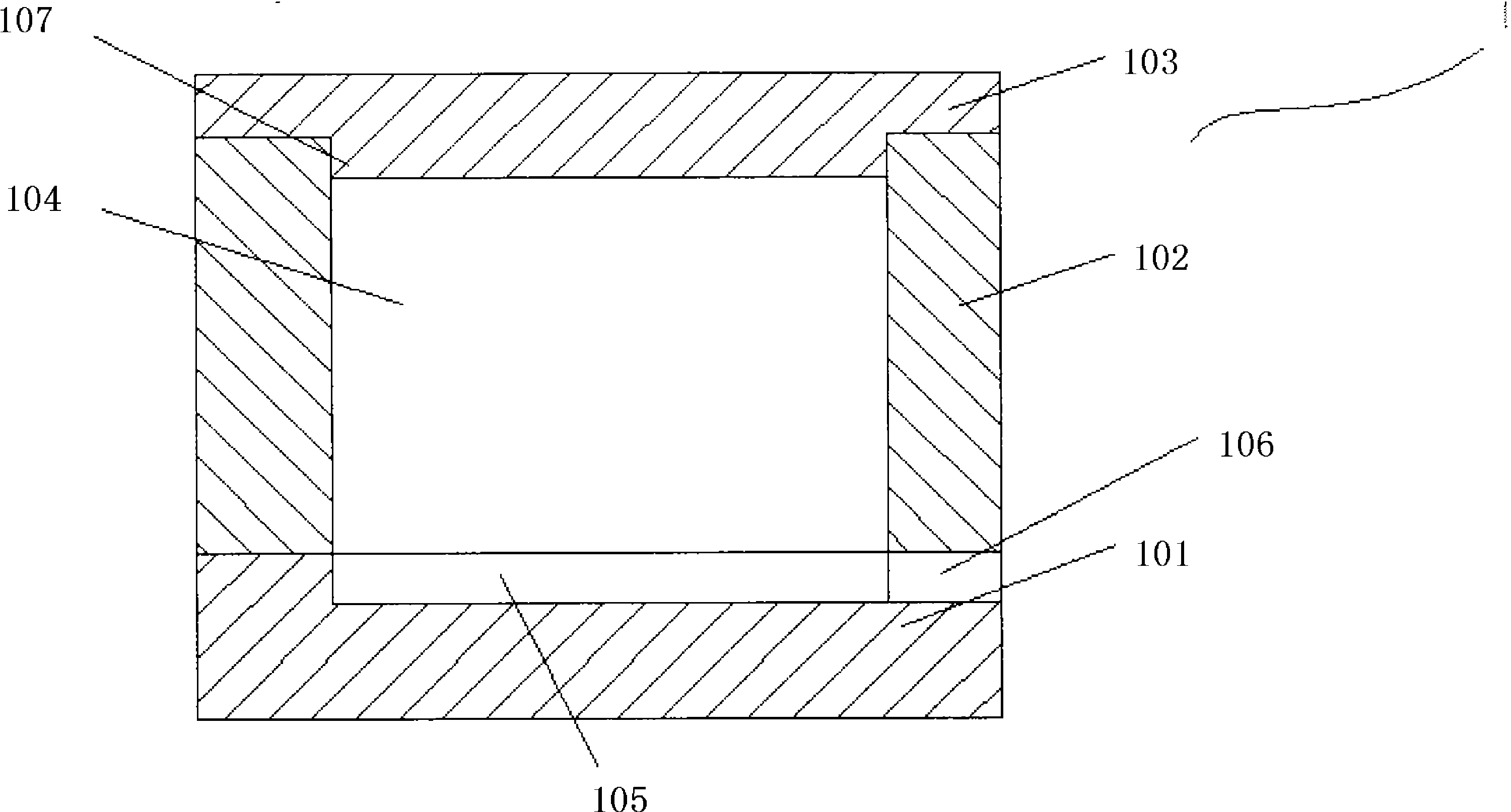

[0016] refer to figure 1 , this embodiment provides an adhesive heating temperature control device during the accelerometer assembly process, including:

[0017] Insulation mold 1;

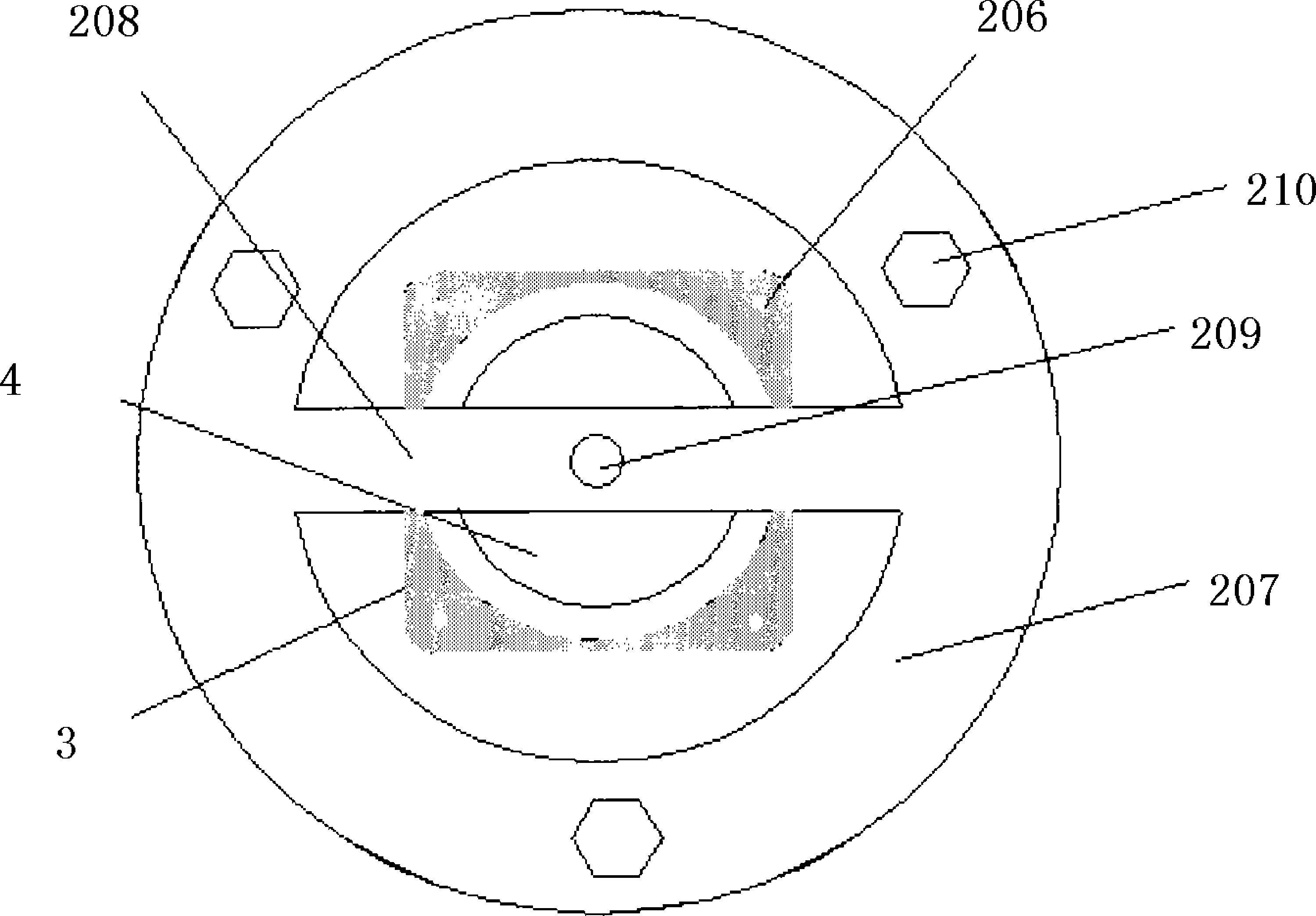

[0018] The heating device 2 arranged in the heat preservation mold 1 is used to uniformly heat the adhesive 5 between the watch case 3 and the watch core 4 during the assembly process of the accelerometer;

[0019] The control device 6 connected with the heating de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com