Nozzle having a nozzle body with heated and unheated nozzle body segments

A technology of body parts and nozzles, applied in the field of injection molding devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

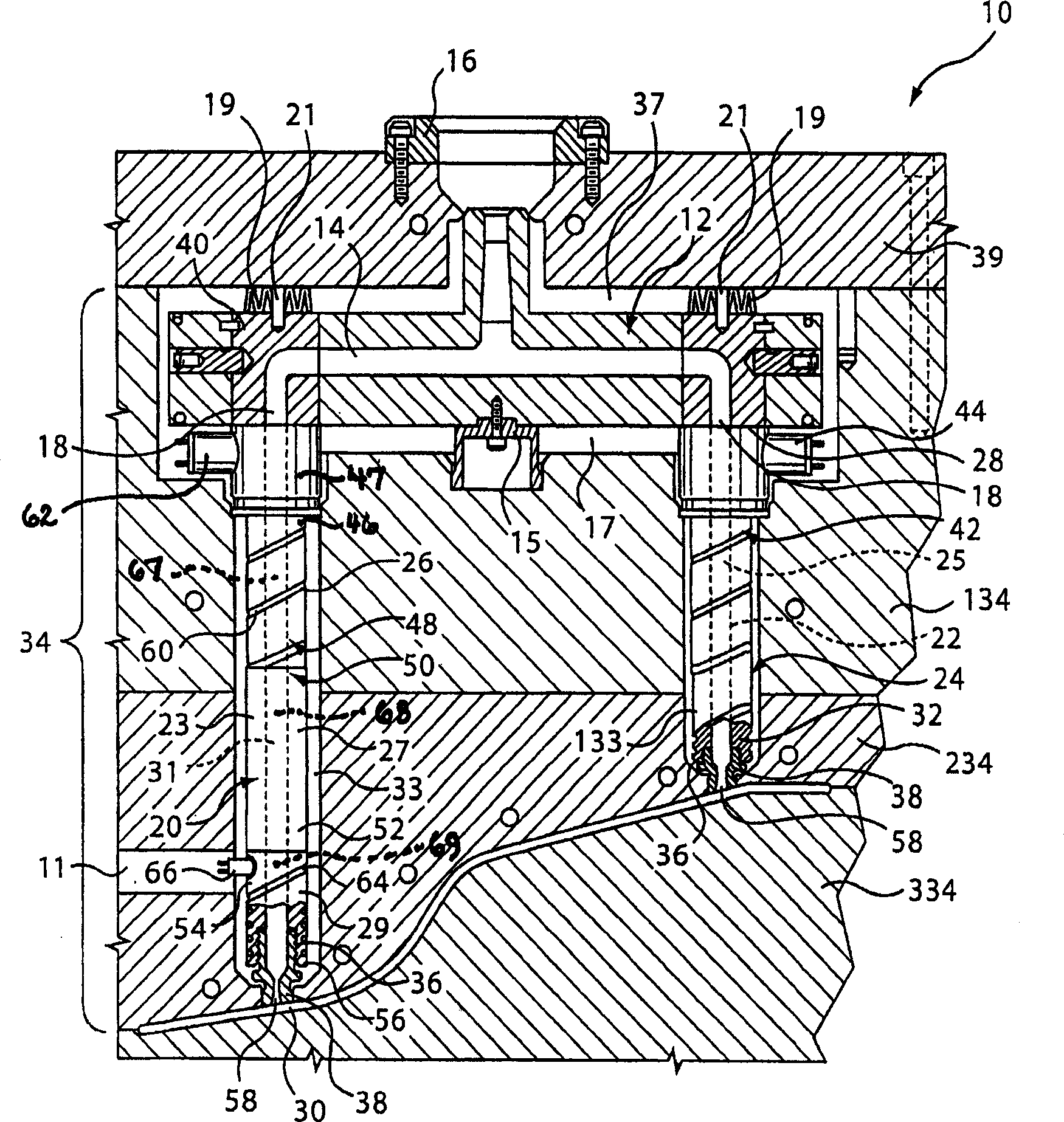

[0031] now refer to figure 1 , generally shown as an injection molding apparatus 10 . Injection molding apparatus 10 includes a manifold 12 having a manifold channel 14 extending therethrough. A manifold sleeve 16 is located at the inlet of the manifold channel 14 to receive a melt flow of moldable material from a machine nozzle (not shown) and to route the melt flow to a manifold outlet 18 . A heating element (not shown) heats the manifold 12 to maintain the melt flow through the melt channel 14 at the desired temperature. The manifold's heating elements may be embedded in or otherwise surround the surface of the manifold 12 . The manifold 12 is held in place by a central retaining ring 15 which spans the insulating space 17 between the hot manifold 12 and the cold plate 134 . Another insulating space 37 with a predetermined width is located between the heat manifold 12 and the cold packing template 39 . The pressure plate 19 is mounted by means of screws 21 to create an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com