Pre-heating contiguous in-line water heater

a contiguous, water heater technology, applied in water heaters, ohmic-resistance heating, immersion heating arrangements, etc., can solve the problem of lack of simple, economical flow detection devices in the ar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

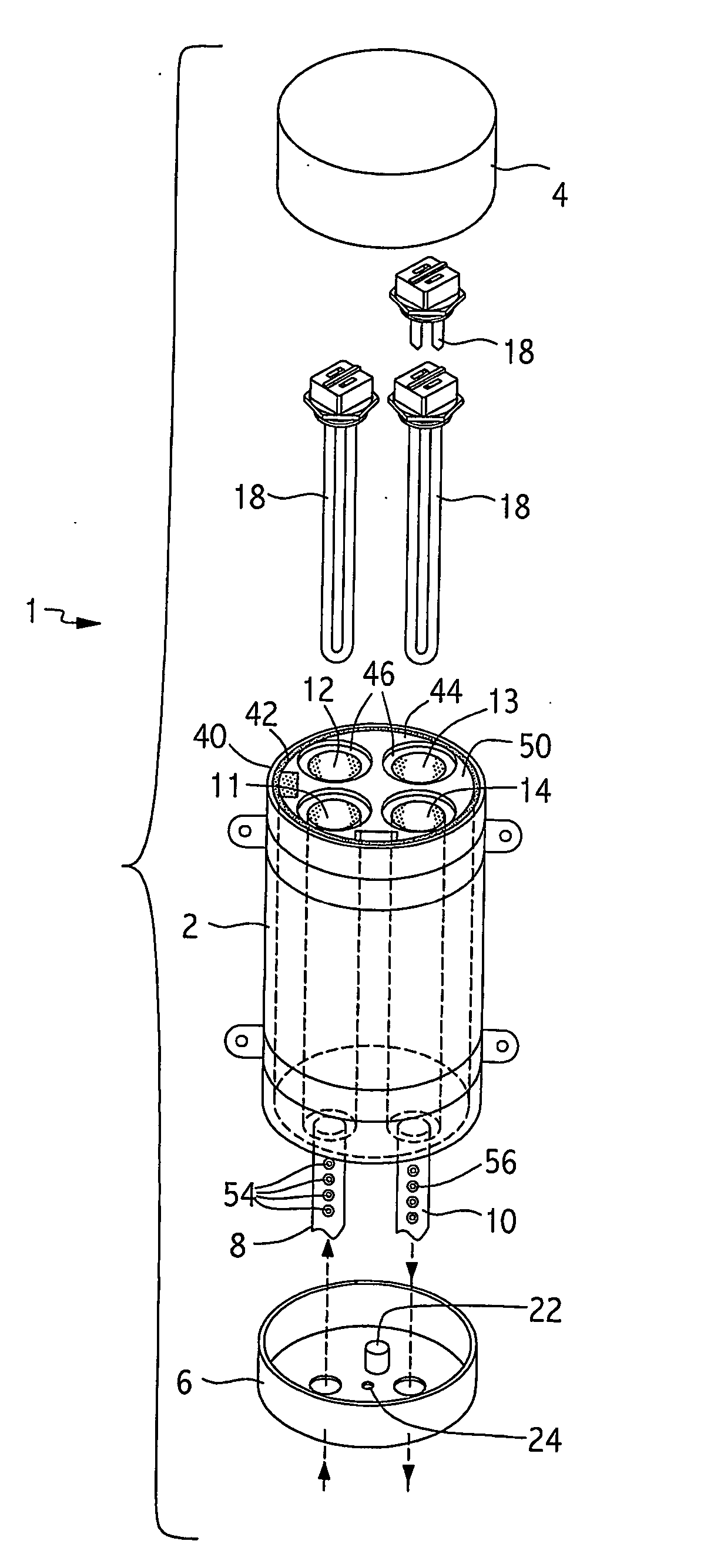

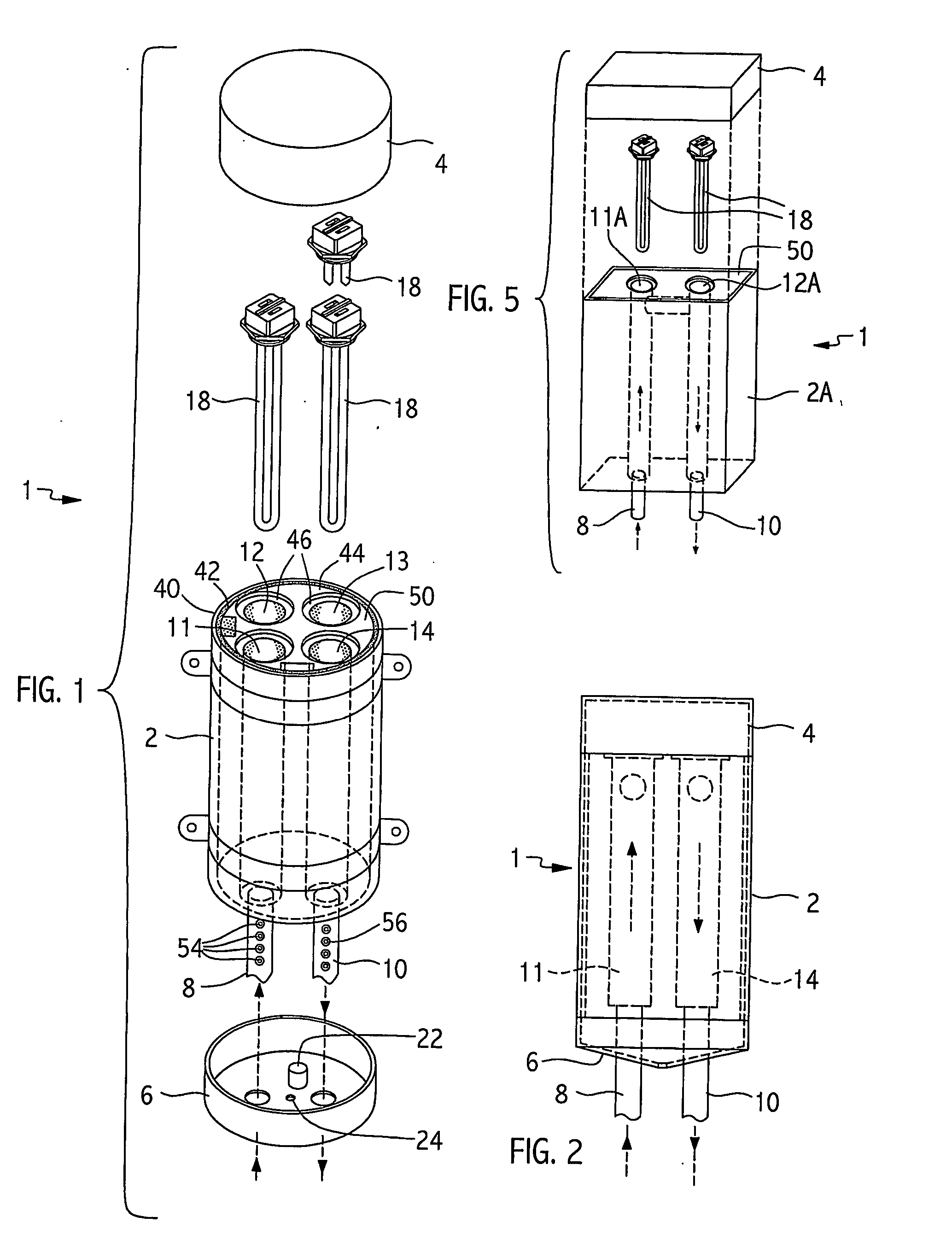

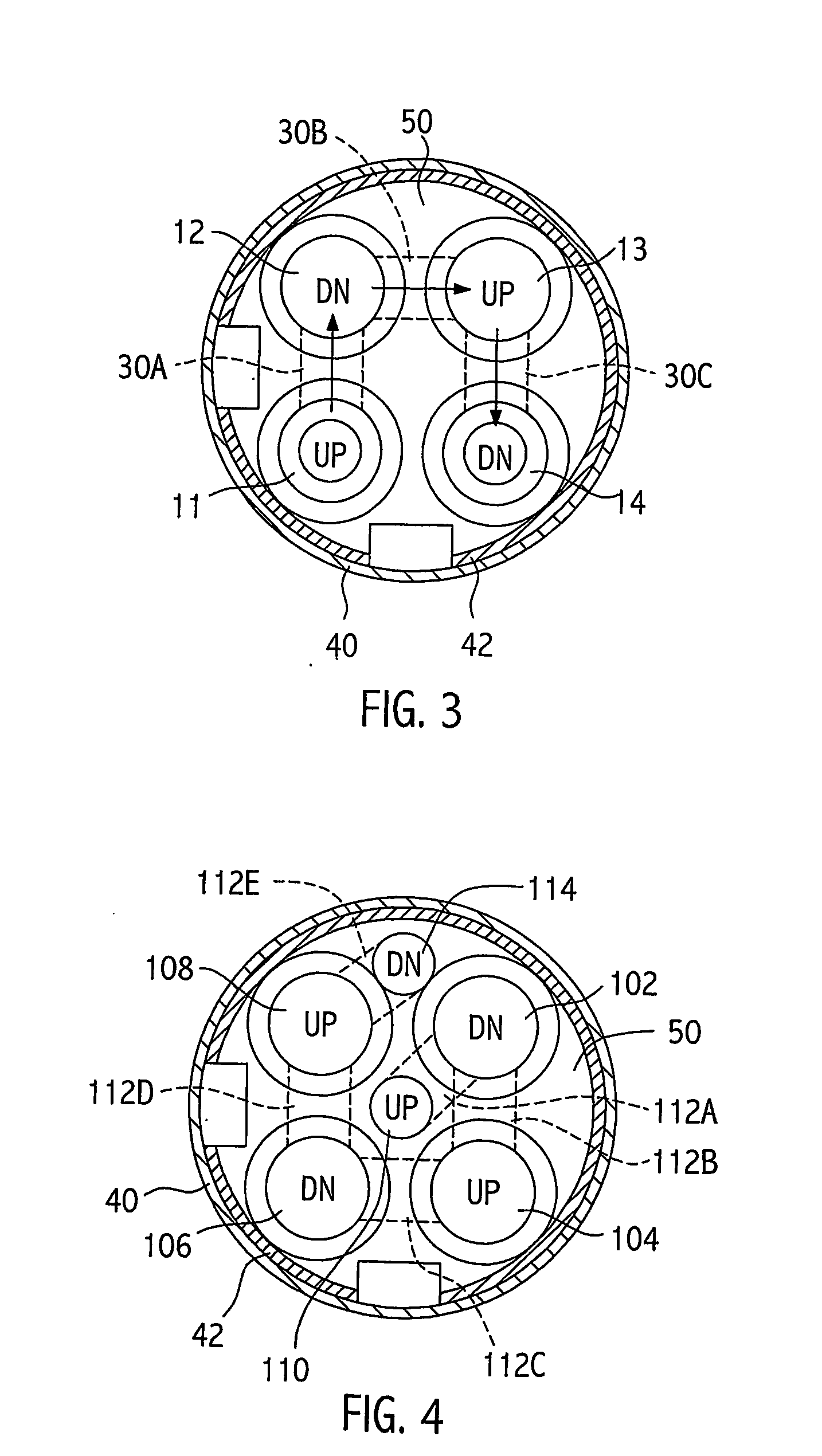

[0020] The present disclosure describes a pre-heating, contiguous in-line water heater. The in-line water heater described comprises a number of unique components (each of which may be used alone or in various combinations), such as, but not limited to, a passive heating means, an improved flow detection device and an improved power transformer unit. A means for control for controlling the in-line water heater and encasement for the in-line water heater are also described.

In-Line Water Heater

[0021] As with conventional water heaters, cold water is fed into the in-line water heater (input water) heated as it travels through the in-line water heater. The in-line water heater described herein has several embodiments. The in-line water heater is described as being used with water, however, it should be understood that the in-line water heater can be used with other liquids as well, if desired. The embodiments described below are given for the purpose of example only such that one of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com