Fast heating-up control method and device based on photo-thermal type and heating furnace

A heating control and fast technology, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve the problem of abnormal heating time, lack of data analysis and protection measures, lack of database support for temperature control system, affecting the photothermal heating furnace Temperature accuracy and other issues to ensure accuracy, facilitate precise control, and facilitate repair and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

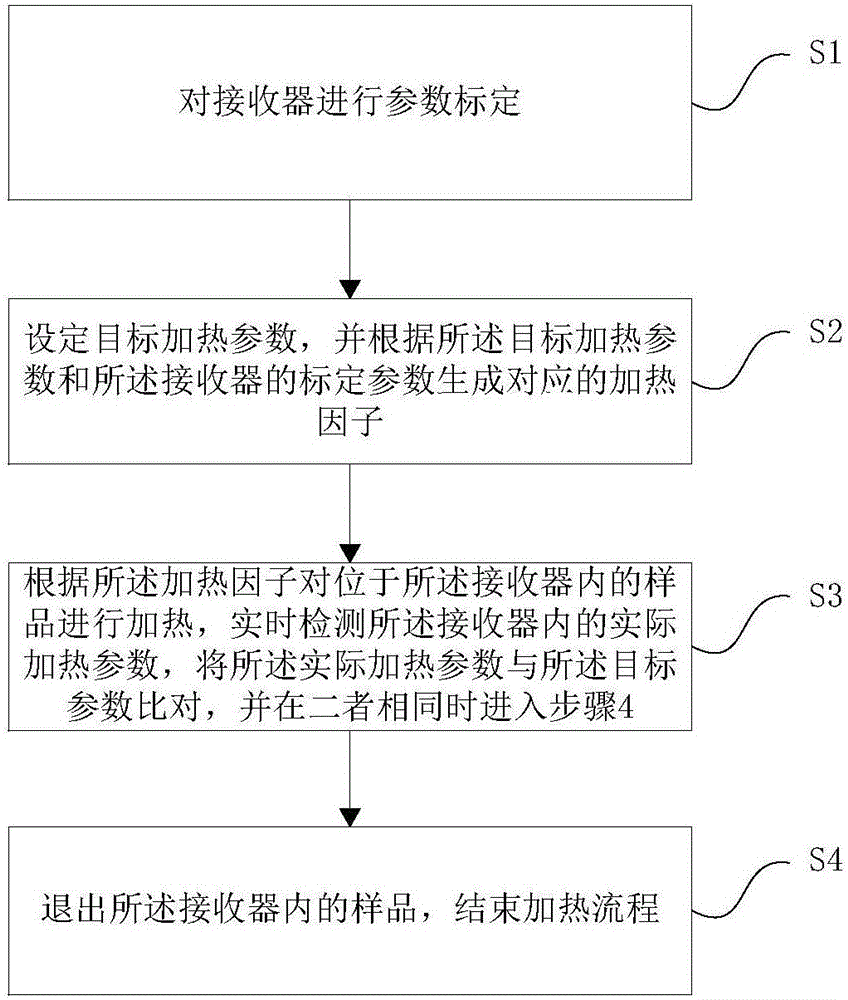

[0056] Embodiment 1. A rapid temperature rise control method based on photothermal type. The following will combine figure 1 A photothermal-based rapid temperature rise control method of the present invention is introduced in detail.

[0057] Such as figure 1 As shown, a rapid temperature rise control method based on photothermal method includes the following steps:

[0058] Step 1: Calibrate the parameters of the receiver where the sample is placed;

[0059] Step 2: setting target heating parameters, and generating corresponding heating factors according to the target heating parameters and calibration parameters of the receiver;

[0060] Step 3: According to the heating factor, the sample located in the receiver is heated by light, the actual heating parameter in the receiver is detected in real time, the actual heating parameter is compared with the target heating parameter, and the If both are the same, go to step 4;

[0061] Step 4: Eject the sample in the receiver t...

Embodiment 2

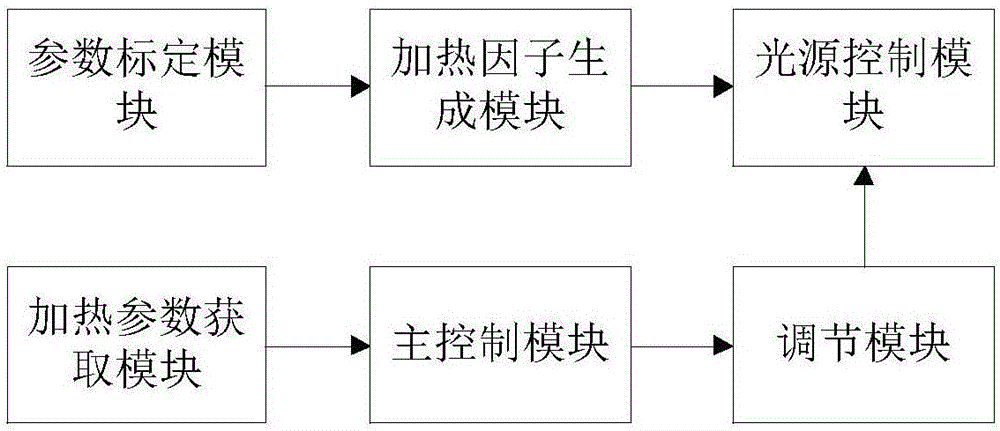

[0079] Embodiment 2. A rapid temperature rise control device based on photothermal type. The following will combine Figures 2 to 5 A photothermal-based rapid temperature rise control device of the present invention is introduced in detail.

[0080] Such as figure 2 As shown, a rapid temperature rise control device based on photothermal type, including:

[0081] The parameter calibration module is used to perform parameter calibration on the receiver where the sample is placed;

[0082] A heating factor generating module, configured to set a target heating parameter, and generate a corresponding heating factor according to the target heating parameter and the calibration parameter of the receiver;

[0083] A light source control module, configured to control the light source to heat the sample in the receiver according to the heating factor;

[0084] A heating parameter acquisition module, used for real-time detection of actual heating parameters in the receiver;

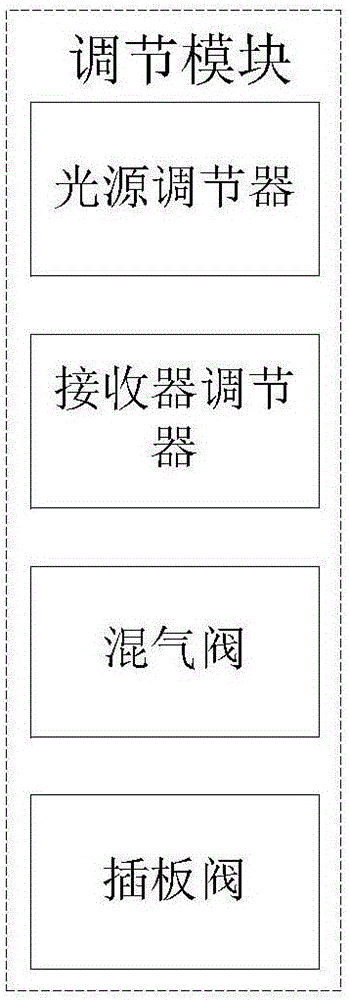

[0085...

Embodiment 3

[0092] Embodiment 3. A fast heating furnace based on photothermal type. A photothermal-based rapid heating furnace of the present invention will be described in detail below.

[0093] A photothermal-based rapid heating furnace includes a light source, a receiver, a data acquisition circuit and the control device.

[0094] The control device generates a corresponding heating factor according to the set target heating parameter and the calibration parameter of the receiver, and controls the light source to heat the sample located in the receiver according to the heating factor; the data The acquisition circuit detects the actual heating parameter in the receiver in real time, and the control device controls the light source to stop heating when the actual heating parameter in the receiver is the same as the target heating parameter, and exits the sample in the receiver.

[0095] In this embodiment, the data acquisition circuit includes one or more of a temperature sensor, an ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com