Cell sorter micro-fluidic chip based on immunomagnetic separation technology and application thereof in aspect of enrichment of rare cells

An immunomagnetic separation and microfluidic chip technology, which is applied in the direction of microorganisms, analytical materials, biological material sampling methods, etc., can solve the problems of bulky, expensive equipment, large amount of cells, etc., to reduce dead volume and low manufacturing cost , Improve the effect of analysis throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

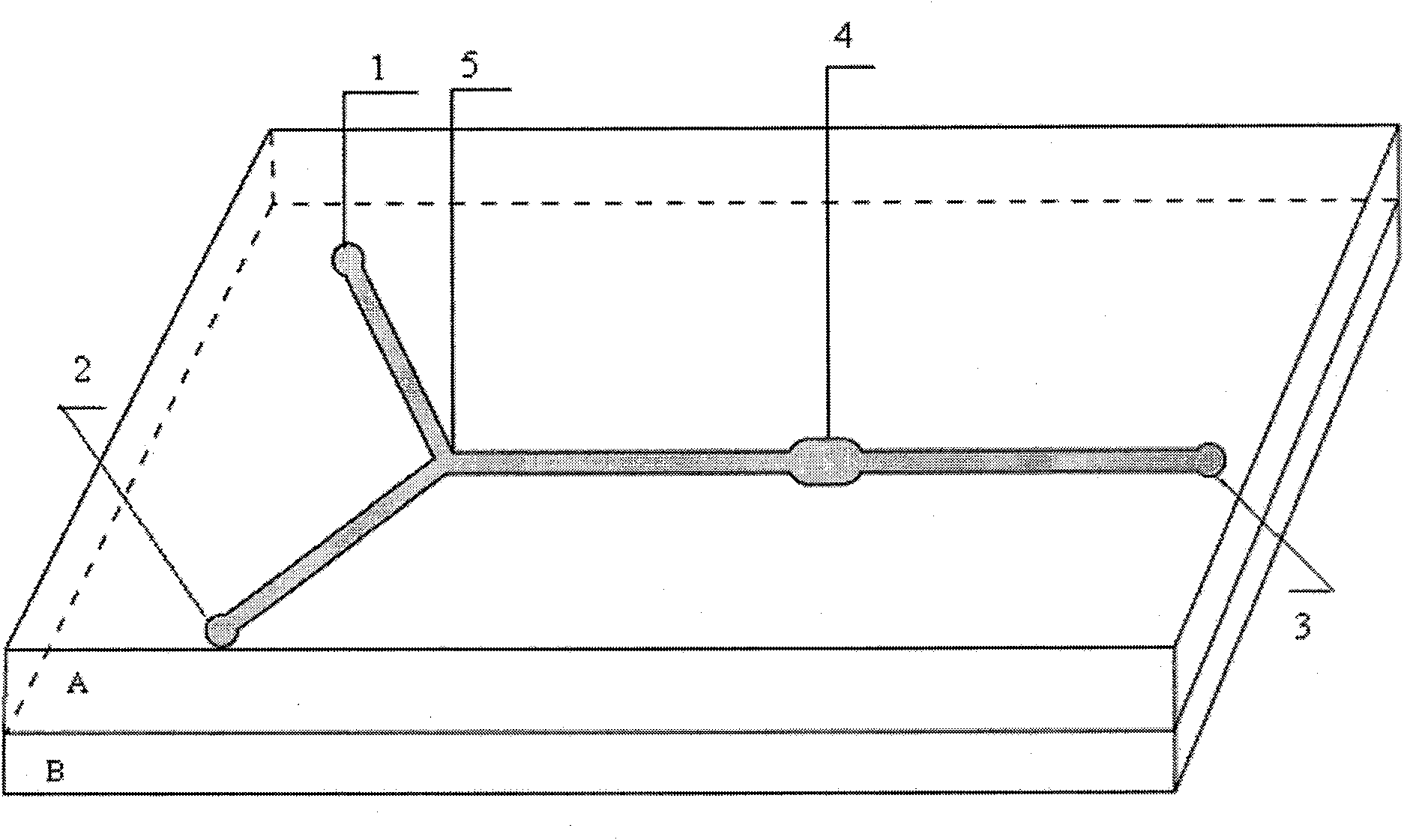

[0047] Embodiment 1 The structure of the chip of the present invention

[0048] The chip of the present invention comprises a substrate and a cover sheet bonded together, the substrate is provided with a Y-shaped microchannel and a sample pool (1) and a buffer pool (2) respectively located at two ends of the upper part of the Y-shaped microchannel, and The waste liquid tank (3) located at the lower end of the Y-shaped microchannel is designed with an antigen-antibody immune reaction chamber (4) on the microchannel at a distance of 10 mm from the intersection point (5) of the Y-shaped microchannel, and the reaction chamber (4) is a circle Angular rectangular groove, the width is 4 times the width of the microchannel, and the length is 2mm. Place permanent magnets symmetrically on the upper and lower sides of the antigen-antibody immune reaction chamber (4), inject the magnetic beads with specific antibodies on the surface from the sample pool (1), and then the buffer solution f...

Embodiment 2

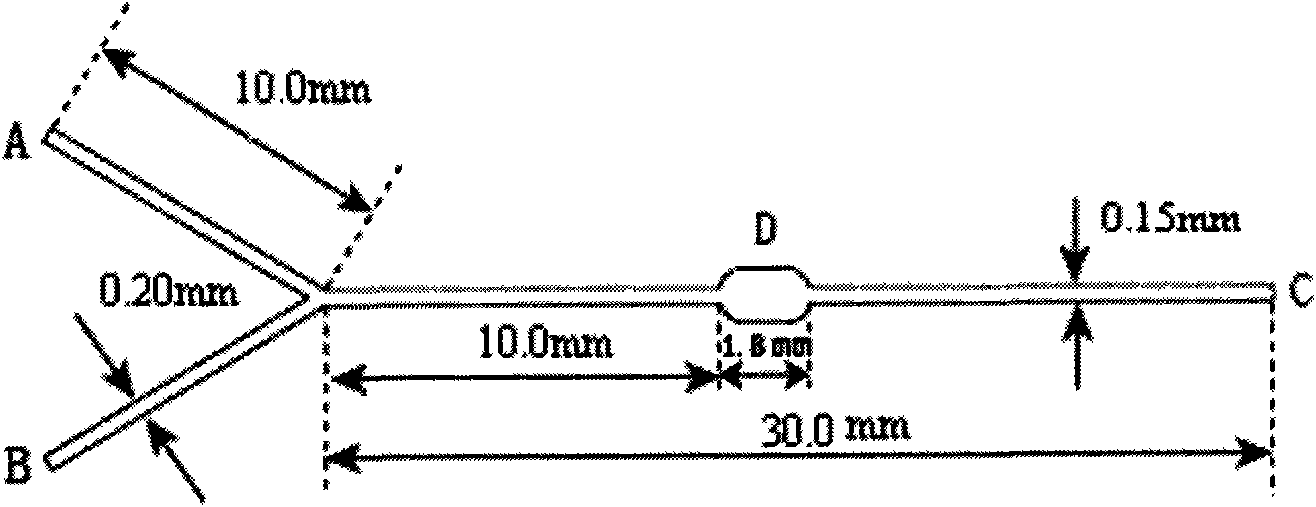

[0049] Embodiment 2 takes glass as the substrate, and PDMS is the chip production of the present invention as the cover sheet

[0050] (1) Fabrication of glass substrate: for the size design of the microchannel on the mask film, see figure 1 . Place the mask film on a 63mm×63mm×1.5mm uniform chromium plate, expose to ultraviolet light (wavelength 365nm) for 7 minutes, develop in the developer for 100 seconds, and then dry it at 100°C for half an hour. The chromium film was etched with a chromium film etching solution (cerium sulfate: perchloric acid: water=50 g: 15 ml: 300 ml) at room temperature, then rinsed with high-purity water, and dried. Through digital microscope photography, it is measured that the channel size on the chromium plate increases by about 30 μm. With 0.5M HF / 0.5M NH 4 F etchant etches bare borosilicate glass at a rate of about 10 μm min -1 After etching for 10 minutes, remove the residual photoresist layer and chromium film with acetone and chromium f...

Embodiment 3

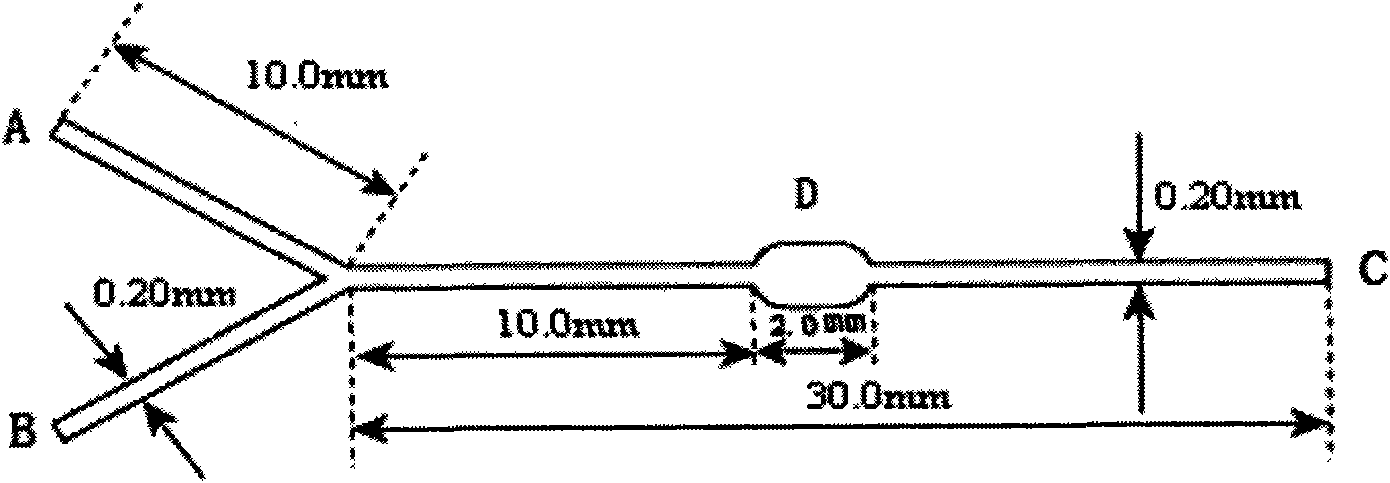

[0053] Embodiment 3 takes PDMS as the substrate, and the chip of the present invention made of glass as the cover sheet

[0054] (1) Fabrication of PDMS substrate: for the size design of the microchannel on the mask film, see figure 2 . Place the wafer in concentrated H 2 SO 4 / H 2 o 2 (3 / 1) The solution was boiled slightly for 30 minutes, and after cooling, it was taken out and rinsed with deionized water until neutral, ultrasonicated with acetone for 5 minutes, and then heated on a heating plate for 30 minutes.

[0055] (2) Spin and coat a thin layer of SU-8 photoresist on the silicon wafer, and make the thickness of the glue layer about 50 μm by controlling the speed of the spin. Ultraviolet rays pass through a photomask to expose the photoresist, and the unexposed parts are dissolved with a developer. The raised SU-8 structure on the surface of the silicon wafer serves as a positive mold for the PDMS substrate. The positive silicon mold was then silanized for 1 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com