Membrane separation method of zero discharge of electroplating waste water treatment

A technology for electroplating wastewater and membrane separation, which is used in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problem, to achieve the effect of high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

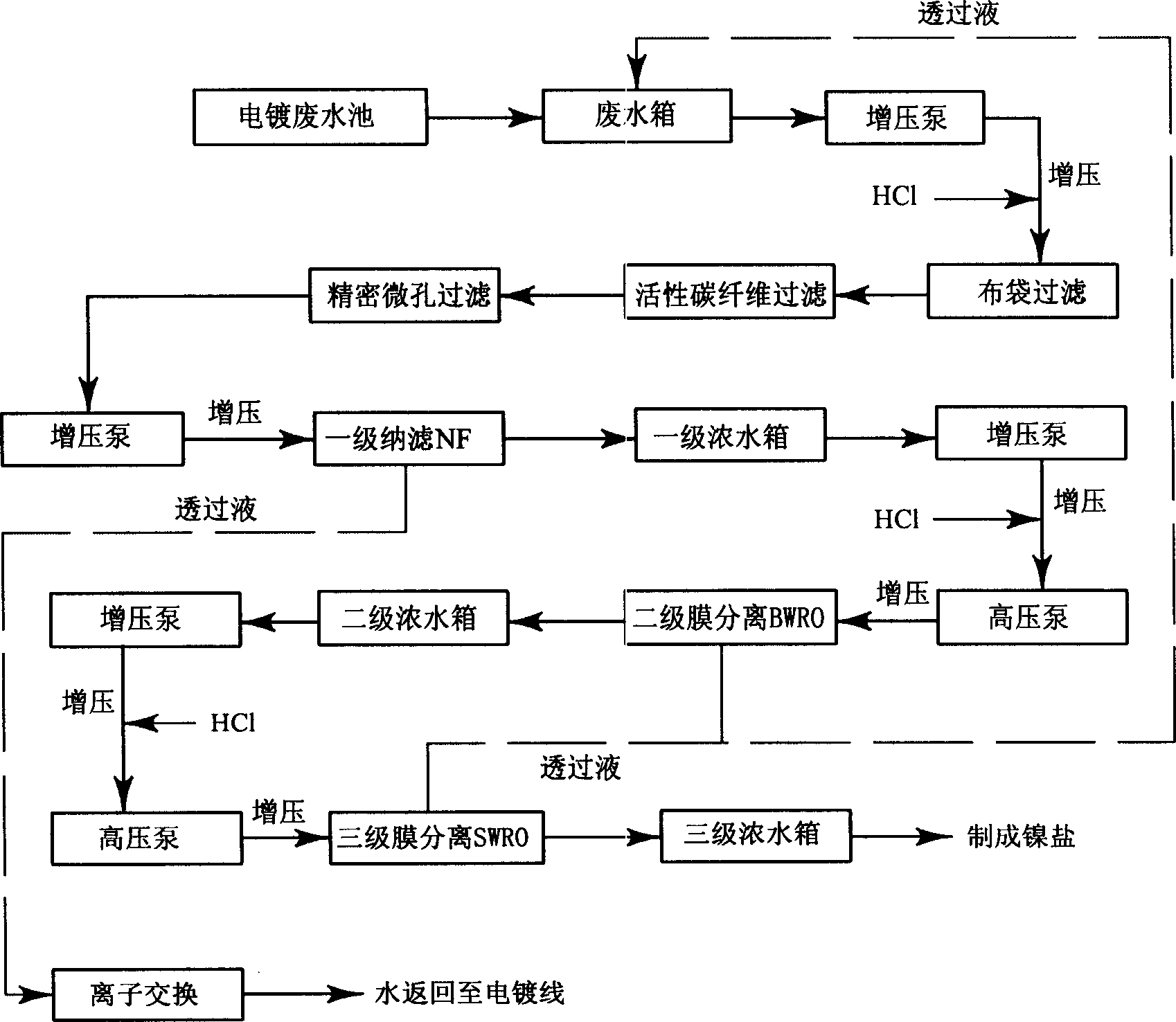

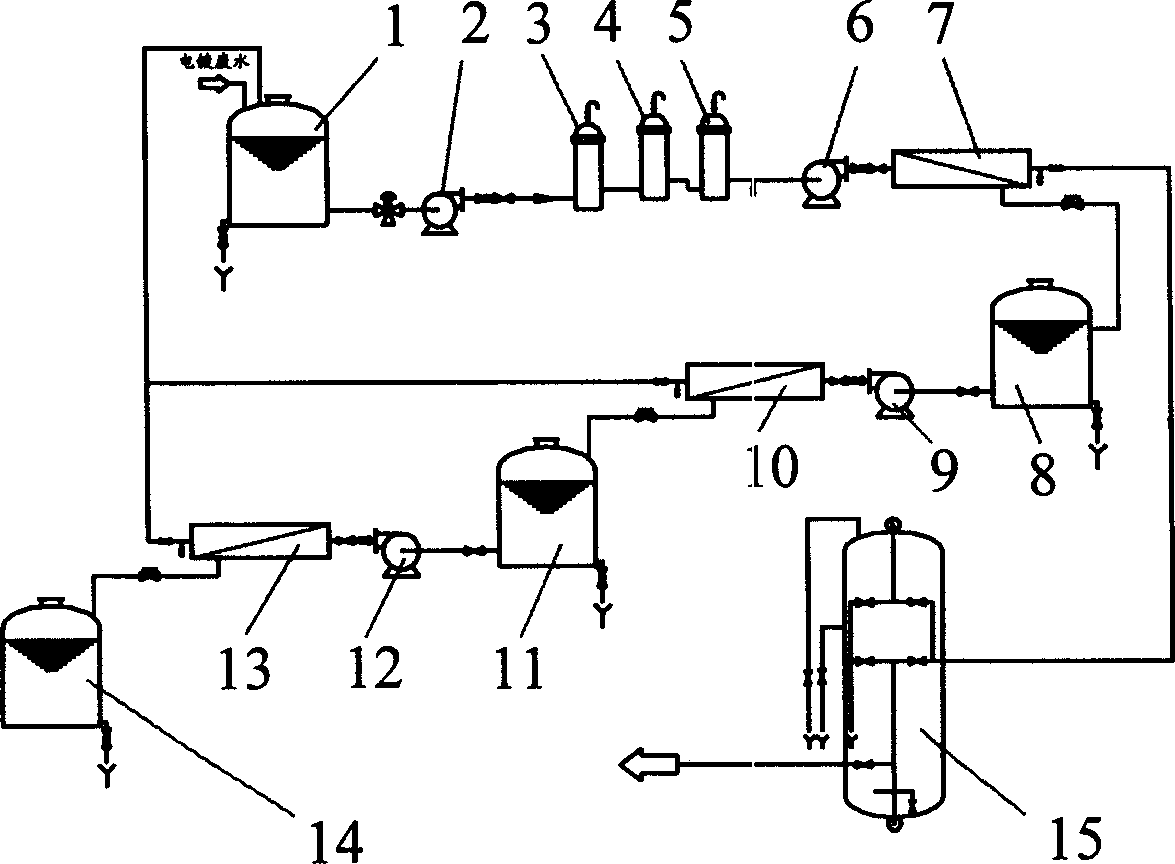

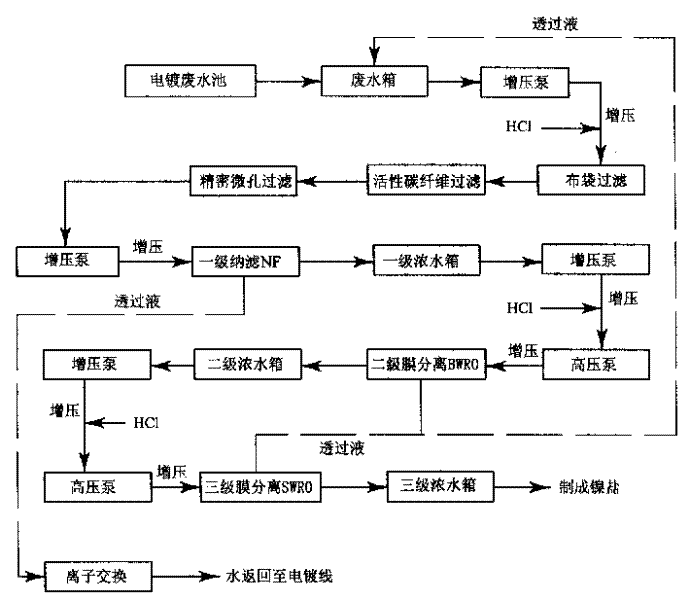

[0031] Embodiment 1: electroplating nickel wastewater treatment

[0032] 1. Pretreatment

[0033] Firstly, the wastewater stock solution is taken from the electroplating nickel wastewater pool, raised to the wastewater tank 1, then boosted to 0.4Mpa by the booster pump 2, and filtered under pressure by using a 10 μm bag filter 3, and the anode slime, Larger suspended impurities such as foam fragments are filtered out; then the activated carbon fiber filter 4 is used to absorb the petroleum organic matter in the wastewater by using its carbon fiber to reduce the pollution of the organic matter to the membrane element; The organic microfiltration membrane with a high pore size of 5 μm further filters the wastewater and removes fine suspended solids in the wastewater, thereby protecting the membrane elements and prolonging the service life of the membrane elements. In order to prevent the generation of Ni(OH) during concentration 2 Precipitation, adjust the pH value of the rins...

Embodiment 2

[0043] Example 2: 50m 3 / h Electroplating Nickel Wastewater Treatment and Recycling

[0044] The water intake of the design system is 50m 3 / h, choose the pretreatment bag filter with a pore size of 10um. The nickel electroplating wastewater is first filtered through the bag, and the large suspended particles in the wastewater will be removed, and then filtered by activated carbon. Activated carbon fiber filter element is used in the activated carbon filter, and finally the waste water passes through a 5um precision filter. The pretreated nickel electroplating wastewater is pre-concentrated through the nanofiltration membrane treatment system.

[0045] The first-stage nanofiltration NF concentration system adopts roll-type NF membrane modules with a water intake of 50m 3 / h, divided into two groups A and B, each group operates independently. The wastewater is concentrated 10 times after the first stage of nanofiltration, and the membrane concentrate is 5m 3 / h is used as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com