Curtain type hollow fiber membrane yarn end fastening technique

A fixed and reinforced fiber membrane technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as broken wires, affecting the stable operation of membrane bioreactors and meeting water standards, so as to reduce the problem of broken wires Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

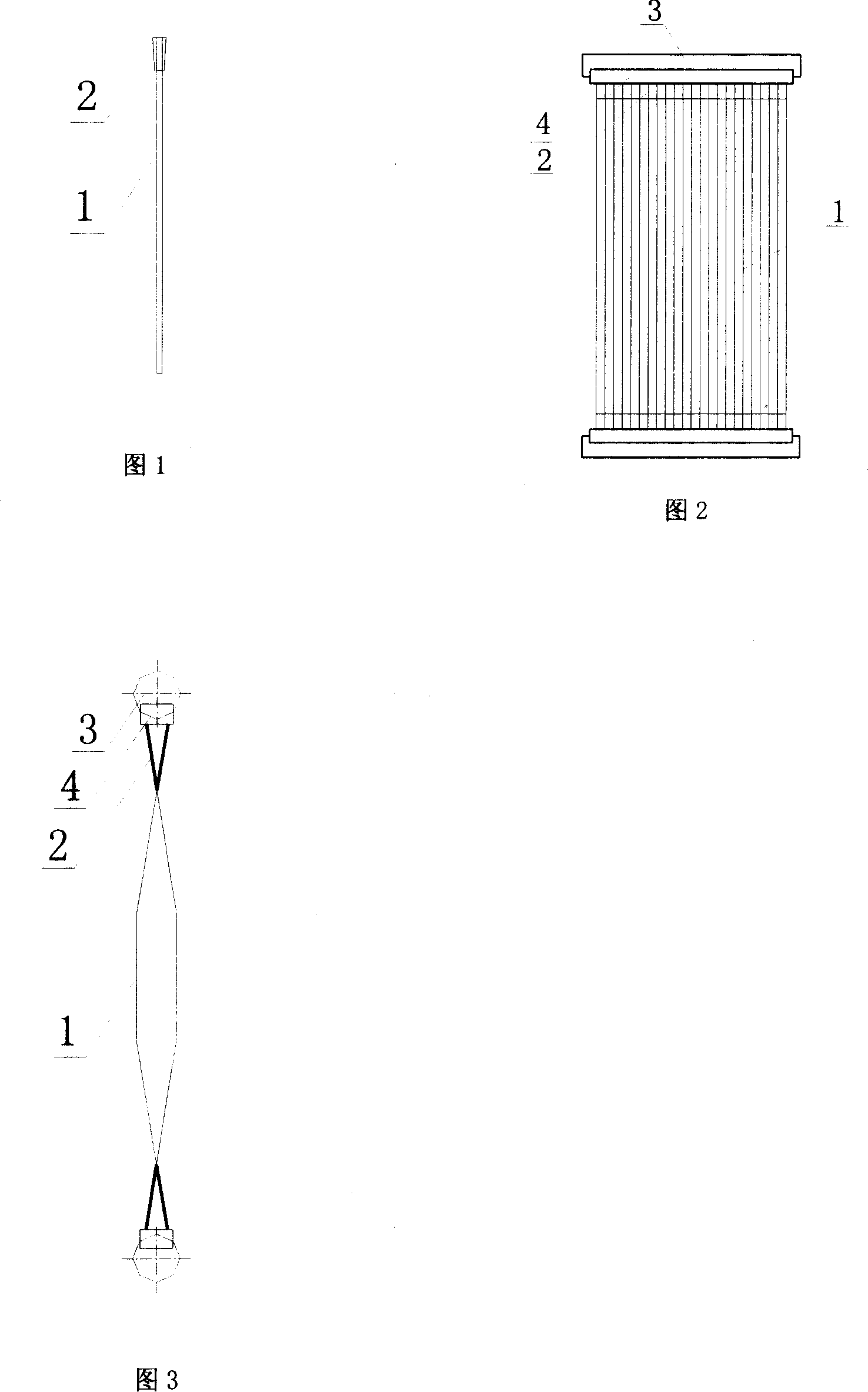

Method used

Image

Examples

Embodiment Construction

[0007] Contains COD 200~500mg / L, BOD 5 100~300mg / L, ammonia nitrogen 50~160mg / L, SS 20~50mg / L, water 10-15m 3 / h of domestic sewage enters the membrane bioreactor for treatment, and the system uses the end fixing and strengthening technology of the present invention to domestically produced curtain-type hollow fiber membrane modules with low mechanical strength. When the air-water ratio is 10-30, the blowing volume is 5m 3 / hr, temperature 12~29℃, pH 6.5~8.0, stable operation for 6 months, the flux of this hollow fiber membrane module is stable at 10-15L / m 2 ·h. The operating pressure is 16-20kpa. Compared with untreated modules, the problem of broken wires in membrane modules has been effectively controlled. The COD value of the system effluent varies between 10 and 30mg / L, and is generally stable below 20mg / L. 5 The value fluctuates between 1 and 3mg / L, the ammonia nitrogen is stable below 10mg / L, the SS is stable below 0.3mg / L, and the effluent water quality meets the "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com