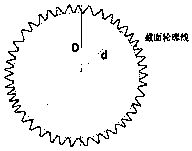

High-speed dry-spray spinning method for preparing deformed section carbon fiber precursor fiber, pre-oxidized fiber or carbon fiber

A technology of precursor fibers and special-shaped cross-sections, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, and can solve problems such as undiscovered reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

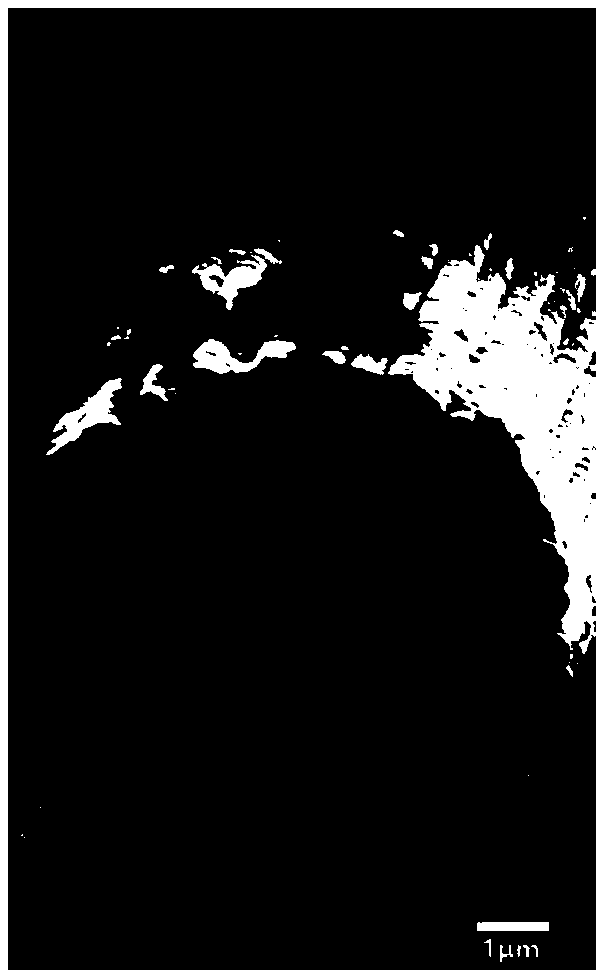

Embodiment 1

[0073] Add acrylonitrile, methyl acrylate and itaconic acid (97:2:1 in molar ratio) to water (total monomer mass concentration: 25%) sequentially according to the ratio, and obtain a molecular weight of 80,000, A PAN-based polymer with a molecular weight distribution coefficient of 1.6 (wherein the comonomer molar content is 3%). The obtained PAN polymer was dissolved in a mixed solution of dimethyl sulfoxide solvent and dimethylacetamide (mass ratio: 15:85) to prepare a spinning solution with a solid content of 30 wt%. The viscosity of the spinning solution is 40Pa.s, the gel point is -25°C, and the gel range is within 8°C. The spinning solution is sequentially filtered using stainless steel metal fiber sintered felts with a precision of 10 μm and 0.2 μm, and then the spinning solution is transferred to a defoaming kettle for degassing, and then spinning. Spinning by dry-jet wet spinning method, the spinning solution temperature is 55°C, the dry spray section is -10°C air, t...

Embodiment 2

[0075]Add acrylonitrile and acrylic acid (99.8:0.02 in molar ratio) to n-heptane (total monomer mass concentration: 6%) in sequence according to the ratio, and obtain PAN with a molecular weight of 950,000 and a molecular weight distribution coefficient of 5.5 through polymerization. Polymer (with a molar comonomer content of 0.02%). The obtained PAN polymer was dissolved in dimethyl sulfoxide to prepare a spinning solution with a solid content of 5.1 wt%. The viscosity of the spinning solution is 110 Pa.s, the gel point is 14°C, and the gel interval is within 6°C. Sequentially filter the spinning solution with a non-woven felt with a precision of 3 μm and 0.5 μm, then transfer the spinning solution to a defoaming tank for degassing, and then spin. Spinning by dry-jet wet spinning method, the spinning solution temperature is 65°C, the dry spraying section is -5°C air, and the spinneret holes are circular spinneret holes with a diameter of 0.065mm. In the spinning process, tw...

Embodiment 3

[0077] Add acrylonitrile and methyl acrylate (94:6 in molar ratio) to the zinc chloride solution (total monomer mass concentration: 25%) in sequence according to the ratio, and obtain a molecular weight of 420,000 and a molecular weight distribution coefficient of 3.3 through polymerization. The PAN polymer (wherein the comonomer molar content is 6%). The obtained PAN polymer was dissolved in dimethylacetamide to prepare a spinning solution with a solid content of 10.5 wt%. The viscosity of the spinning solution is 110 Pa.s, the gel point is 9°C, and the gel interval is within 6°C. The spinning solution is sequentially filtered with stainless steel metal fiber sintered felts with a precision of 5 μm and 2 μm, and then the spinning solution is transferred to a defoaming kettle for degassing, and then spinning. Spinning by dry-jet wet-spinning method, the temperature of the spinning solution is 35°C, the dry spray section is air at -1°C, and the spinneret hole is a circular spi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear viscosity | aaaaa | aaaaa |

| Zero shear viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com