Polyether sulfone-polyurethane blend hollow fiber membrane and preparation method thereof

The technology of polyurethane and polyethersulfone is applied in the field of preparation of polyethersulfone-polyurethane blended hollow fiber membrane and its non-solvent induced phase separation method, which can solve the problems of poor strength of hollow fiber membrane, complicated process and high cost. Achieve the effect of increasing flexibility, reducing wire breakage and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] In the present invention, a preparation method of polyethersulfone-polyurethane blended hollow fiber membrane is also provided, which is prepared by non-solvent-induced phase separation method, and the preparation steps are as follows:

[0058] Step (1): First, put polyethersulfone, polyurethane, polymer pore-forming agent, surfactant, water and solvent in a certain proportion into the reaction kettle, and stir at 50-90°C for more than 20 hours to fully and evenly dissolve;

[0059] Step (2): Then, stop stirring, filter, vacuumize and degas, and lower the temperature to obtain a casting solution at 30~70°C;

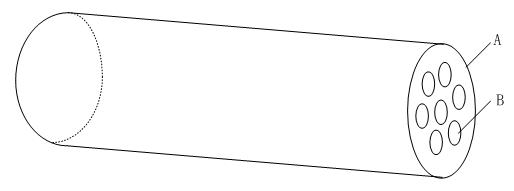

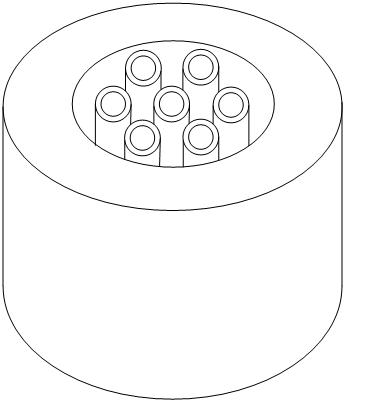

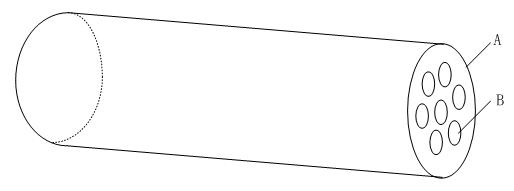

[0060] Step (3): Next, transport the casting solution to a seven-round tube spinneret at 30-60°C, and pour an internal coagulation solution at 20-60°C into the seven round tubes to form inner holes and extrude hollow fiber;

[0061] Step (4): Finally, pass the hollow fiber through an air distance of 50-300mm, enter the external coagulation liquid at 20-60°C for co...

Embodiment 1

[0065] Example 1: Weigh 15% of polyethersulfone, 2% of polyurethane, 15% of polyethylene glycol, 3% of polyvinylpyrrolidone, 1% of water, and 64% of dimethylacetamide by weight percentage and put them into the reaction kettle. Stir at 80°C for 20 hours, then stop stirring, filter, vacuumize and defoam, and cool down to obtain a 50°C casting liquid, which is transported to a seven-round tube spinneret at 50°C through a metering pump. Deionized water at 30°C is extruded into a hollow fiber with seven inner holes, then passes through an air distance of 200mm, enters an aqueous solution with 30% dimethylacetamide content at 30°C and solidifies, and then collects the filaments , to obtain a polyethersulfone-polyurethane mixed hollow fiber membrane. The prepared polyethersulfone-polyurethane blended hollow fiber membrane has an inner diameter of 0.92mm, an outer diameter of 4.26mm, and a pure water flux of 1800L / M 2 ·H (0.1MPa, 25°C), with an average pore diameter of 0.13μm, a tens...

Embodiment 2

[0068] Example 2: Weigh 13% of polyethersulfone, 3% of polyurethane, 15% of polyethylene glycol, 1% of water, and 68% of dimethylacetamide in the reaction kettle by weight percentage, and stir at 80°C for 20h , then stop stirring, filter, vacuumize and defoam, and lower the temperature to obtain a 50°C casting solution, which is transported to a seven-round tube spinneret at 50°C through a metering pump, and 20% bismuth at 30°C is passed into the seven round tubes The aqueous solution containing methyl acetamide is extruded into a hollow fiber with seven inner holes, and then passes through the air distance of 200mm, enters the aqueous solution water with 30% dimethyl acetamide content at 30 ℃ and solidifies, and then the membrane filament collected to obtain a polyethersulfone-polyurethane blended hollow fiber membrane. The prepared polyethersulfone-polyurethane blended hollow fiber membrane has an inner diameter of 0.96mm, an outer diameter of 4.30mm, and a pure water flux o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com