Method for preparing recycled polyester high-purity synthetic particle

A recycled polyester, high-purity technology, applied in the field of preparation of synthetic particles, can solve the problems of small molecules with high impurity content, increased cost, large viscosity difference, etc. Uniform extrudate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

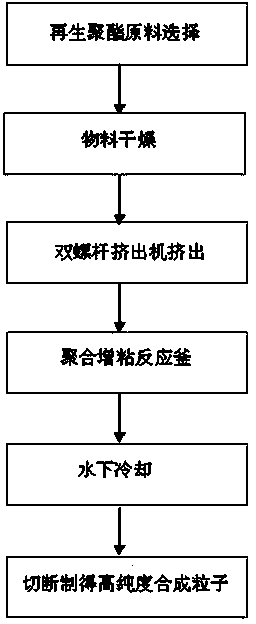

[0025] A method for preparing high-purity synthetic particles, comprising the following steps:

[0026] Step 1: Selection of raw and auxiliary materials, raw materials include waste silk in the production process of chemical fiber enterprises, leftovers of chemical fiber non-woven, textile and clothing fabric manufacturers, waste and old clothing and textiles, etc. Regenerated polyester foam of various colors;

[0027] Step 2: Dry the material, put the recycled polyester foam materials of various colors into the drum, heat them with steam, and then use a vacuum pump to remove the water and dry them;

[0028] Step 3: The recycled raw material after drying is extruded by a twin-screw extruder, and then enters a polymerization viscosifying reactor for viscosifying reaction to obtain a high-viscosity recycled melt, and then filters out small molecular impurity particles through a melt filter Enter the next process;

[0029] Step 4: Reaction The filtered regenerated polyester melt...

Embodiment 1

[0031] The raw material is recycled polyester polyester foam with an impurity content of less than 2 / 10,000 and an intrinsic viscosity of 0.55dl / g; the material is put into the drum and heated with steam at a temperature of 158°C, and then used The vacuum pump is vacuumed for 8 hours to remove the water, so that the water content of the raw materials is not higher than 0.02%. During the process, the temperature in each zone of the twin-screw extruder is 268~285°C; it is cooled under water to normal temperature and cut off to obtain the required high-purity synthetic particles. The particle quality index has been tested: particle size: 31.6 g / piece; particle size: 99.2%; water content: 0.14%; viscosity: 0.71 η.

Embodiment 2

[0033] The raw material is recycled polyester polyester foam with an impurity content of less than 2 / 10,000 and an intrinsic viscosity of 0.60dl / g; the material is put into the drum and heated with steam at a temperature of 158°C, and then used The vacuum pump is vacuumed for 8 hours to remove the water, so that the water content of the raw materials is not higher than 0.02%. During the process, the temperature in each zone of the twin-screw extruder is 268~285°C; it is cooled under water to normal temperature and cut off to obtain the required high-purity synthetic particles. The particle quality index has been tested: particle size: 29.8 g / piece; particle size: 98.8%; moisture content: 0.17%; viscosity: 0.76 η.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com