Polyacrylonitrile-based carbon fibers as well as preparation method and application thereof

A technology of polyacrylonitrile-based carbon fiber and polyacrylonitrile fiber, which is applied in the fields of fiber chemical characteristics, synthetic polymer artificial filament chemical post-treatment, textiles and papermaking, etc. It can solve the problems of fiber burning and other problems, and achieve the improvement of mechanical properties, The effect of reducing broken wires and reducing the formation of skin-core structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

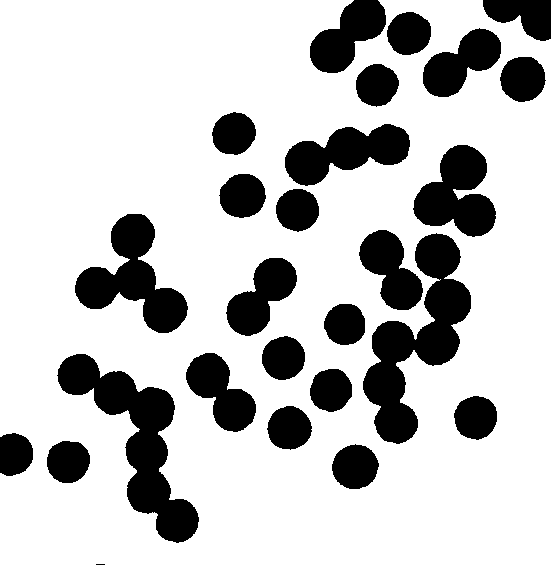

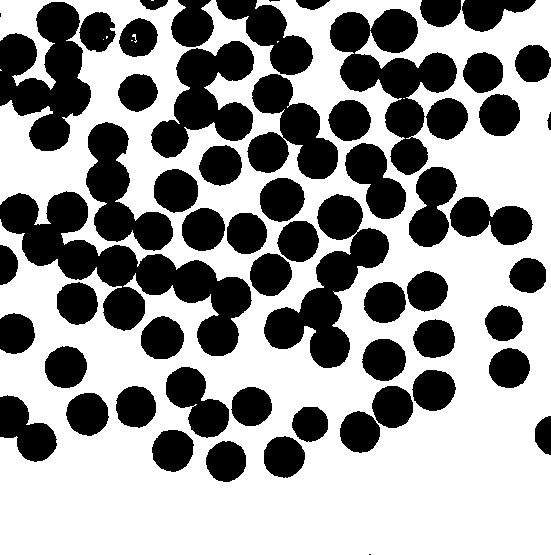

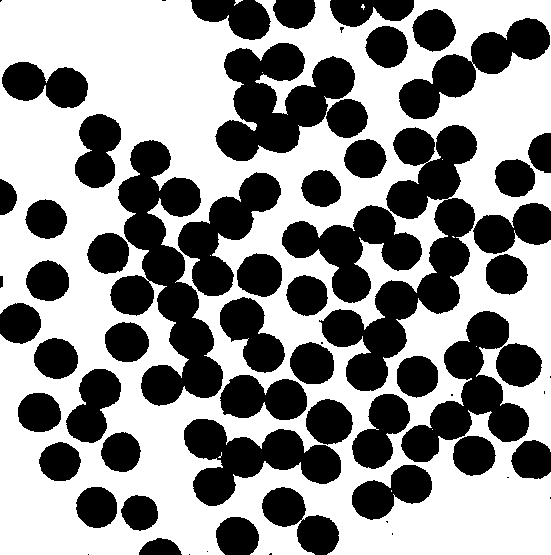

Image

Examples

preparation example Construction

[0082] The invention provides a kind of preparation method of polyacrylonitrile base carbon fiber, comprises the following steps:

[0083] Prepare humidification solution: dissolve oxygen-enriched substance, siloxane, and borate in water to prepare humidification solution;

[0084] Precursor humidification: immerse the polyacrylonitrile precursor in the soaking device equipped with a humidifying solution, the content of the humidifying solution attached to the precursor is 1~30wt% of the polyacrylonitrile precursor, and obtain the polyacrylonitrile fiber after humidification;

[0085] Heat treatment: heat-treat the humidified polyacrylonitrile fiber in an oxidation furnace, the oxygen content in the oxidation furnace is 1~30v%, and the temperature is 100~305℃;

[0086] Carbonization: Carbonize the heat-treated polyacrylonitrile fibers to prepare polyacrylonitrile-based carbon fibers.

[0087] Wherein, the resistivity of water in the step of preparing the humidifying solution ...

Embodiment 1

[0135] Based on the total amount of humidifying solution, the content of octamethylcyclotetrasiloxane is 0.1wt%, the content of trimethyl borate is 0.1wt%, and the content of potassium permanganate is 25wt%;

[0136] The wetting solution is evenly attached to the surface of the raw silk by the wetting device, so that the content of the humidifying solution is 30wt% of the raw silk.

[0137] The humidified fiber is heat treated in the oxidation furnace, the heat treatment is in the range of 100-250 °C for 53 minutes, the oxygen content is 23v%, and the draft ratio is 5%; the heat treatment is in the range of 235-305 °C for 53 minutes, and the heat medium gas is filled with nitrogen. The oxygen content is 19v%, and the draft ratio is 0%.

[0138] Carbonize at a low temperature of 290-910°C for 2 minutes, and the draw ratio is 2%; carbonize at a high temperature at 850-1550°C for 2 minutes, and the draw ratio is -1%, to obtain polyacrylonitrile-based carbon fibers.

[0139] The ...

Embodiment 2

[0141] Based on the total amount of the humidifying solution, the content of decamethylcyclopentasiloxane is 0.5wt%, the content of tris(trimethylsilane) borate is 0.5wt%, and the content of sodium percarbonate is 17wt%.

[0142] The wetting solution is evenly attached to the surface of the raw silk by the wetting device, so that the content of the humidifying solution is 20wt% of the raw silk.

[0143] Heat the humidified fibers in an oxidation furnace for 40 minutes at 100-250°C, with an oxygen content of 21v% and a draw ratio of 8%; heat-treat at 235-305°C for 43 minutes, and fill in nitrogen to make the heat medium gas The oxygen content is 17v%, and the draft ratio is -1%.

[0144] Carbonize at a low temperature of 290-910°C for 10 minutes, and the draw ratio is 0%; carbonize at a high temperature at 850-1550°C for 13 minutes, and the draw ratio is -2%, to obtain polyacrylonitrile-based carbon fibers.

[0145] The measured tensile strength of the polyacrylonitrile-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com