Splicing Tape

a technology of splicing tape and adhesive, applied in the direction of film/foil adhesive, photosensitive materials, instruments, etc., can solve the problems of insufficient control of the strength of the cleavable layer, no splicing, waste of 2% of the material on each roll, etc., and achieve the effect of low surface energy and high surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]Web-fed processes may run at speeds of greater than 1200 meters per minute (about 4000 feet per minute). Continuous, reliable production demands that the process, usually a printing or a coating process, run uninterrupted for as long a period of time as possible. Running at such high speed also means that it may be both difficult and essential to change from the running roll to a replacement roll with virtually no interruption, as described above.

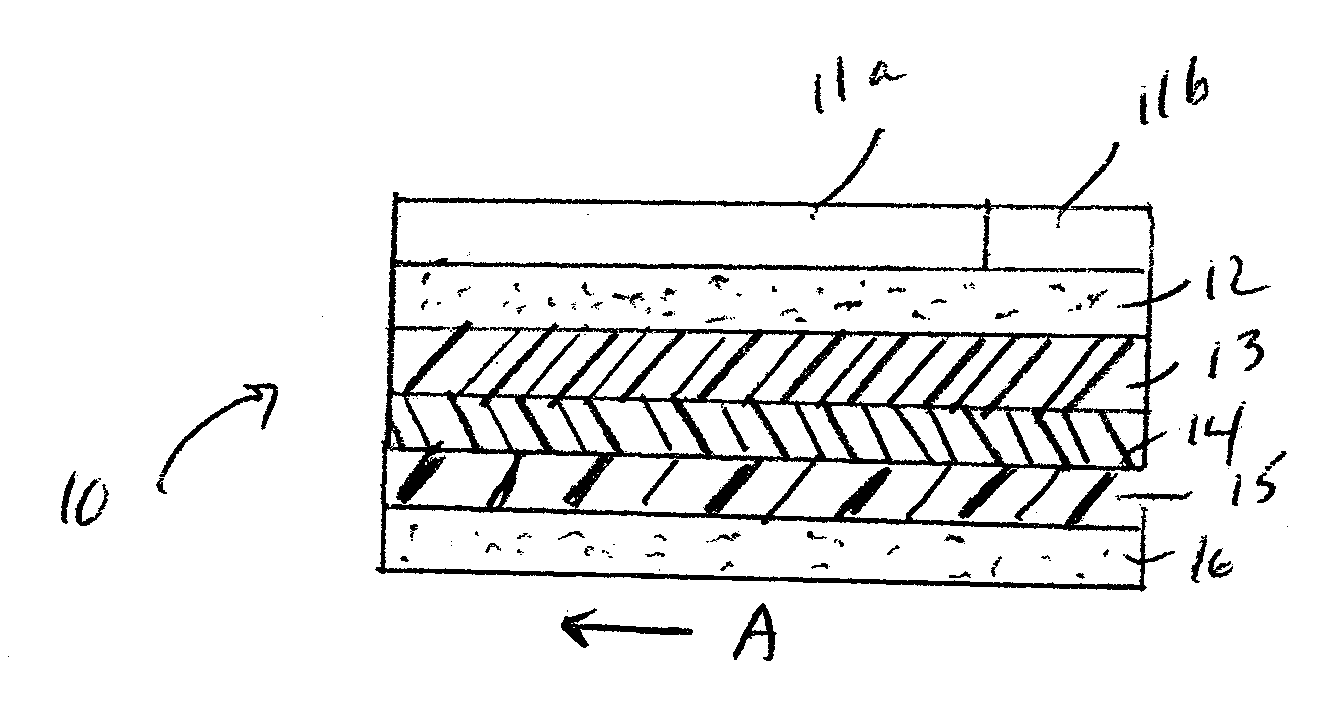

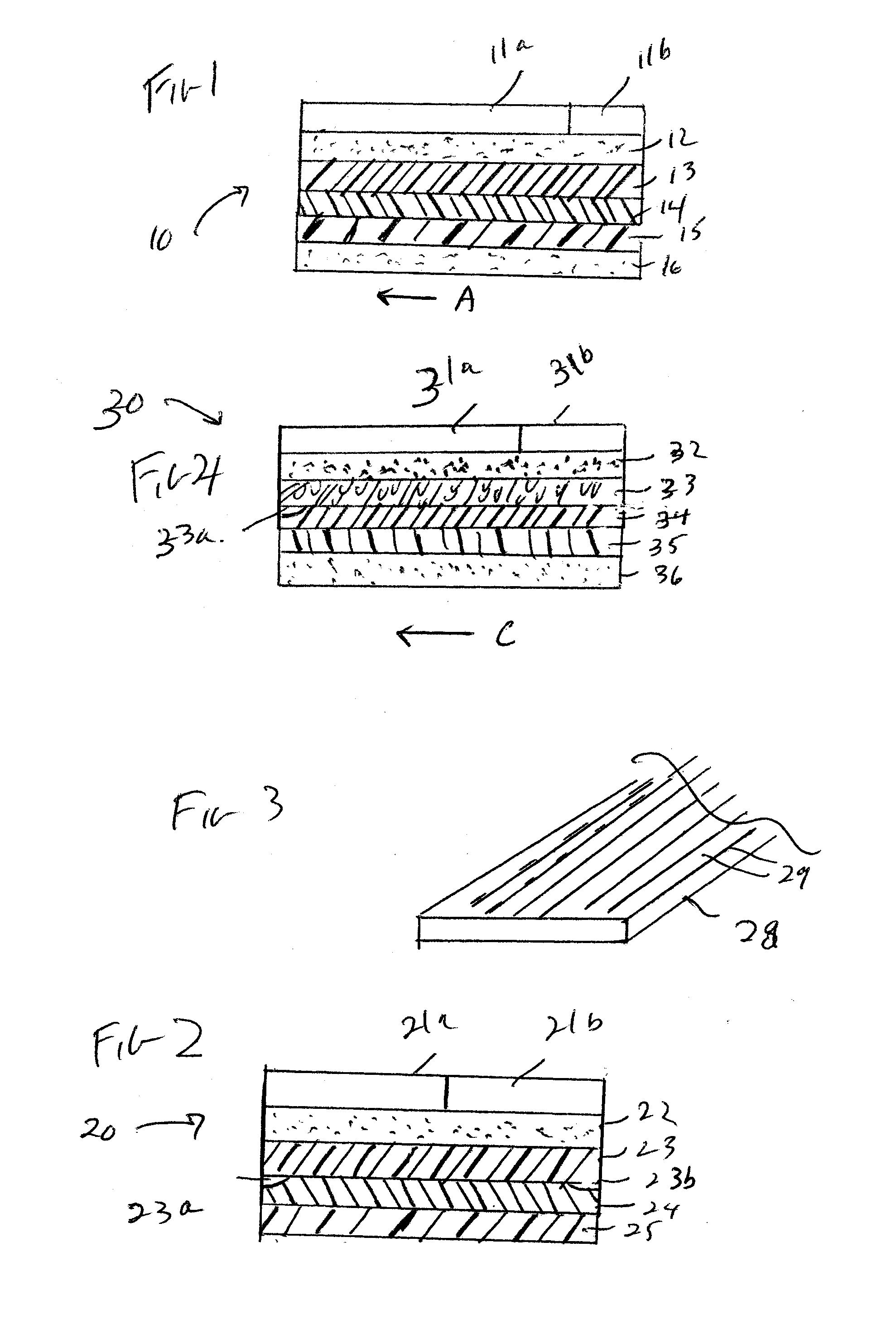

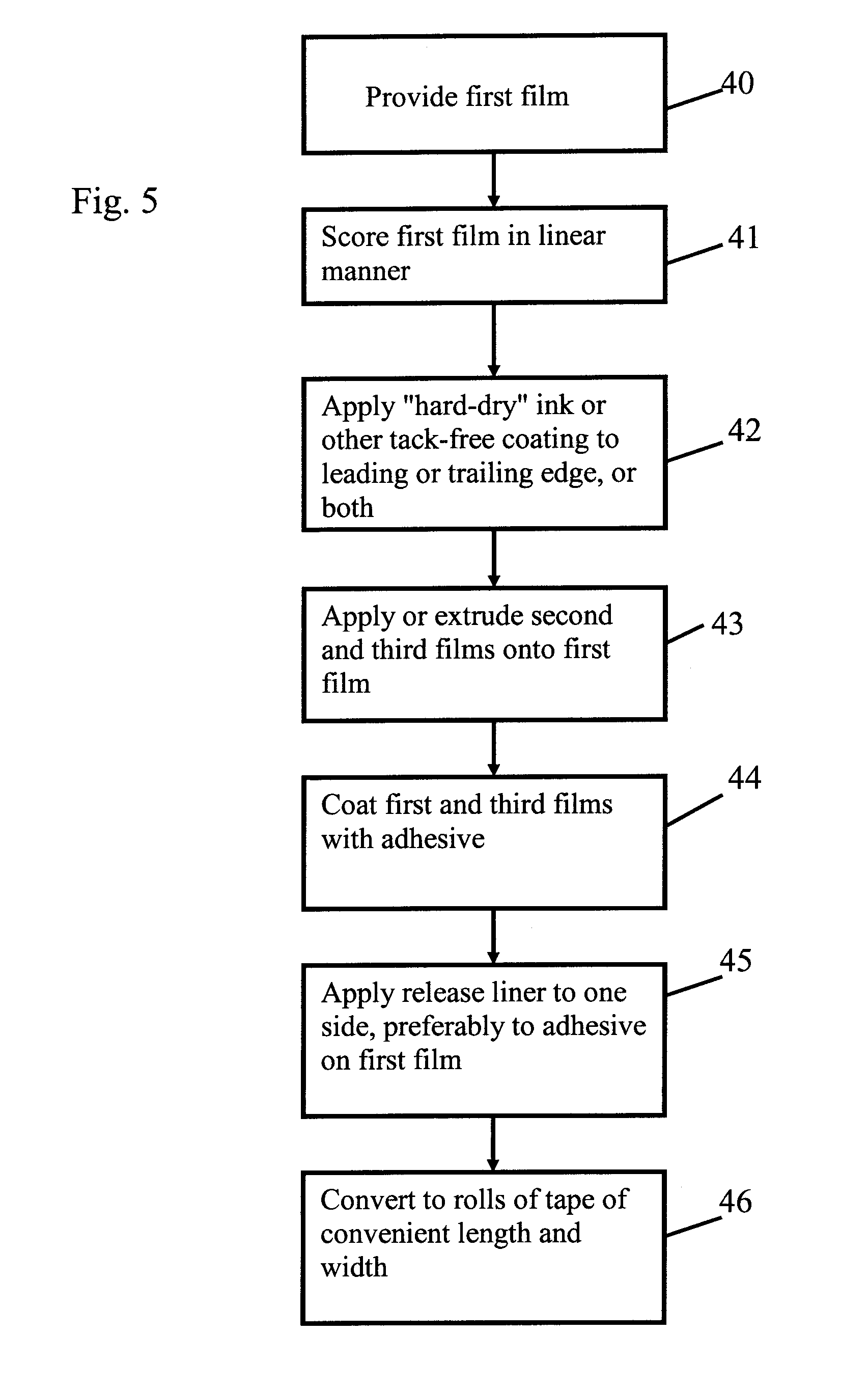

[0023]The process for making the change generally takes place with embodiments of the invention as follows. A replacement roll is readied for its place in the line by placing a splicing tape between its top layer and its second layer. The bottom layer of the splice is adhered to the second layer of the roll, and a portion of the release liner of the splice, the portion nearer the trailing edge, is removed. The top layer of the replacement roll is adhered to the exposed portion of the adhesive. When the end of the running roll nears, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com