Patents

Literature

281results about "Cutting/splicing processed material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

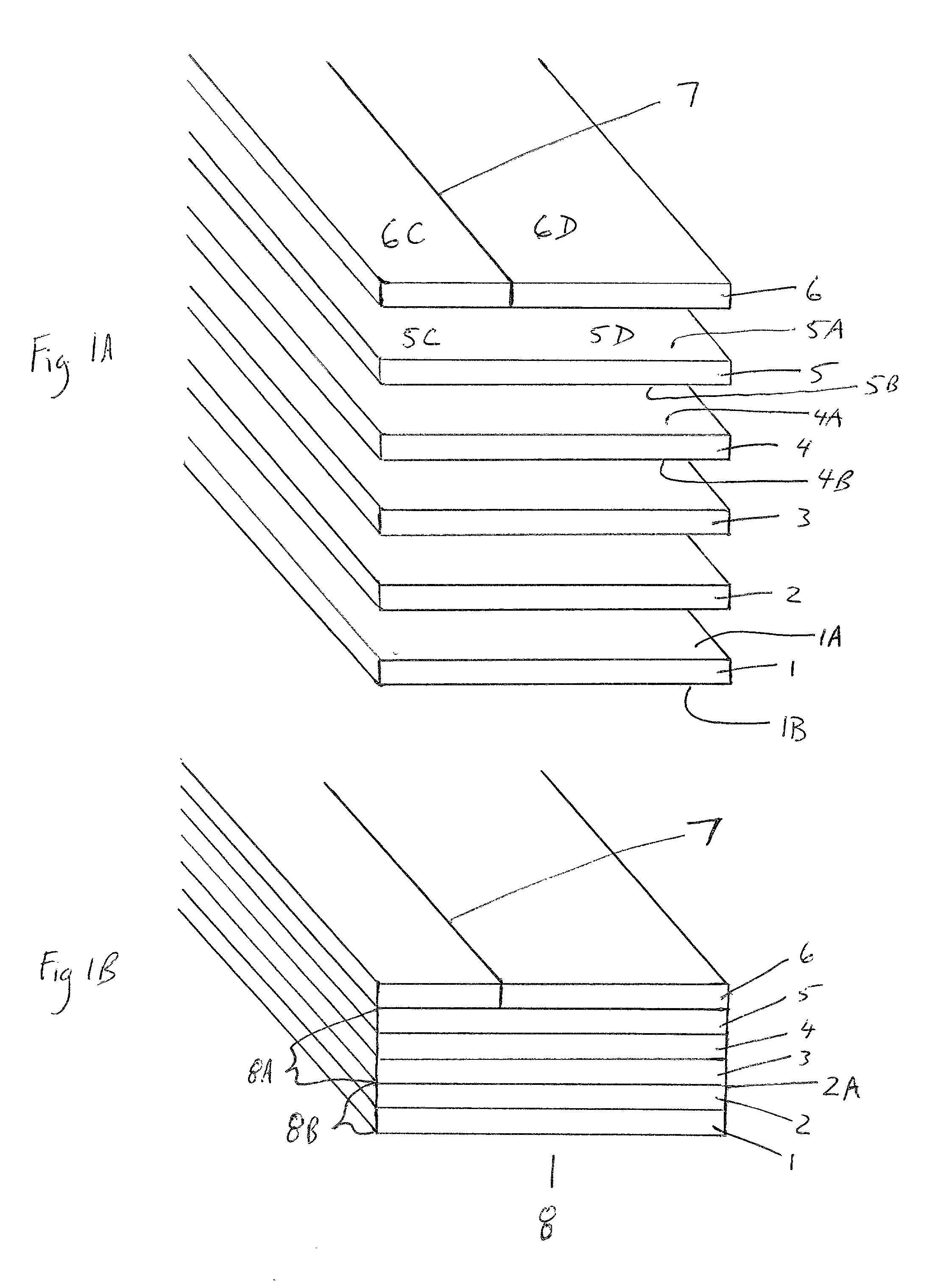

Method for subdividing multilayer optical film cleanly and rapidly

InactiveUS6991695B2Reduce electrostatic attractionPaper/cardboard articlesOptical articlesPolymerLaser

Owner:3M INNOVATIVE PROPERTIES CO

Method for subdividing multilayer optical film cleanly and rapidly

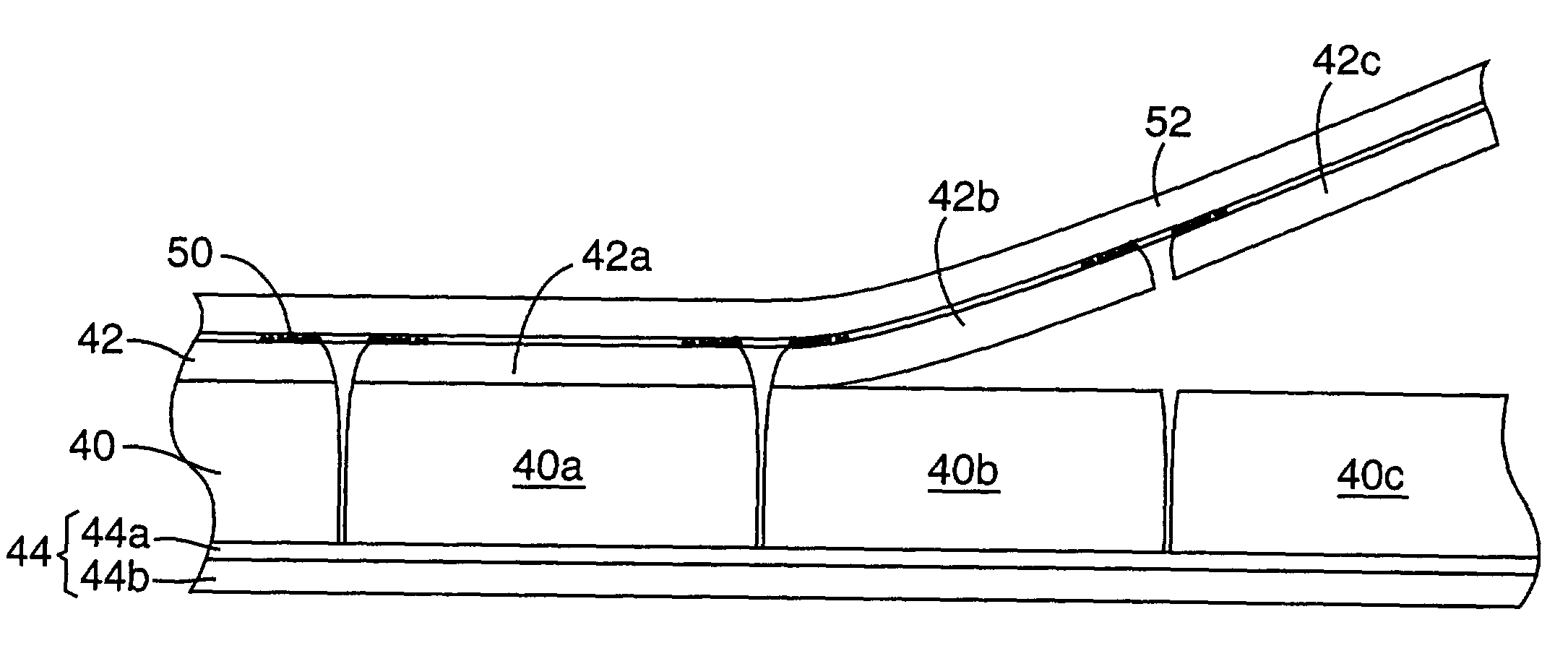

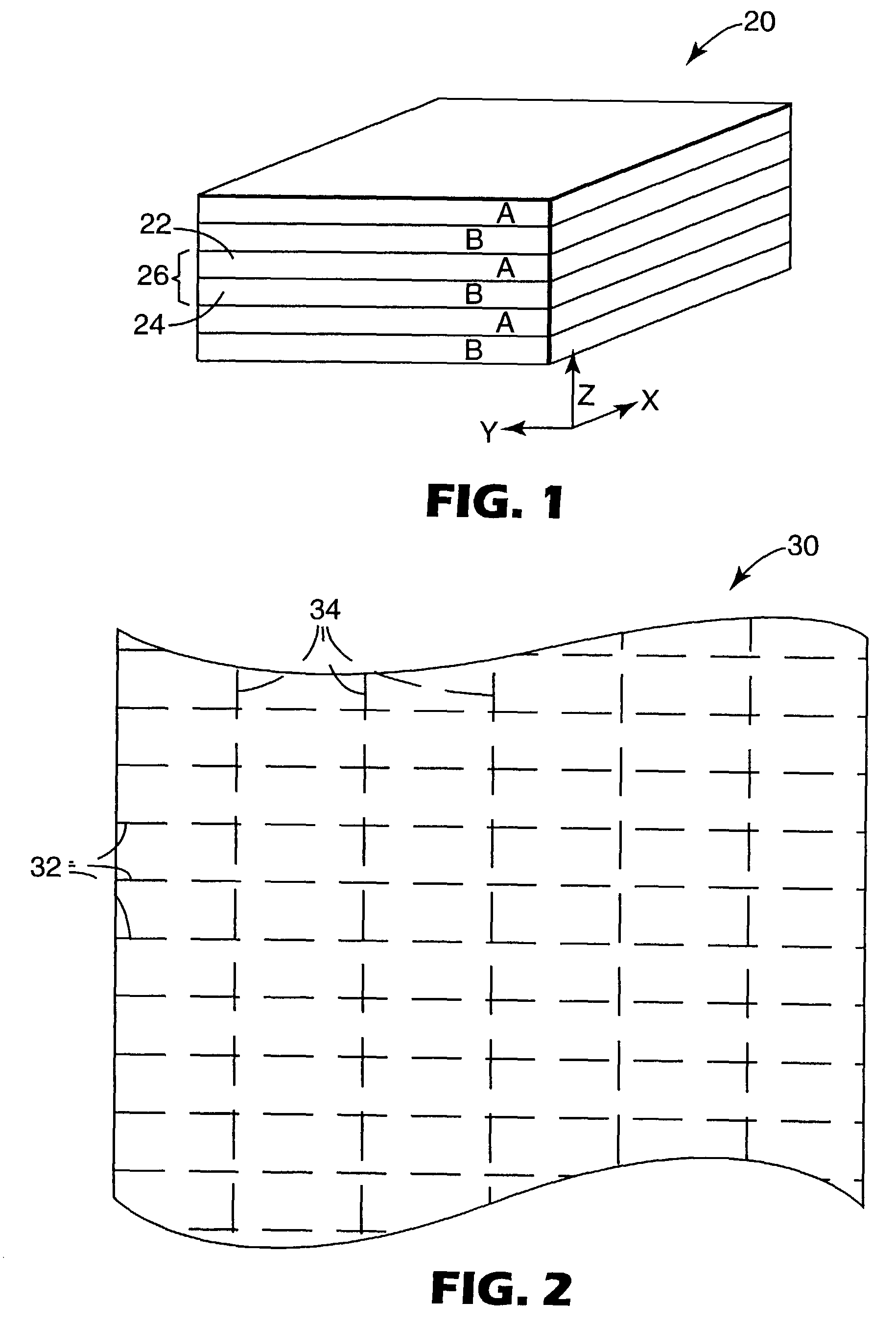

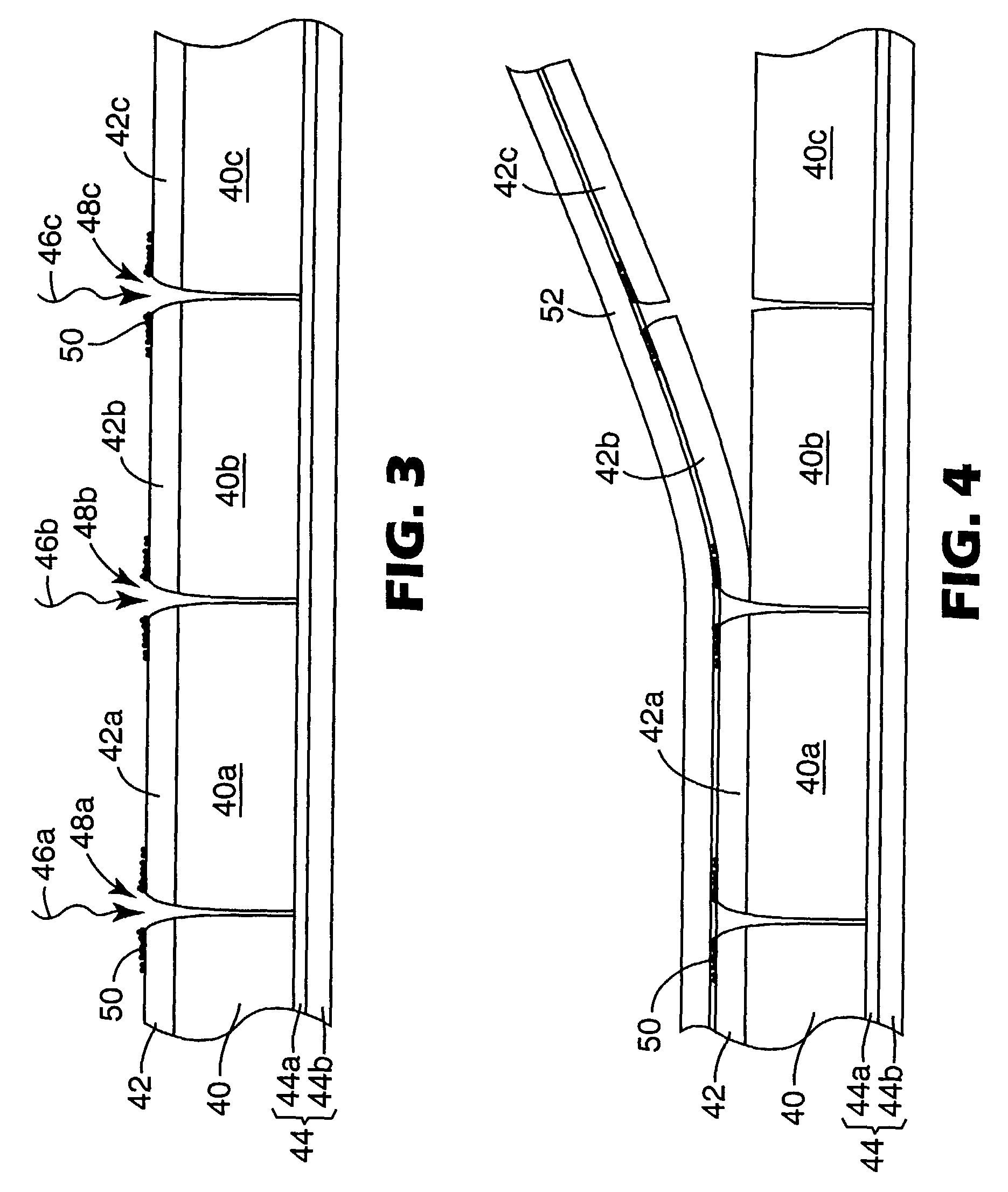

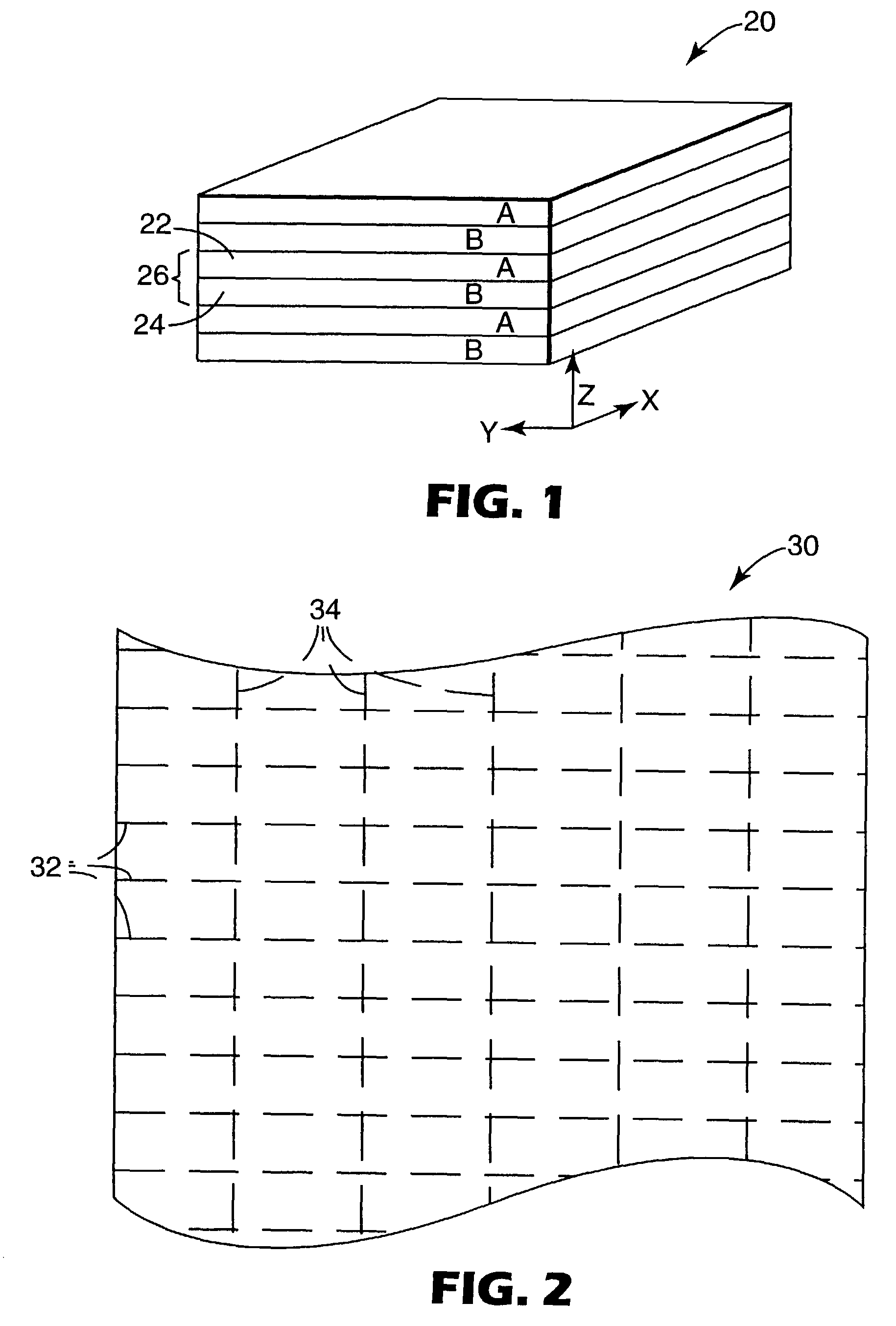

Polymeric multilayer optical films, and laminate bodies that include such films, are cut or subdivided into one or more discrete pieces by removably applying a first and second liner to opposed major surfaces of the multilayer optical film. Laser radiation is then directed at the multilayer optical film through the first liner in such a way as to produce cut lines that define a plurality of pieces of the first liner and of the multilayer optical film. Thereafter, the plurality of pieces of the first liner are removed from the plurality of pieces of the multilayer optical film while the pieces of multilayer optical film are supported by the second liner. Application of the first liner to the multilayer optical film can be accomplished with electrostatics.

Owner:3M INNOVATIVE PROPERTIES CO

Methods for producing composite webs with reinforcing discrete polymeric regions

InactiveUS6942894B2Increased formationRaise transfer toAdhesive processesLayered productsFiberPolymer

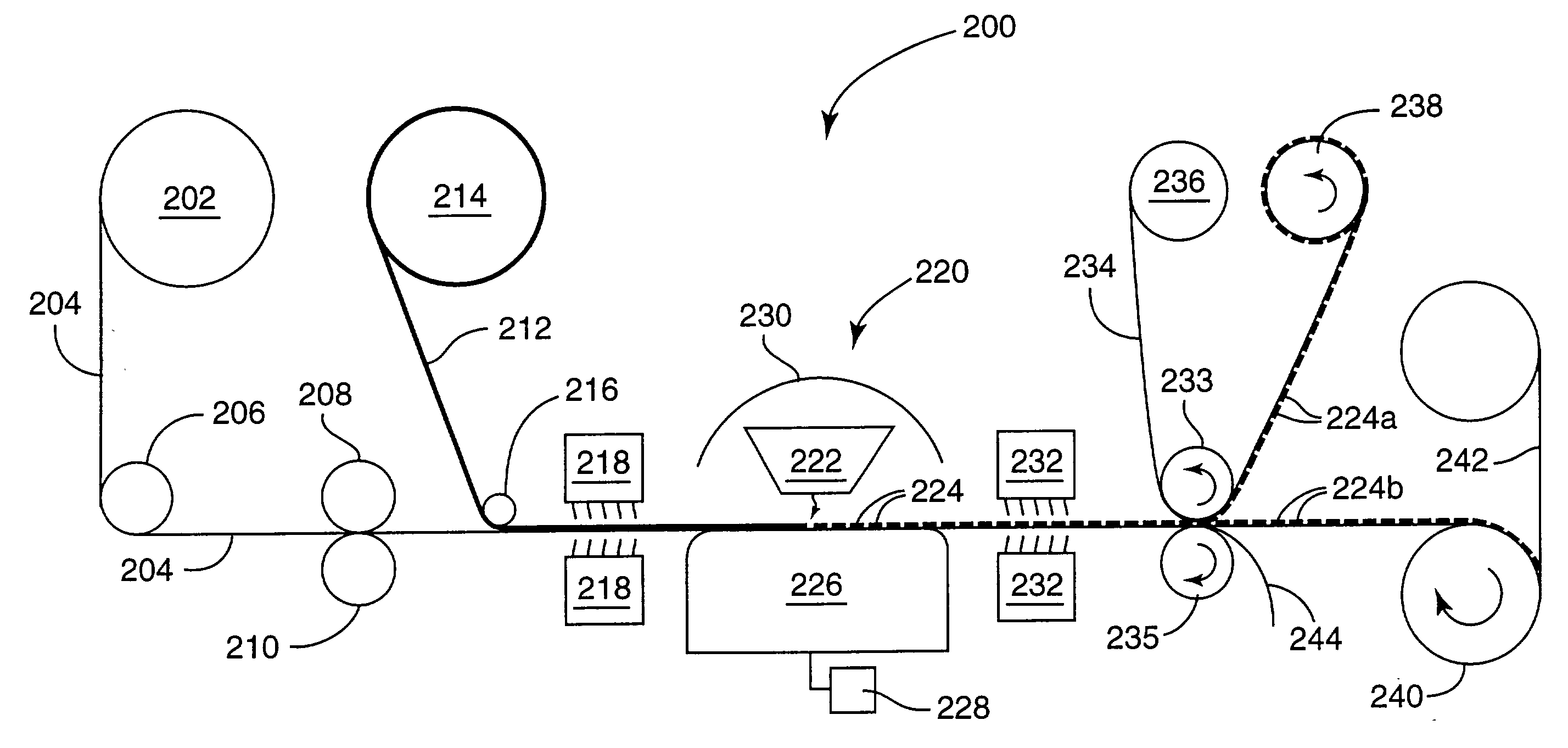

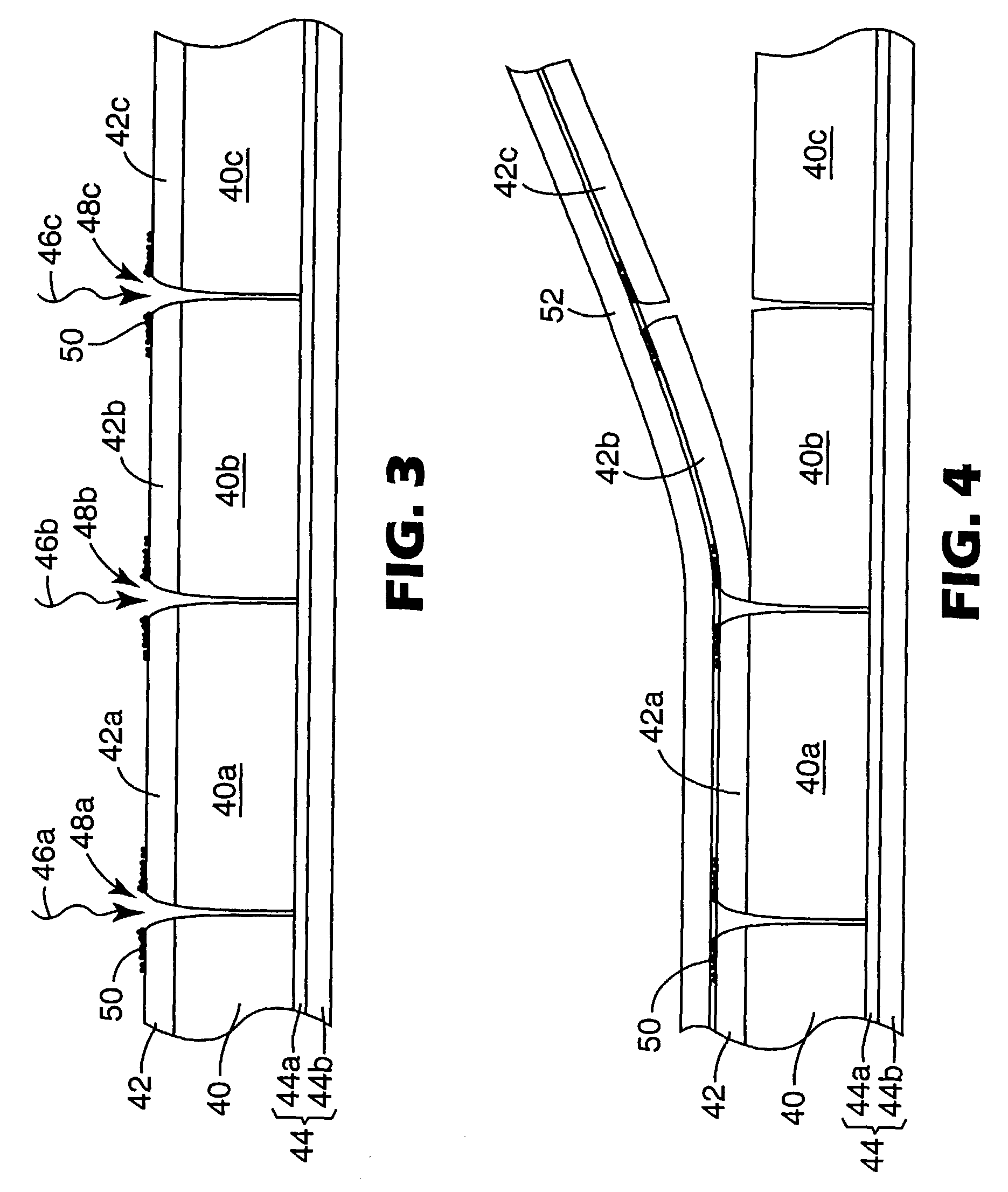

Methods of manufacturing composite webs including a substrate with one or more reinforcing discrete polymeric regions located on or within the composite web are disclosed. Molten nonelastomeric thermoplastic material of the discrete polymeric region is forced against the substrate by a transfer roll. If the substrate is porous, fibrous, etc., a portion of the nonelastomeric thermoplastic composition may infiltrate the substrate and / or encapsulate fibers of the substrate.

Owner:3M INNOVATIVE PROPERTIES CO

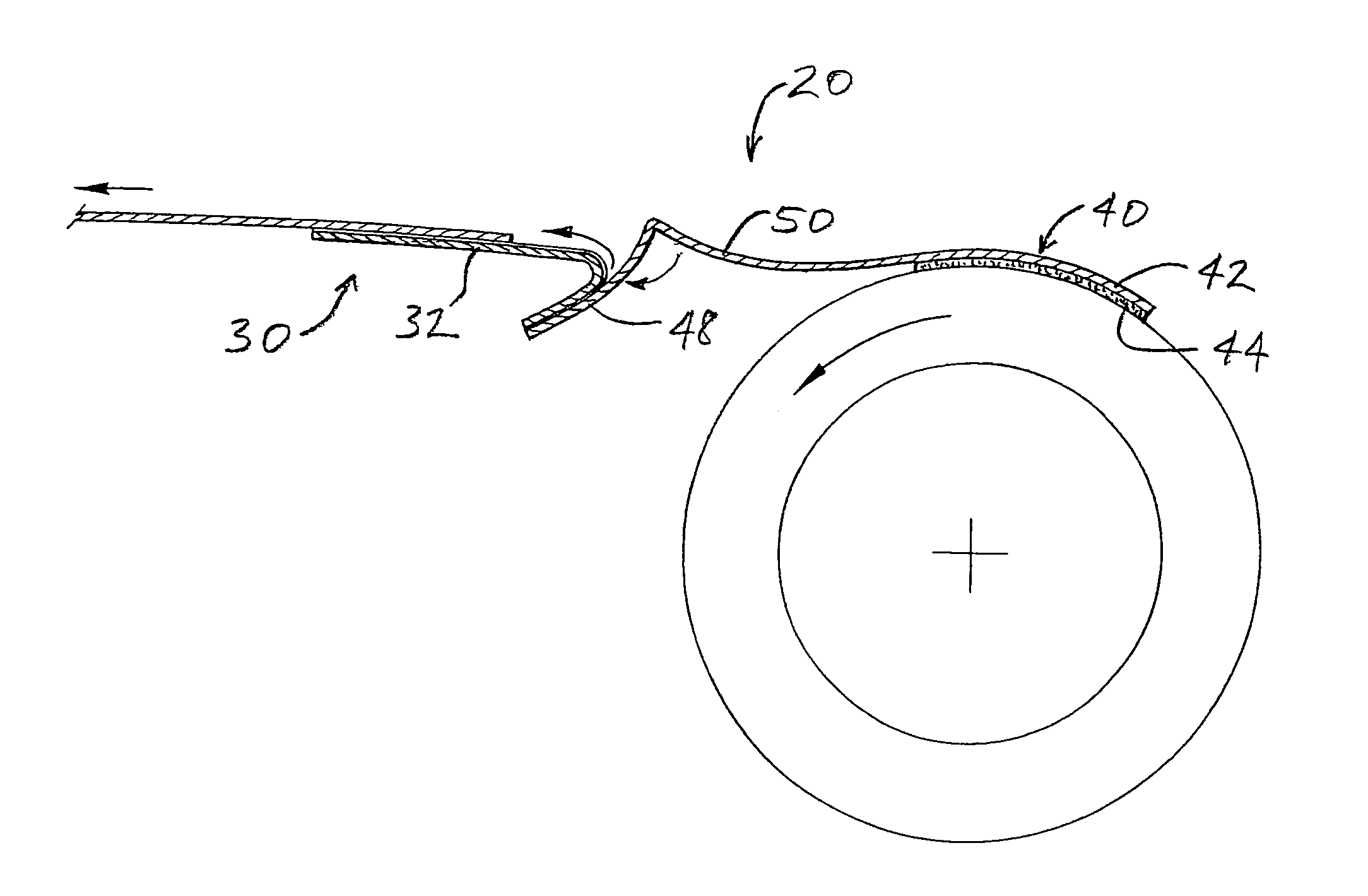

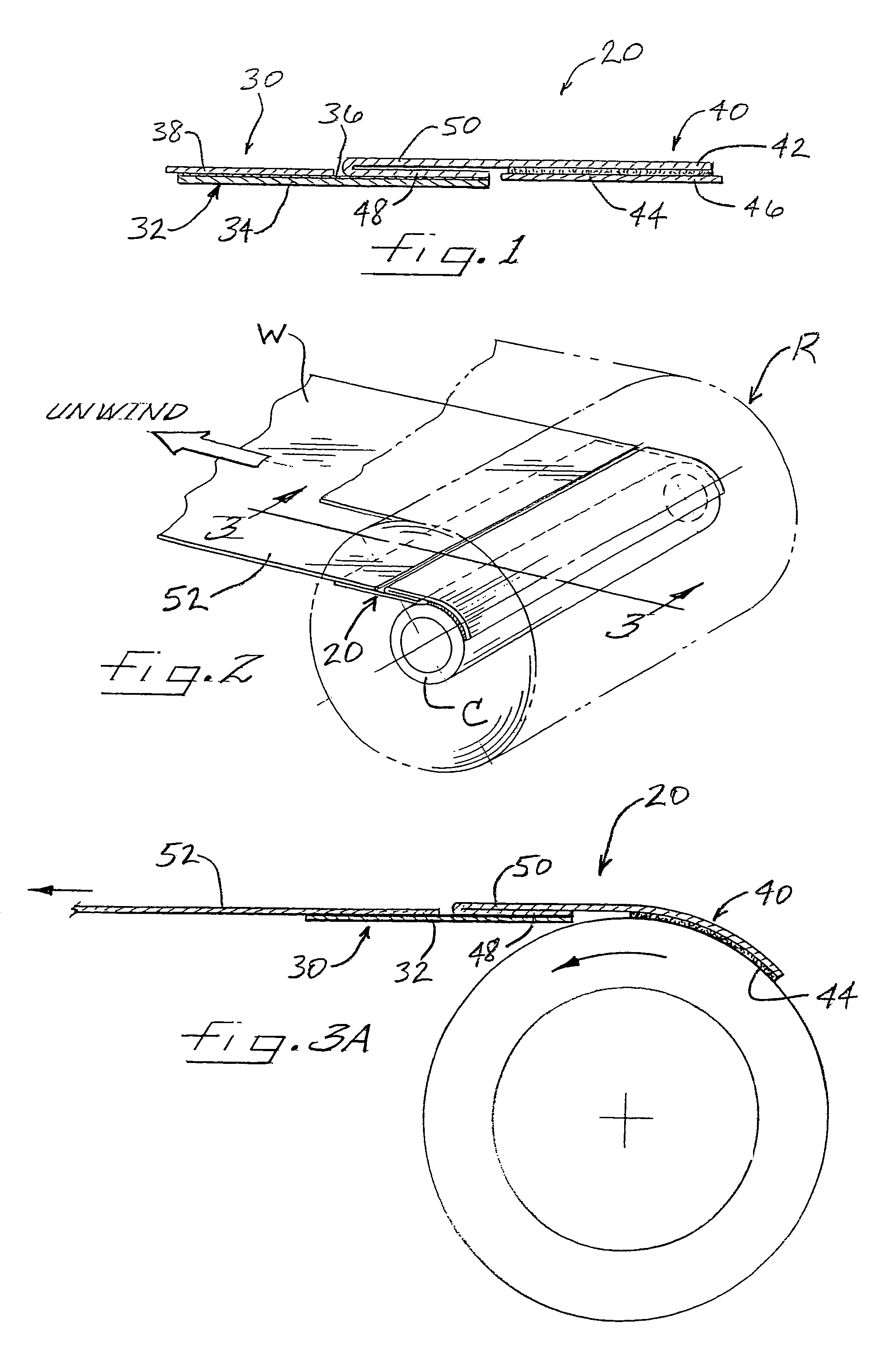

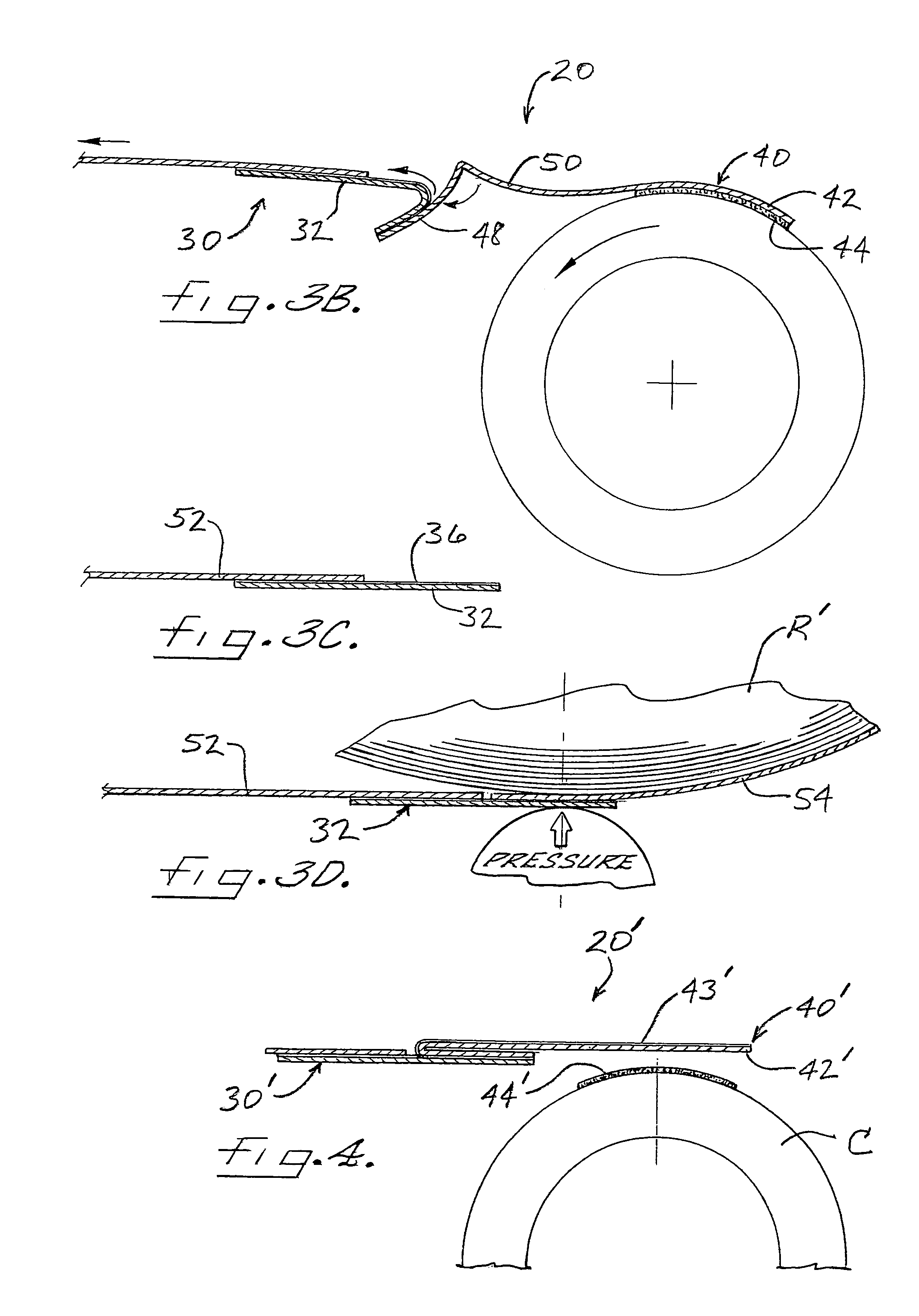

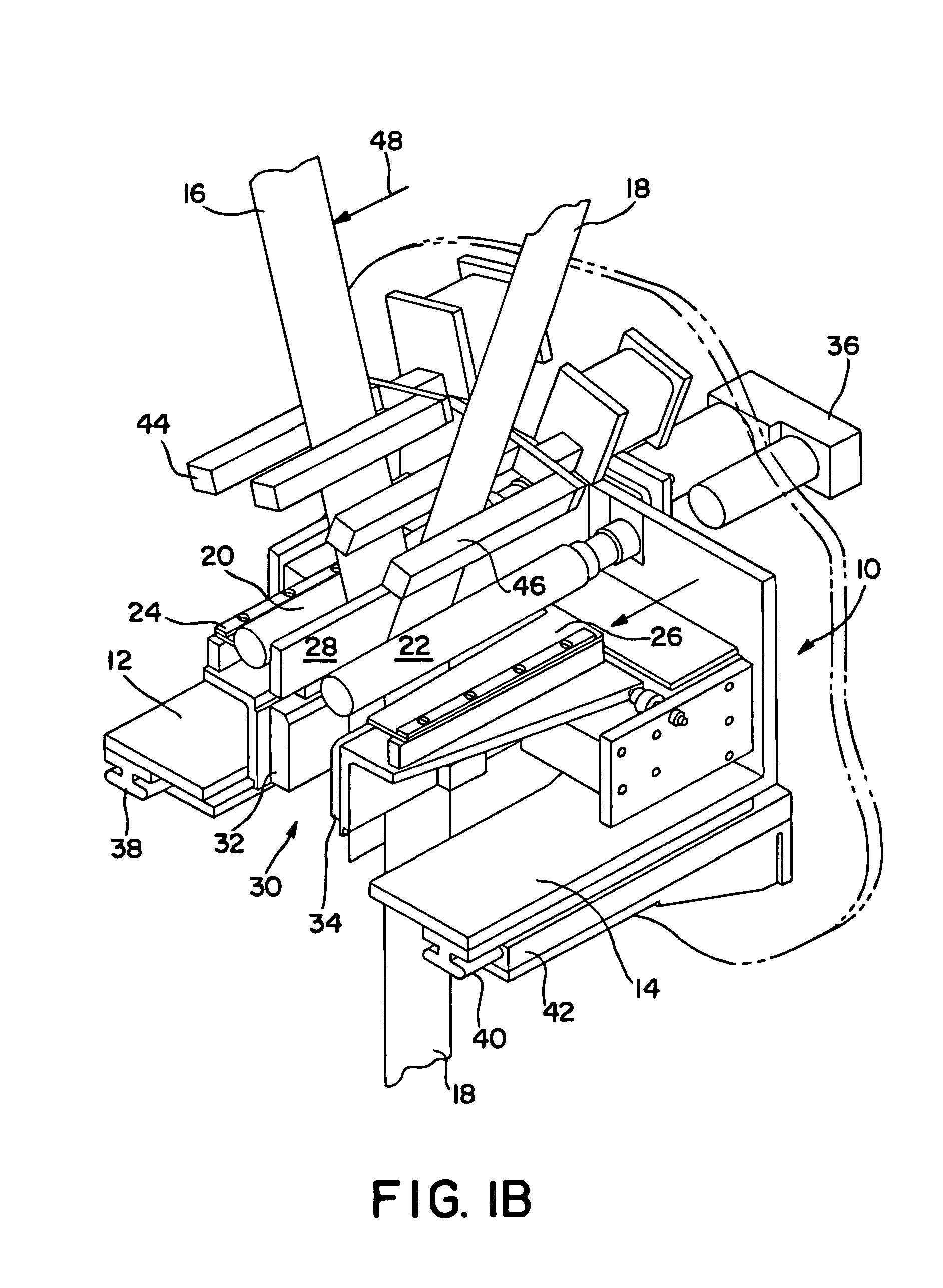

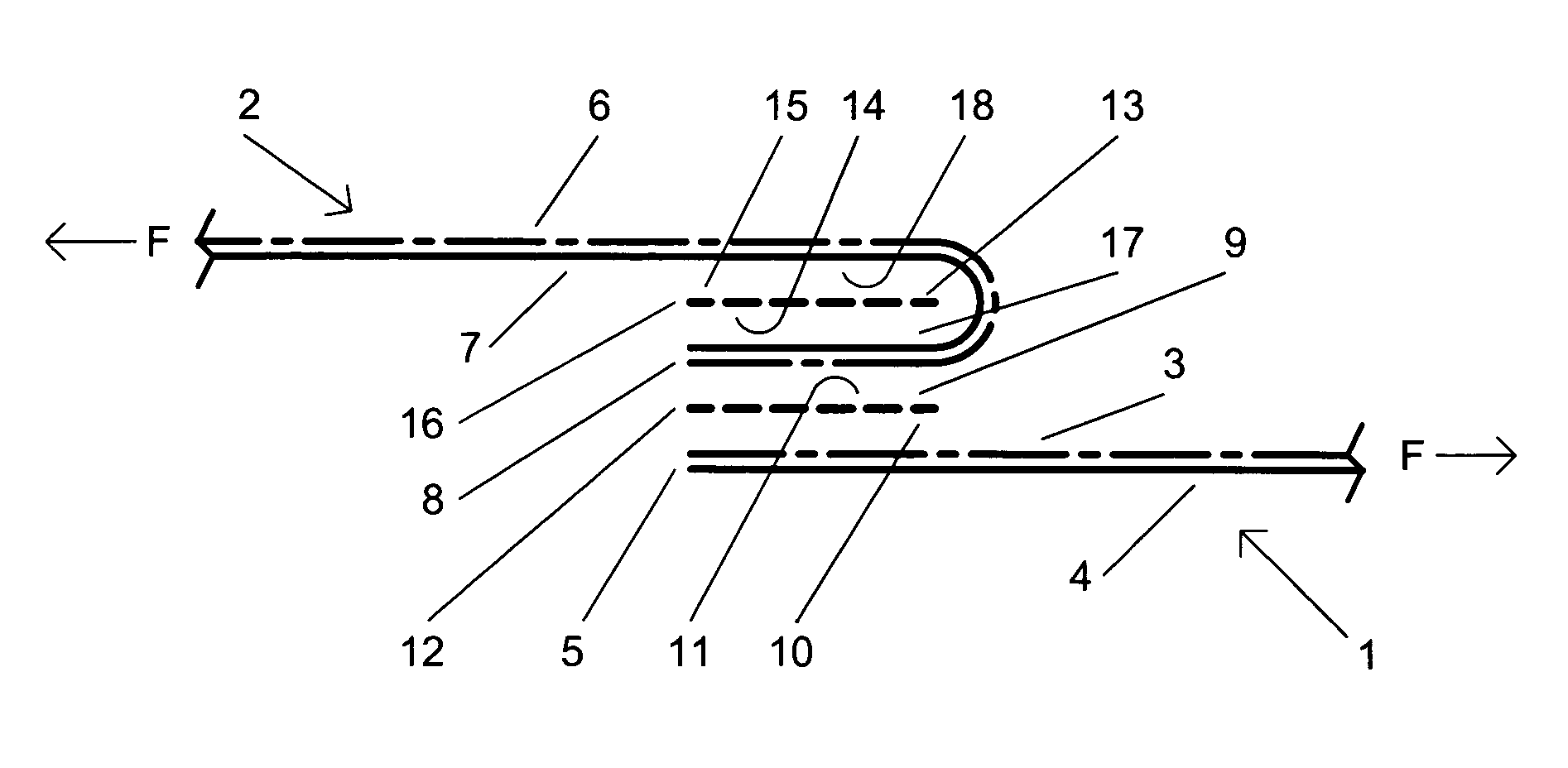

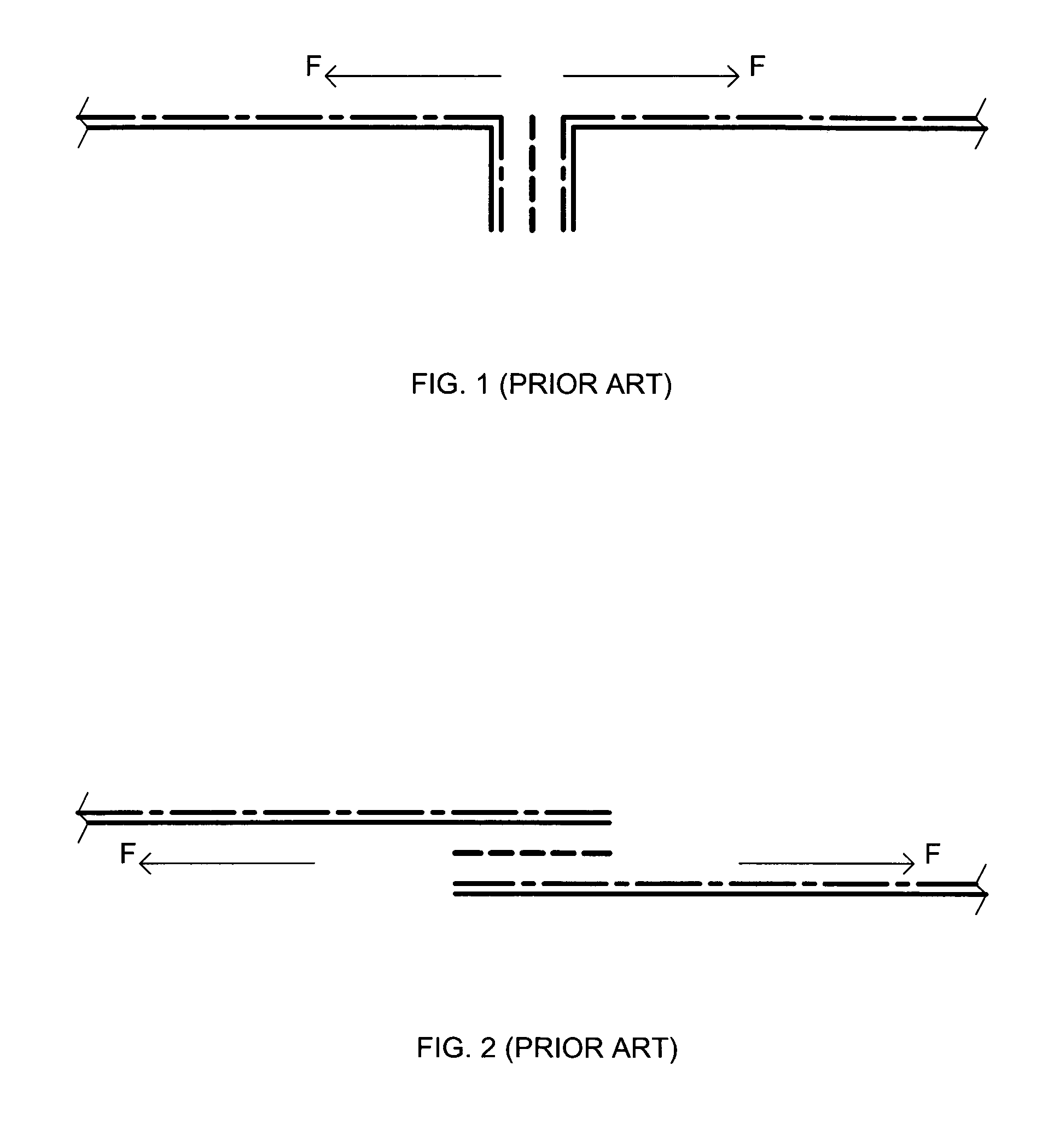

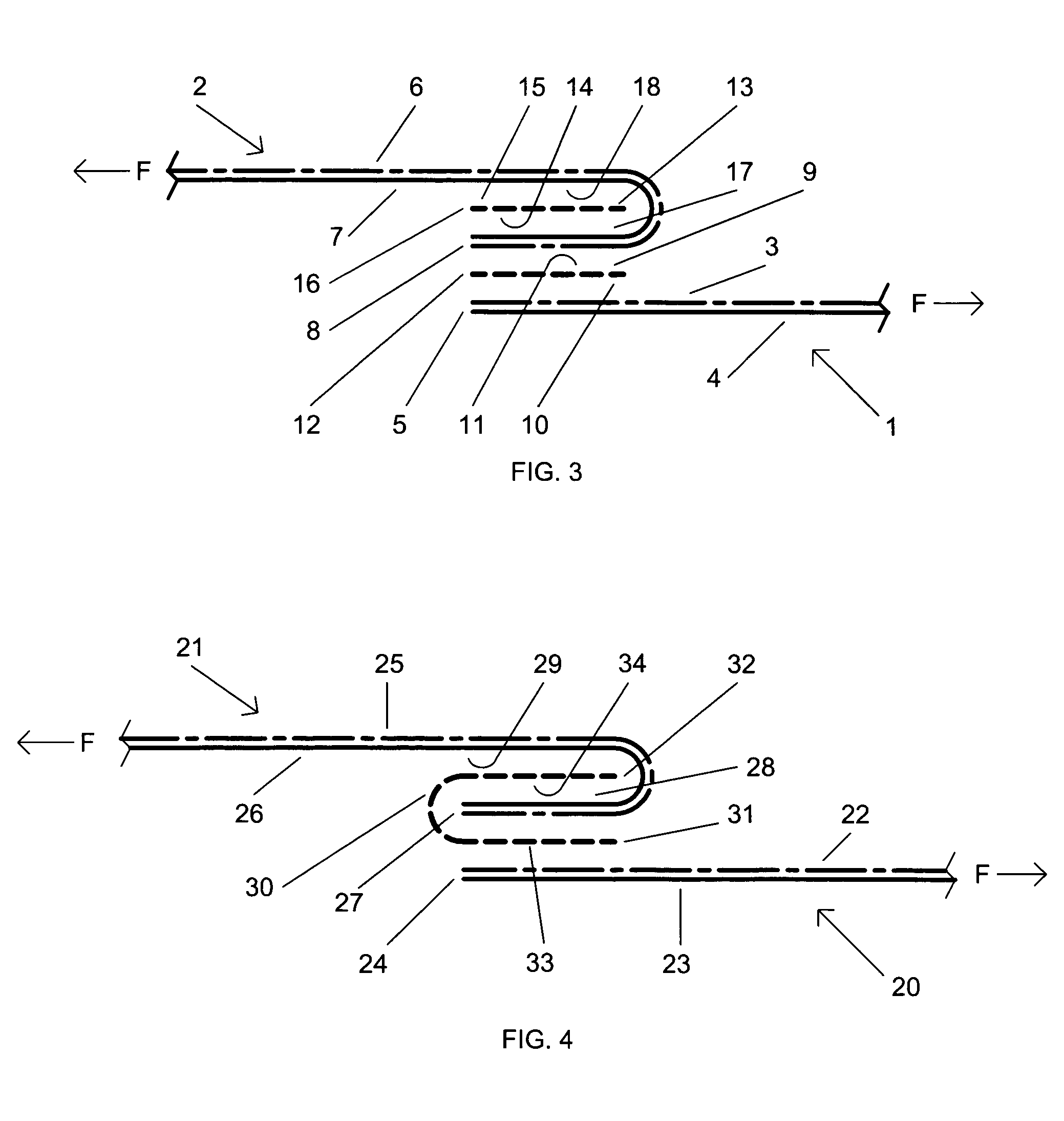

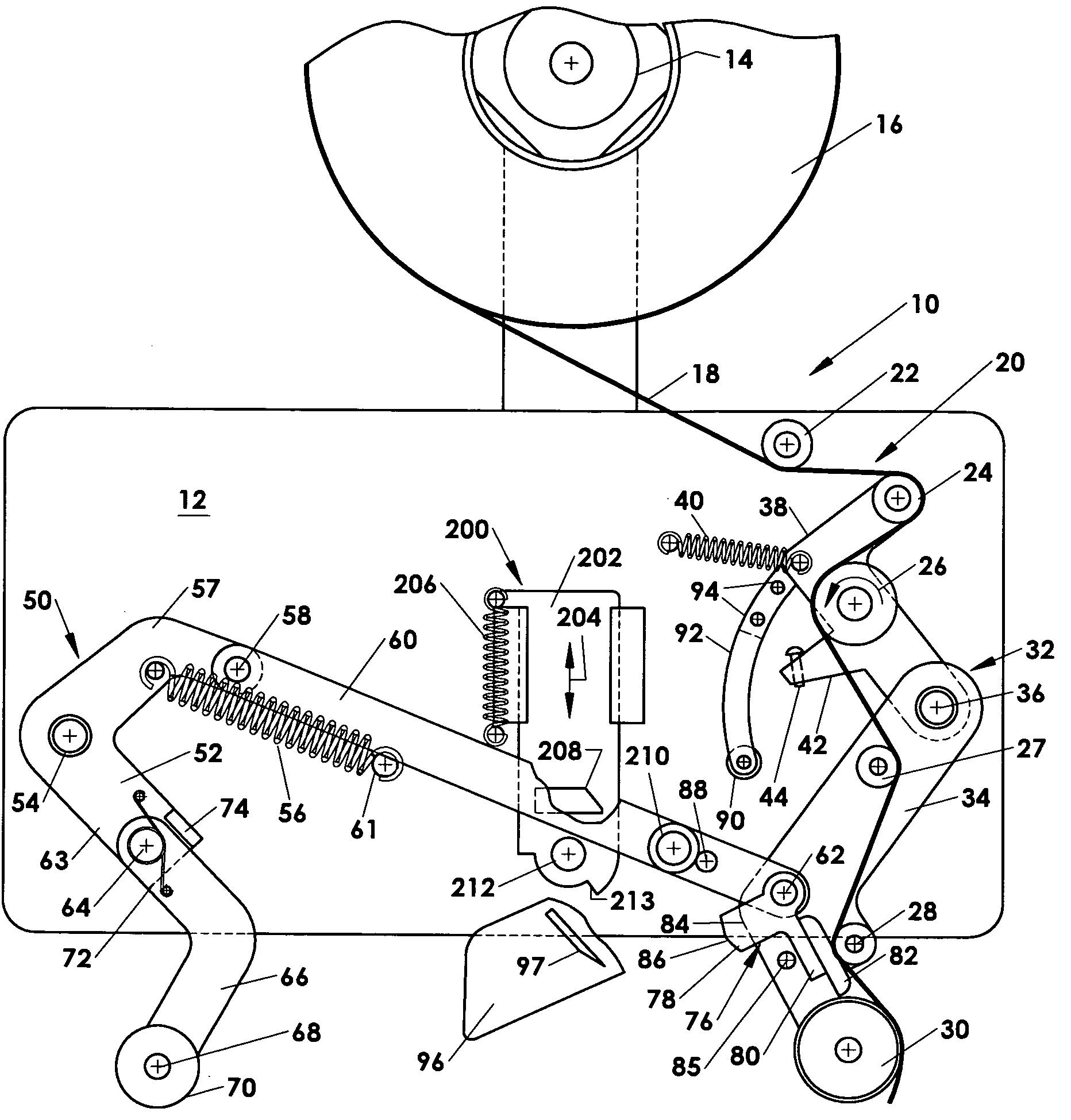

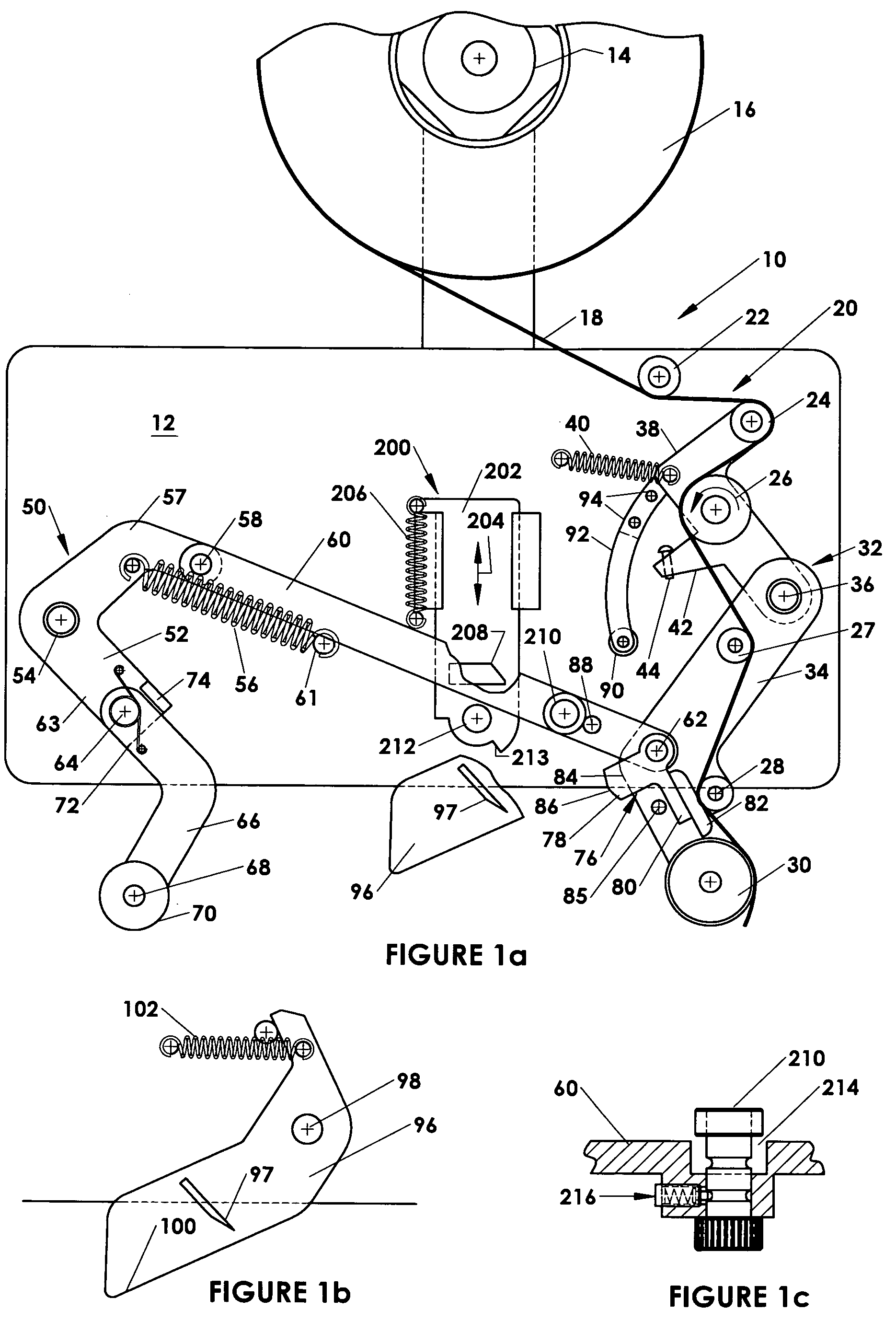

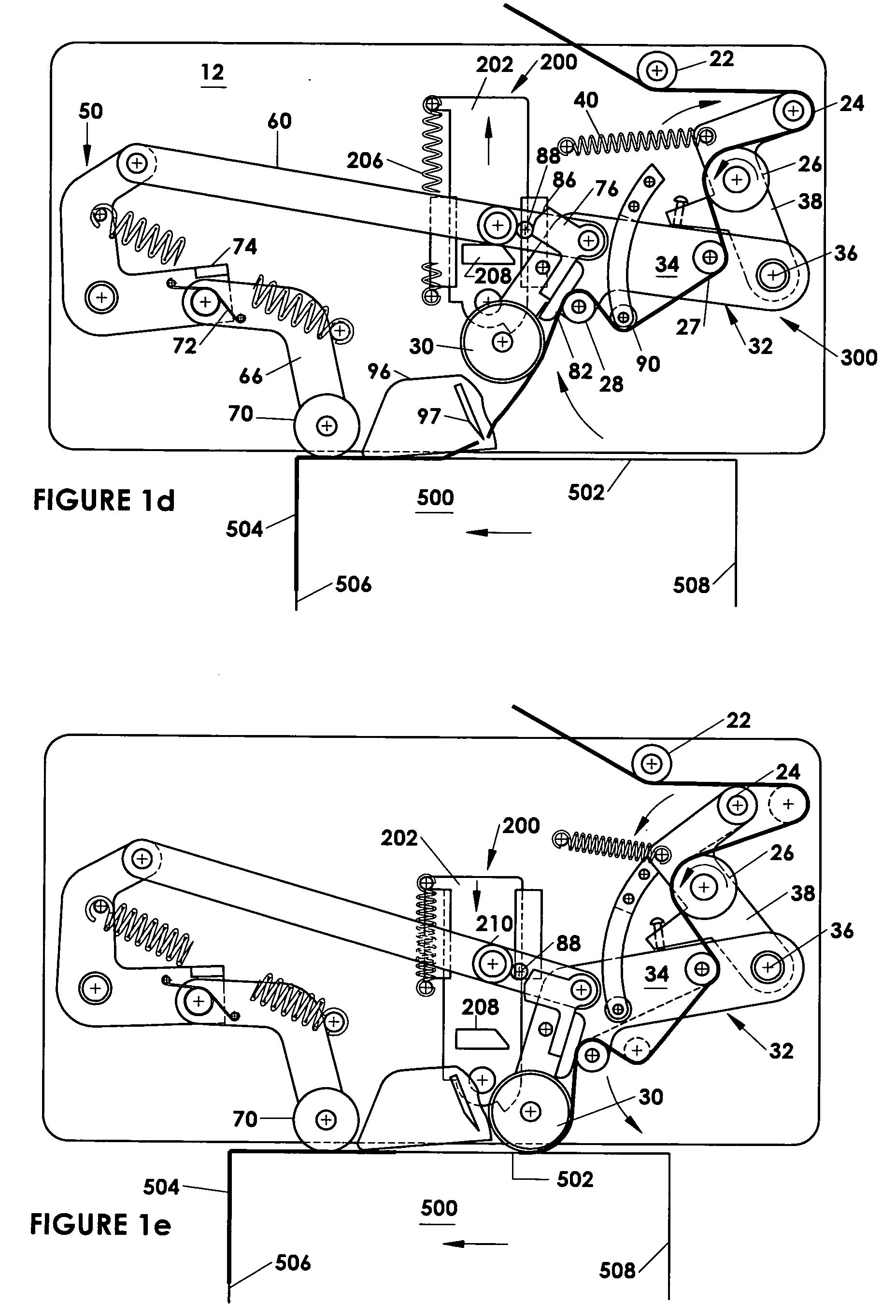

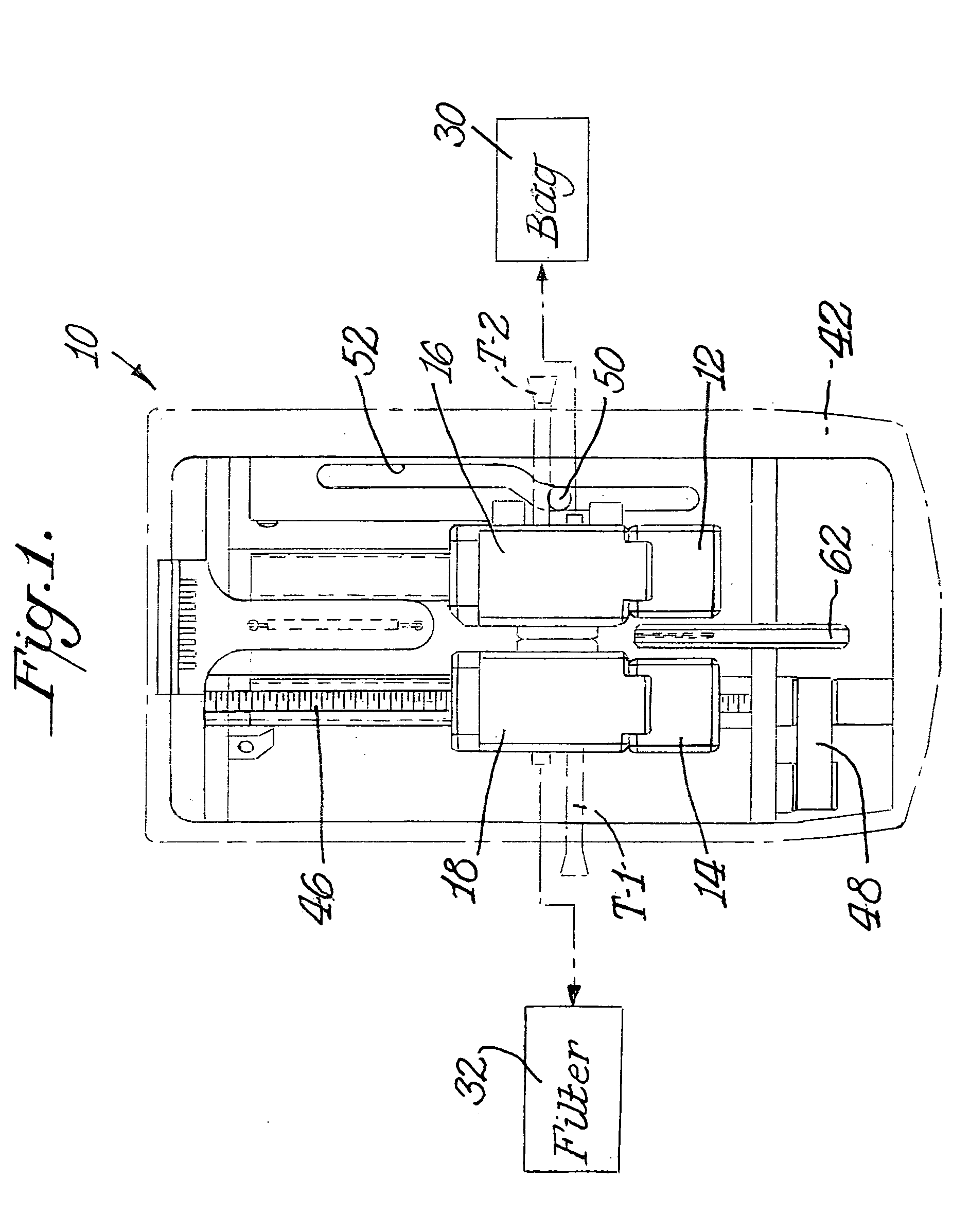

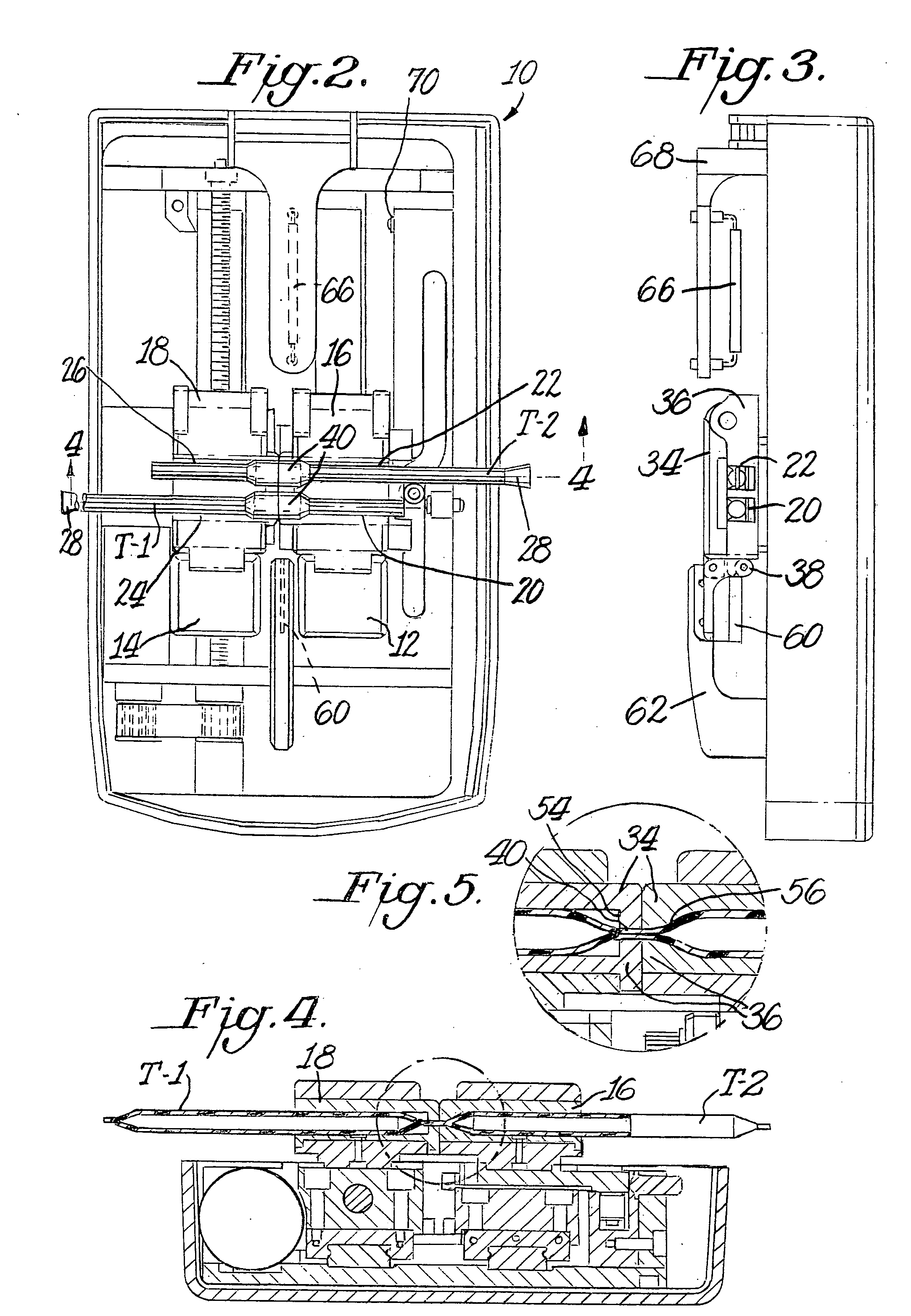

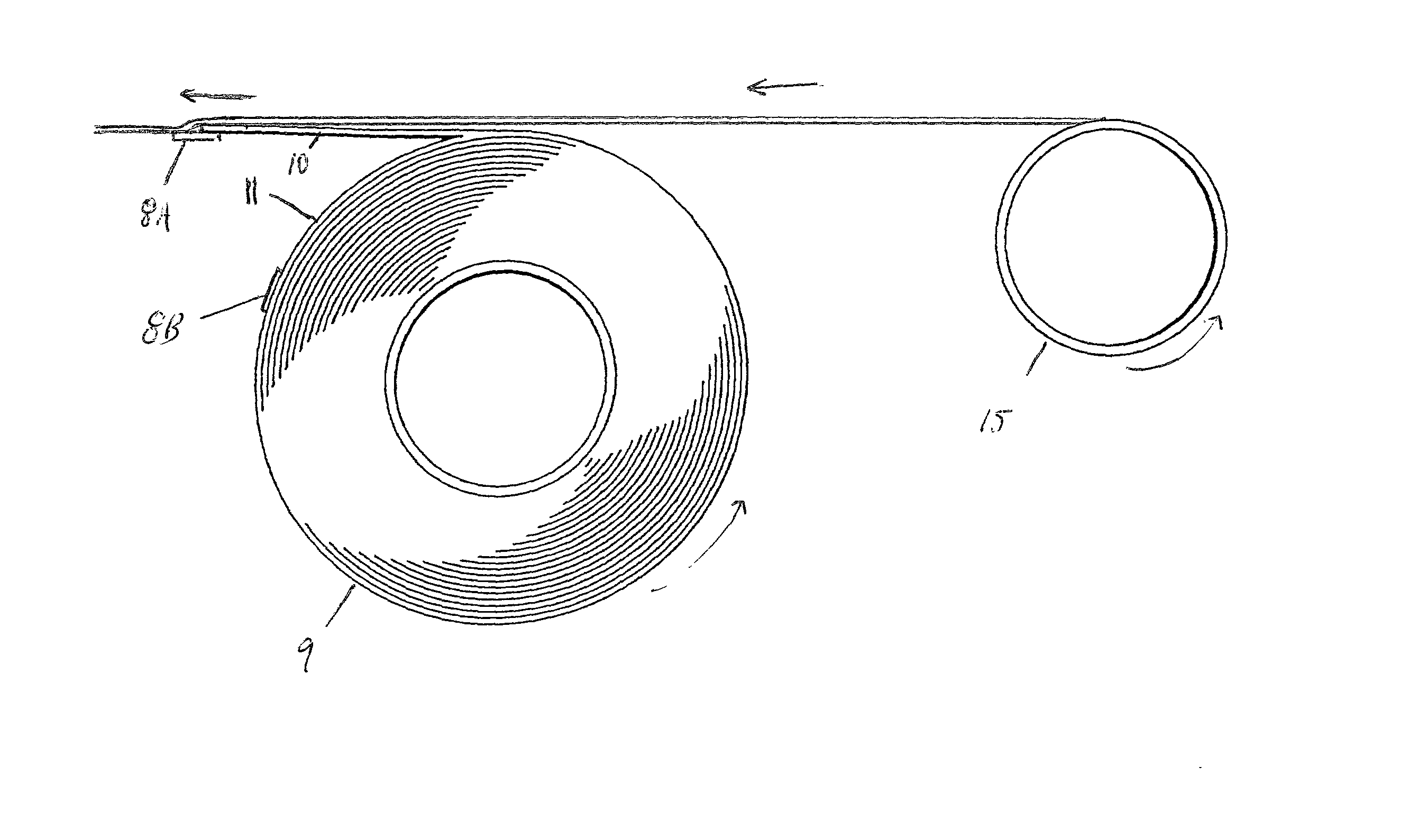

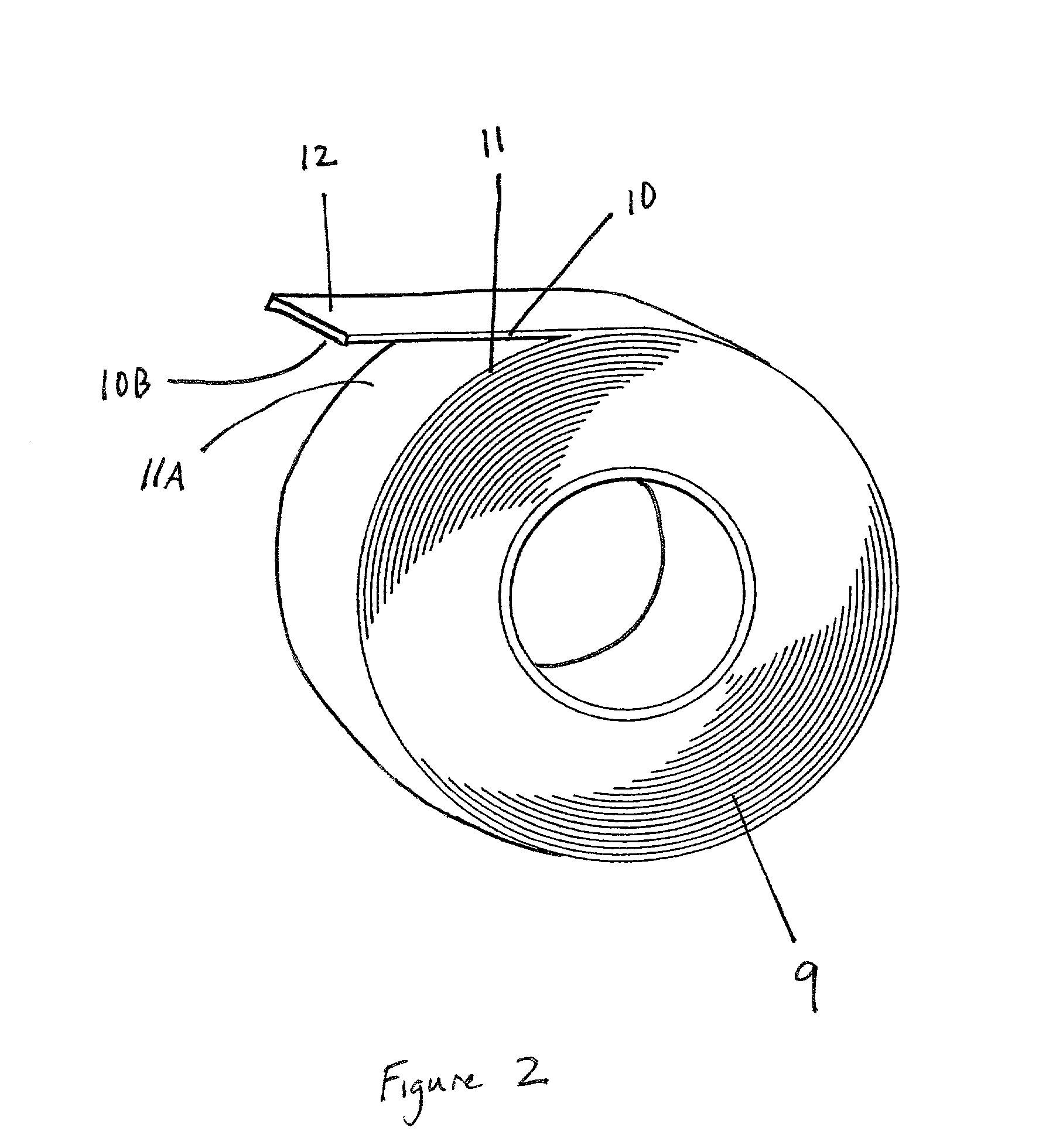

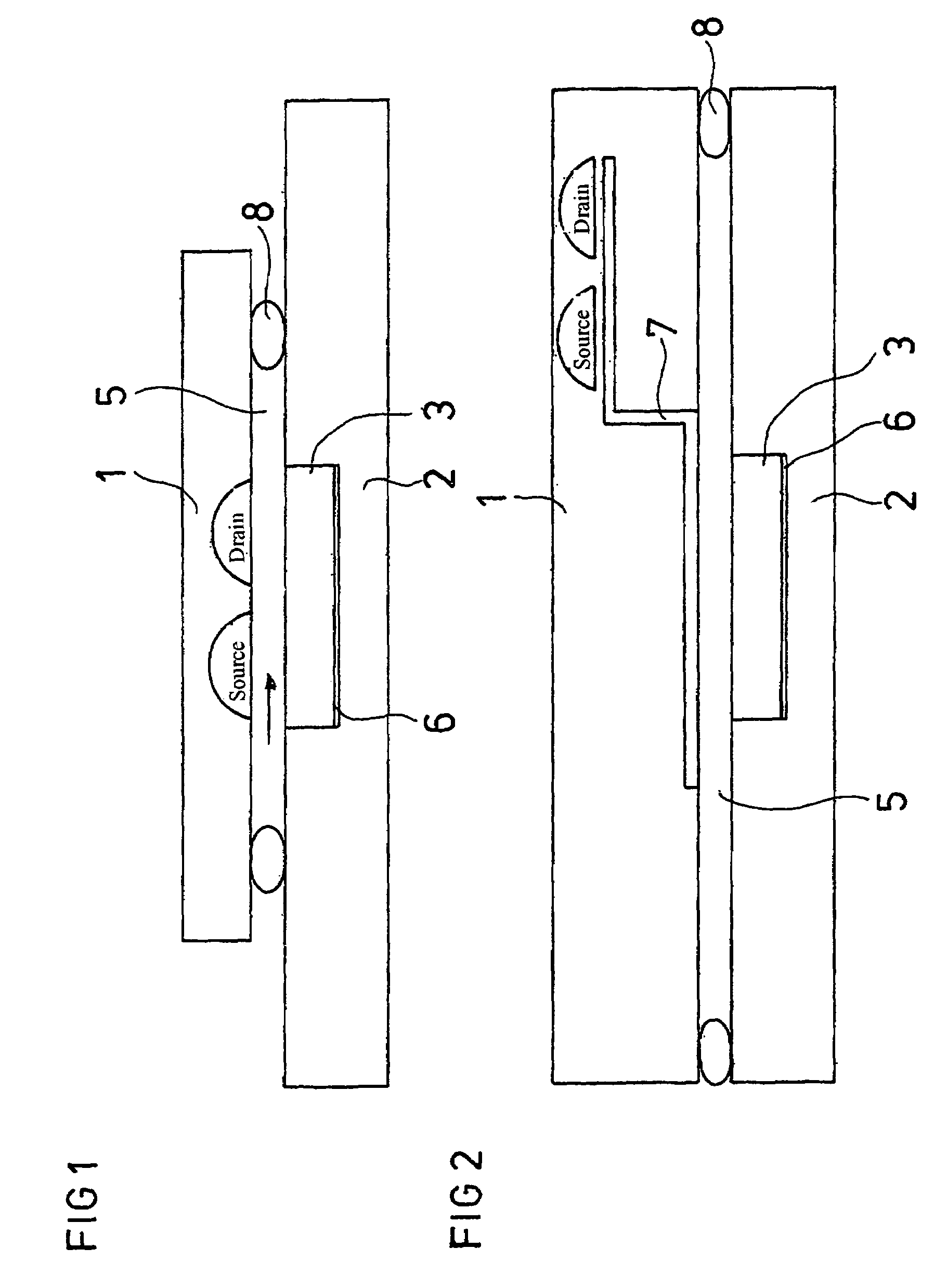

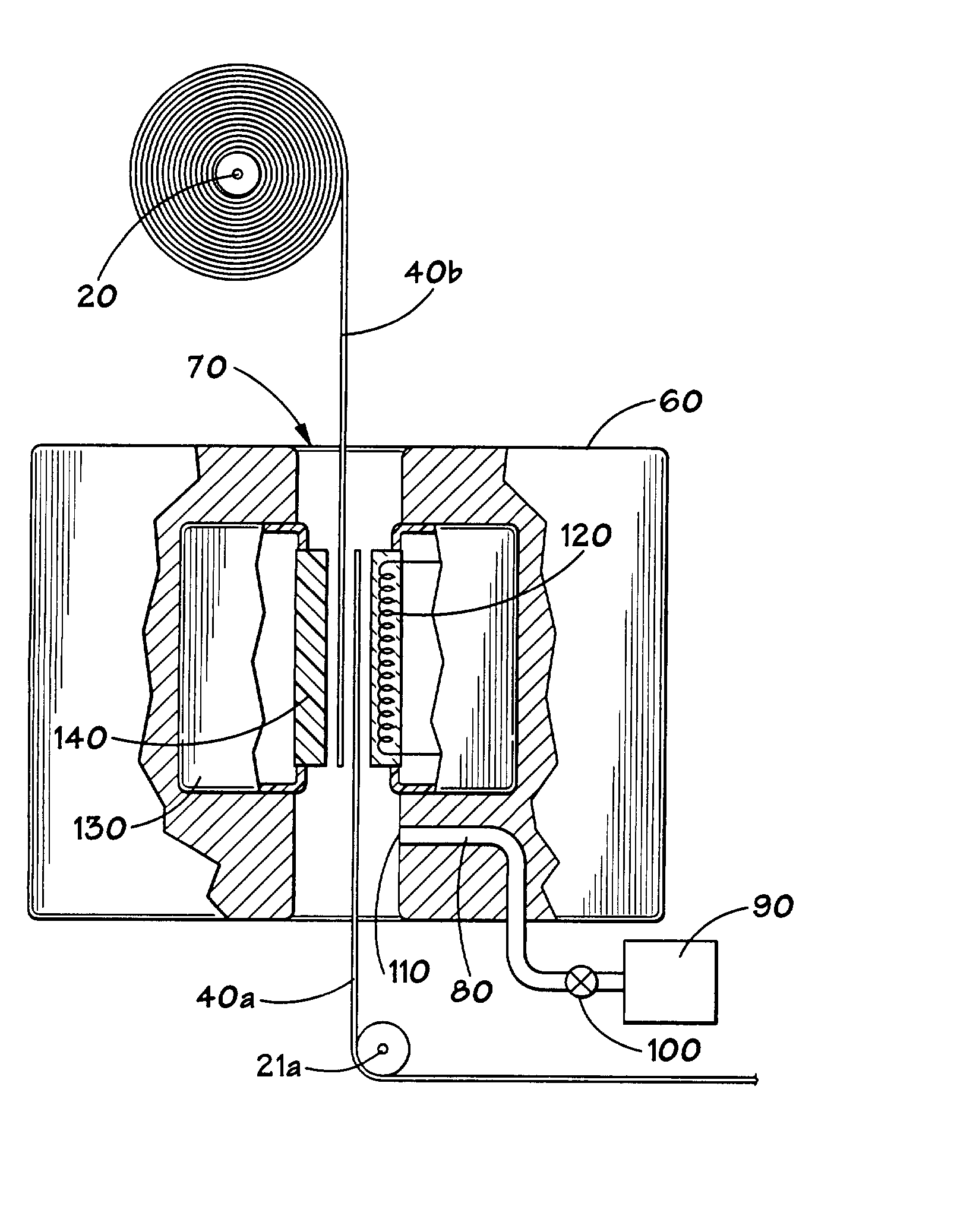

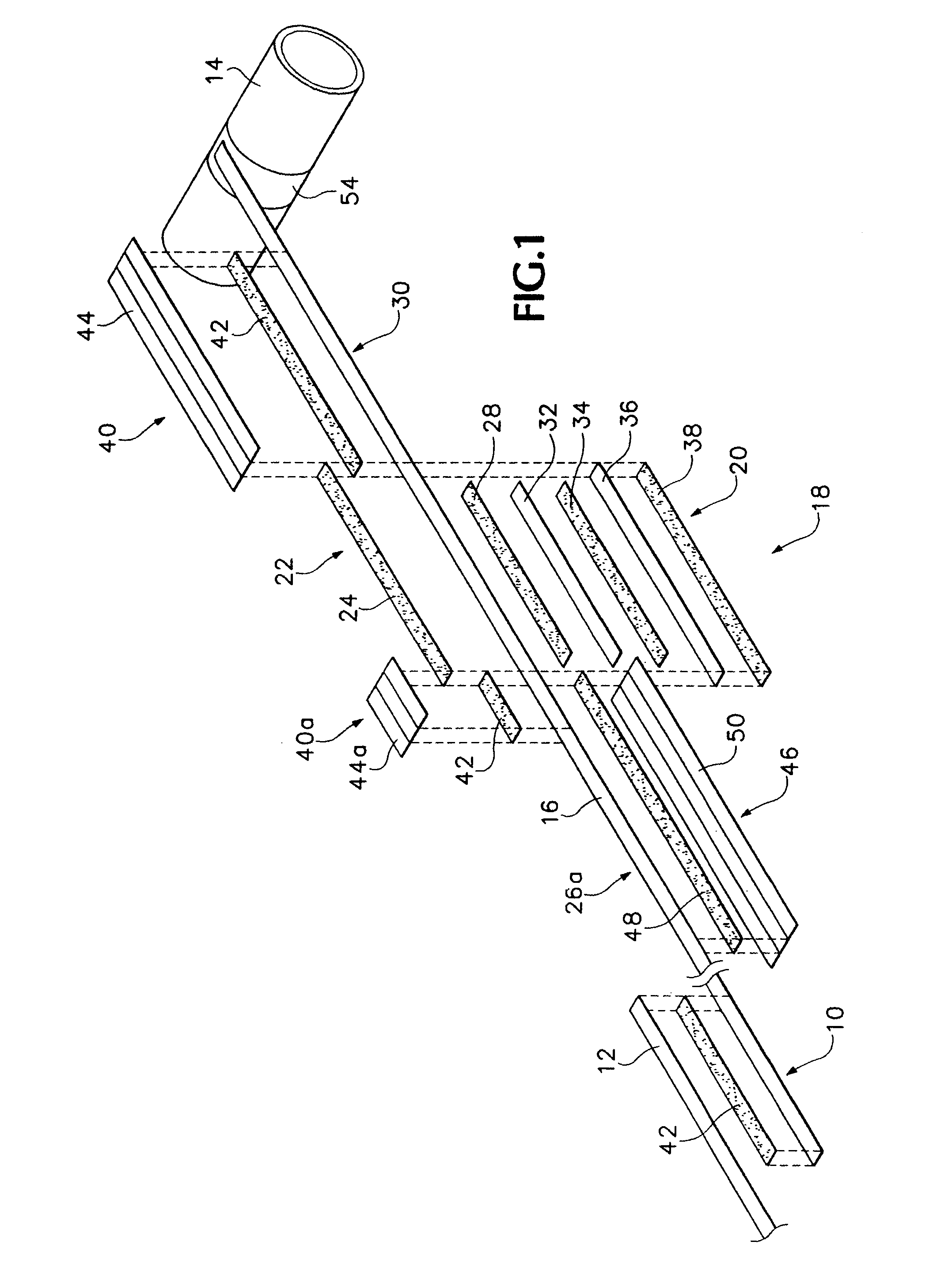

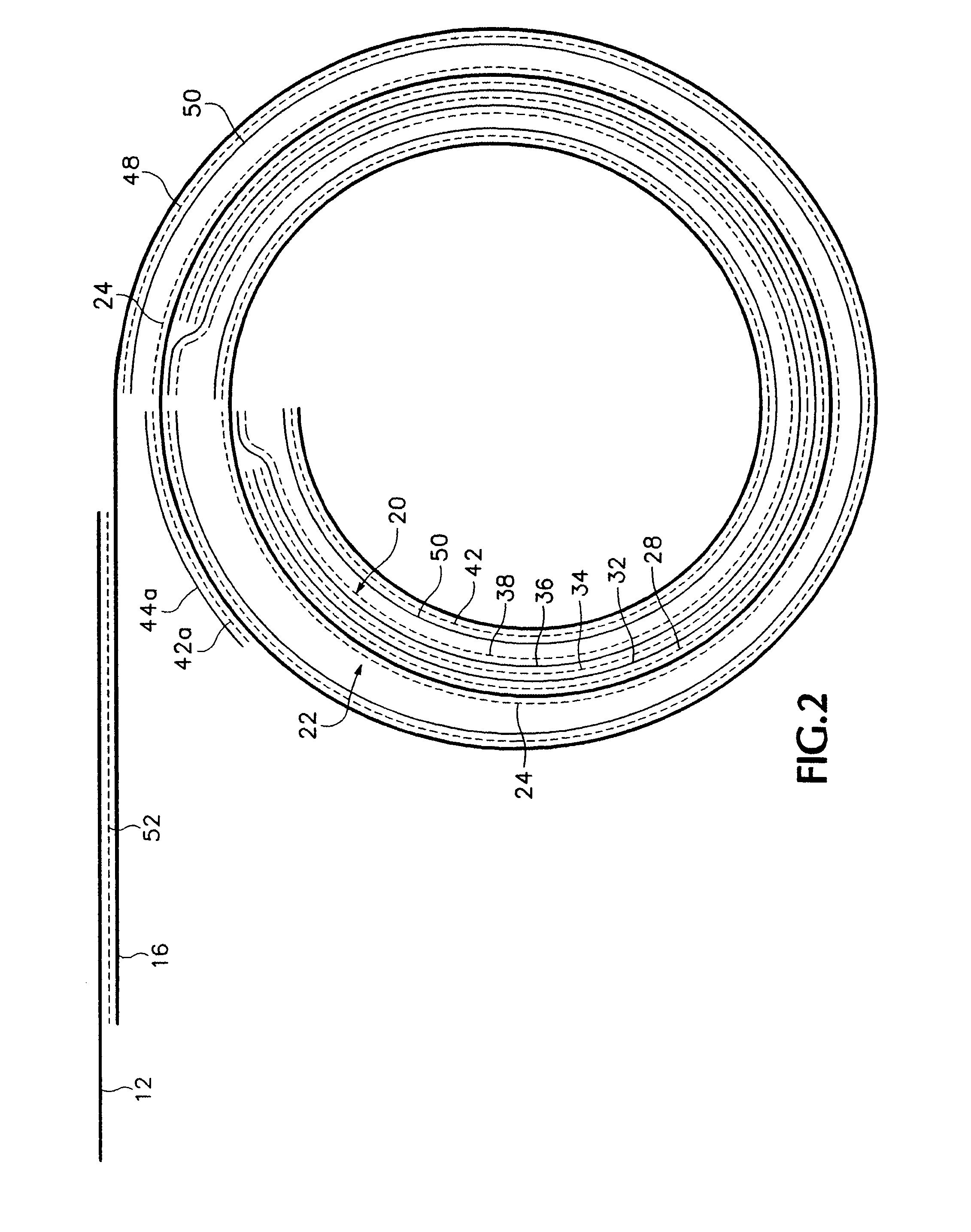

Dual-functioning mechanism for startup during winding of web material and for splicing during unwinding

InactiveUS7078082B2Avoid stickingMechanical working/deformationPaper/cardboard wound articlesAdhesiveCore component

A tail end of a web is attached to a winding core via a two-component mechanism having a core component attached to the core and a web component attached to the web, the two components being attached to each other in releasable fashion. The mechanism assists startup of winding. Upon completion of unwinding, the web component detaches from the core component to expose a region of adhesive on a part of the web component that extends from the tail end of the web. The tail end thus can be spliced to a leading end of another web by attaching the leading end to the exposed adhesive on the web component.

Owner:SONOCO DEV INC

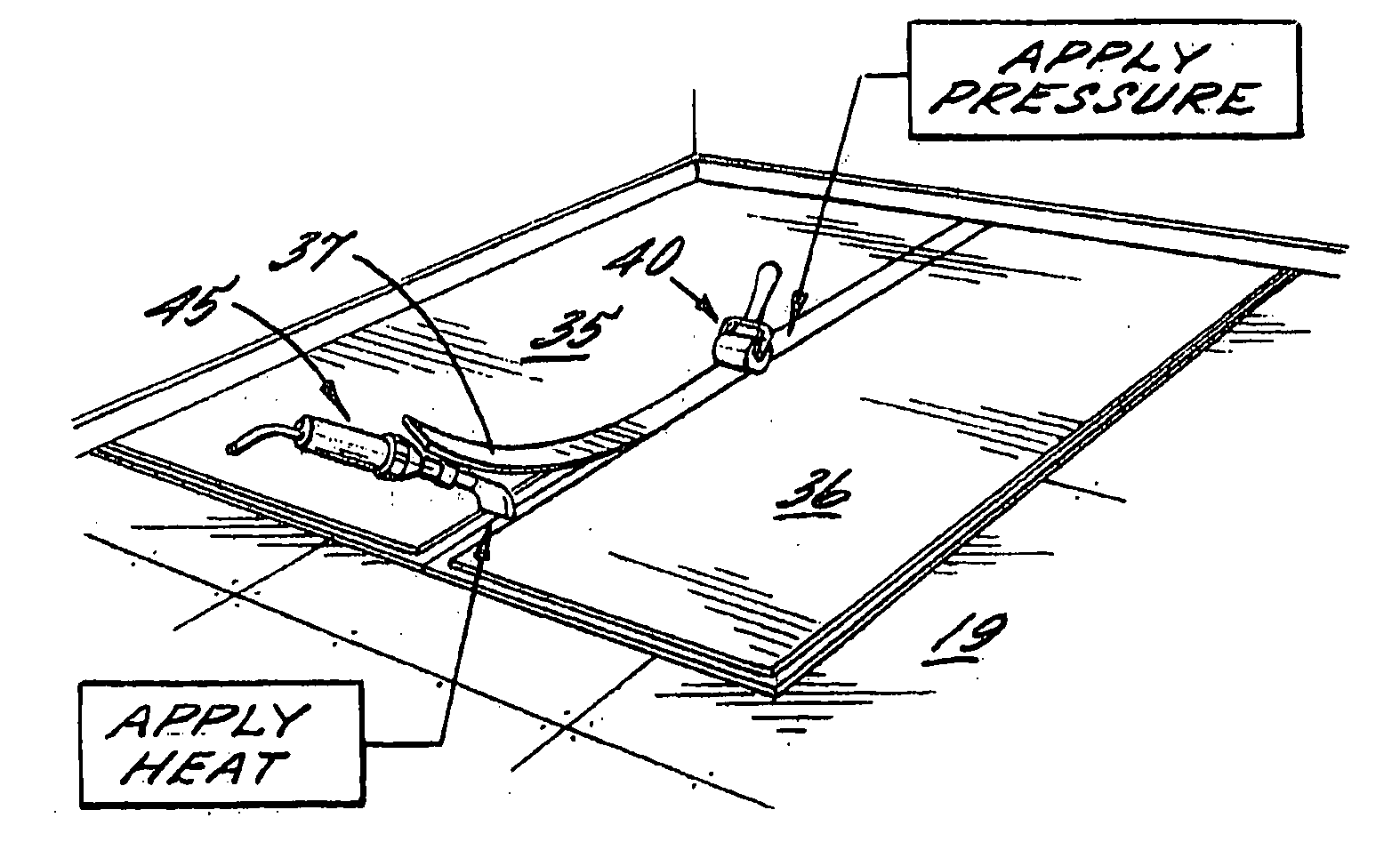

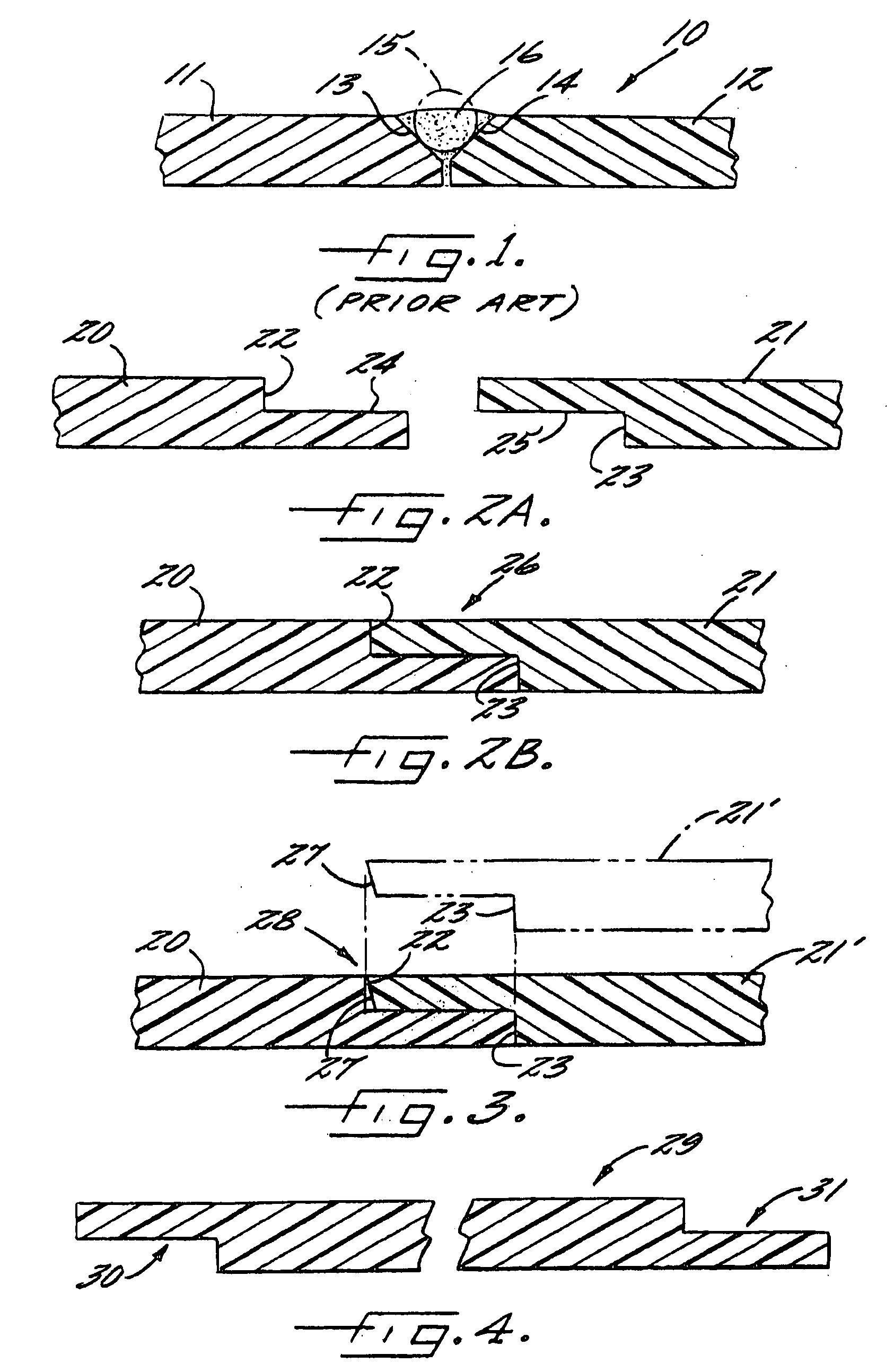

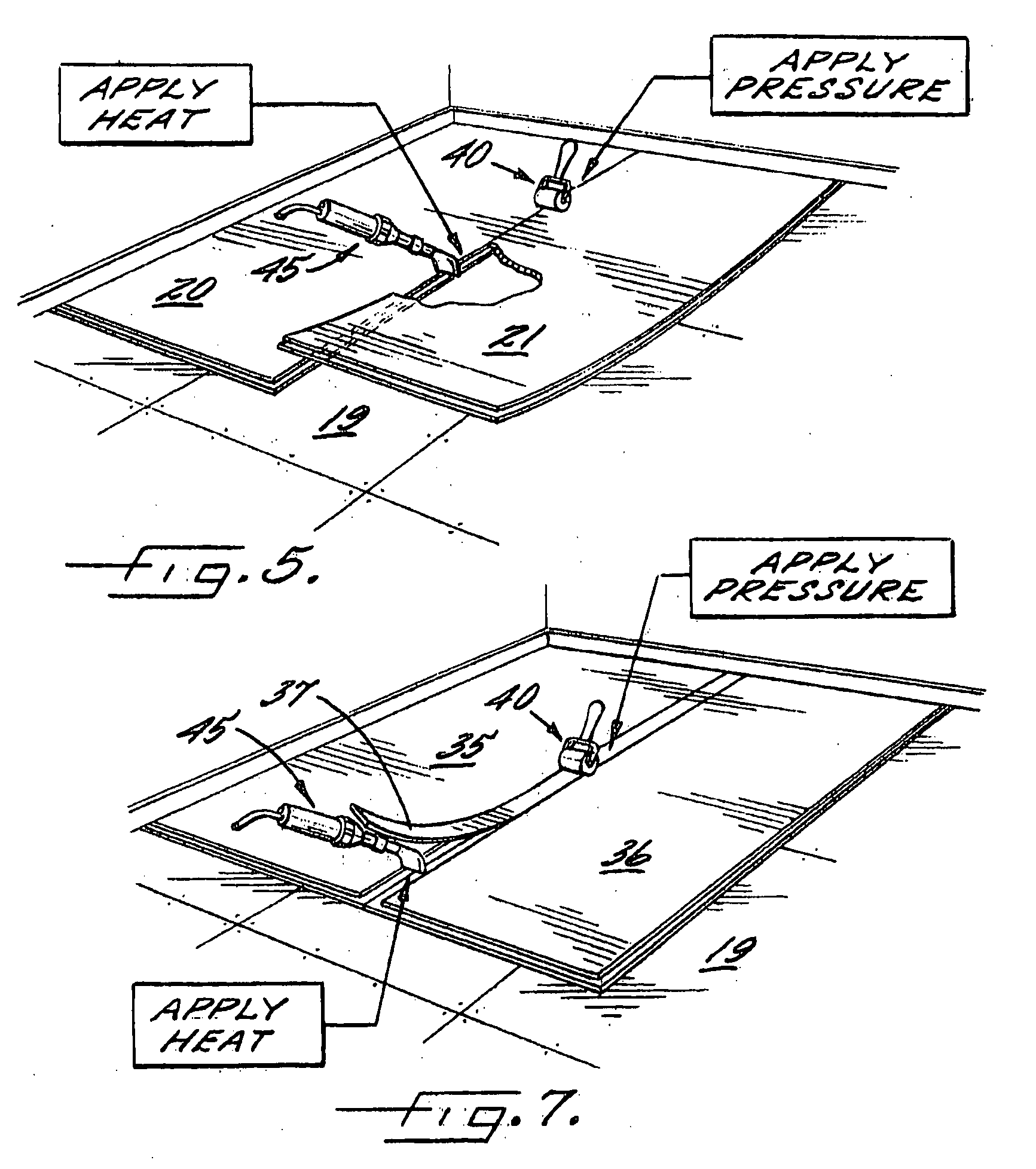

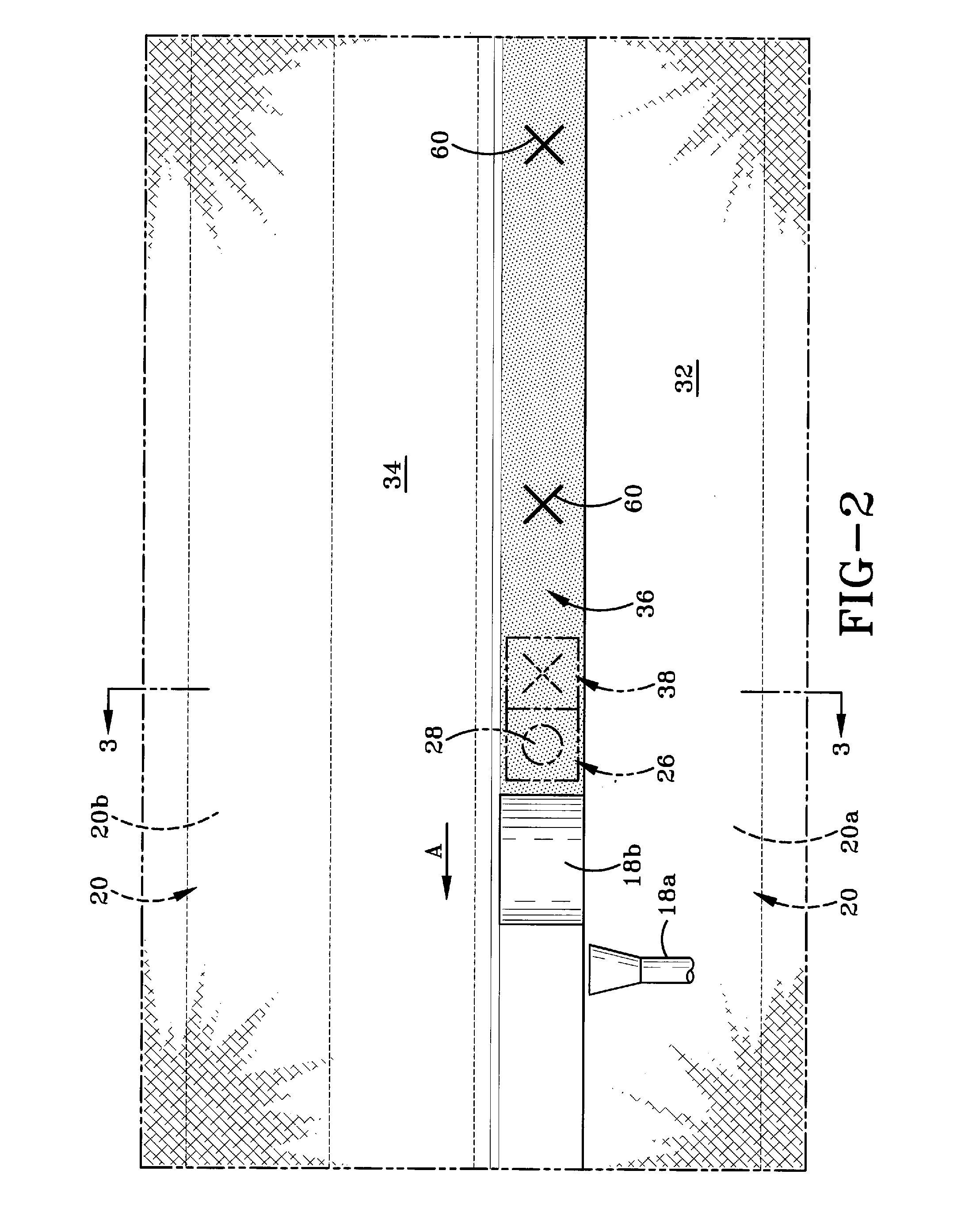

Installation Method for Non-Slip Sanitary Flooring

A method of installing flooring and resulting structure are disclosed. The method is particularly useful for sanitary nonslip (or slip resistant) applications such as kitchens. The method includes the steps of positioning a first sheet of polymer flooring material with an upwardly-facing step cut along one edge of the first sheet on a floor to be covered, and applying a second sheet of polymer flooring material with a complementary downwardly-facing step cut along one edge of the second sheet to the upwardly facing step cut of the first sheet and to the floor adjacent the first sheet while concurrently sealing or bonding the respective faces to one another in a step lap joint.

Owner:MARTIN JOEL E JR +1

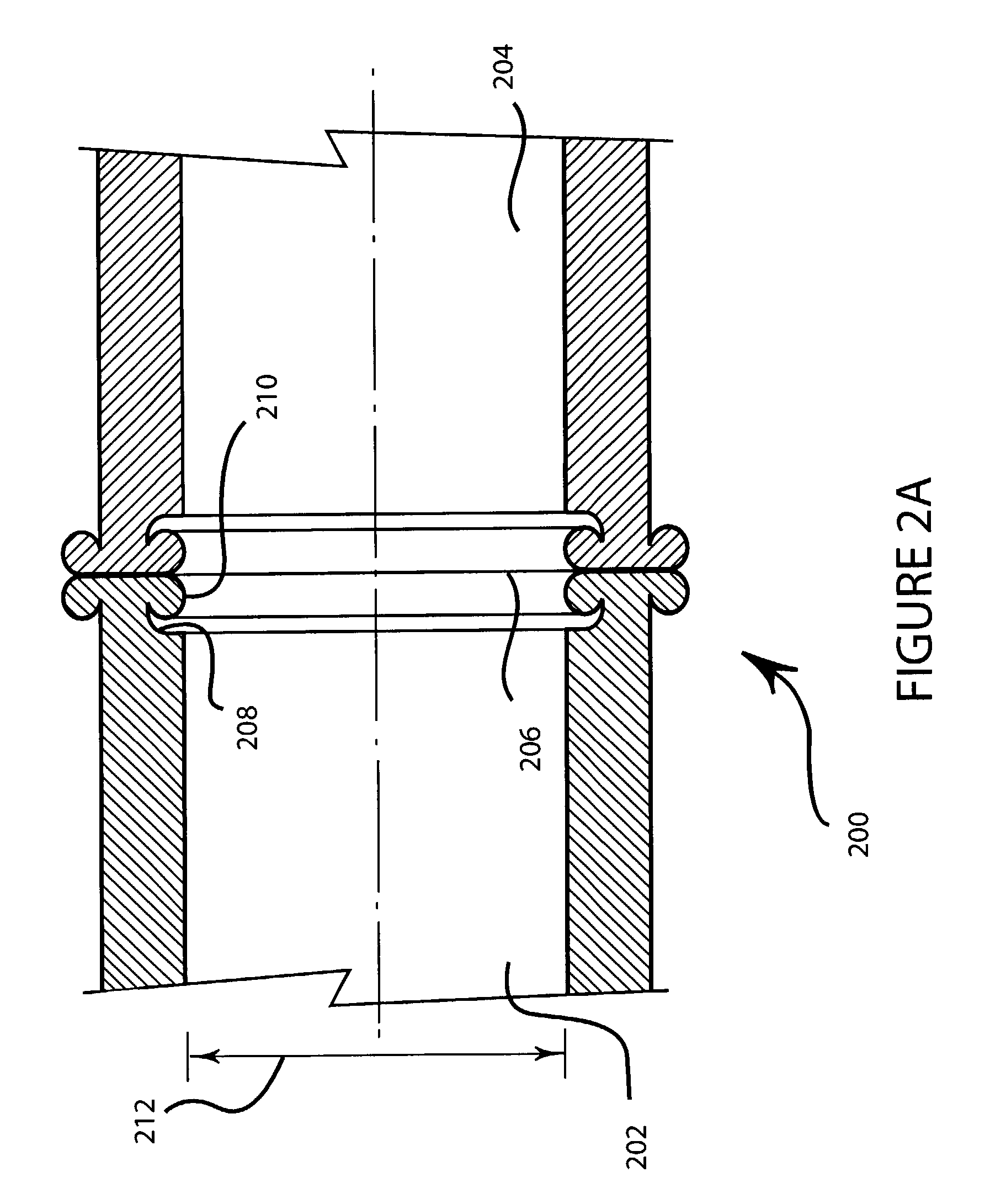

High release nip roll assembly

InactiveUS20080156443A1Reduces nip wrapsFacilitated releaseMechanical working/deformationFilament handlingMechanical engineeringThermoplastic materials

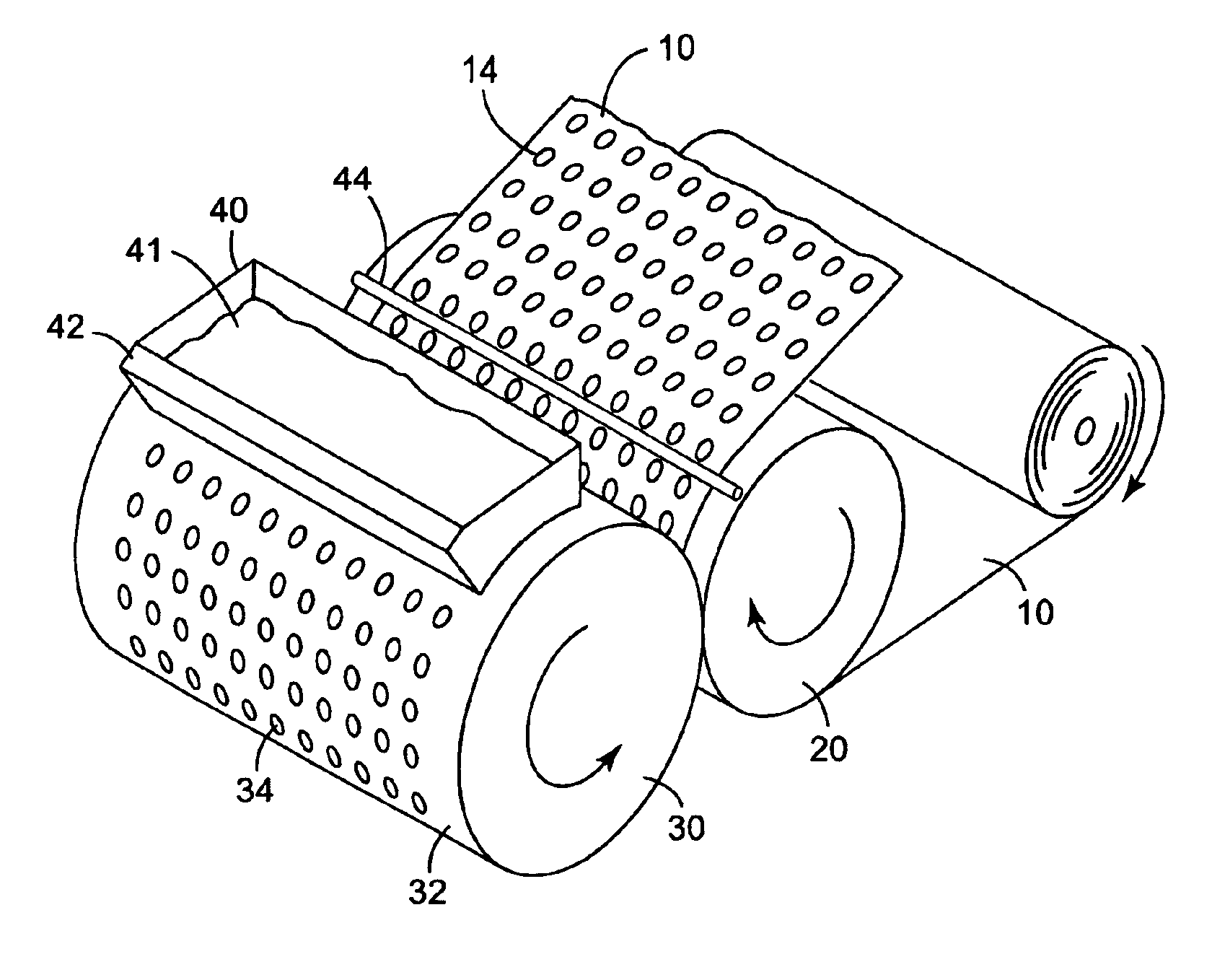

Disclosed herein is a high release nip roll assembly comprising a nip roll with a covering comprising a high release material. The release properties of the nip roll material can permit intermittent contact without the coating adhering to the surface of the roller and wrapping the nip. Also disclosed is a high release nip roll belt is made of a high release material on the top and bottom surfaces of the belt. The belt can be positioned at each end of a nip roll so that areas of the nip roll typically vulnerable to molten thermoplastic material contact are protected by a belt. Also disclosed is a belt making apparatus. Also disclosed is a frame assembly for moving a belt longitudinally along a nip roll. Also disclosed is a rope guide assembly for threading a belt in relation to a nip roll and at least at least one belt roller.

Owner:BEMIS COMPANY INC

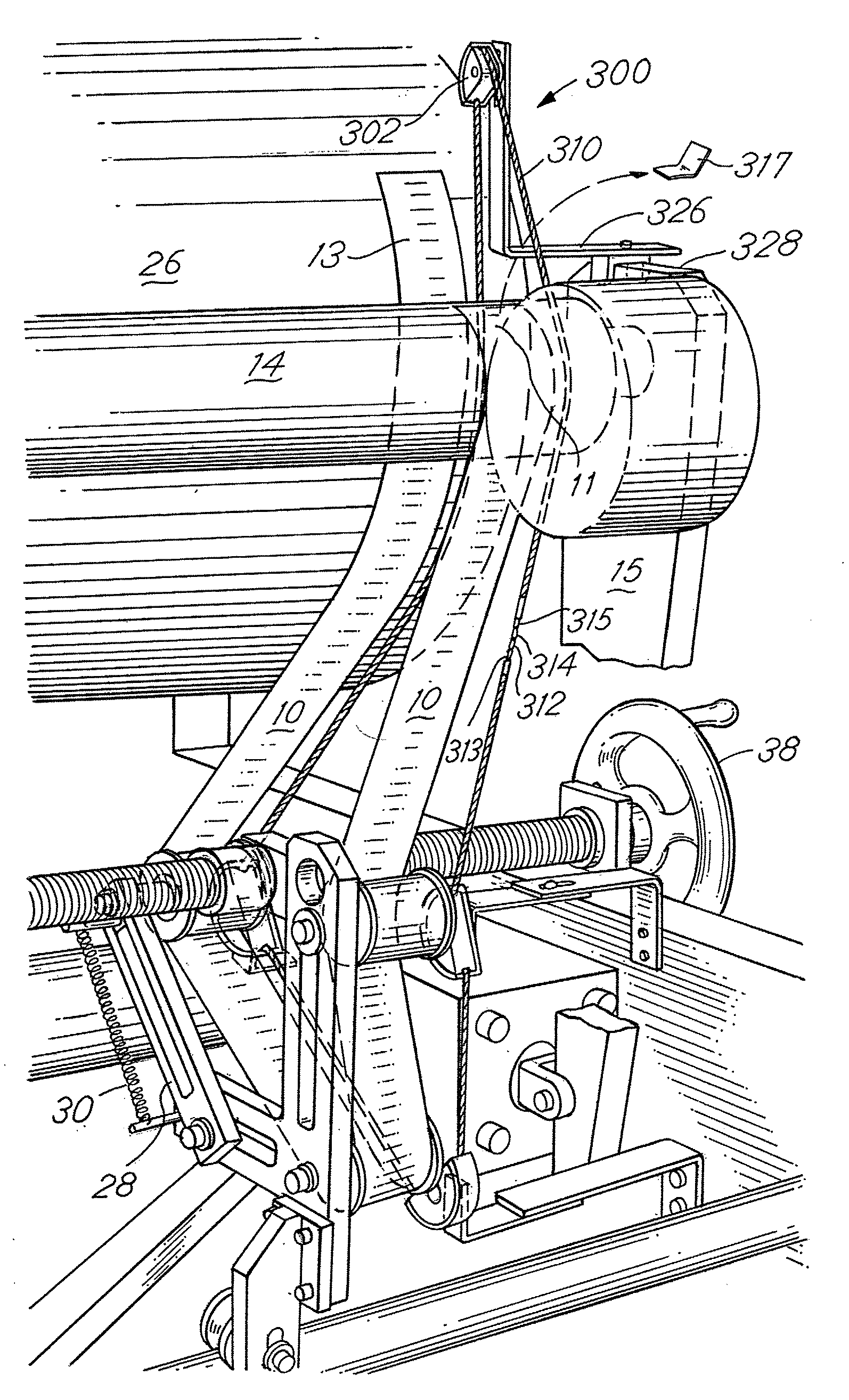

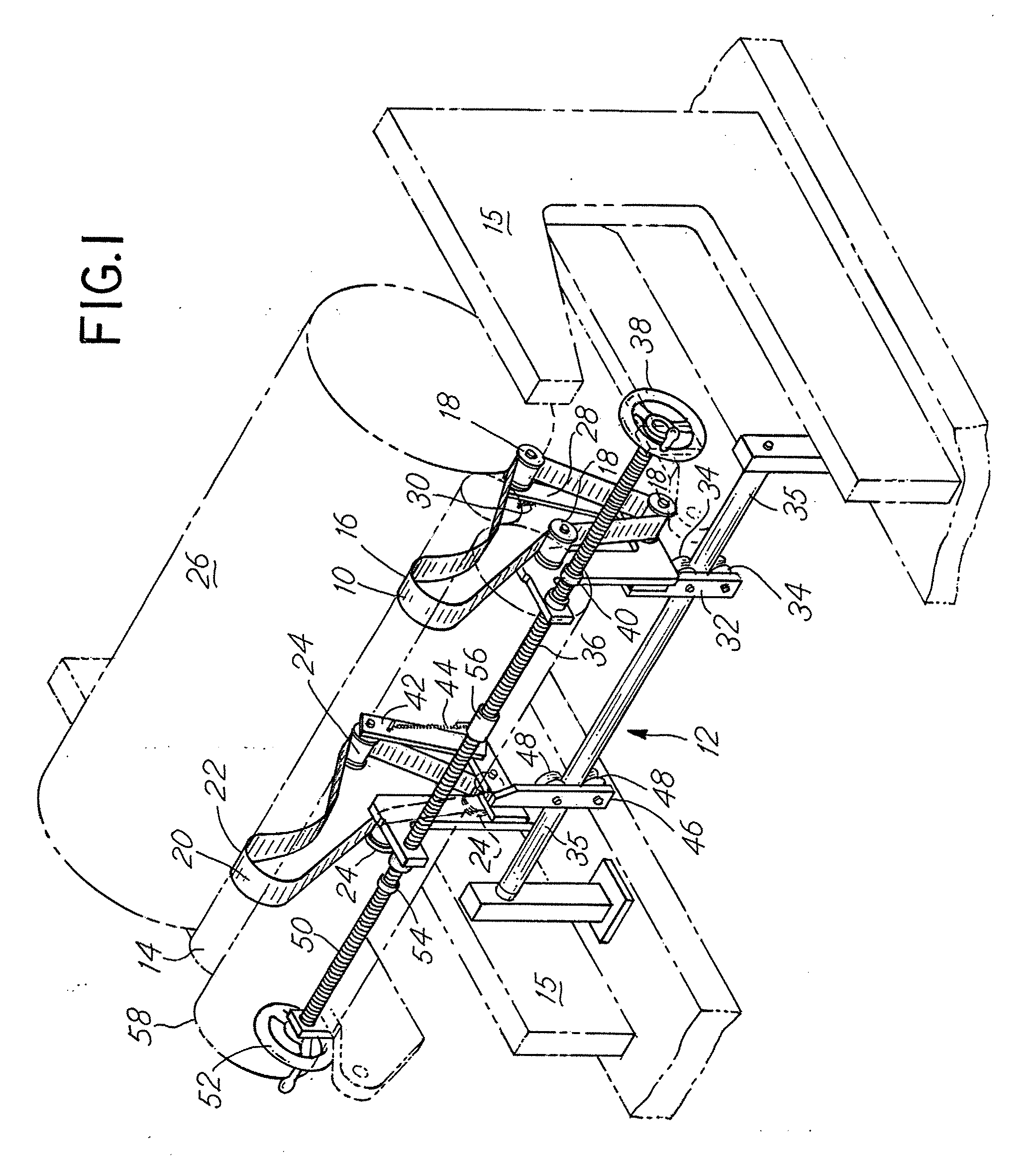

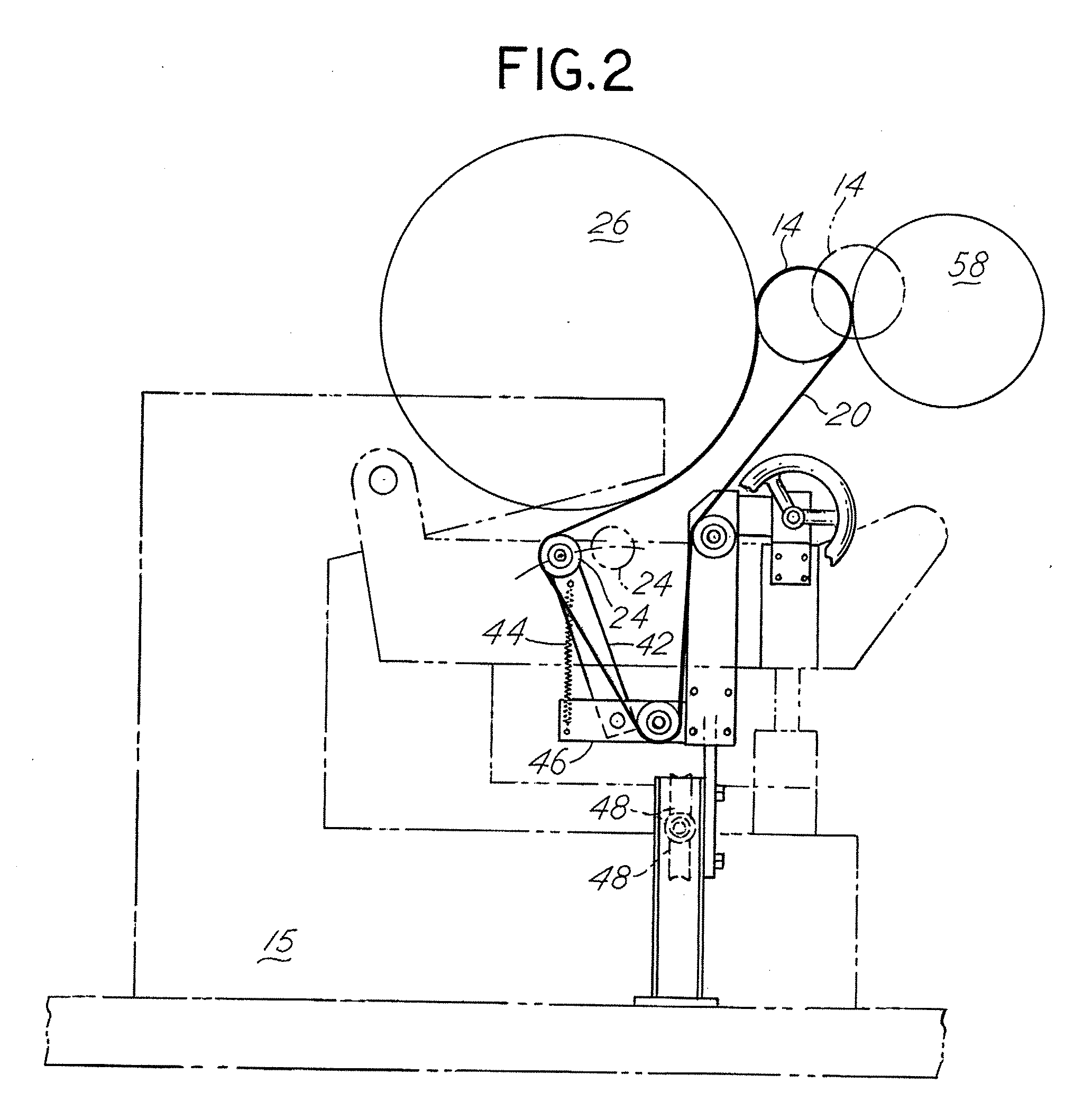

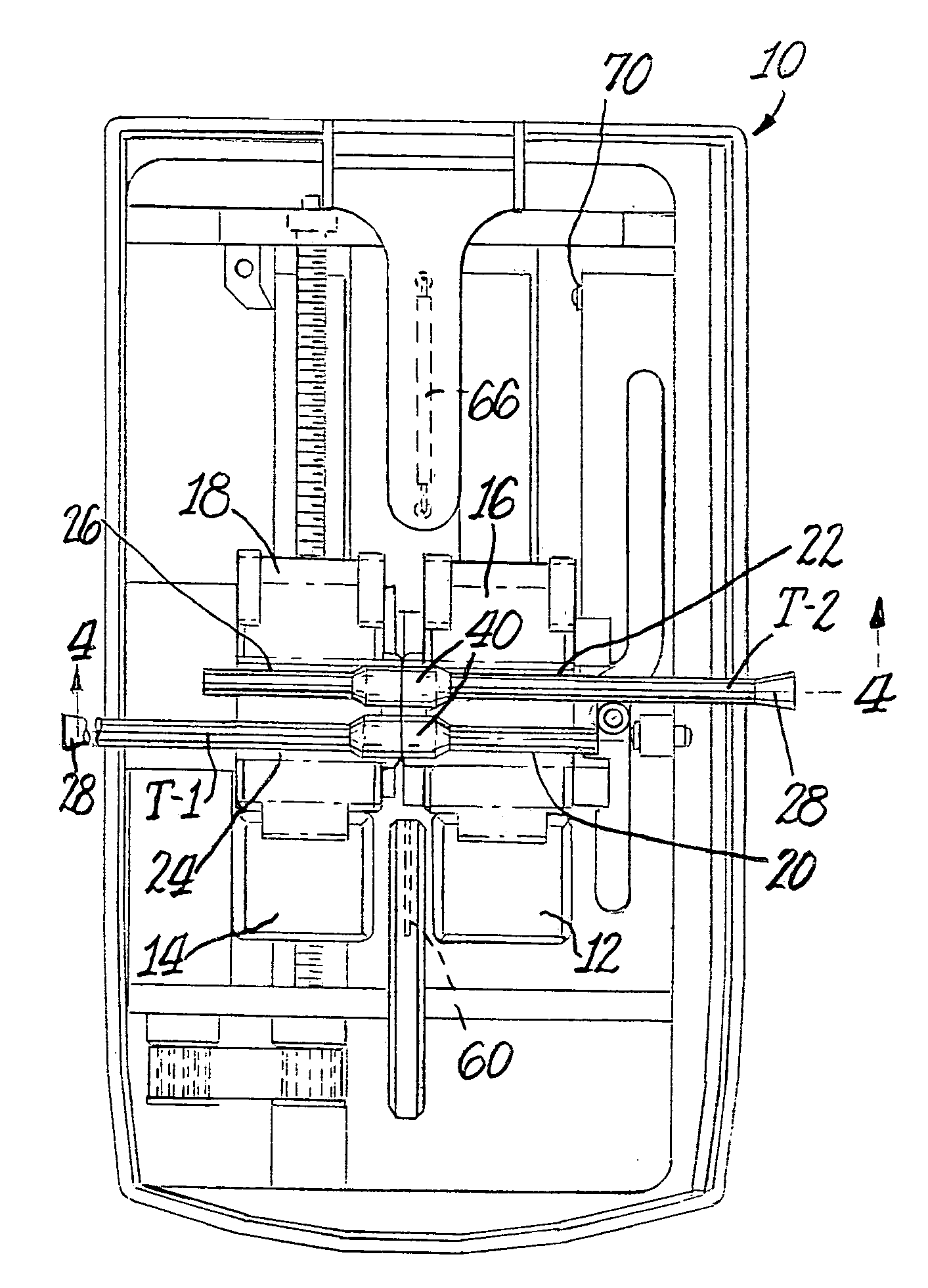

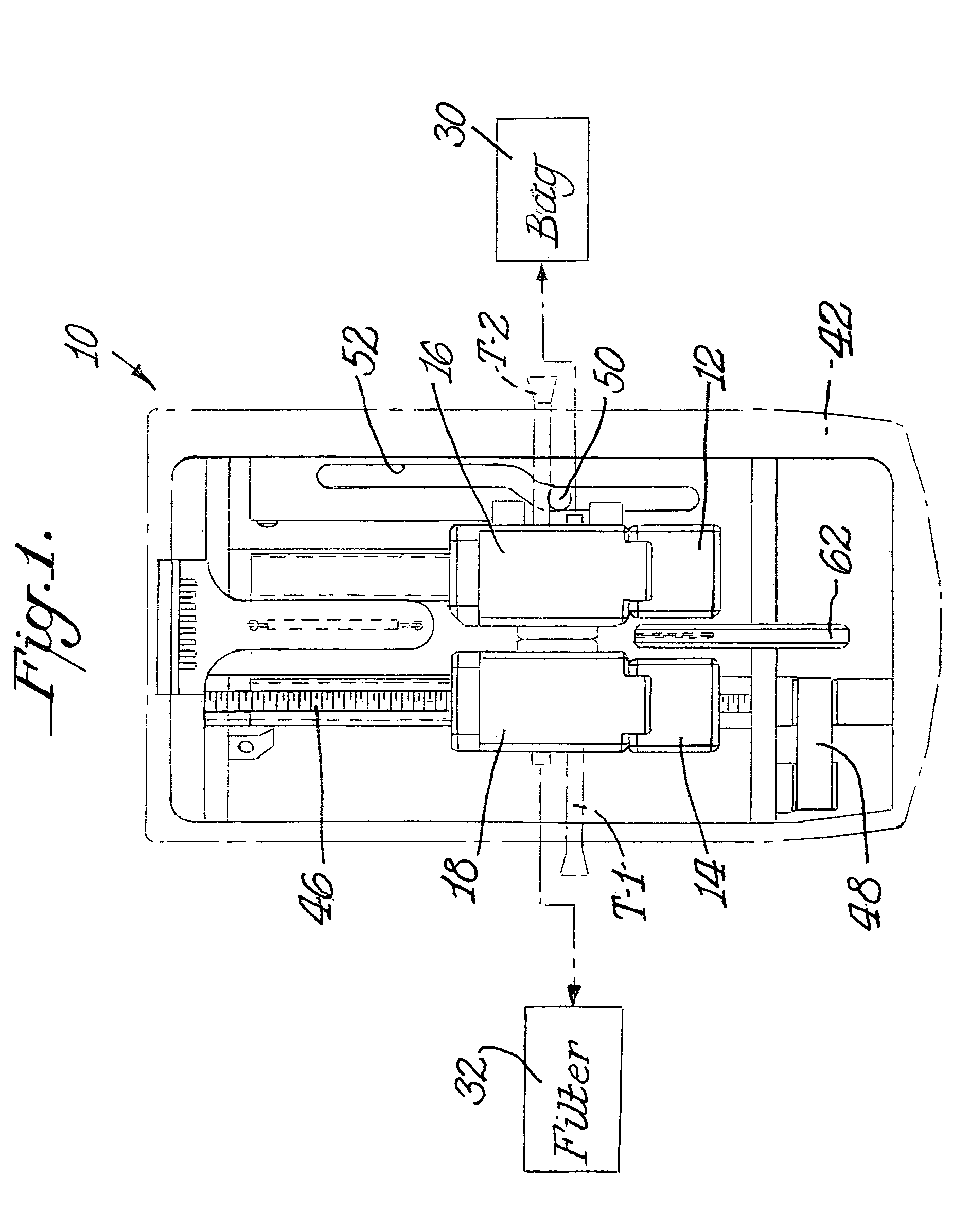

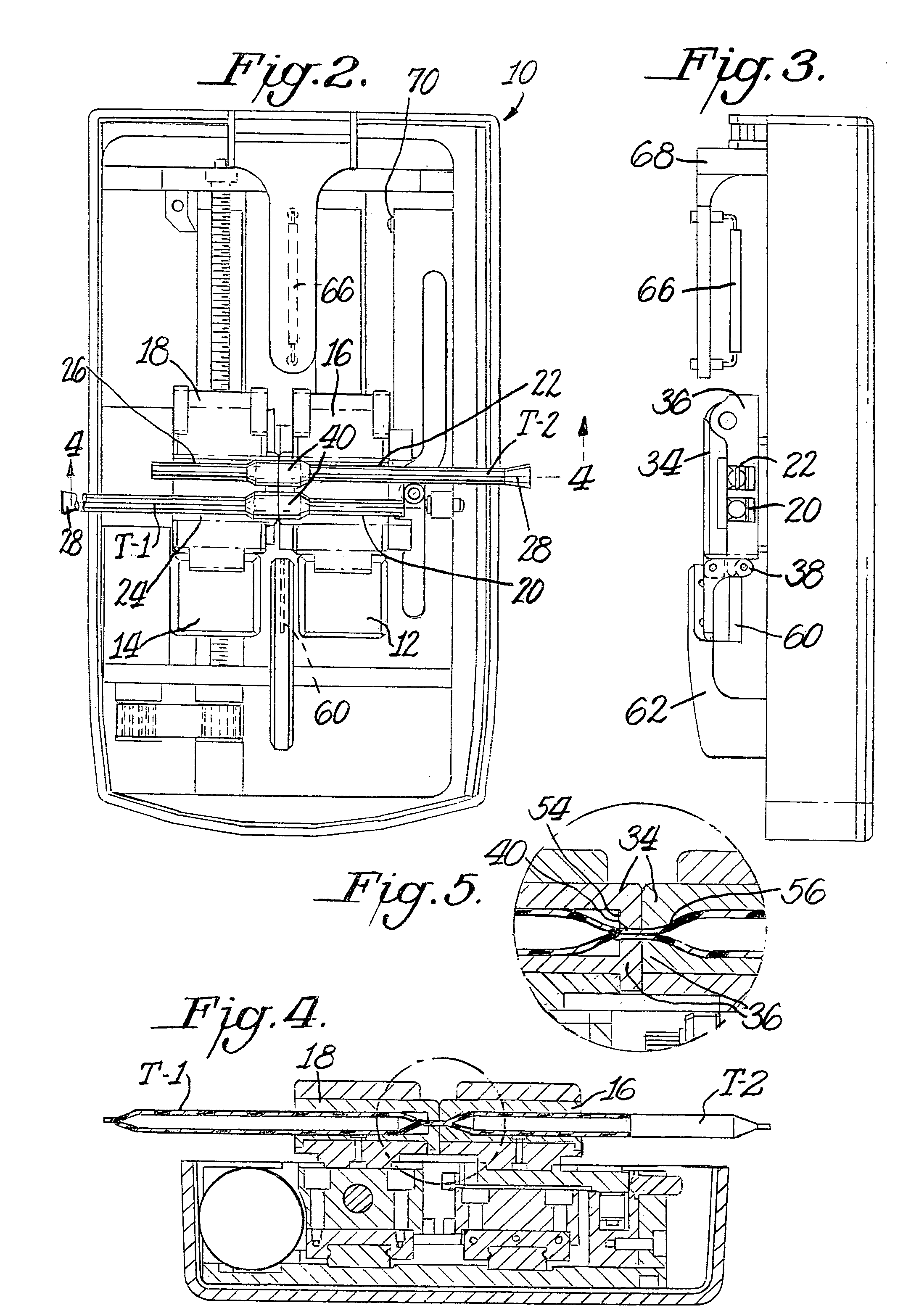

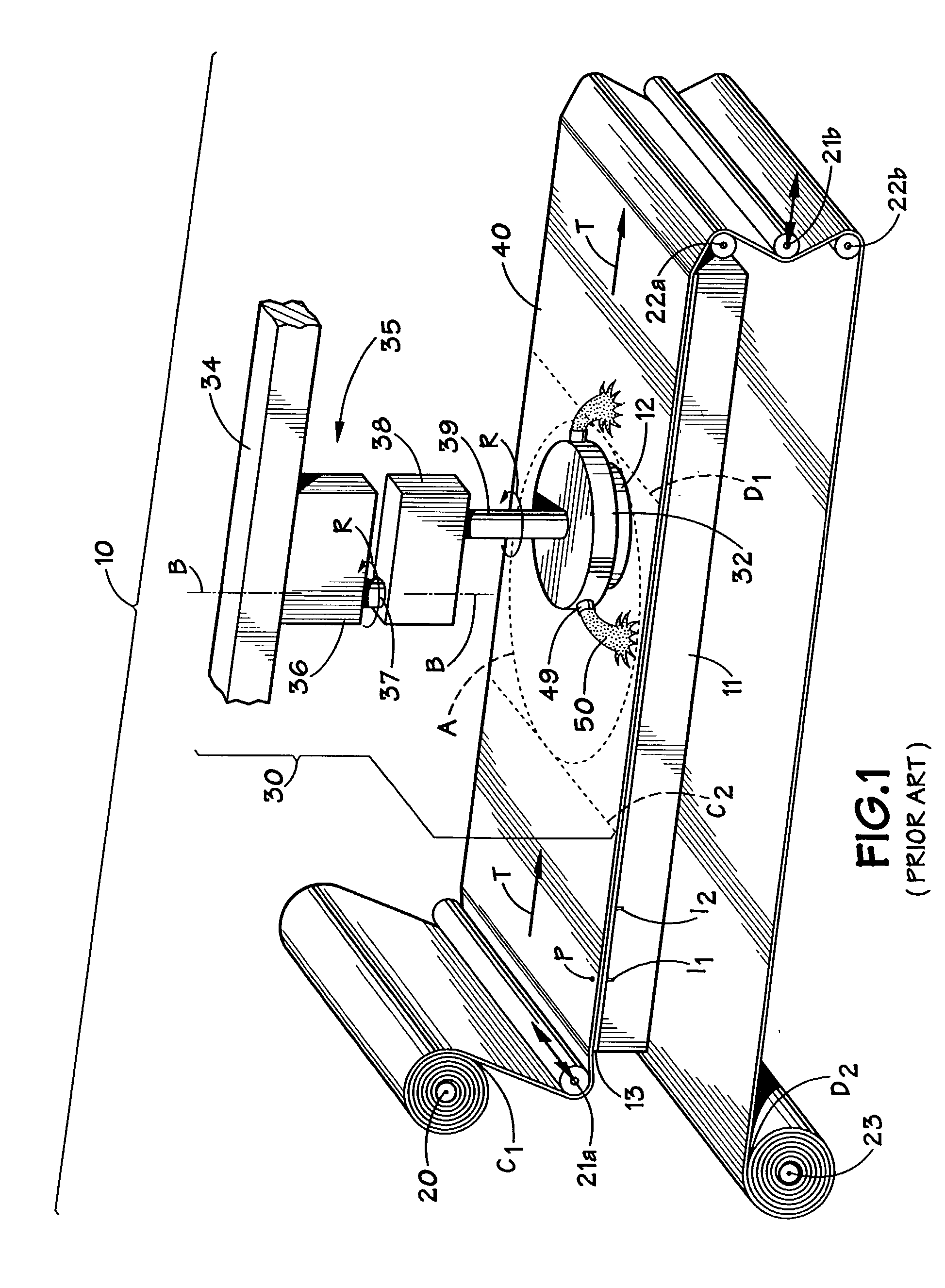

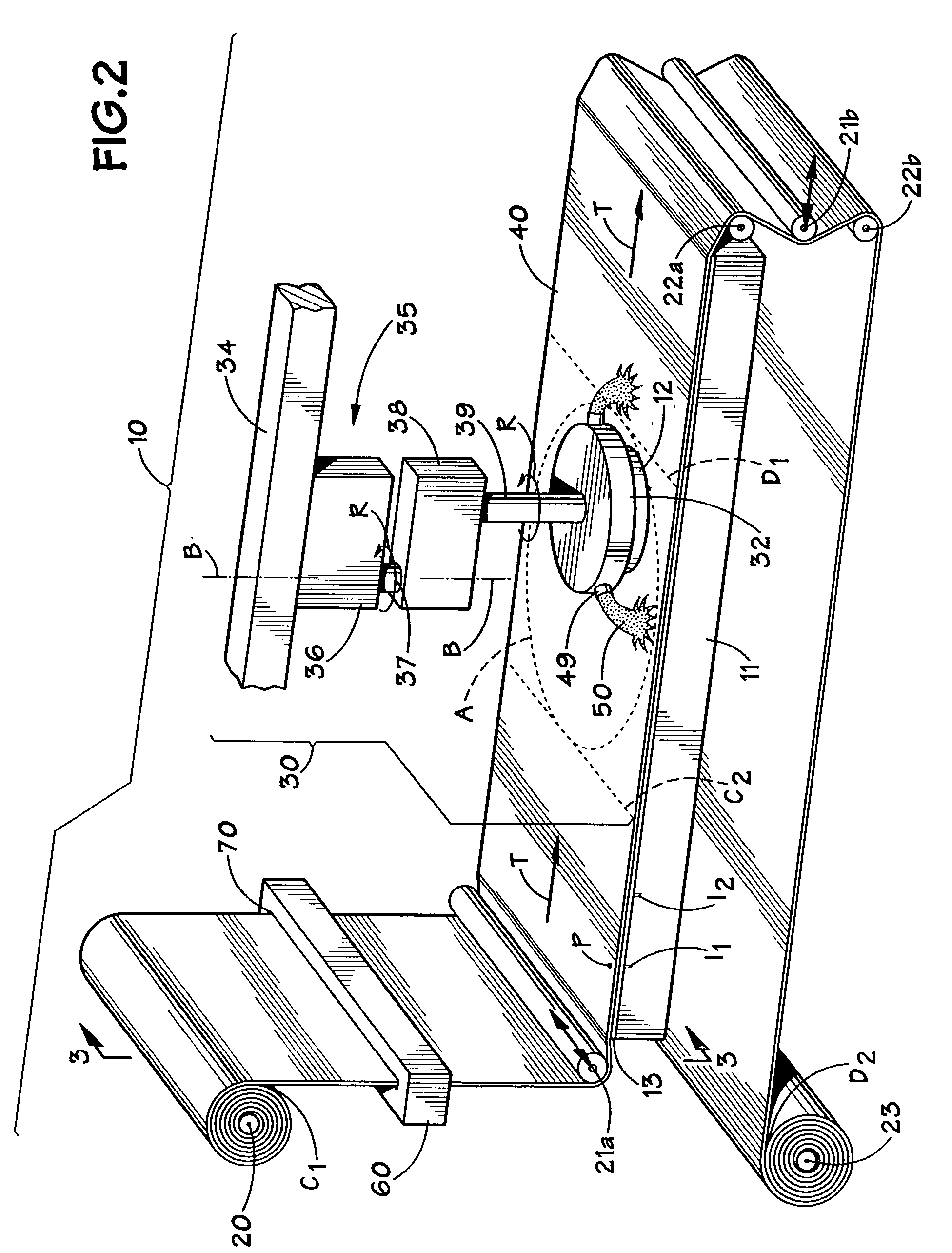

Apparatus and process for aligning materials during a splice

A splicing device is disclosed for splicing a first material to a second material in order to continuously feed the materials into a processing line. The apparatus includes a first roll letoff for unwinding a material into a processing line and a second roll letoff for holding a new material that is to replace the first material. The apparatus includes at least one sensor that indicates the position of one of the materials in the cross machine direction. A controller is used to compare the position of one material to the position of another material. If the materials are out of alignment in the cross machine direction, a shifting device shifts one of the materials until the materials are in alignment. The shifting device, for instance, may shift the splicing assembly itself while one of the materials is anchored to the splicing assembly.

Owner:KIMBERLY-CLARK WORLDWIDE INC

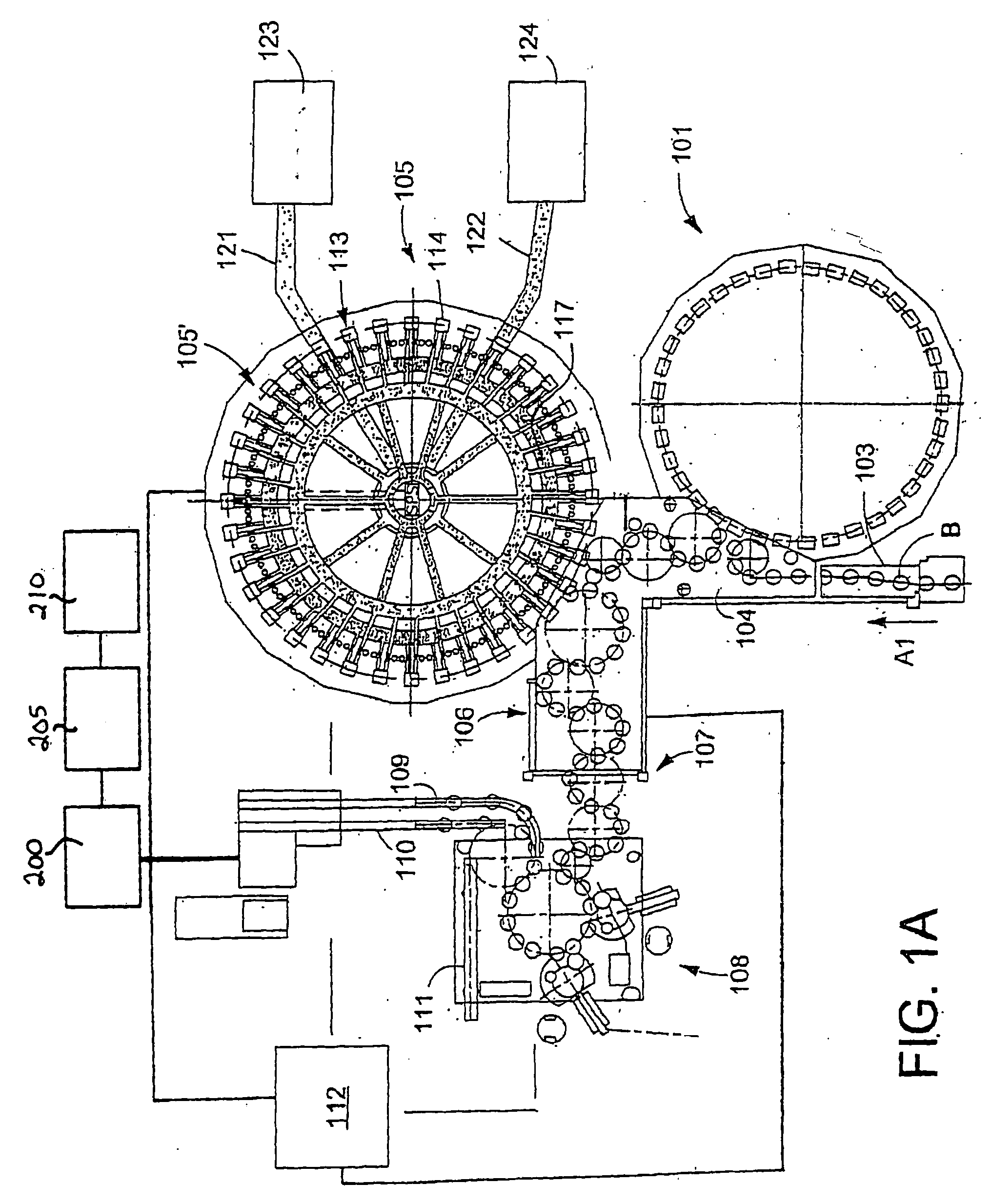

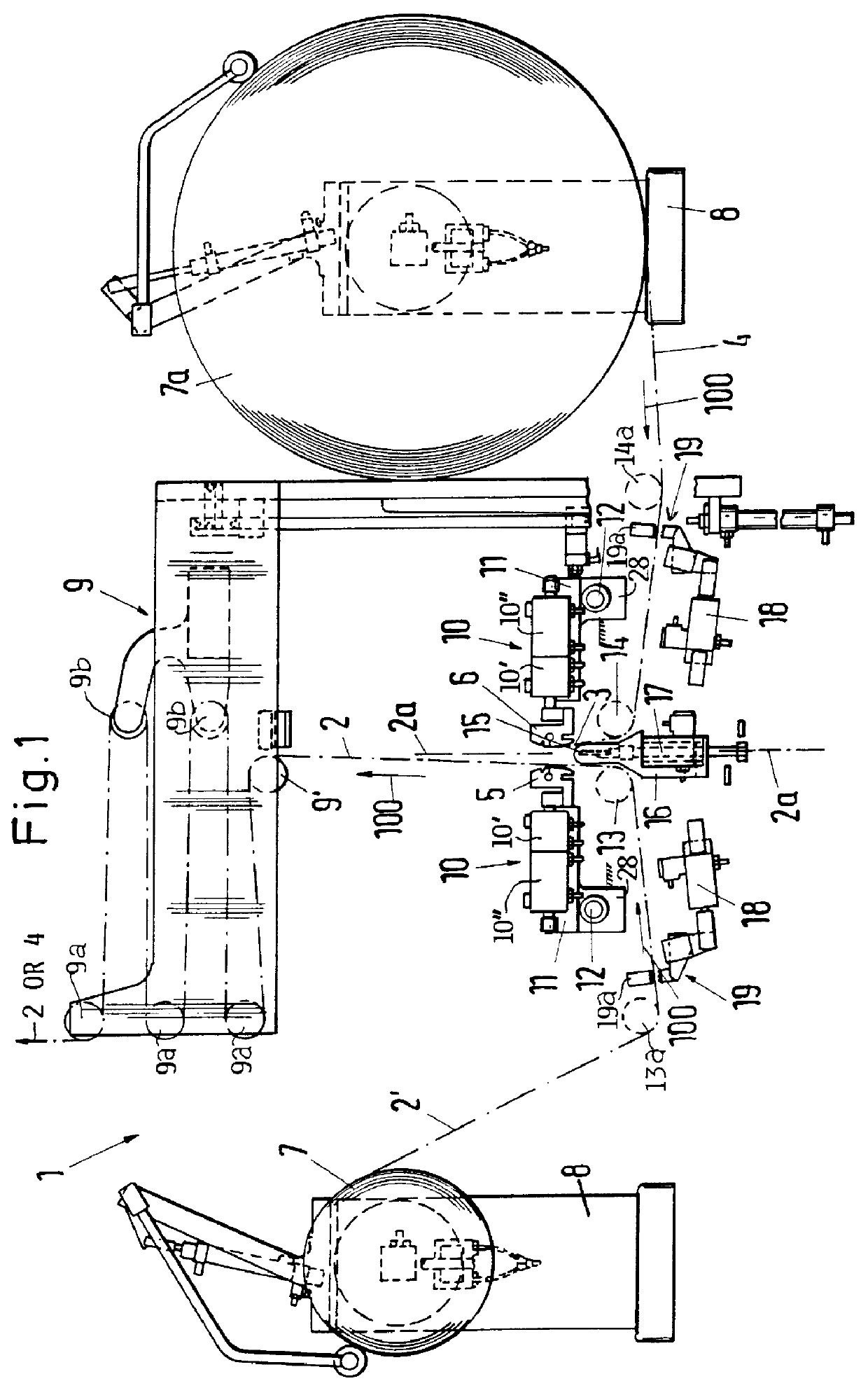

Beverage bottling plant for filling bottles with a liquid beverage material having a machine and method for wrapping filled bottles

InactiveUS20060026926A1Smooth and accurate connectionAccurate connectionMechanical working/deformationWrapping material feeding apparatusTrademarkEngineering

A beverage bottling plant for filling bottles with a liquid beverage material having a machine and method for wrapping filled bottles. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

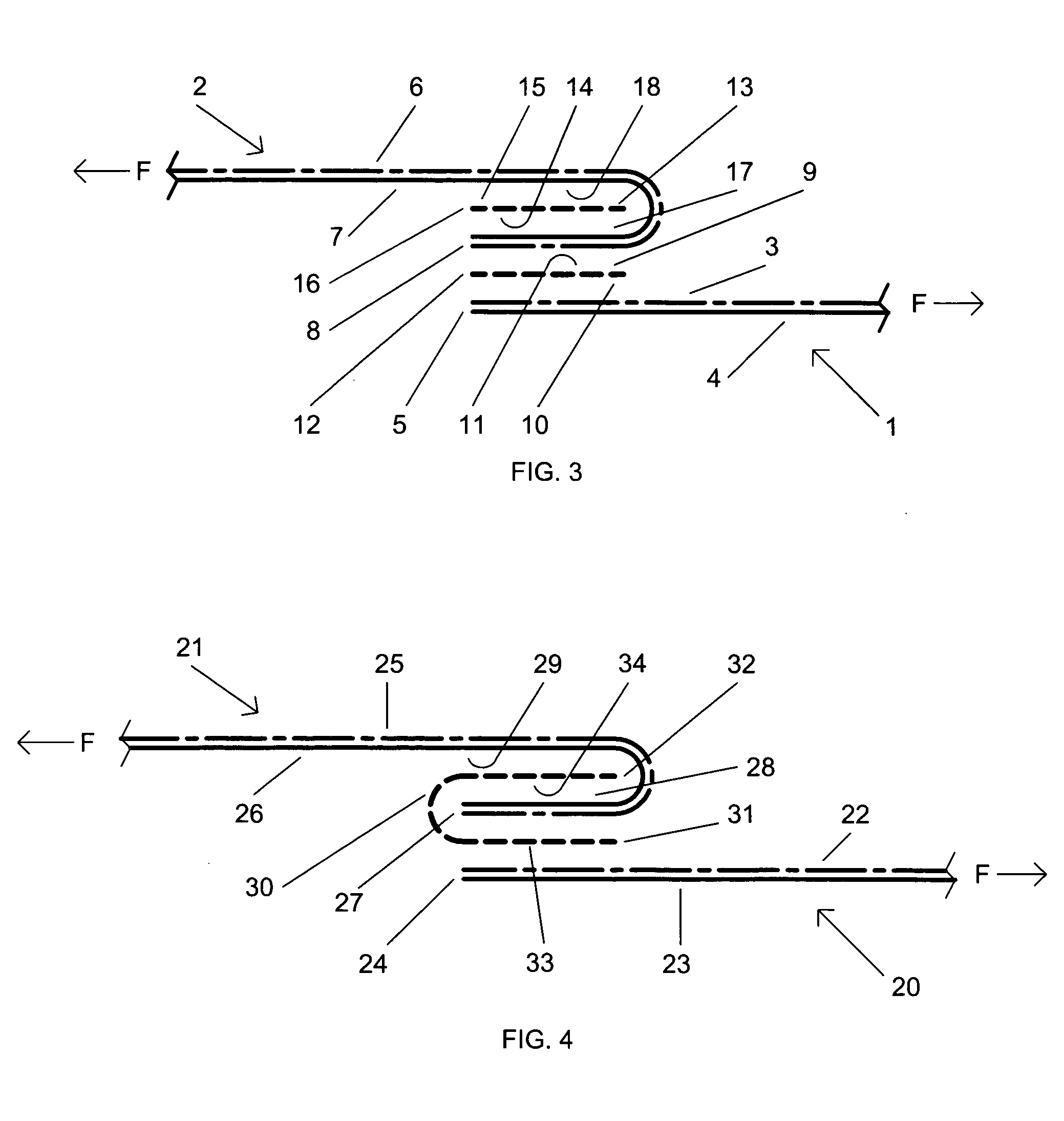

Method of forming and adhesively bonded seam

InactiveUS7005021B2Mechanical working/deformationLamination ancillary operationsEngineeringMechanical engineering

A method of forming a stitchless, adhesively bonded seam for a garment includes positioning an outside surface of a first sheet of fabric adjacent to an outside surface of a second sheet of fabric, and positioning a first strip of adhesive tape between the first and second sheets of fabric. A second strip of adhesive tape is positioned such that a first side is adjacent to a first portion of an inside surface of the second sheet of fabric, and the second sheet of fabric is folded such that a second portion of the inside surface of the second sheet of fabric overlaps a second side of the second strip of adhesive tape. The adhesively bonded seam is formed by applying energy to the first and second sheets of fabric and to the first and second strips of adhesive tape.

Owner:MOUNTAIN HARDWEAR

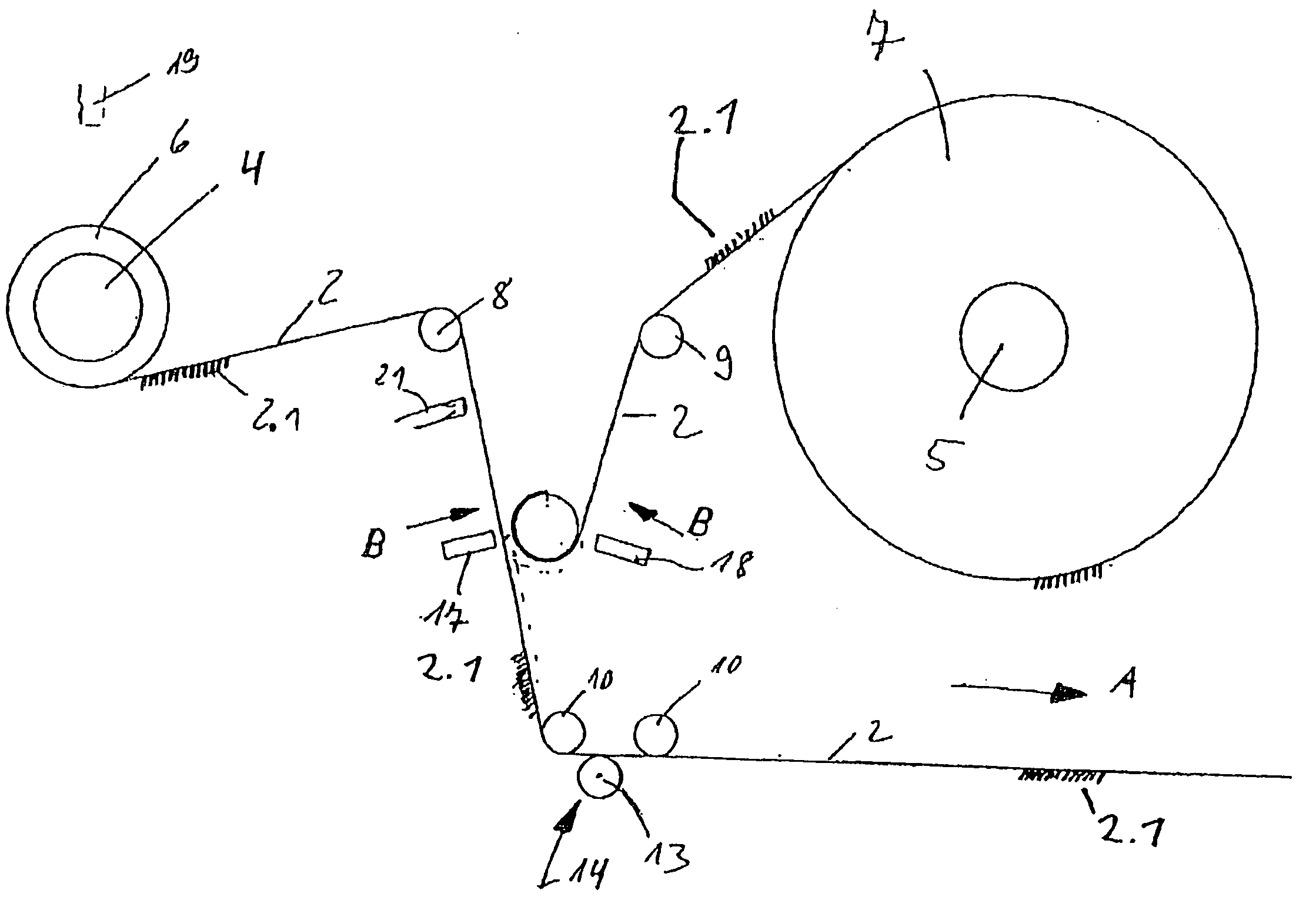

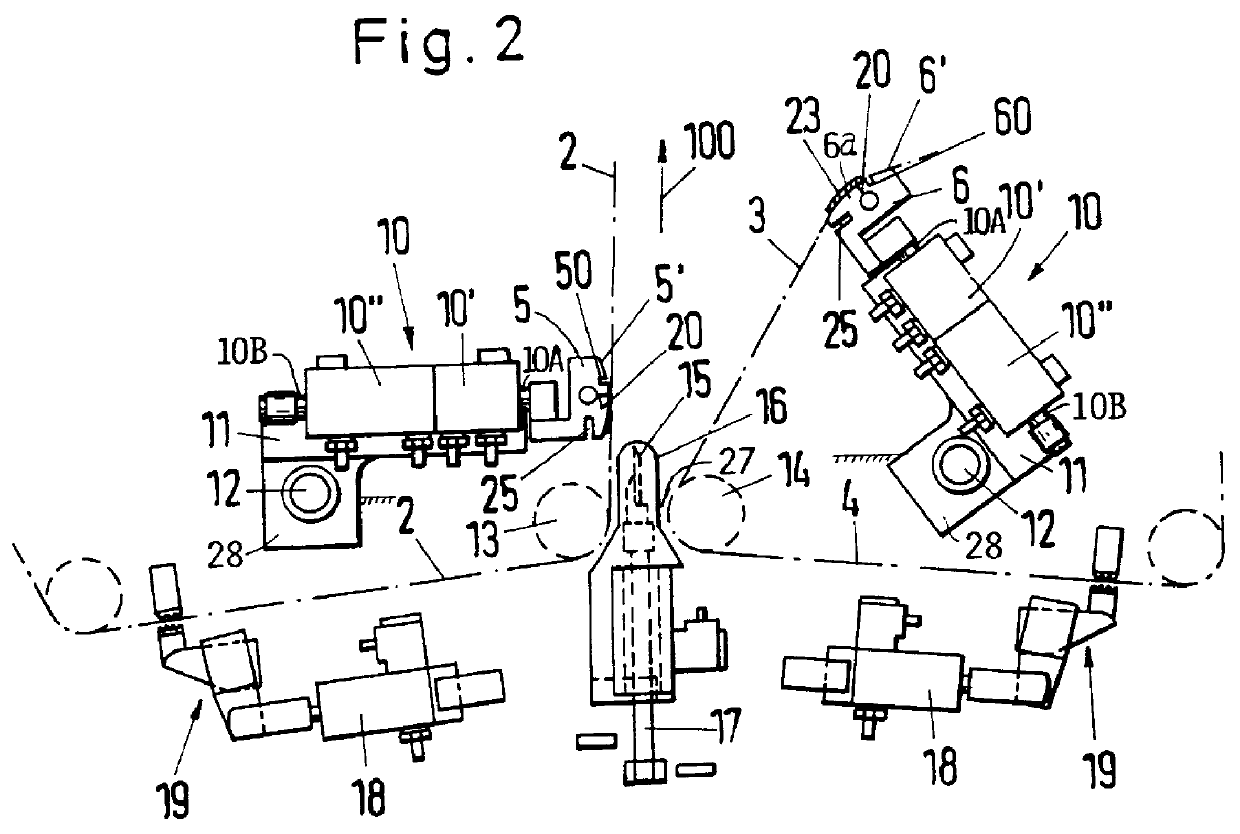

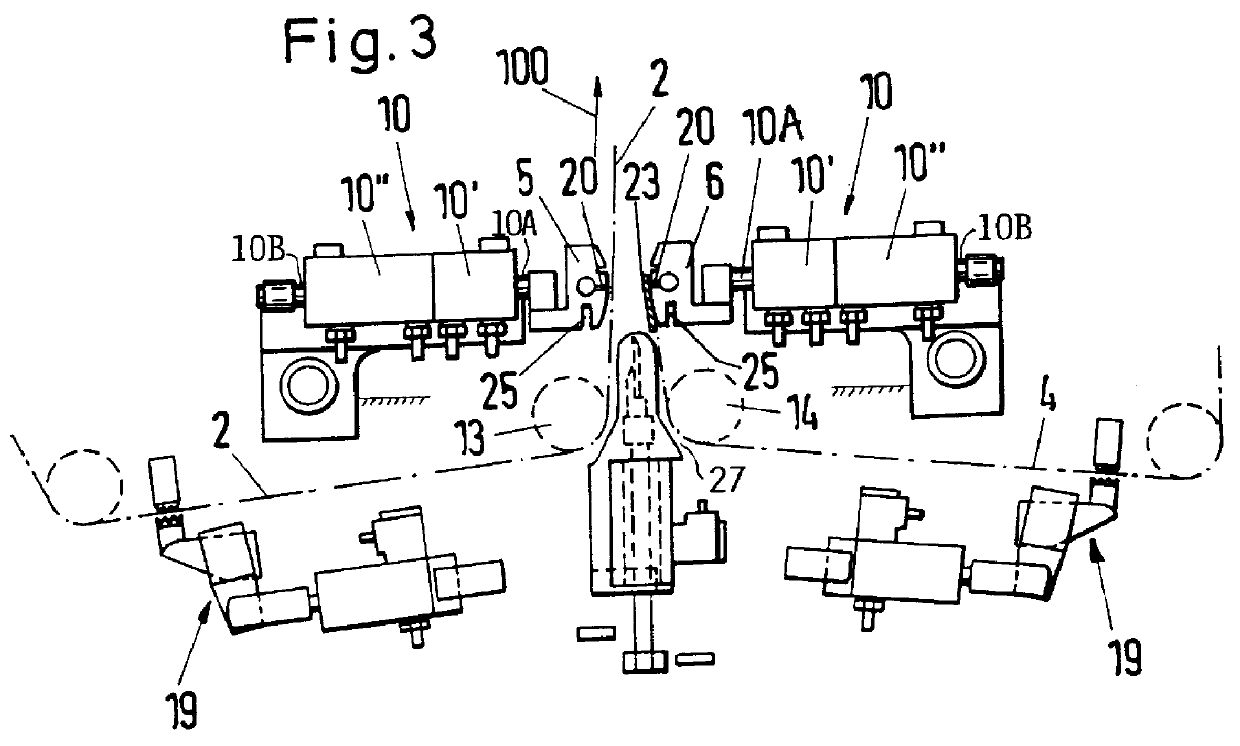

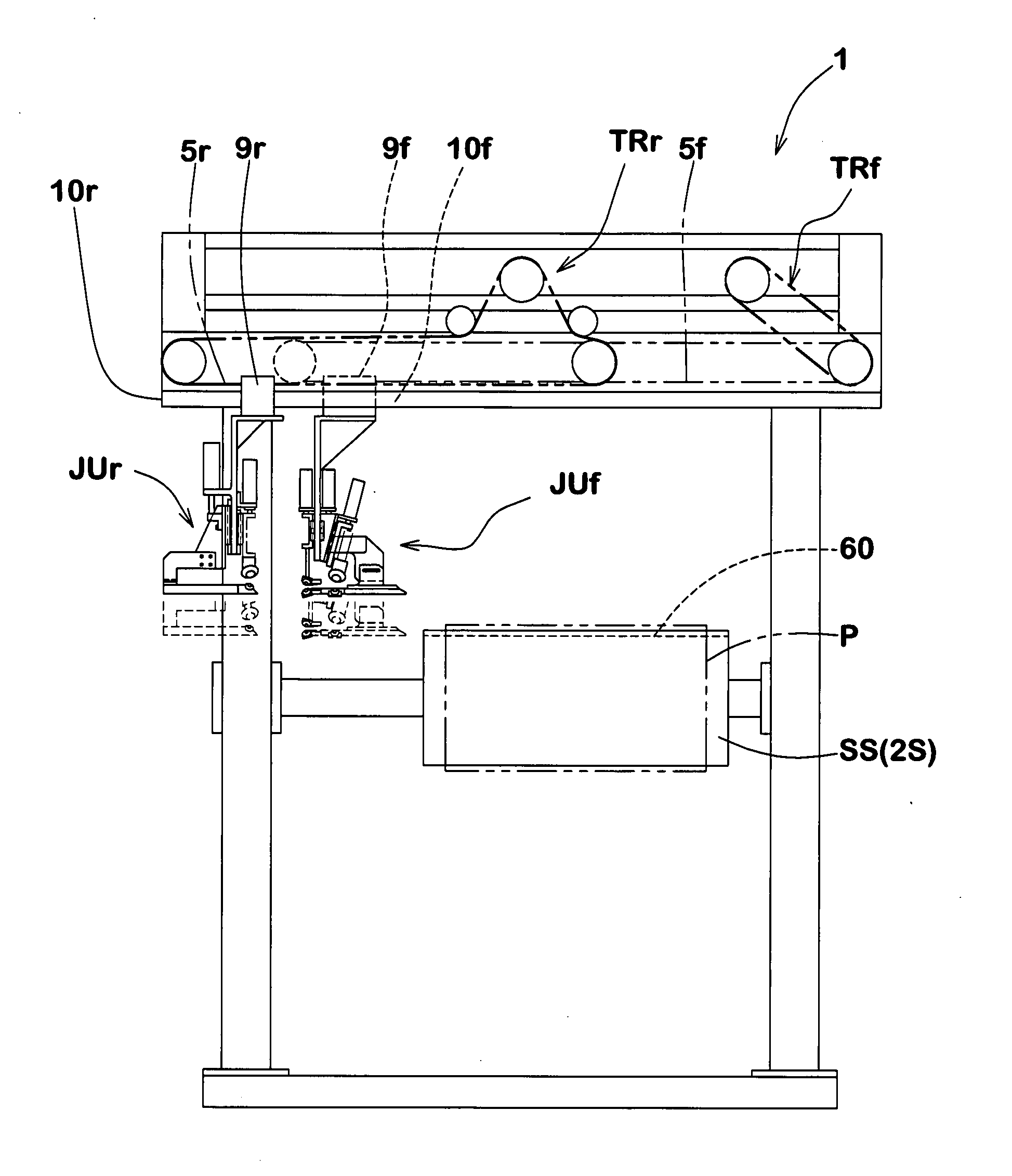

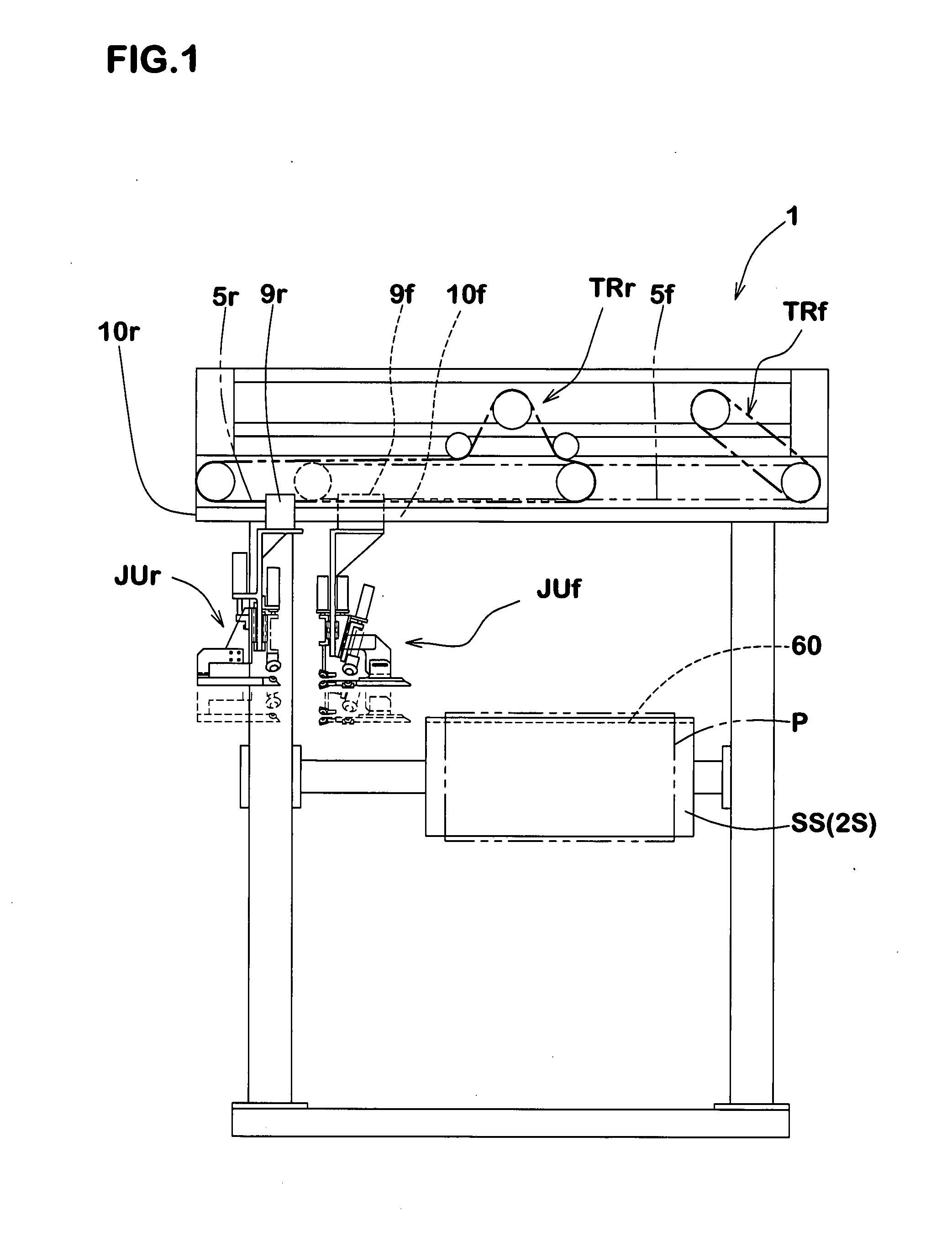

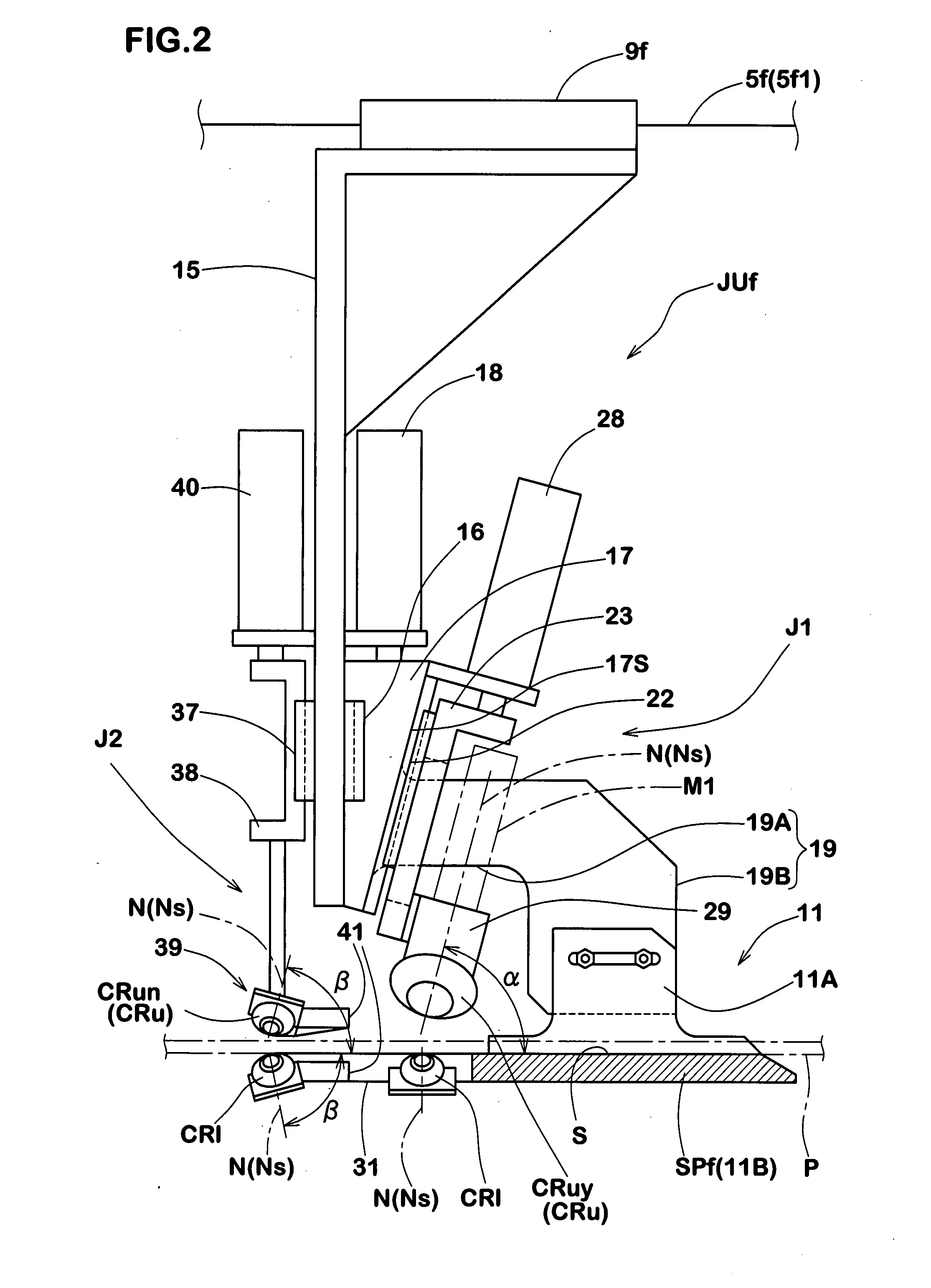

Apparatus for joining ends of material webs to each other

InactiveUS6013148AEasy to operateReduce effortMechanical working/deformationFilament handlingEngineeringMechanical engineering

The ends of material webs or tapes are joined to each other in an apparatus in which two holding and press-on heads are tiltable about fixed journal axes away from two fixed guide rollers for the webs so that a slide carriage for the heads and for the fixed guide rollers is avoided. The holding and press-on heads are mounted outside of the spacing between the guide rollers, but close to these guide rollers, but with a defined spacing from these guide rollers.

Owner:WINKLER DUNNEBIER GMBH

Multi-functional tape applicator

A multifunction tape applicator for applying a section or sections of pressure sensitive adhesive tape to a carton selectively in different carton sealing configurations, namely C-clip; single L-clip, front and back L-clips and sectional skip-gap taping. The multifunction tape applicator comprises a basic tape applicator unit to apply a common C-clip tape from a tape roll with built-in design apparatus for tape applying, tape cutting, tape tension control to facilitate other functions and a mechanical or powered actuation attachment unit which is to be installed onto the modified basic tape applicator unit to actuate other functions based on the requirement of the application.

Owner:LAMUS ENTERPRISES

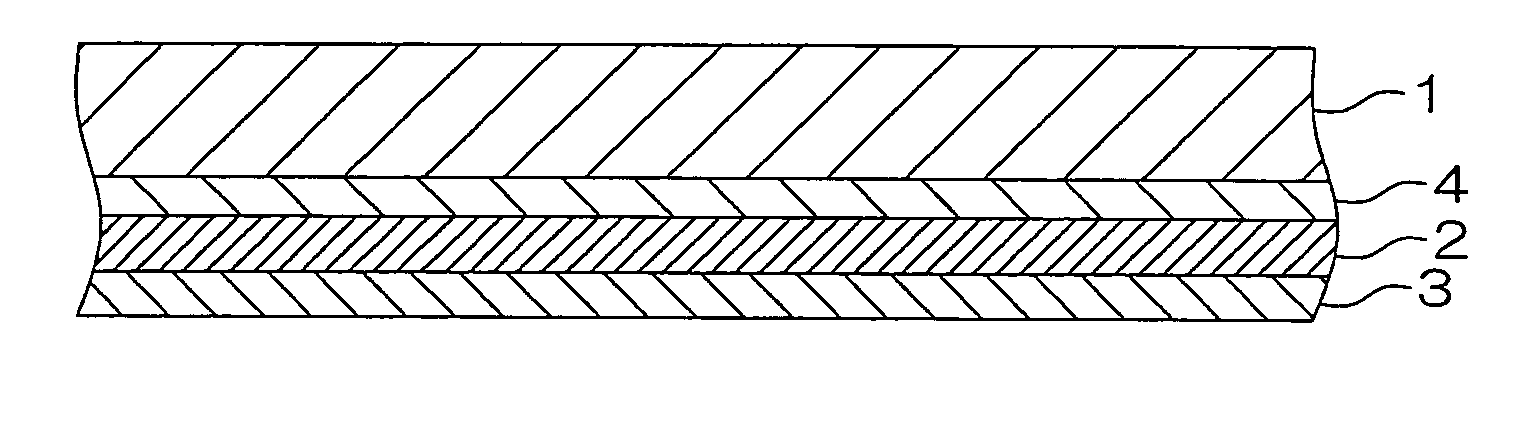

Aqueous dispersion adhesive composition and adhesive film

InactiveUS20080281038A1Improve adhesionAdhesive firmlyMechanical working/deformationFilament handlingMeth-Phosphoric acid

The aqueous dispersion adhesive composition contains an aqueous dispersion copolymer obtained by reacting of a reaction component containing alkyl (meth)acrylate whose linear or branched alkyl group has 4 to 18 carbon atoms, (meth)acrylic acid, a phosphoric acid group-containing vinyl monomer and an alkoxysilyl group-containing vinyl monomer to react; and a crosslinking agent having reactivity with a carboxyl group. In the aqueous dispersion adhesive composition, an amount of the crosslinking agent is from 0.07 to 4 parts by weight per 100 parts by weight of the aqueous dispersion copolymer, and in an adhesive layer made of the aqueous dispersion adhesive composition, an elongation at 90° C. is 200% or less.

Owner:NITTO DENKO CORP

Device for welding plastic tubes

Plastic tubes are welded by first placing the plastic tubes across aligned tube slots in a pair of side by side tube holders. The tubes are clamped to create a fluid free area. The clamps in one of the tube holders are shifted laterally away from the other tube holders to increase the fluid free area of each tube. A cold cutting device cuts through the clamped tubes to create four stub ends. The four stub ends are heated / melted. The stub ends are realigned so that the one stub end in one holder is aligned with the other stub end of the other tube holder and the realigned stub ends are pressed into contact with each other to create a weld seam.

Owner:GENESIS BPS

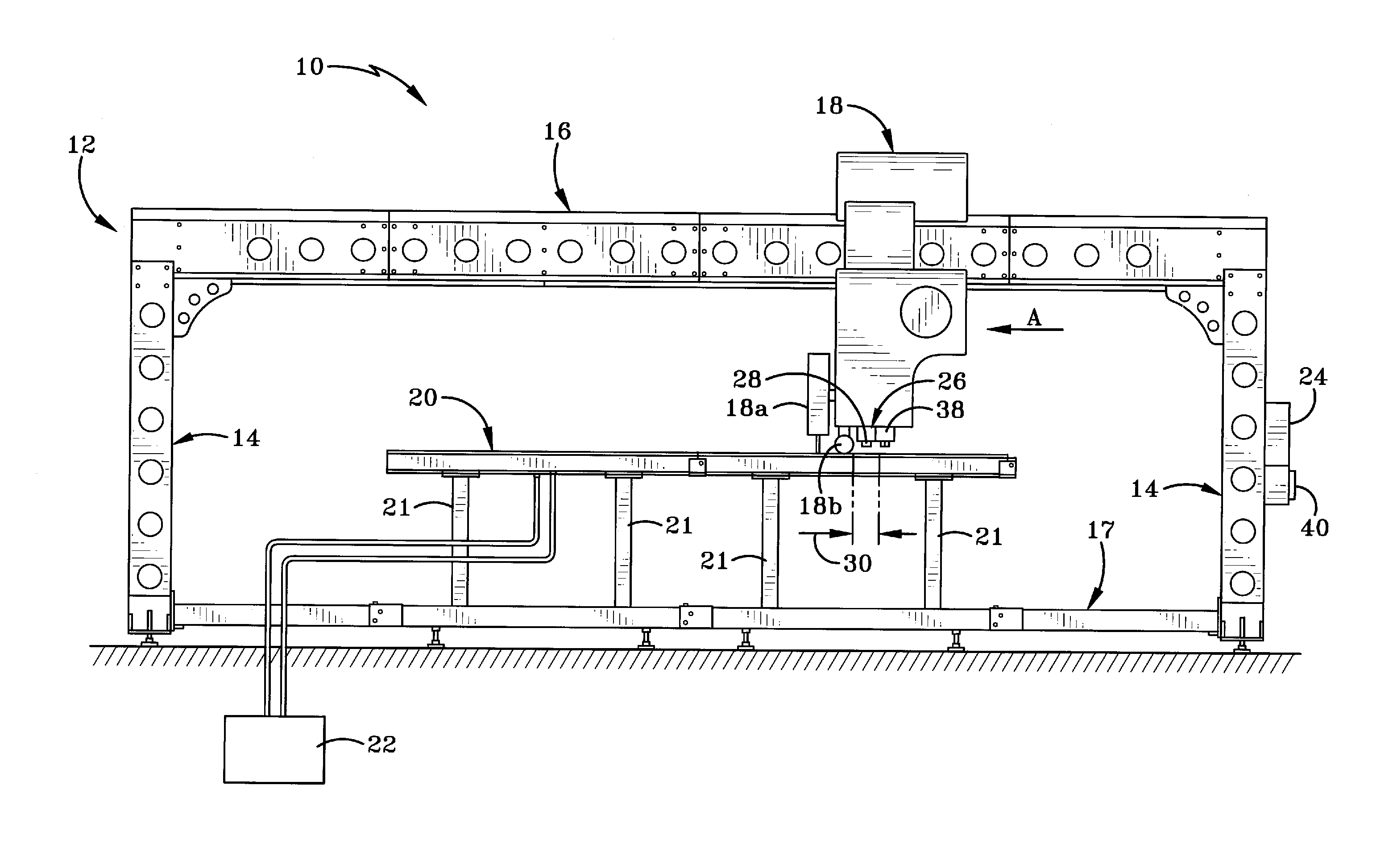

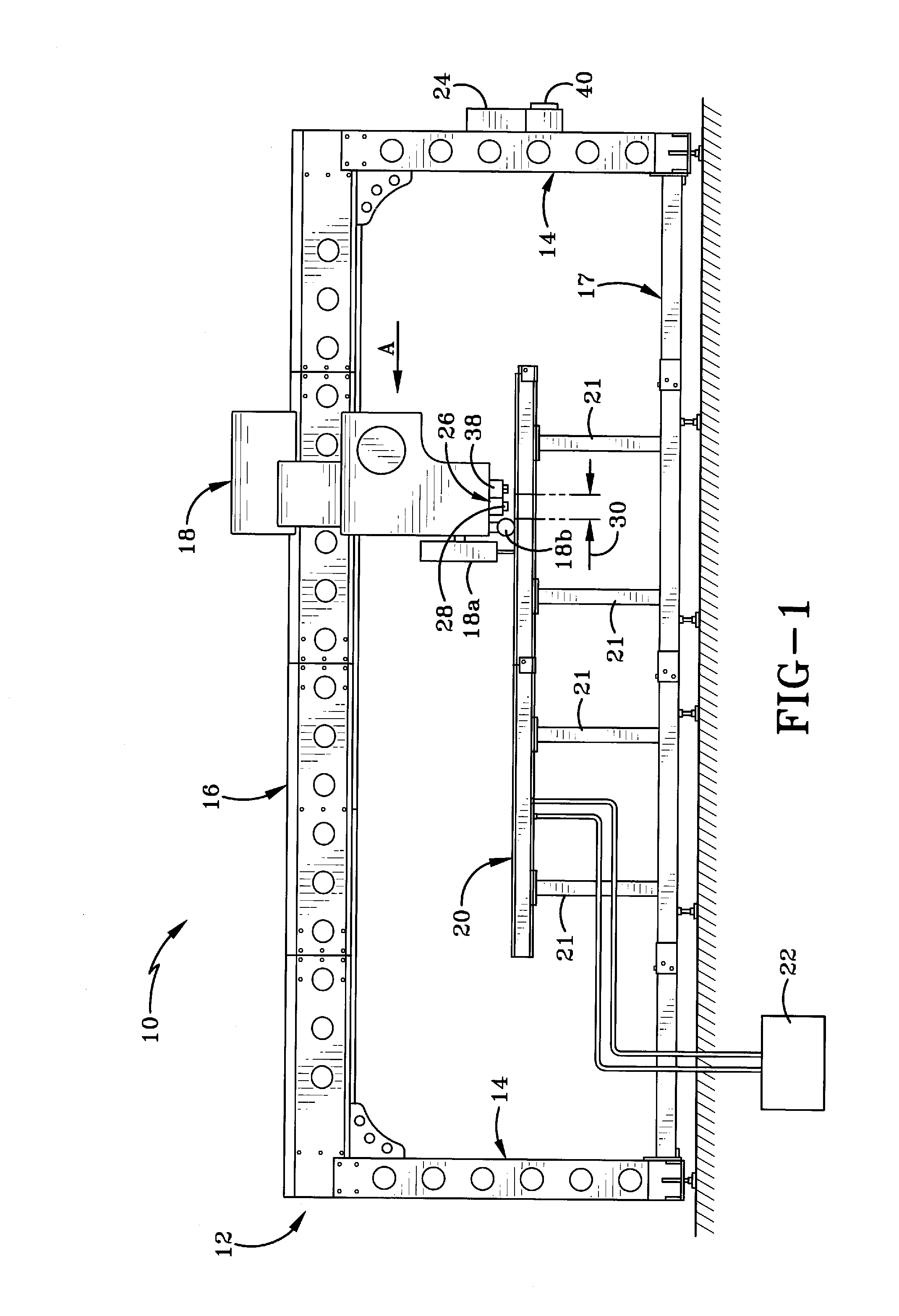

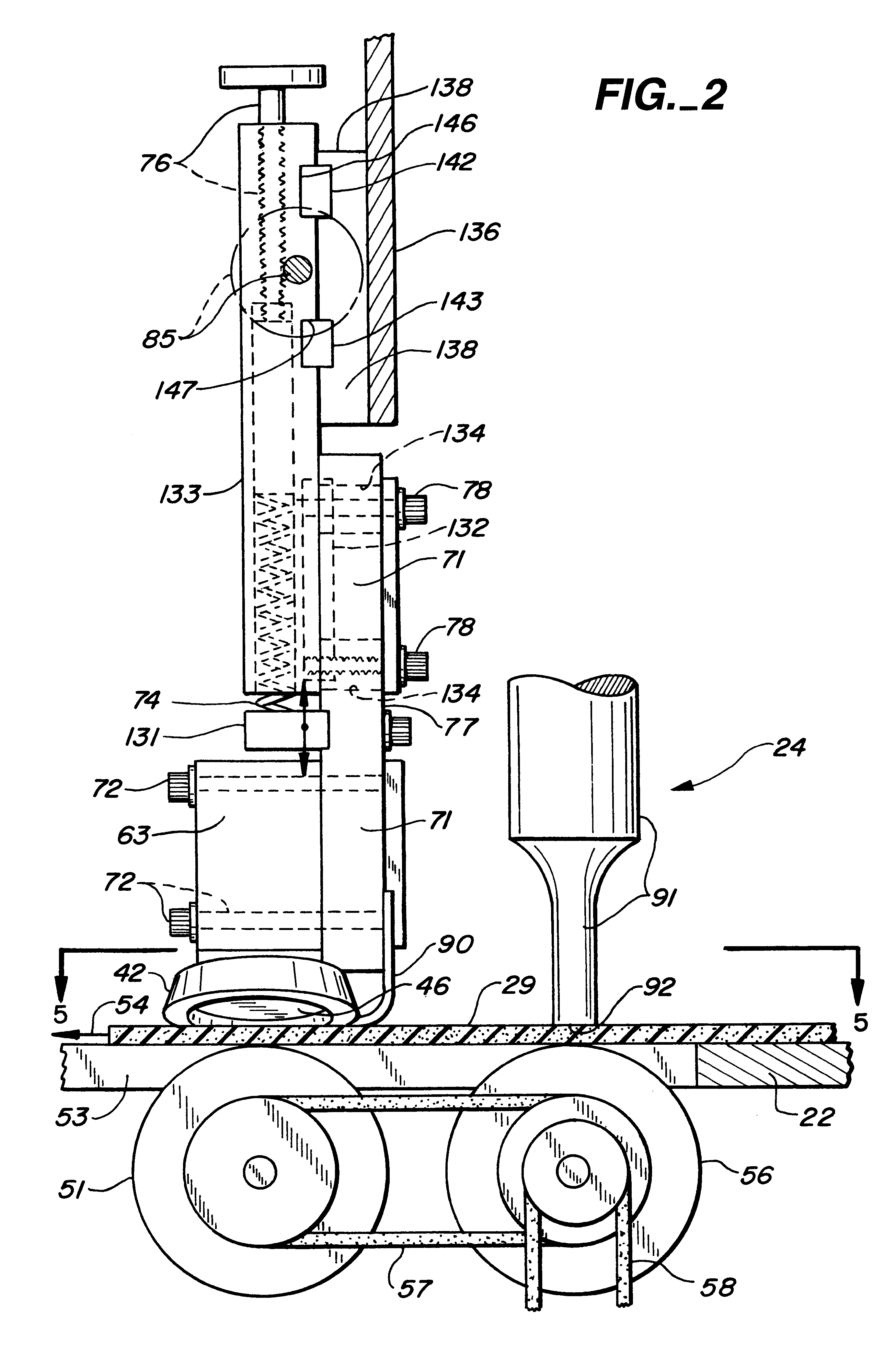

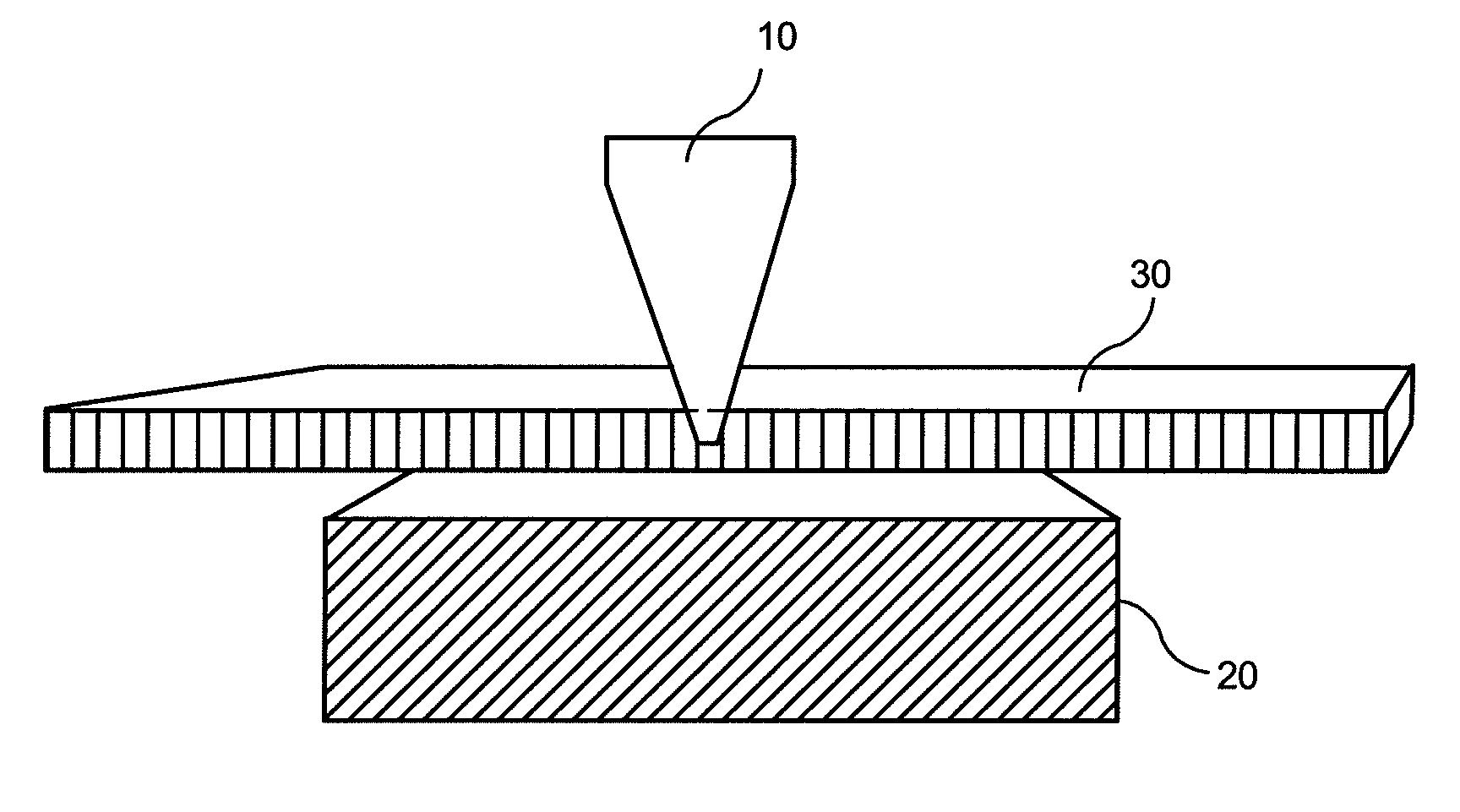

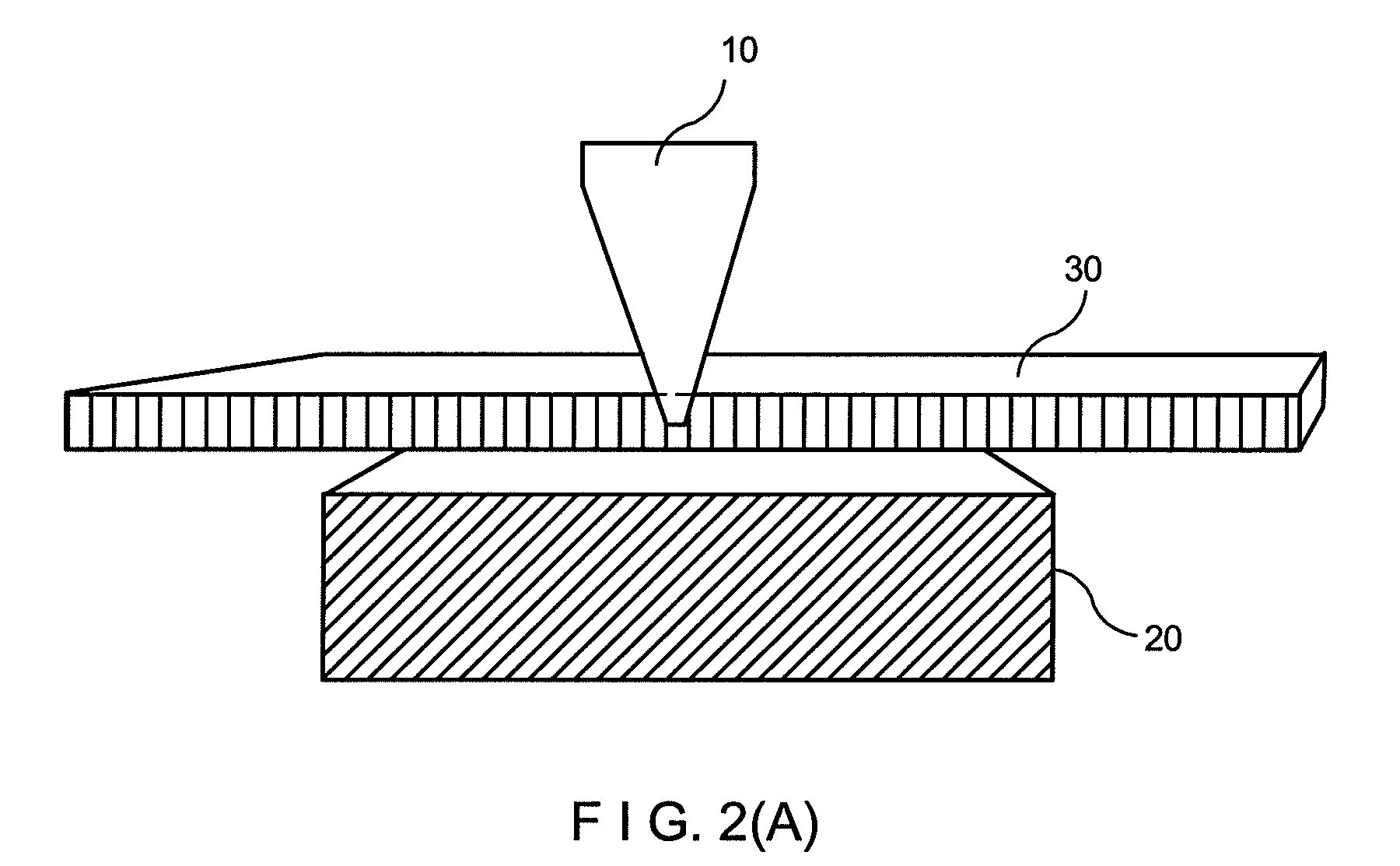

Method and apparatus for controlling welding of flexible fabrics

InactiveUS20140124125A1Improve integrityMechanical working/deformationControlling laminationEngineeringWeld seam

A machine and method for welding first and second fabric panels together. The machine includes a welding head which travels along a frame, applying heat and pressure to an overlapped region of the panels. An infrared camera is positioned to monitor the seam temperature after formation. The camera takes a thermal image across the width of the seam and transmits the data to a central processing unit (CPU). Programming in the CPU compares the thermal image data with a pre-programmed ideal temperature profile. Based on the comparison, the CPU makes adjustments to one or more of the speed of travel of the welding head, and the heat and pressure applied by the welding head, if necessary. The CPU activates an alarm to alert the machine operator if the adjustments aren't successful. The machine further includes a marking assembly for identifying regions on the welded seam which may require post-production testing.

Owner:MILLER WELDMASTER CORP

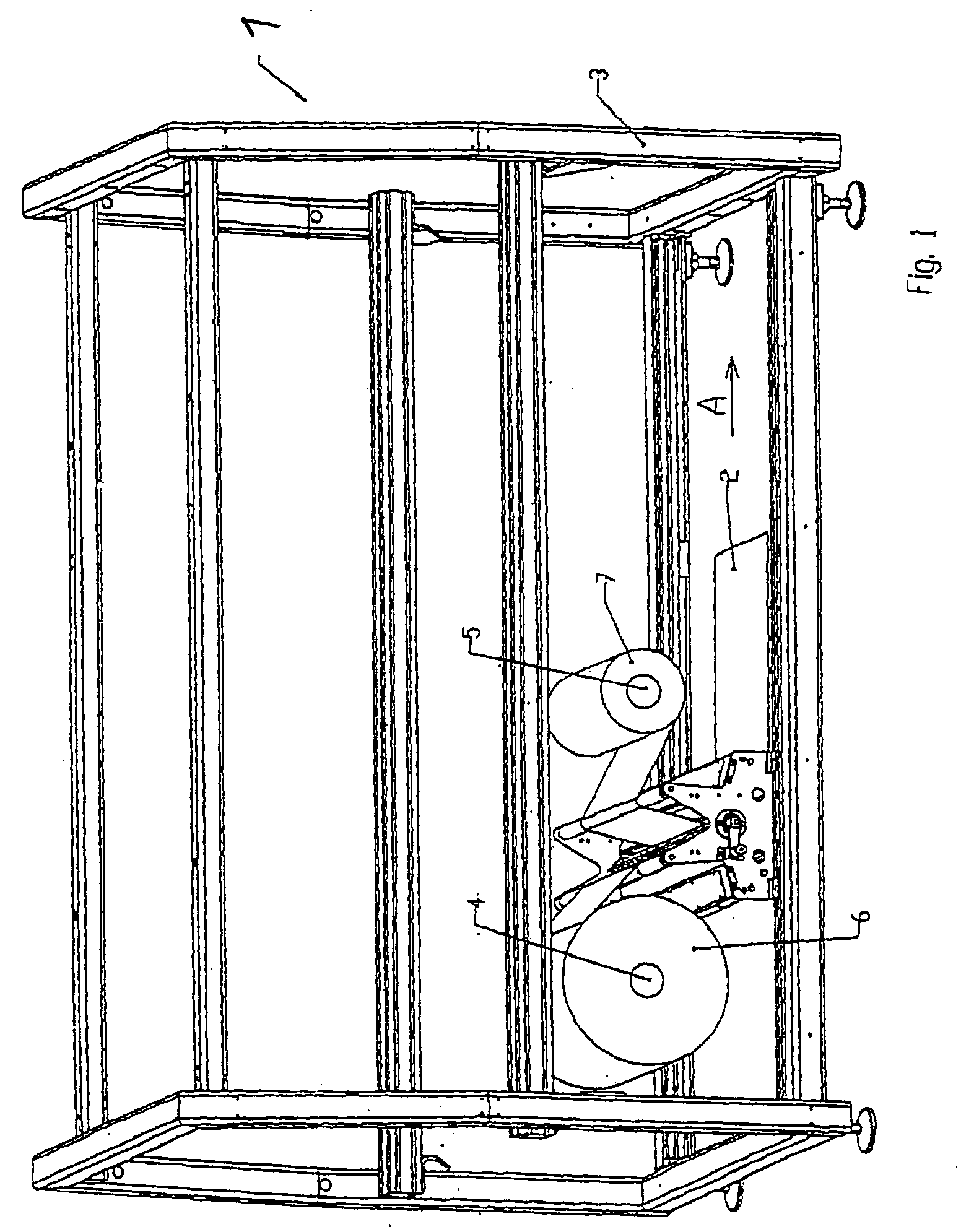

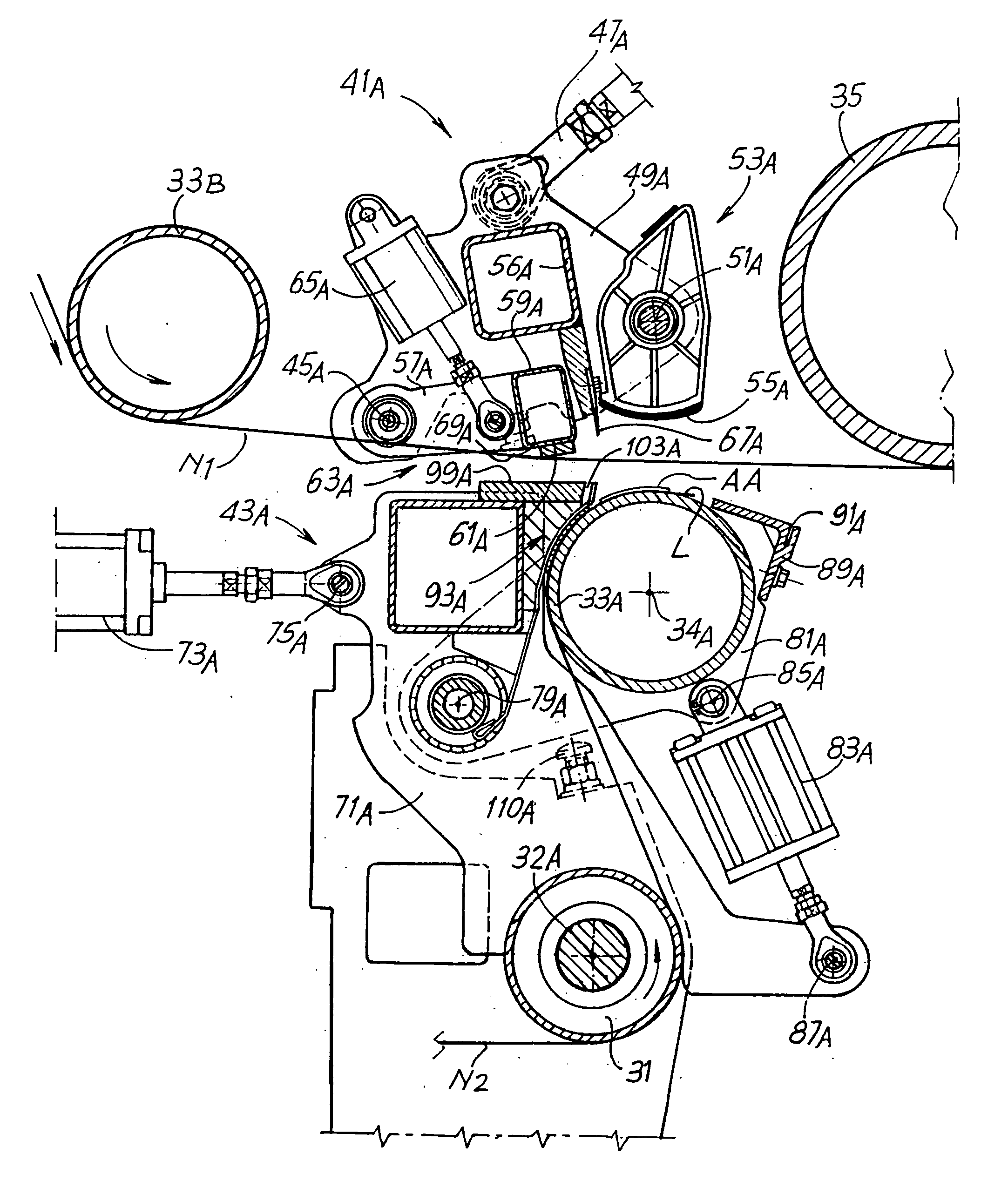

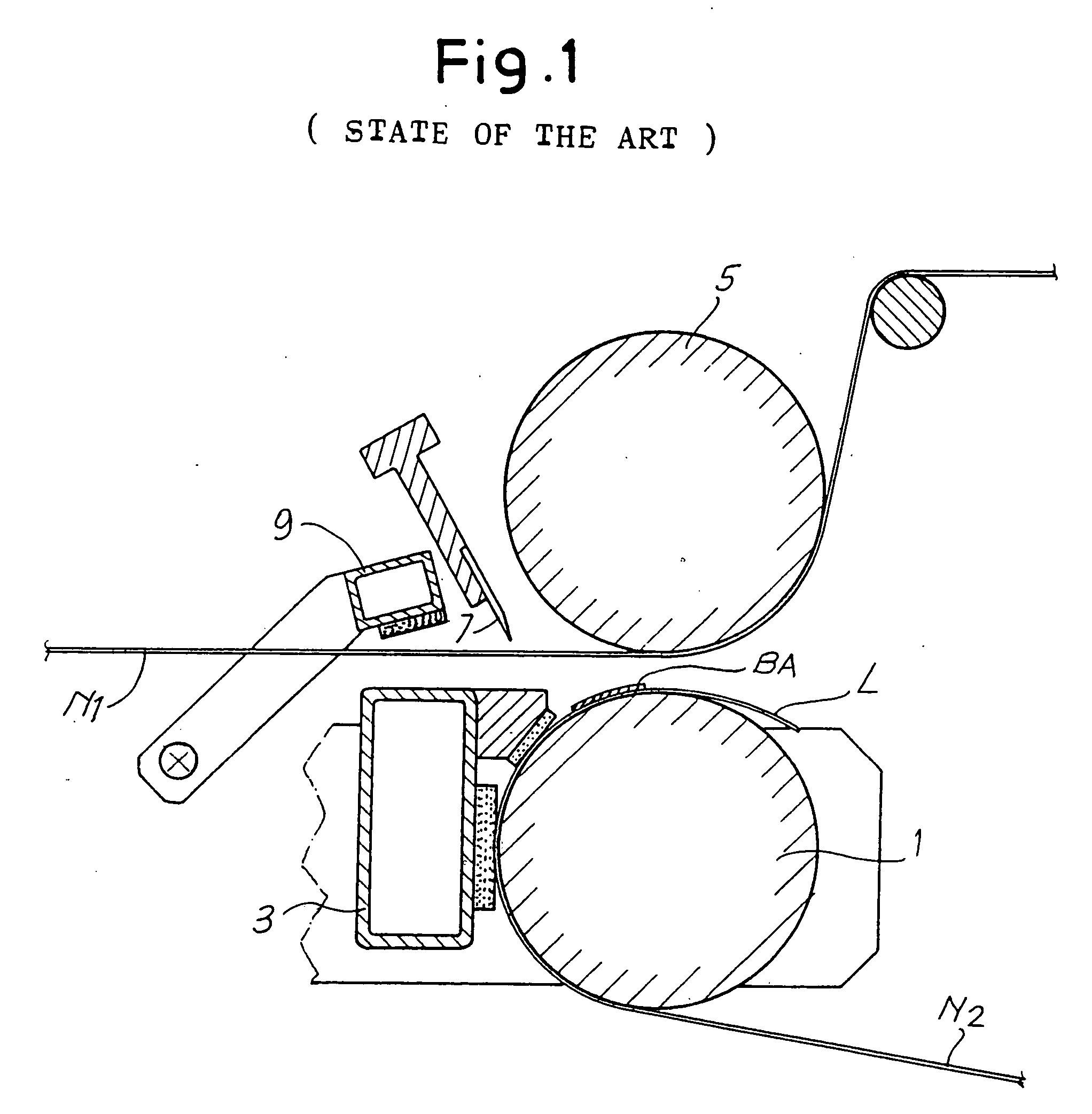

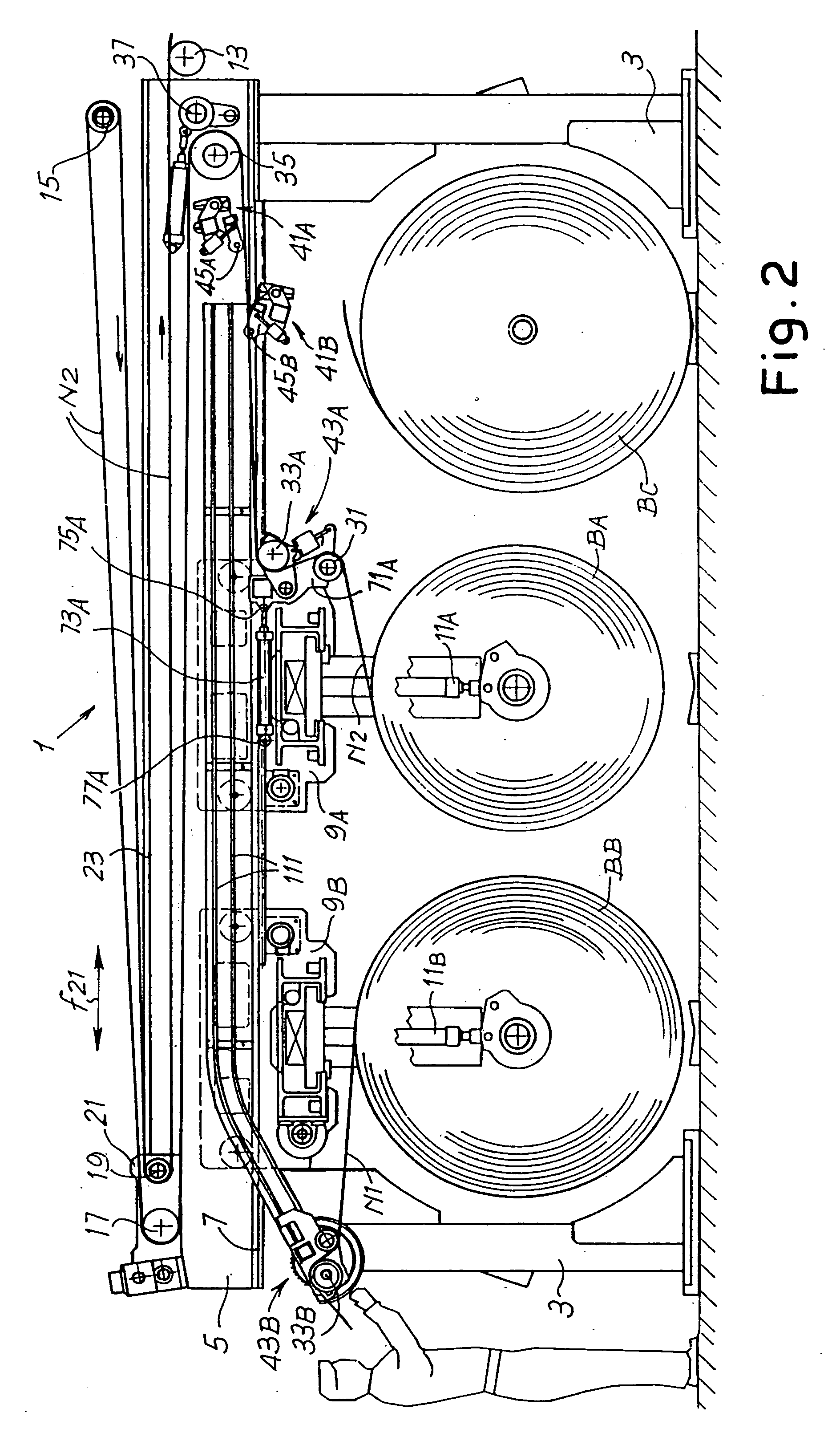

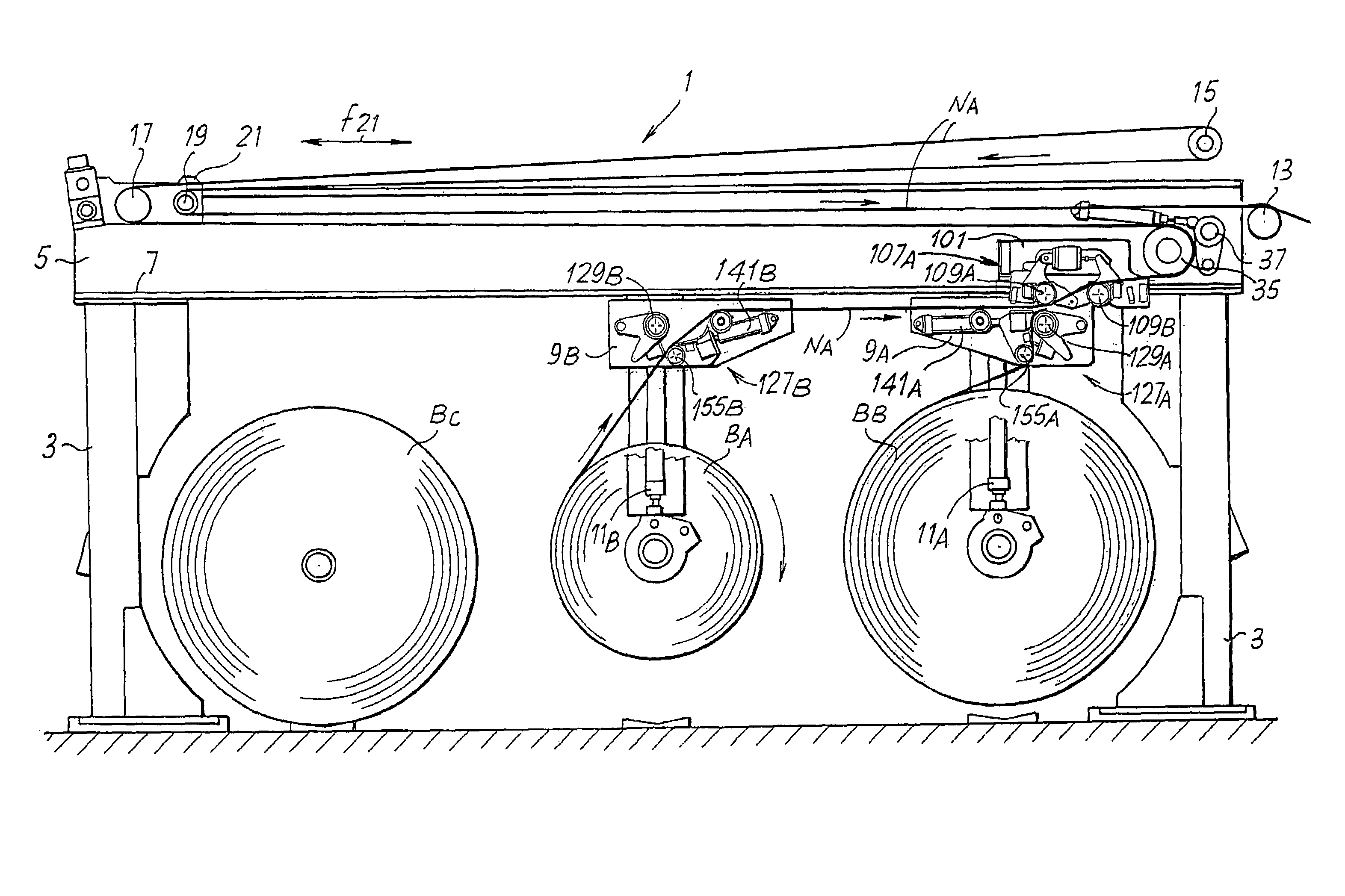

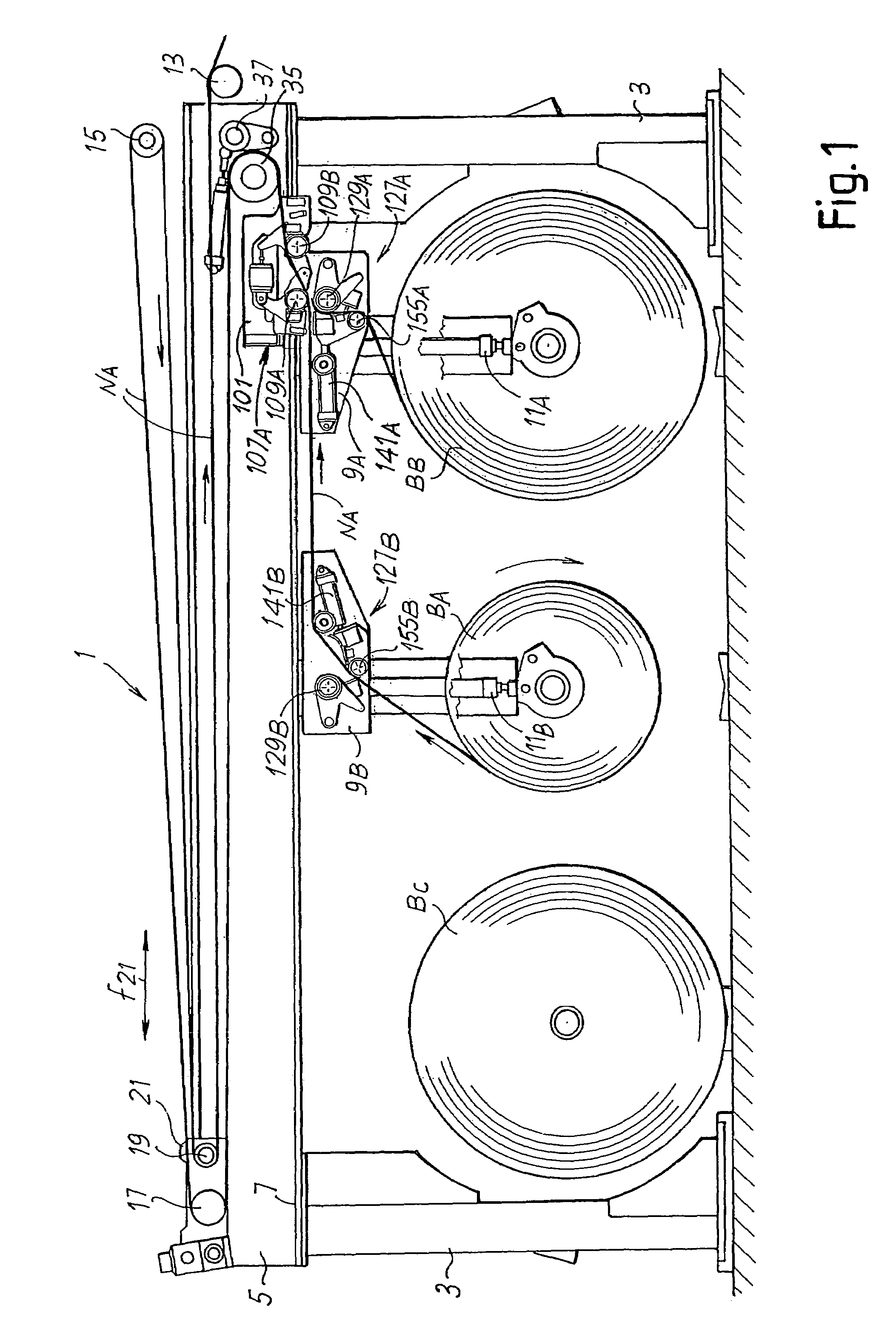

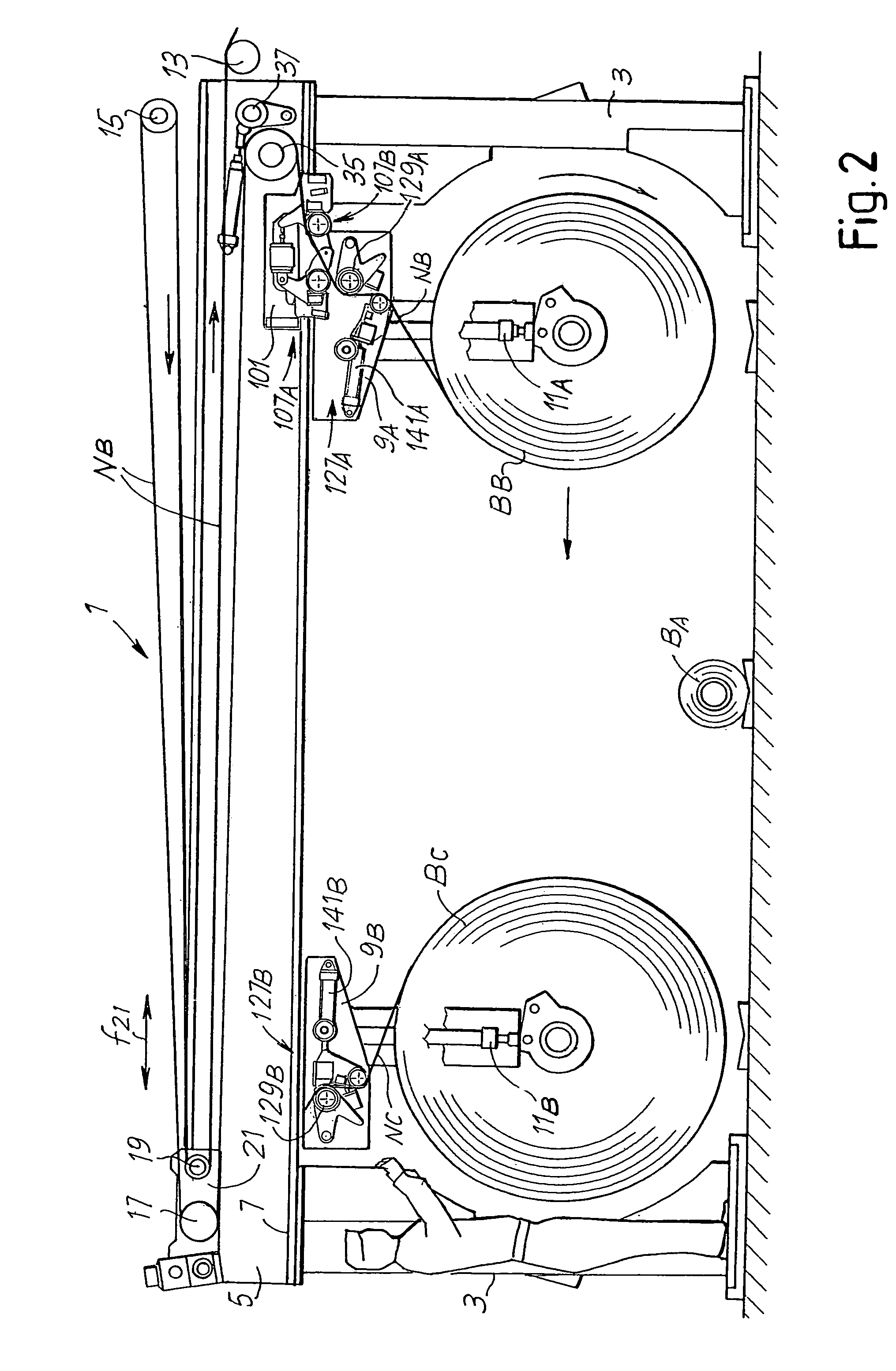

Splicing device for splicing two web materials together, unwinder comprising said slicing device and relative method

InactiveUS20040084133A1Easy constructionFast and reliableMechanical working/deformationFilament handlingCounter pressureEngineering

The splicing device comprises two heads (41A, 43A; 41B, 43B), each of which has: a roller (33A; 33B) associated with a clamping bar (93A; 93B) to hold between said roller and said clamping bar an initial edge (L) of the second web material; a counter-pressure member (53A; 53B) cooperating with said roller to press said first and second web materials against each other; and a cutting member (67A; 67B).

Owner:FOSBER

Splicing device to join together two web materials, unwinding device comprising said splicing device

Owner:FOSBER

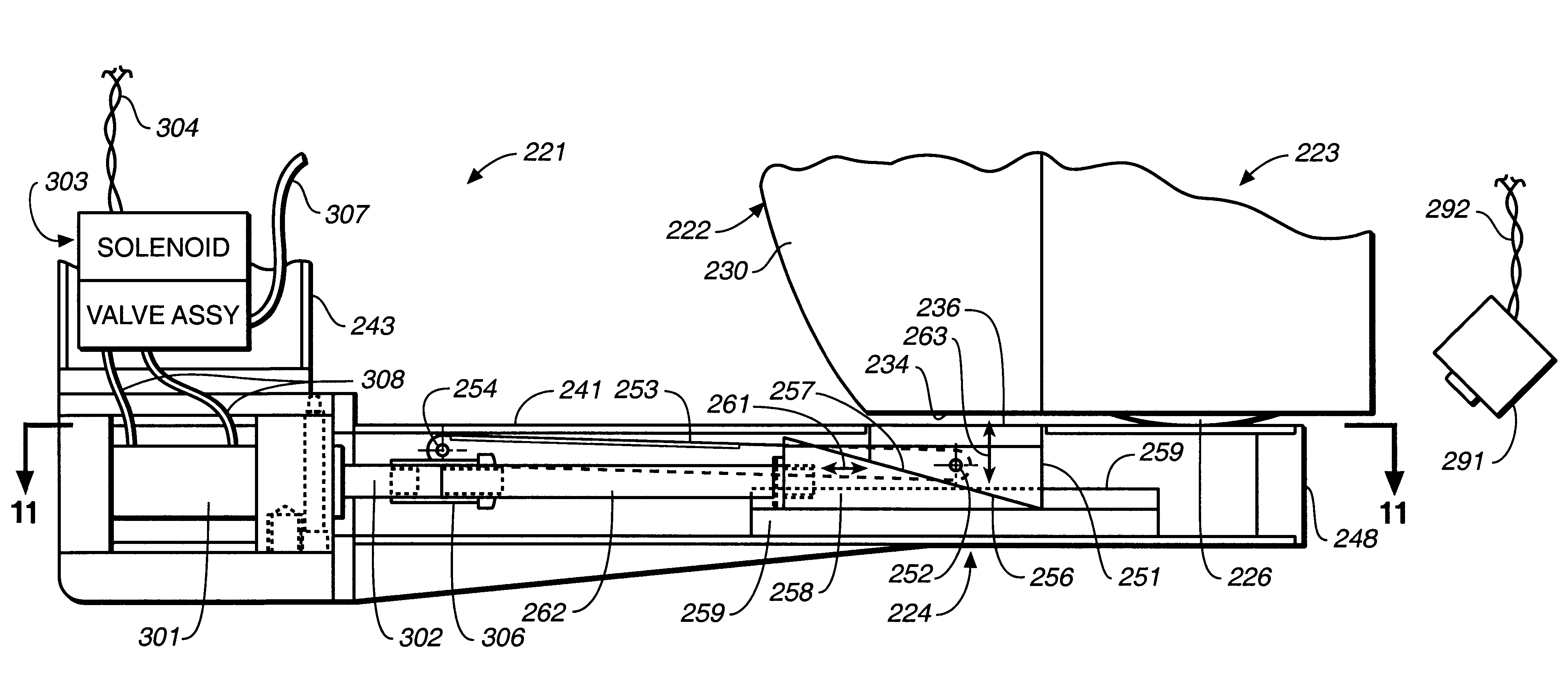

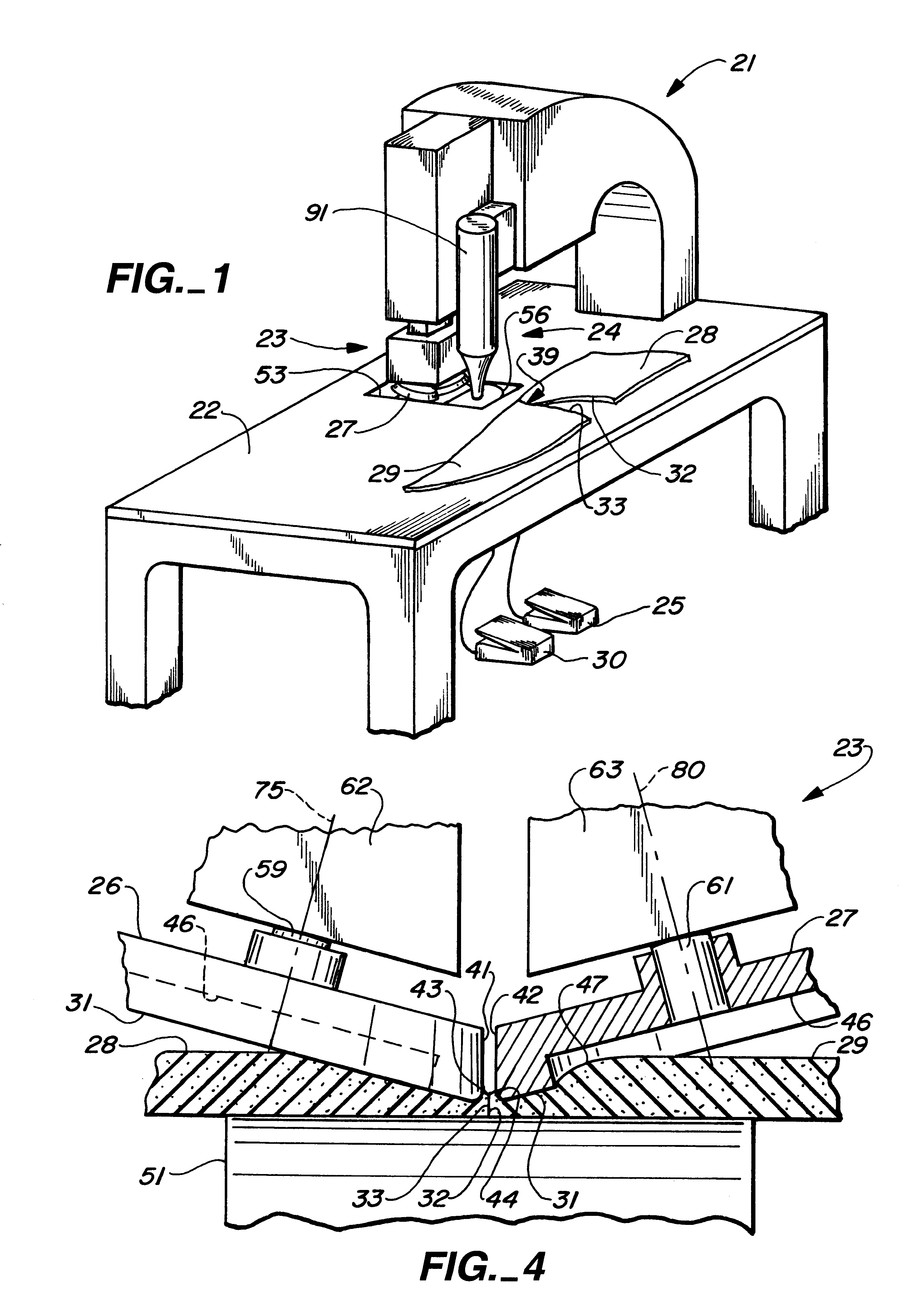

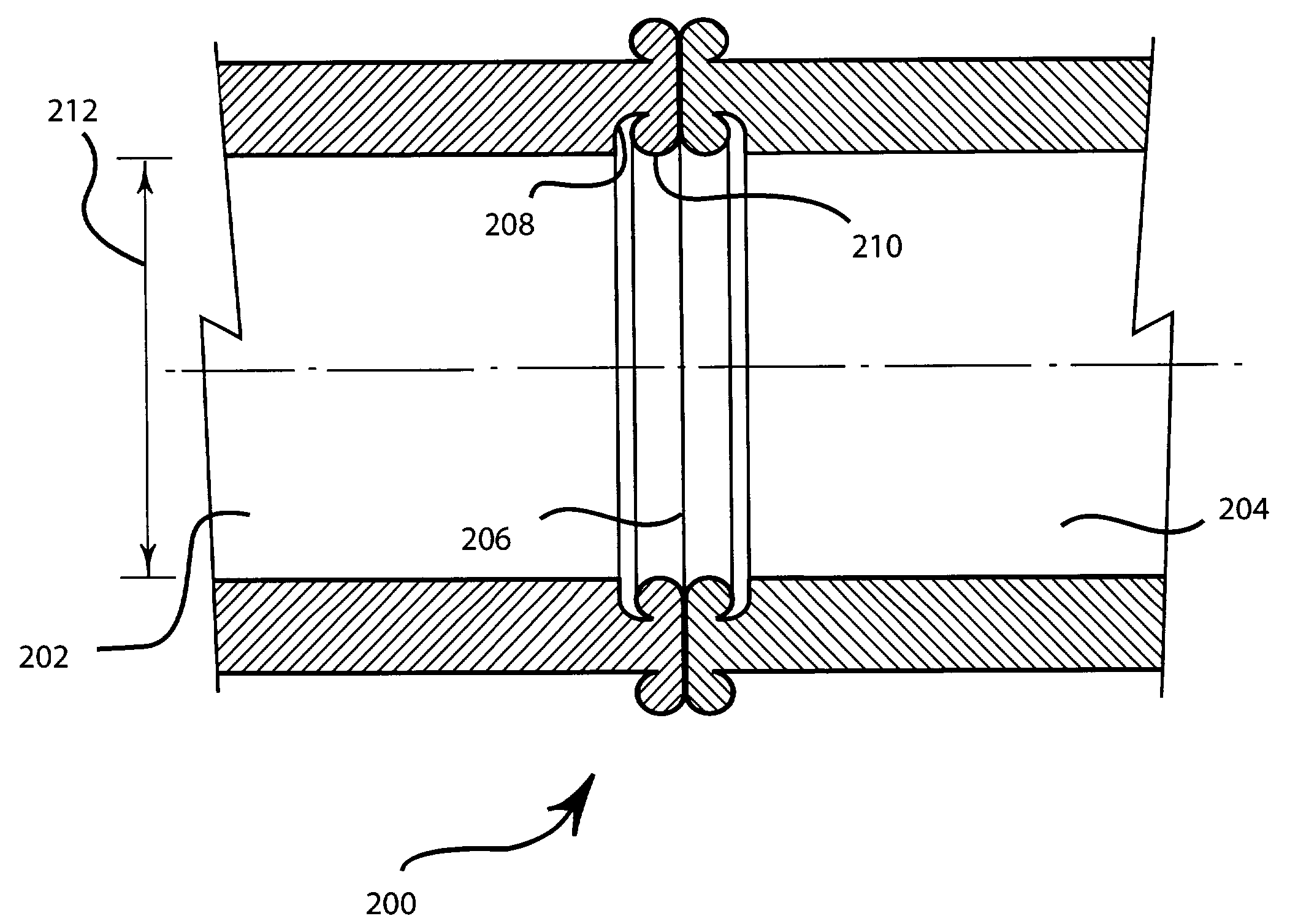

Apparatus and method for forming an adhesively bonded seam between resiliently compressible fabric sheets

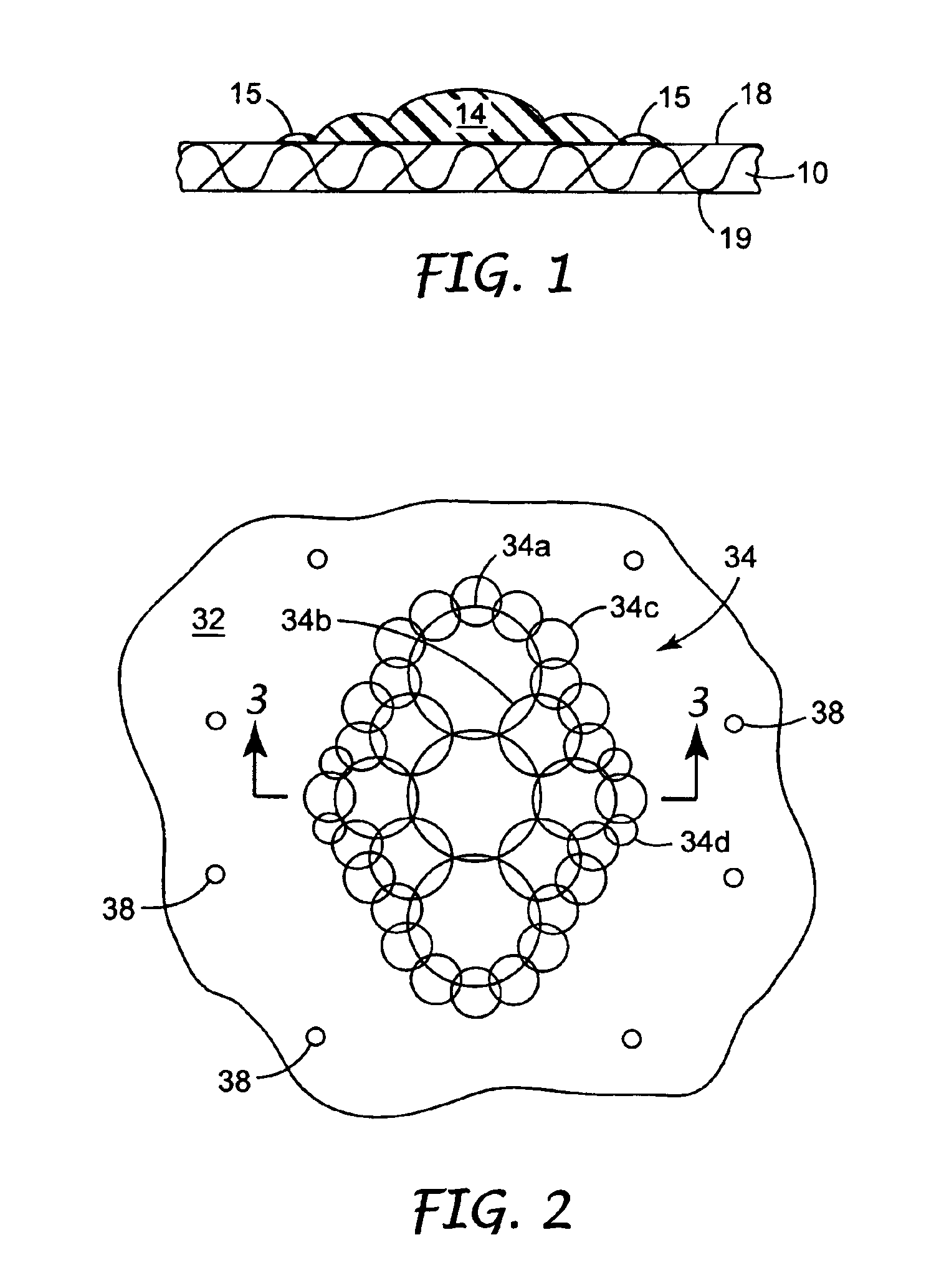

InactiveUS6375770B1Sufficient sonic energyRaise transfer toMechanical working/deformationGarmentsUltrasonic sensorEnergy coupling

An apparatus (21, 221, 231) for forming a butt seam (33, 233, 354) between opposed edges (32, 33, 231, 232) of resiliently compressible, fully cured, elastomeric, fabric sheets (28, 29, 228, 229, 351, 352), such as foamed neoprene for wet suits and dry suits. In some embodiments (21, 221) the apparatus includes fabric manipulating assembly (23, 223) which continuously compresses the sheets proximate and inwardly of the edges, preferably by a roller assembly (26, 27, 226, 227), to firmly press the opposed edges of the flexible and compressible sheets (28, 29, 228, 229) tightly together during movement and bonding along the seam (33, 233). The apparatus (21, 221, 331) preferably includes adhesive activation device in the form of an ultrasonic transducer (24, 222, 322) which contacts the neoprene pieces to activate a dry neoprene cement carried on the edges of the fabric pieces. Embodiments (221, 321) are shown which include a force applying assembly (224, 324) that hammers the foam pieces against the ultrasonic transducer horn (222), or the horn (322) against the foam pieces, to enhance sonic energy coupling and to simultaneously press the pieces together for improved adhesive bonding. A method for forming the butt seam (33, 233, 354) is described.

Owner:O'NEILL

Polymer adhesive splicing of water-soluble, orally ingestible thin film webs

InactiveUS20060207721A1Mechanical working/deformationAdhesive processes with surface pretreatmentPolymer adhesiveWater soluble

A method is provided to splice and / or repair films. The method comprises: a) applying a splicing composition to a first water-soluble, orally-ingestible film, a second water-soluble, orally-ingestible film or to both films; b) overlapping the first water-soluble, orally-ingestible film on the second water-soluble, orally-ingestible film to form a splice between the first water-soluble, orally-ingestible film and the second water-soluble, orally-ingestible film; and c) allowing the splice to dry or cure, wherein the splicing composition comprises at least one animal-consumable solvent and, optionally, at least one orally-ingestible polymer.

Owner:SLOMINSKI GREG +1

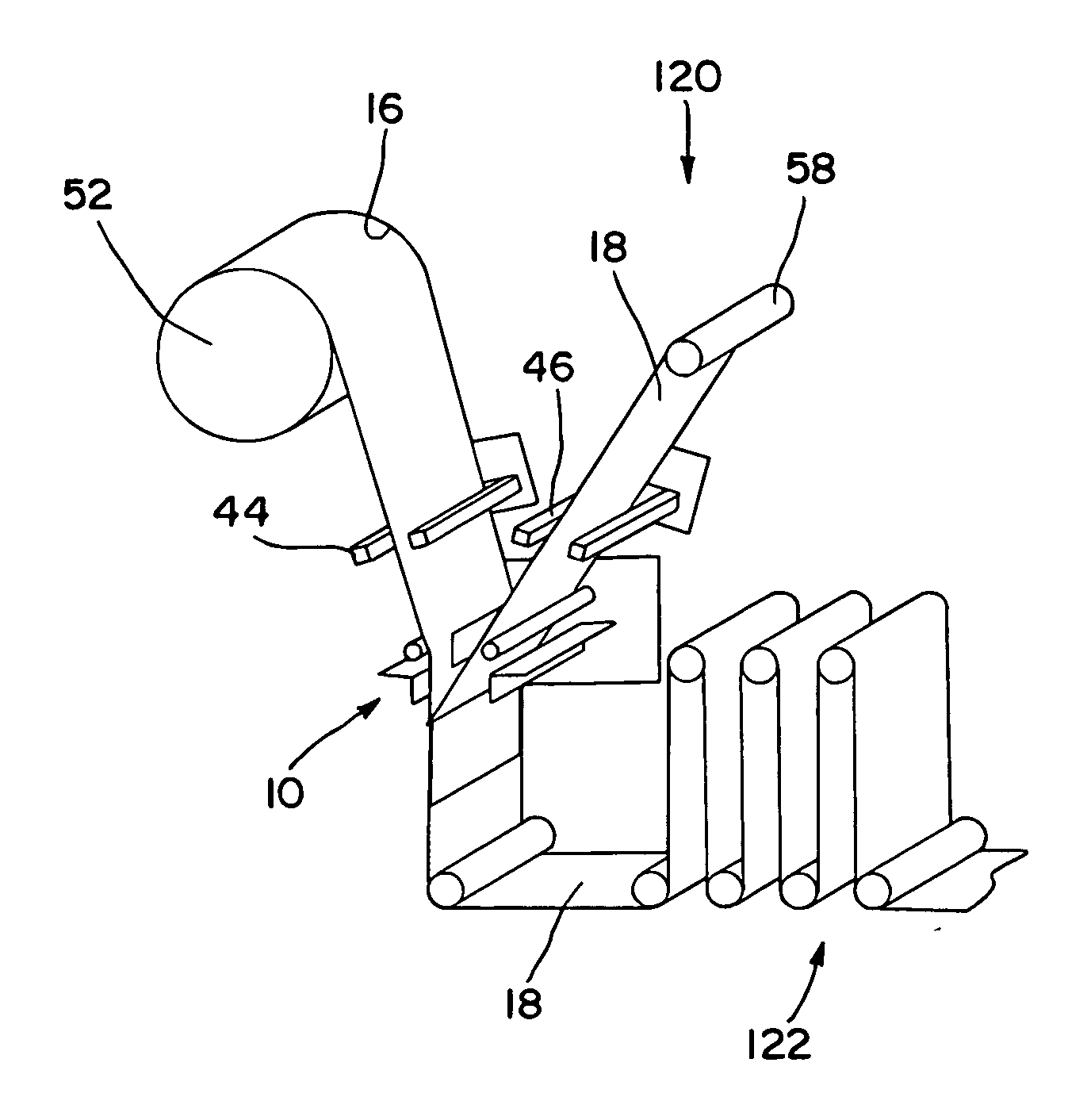

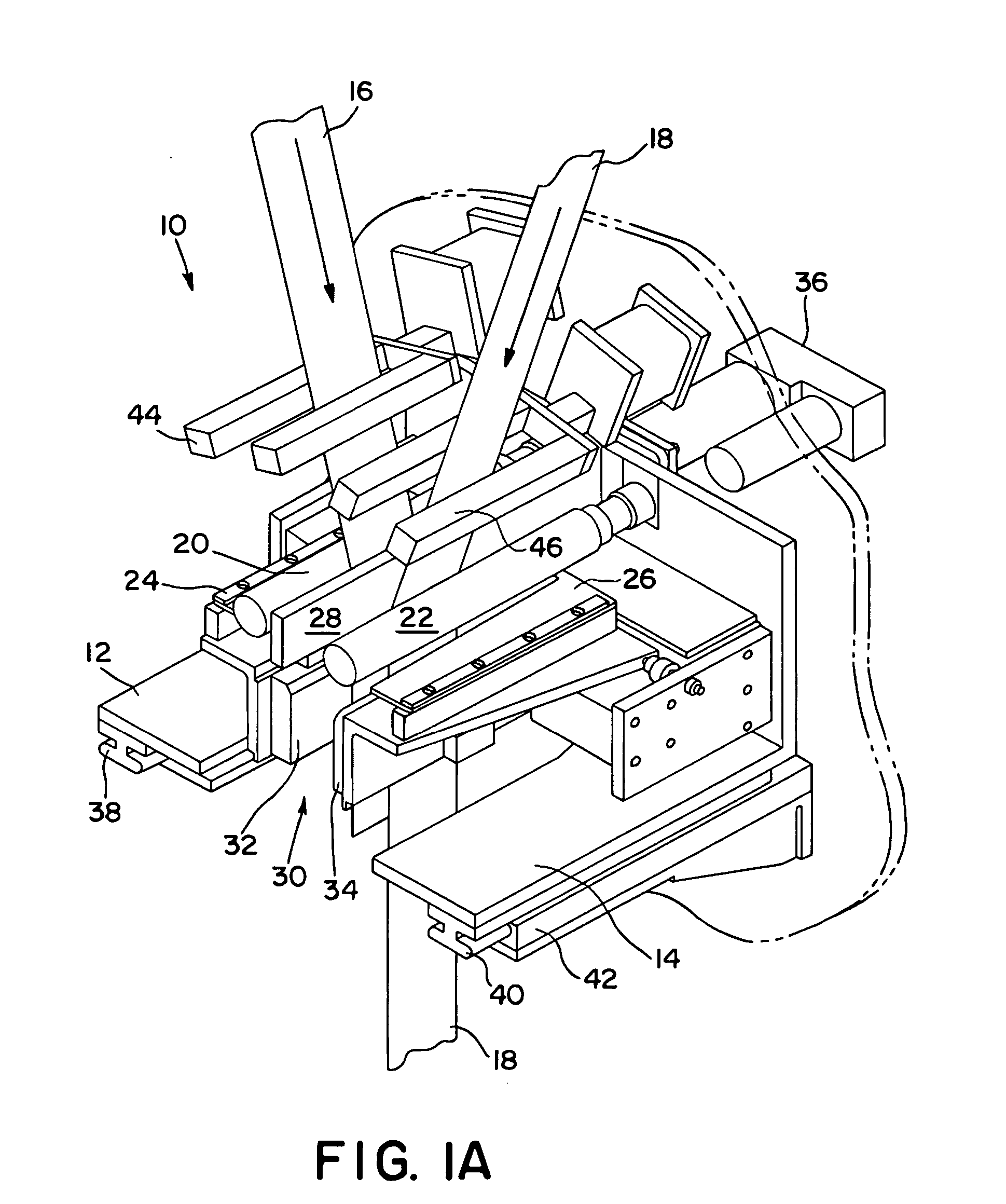

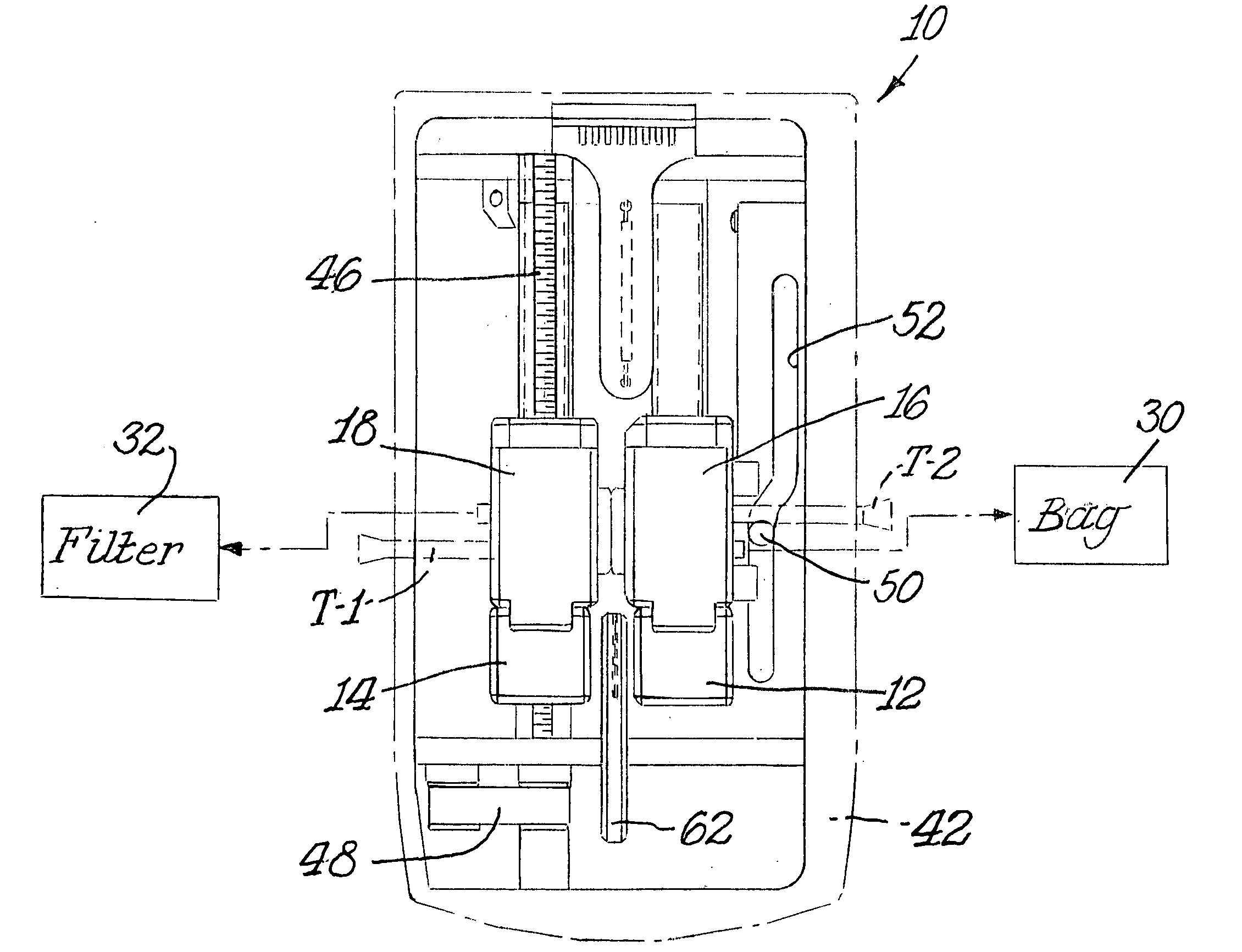

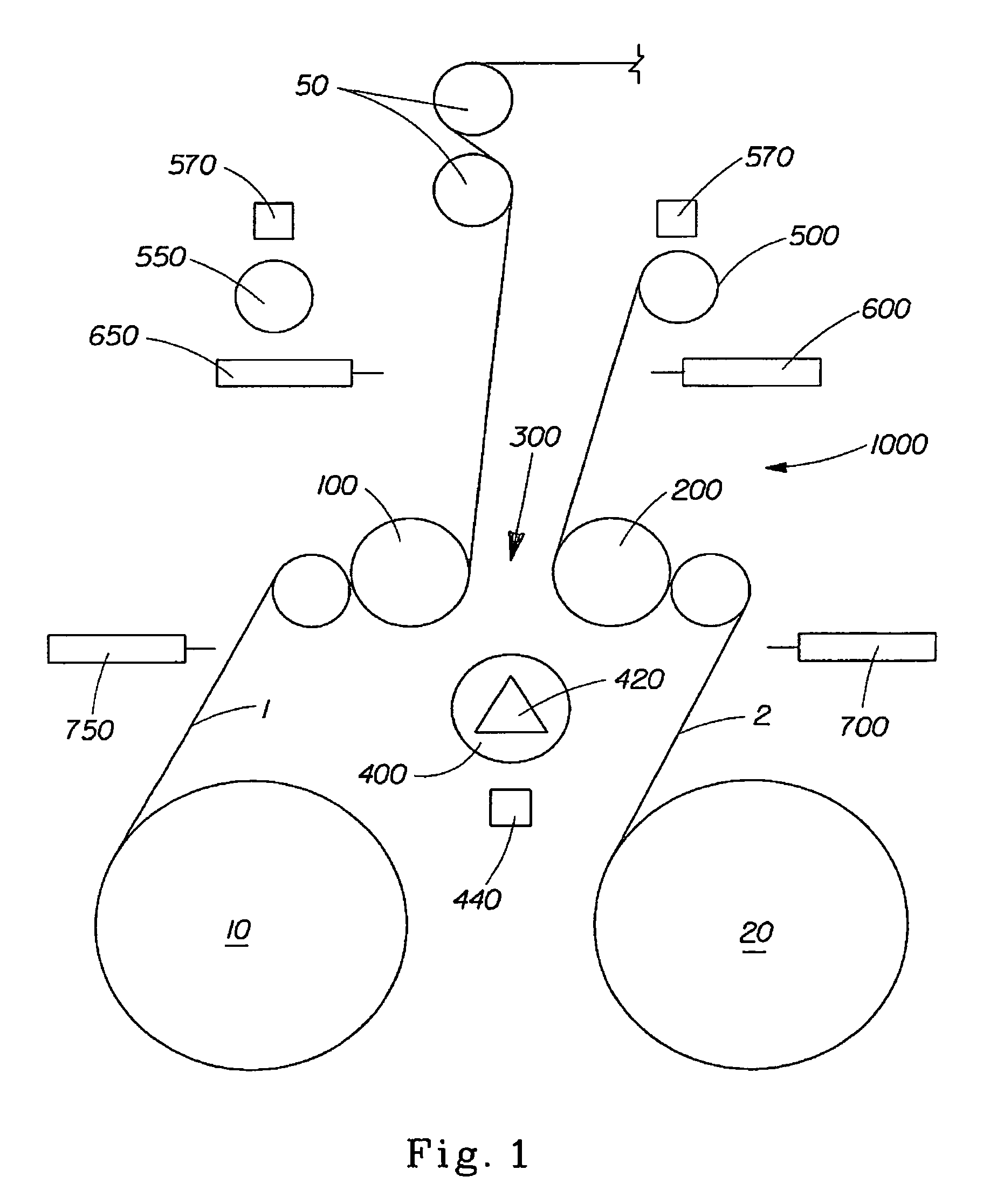

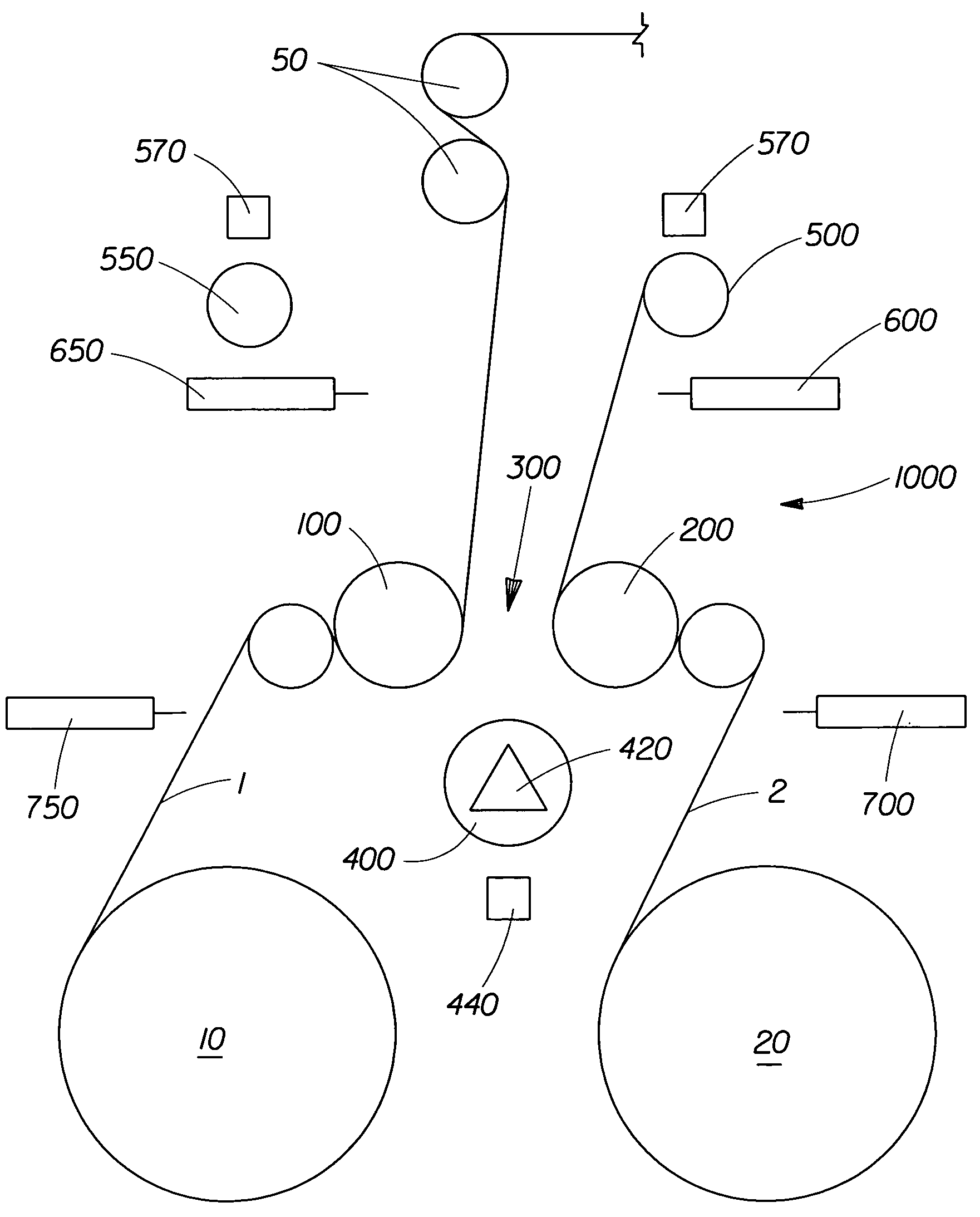

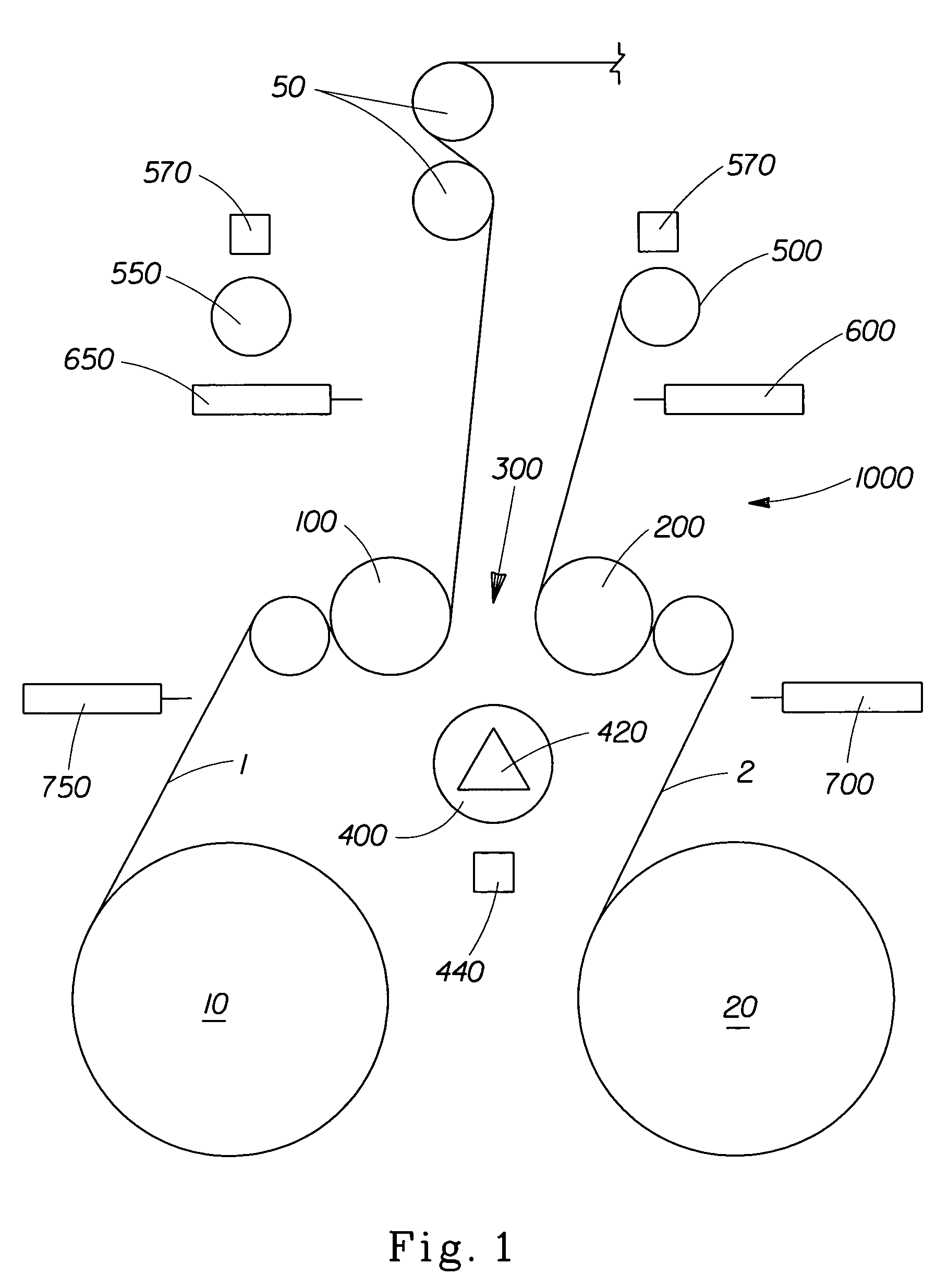

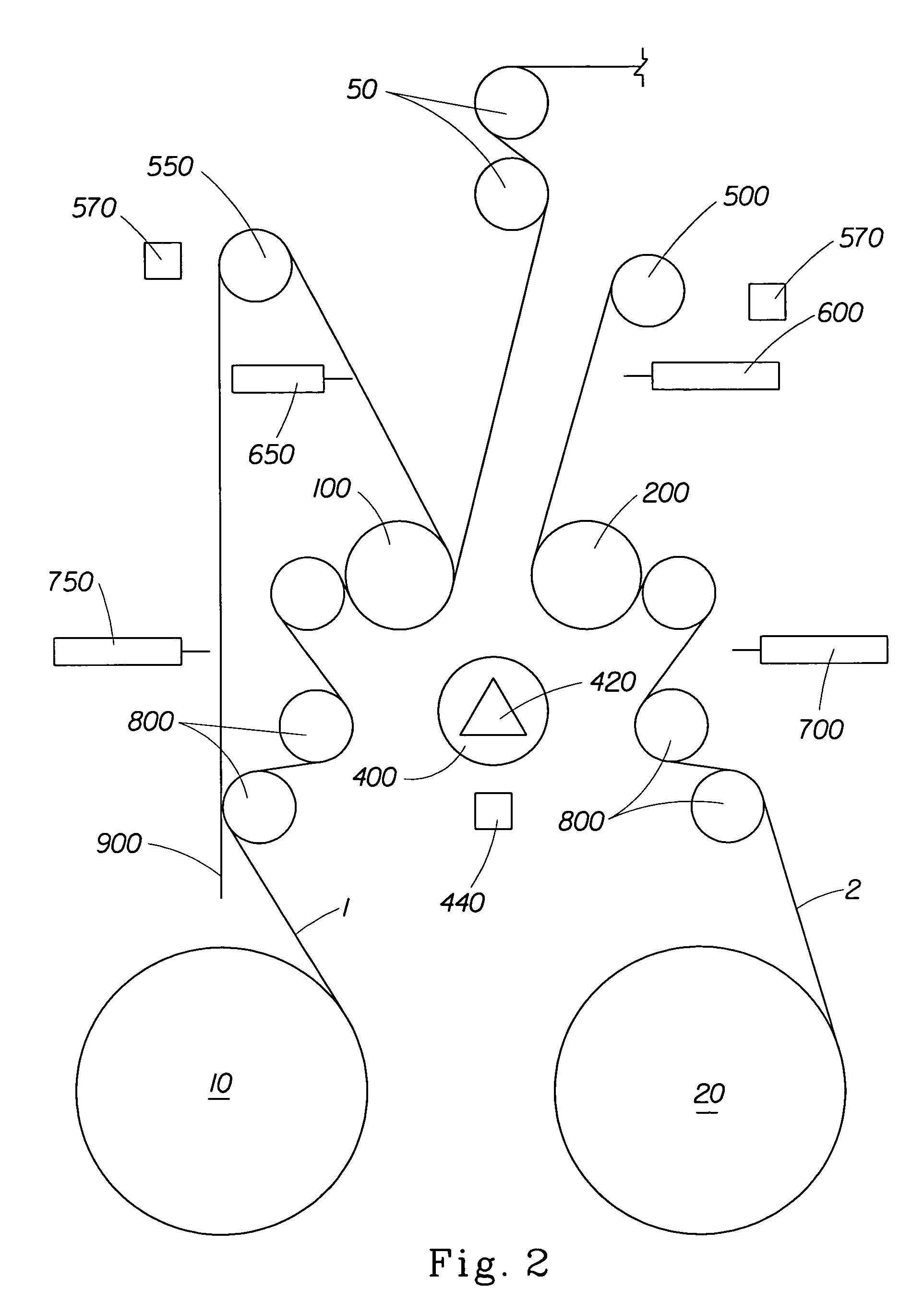

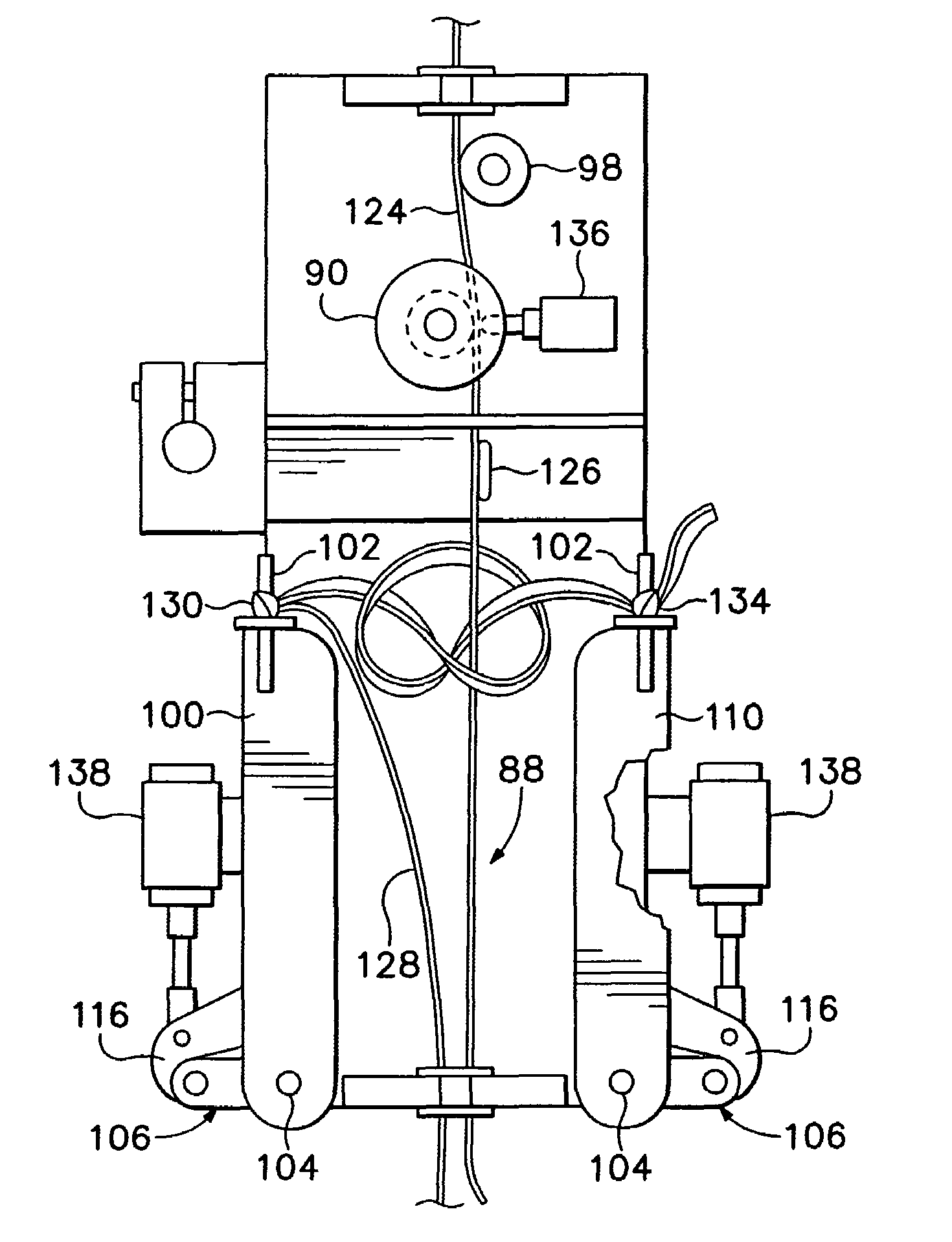

Method and apparatus for splicing a web material

An apparatus and method for splicing web materials. The apparatus comprises a first nip roller, a second nip roller and an adhesive roller. The apparatus further comprises a first wind up roller and a second wind up roller. The apparatus also comprises a pair of infeed web cutting elements, and a pair of outfeed web cutting elements. First and second webs are received from upstream web supplies. One web proceeds downstream and the other is wound on a wind up roller. Adhesive is applied to one web and the two webs together with the adhesive pass between the nip rollers. One web is separated between the upstream supply and the splice and the other is separated between the splice and the wind up roller. The splice may proceed downstream.

Owner:THE PROCTER & GAMBLE COMPANY

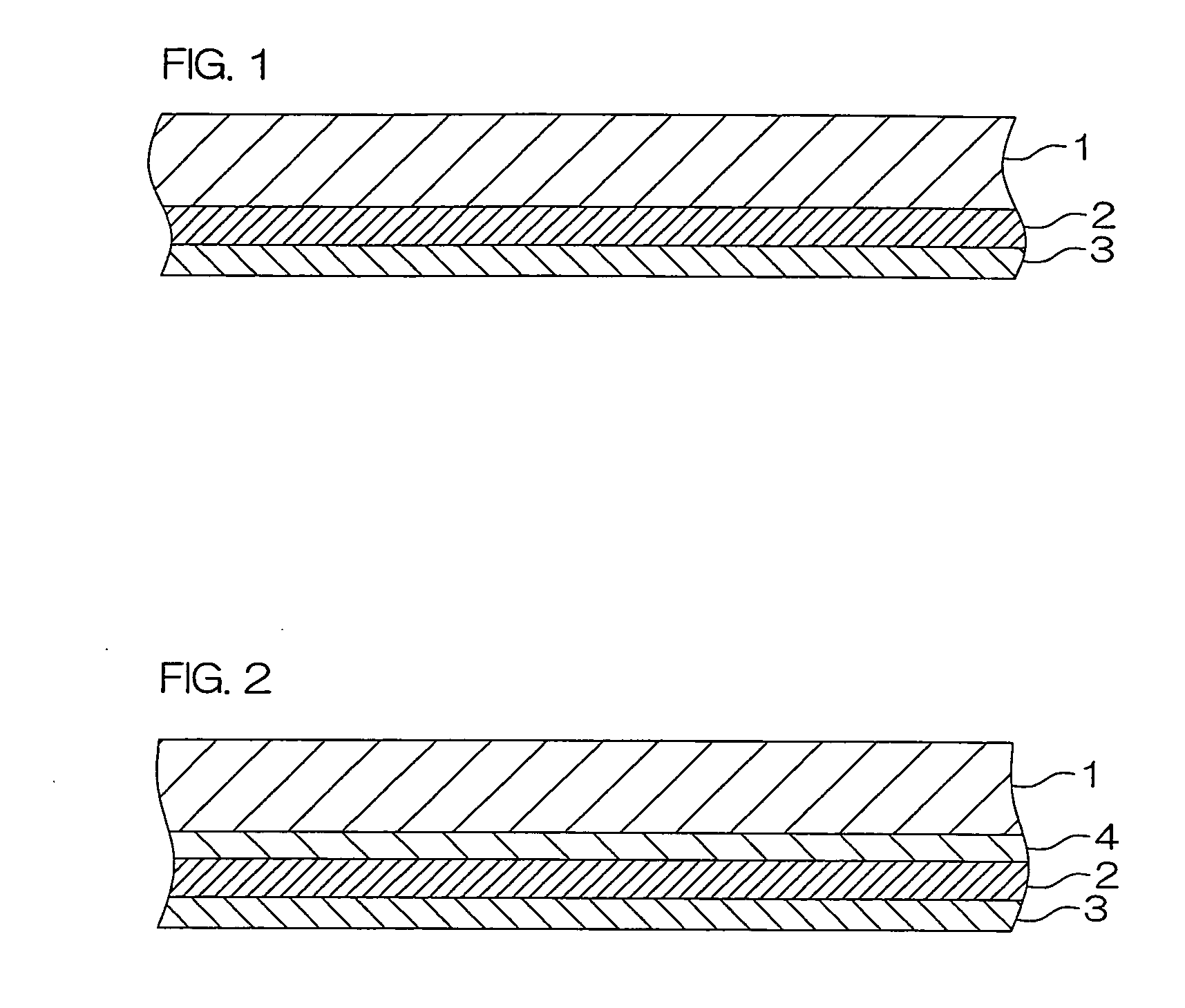

High-speed web-splicing tape and method of use thereof

InactiveUS20030010422A1Avoid damageHigh strengthMechanical working/deformationFilm/foil adhesivesEngineeringMechanical engineering

An adhesive tape for use in high-speed web-splicing which provides for adherence of the loose end of a web reel to the reel before allowing the tape to separate along a specific interface between two non-adhesive layers upon connection to a depleted web. The separation of tape along the specific interface results in the absence of any exposed adhesive surfaces.

Owner:SPECIALITY TAPES DIV OF RSW

Device for welding plastic tubes

Plastic tubes are welded by first placing the plastic tubes across aligned tube slots in a pair of side by side tube holders. The tubes are clamped to create a fluid free area. The clamps in one of the tube holders are shifted laterally away from the other tube holders to increase the fluid free area of each tube. A cold cutting device cuts through the clamped tubes to create four stub ends. The four stub ends are heated / melted. The stub ends are realigned so that the one stub end in one holder is aligned with the other stub end of the other tube holder and the realigned stub ends are pressed into contact with each other to create a weld seam.

Owner:GENESIS BPS

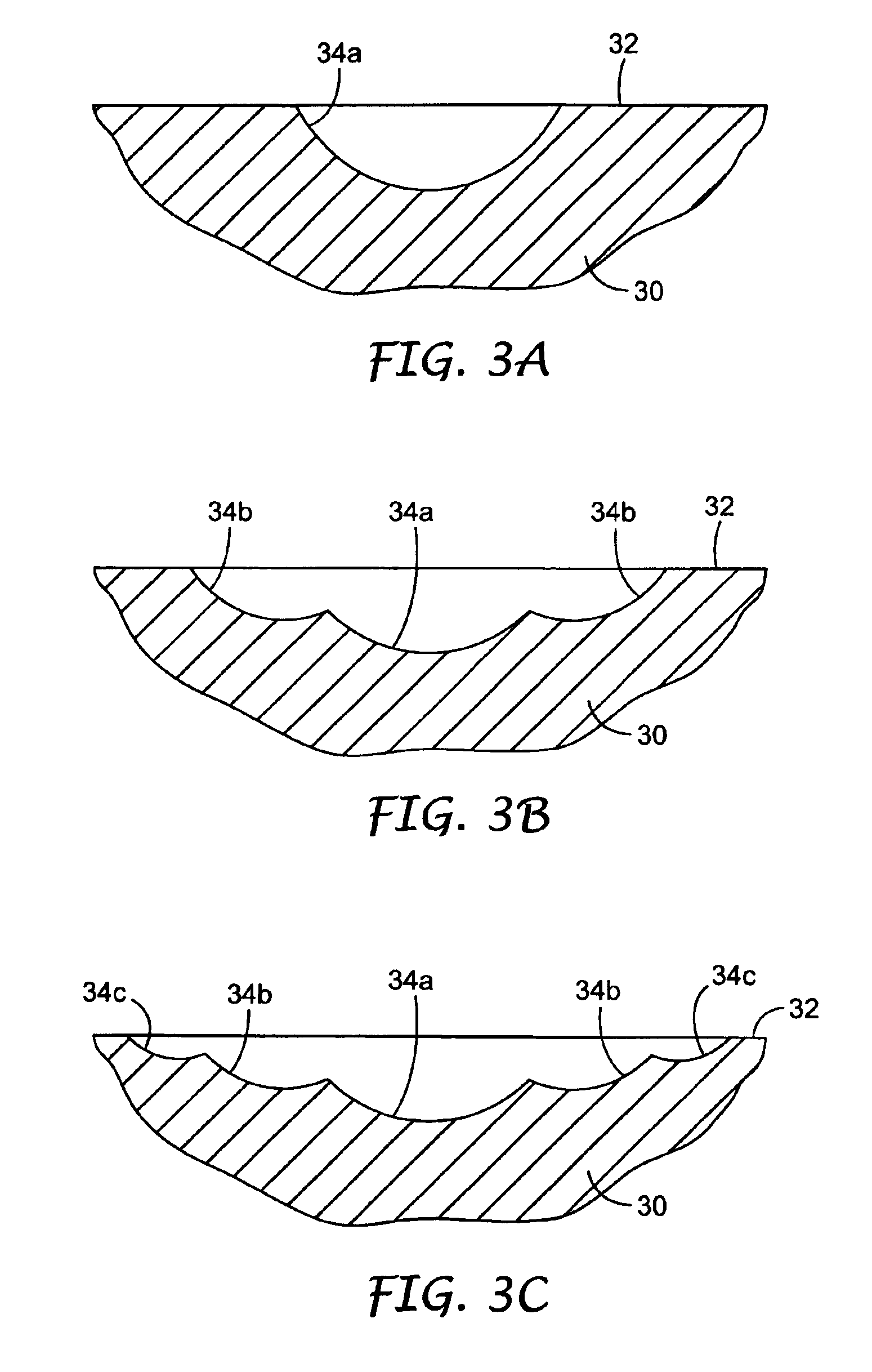

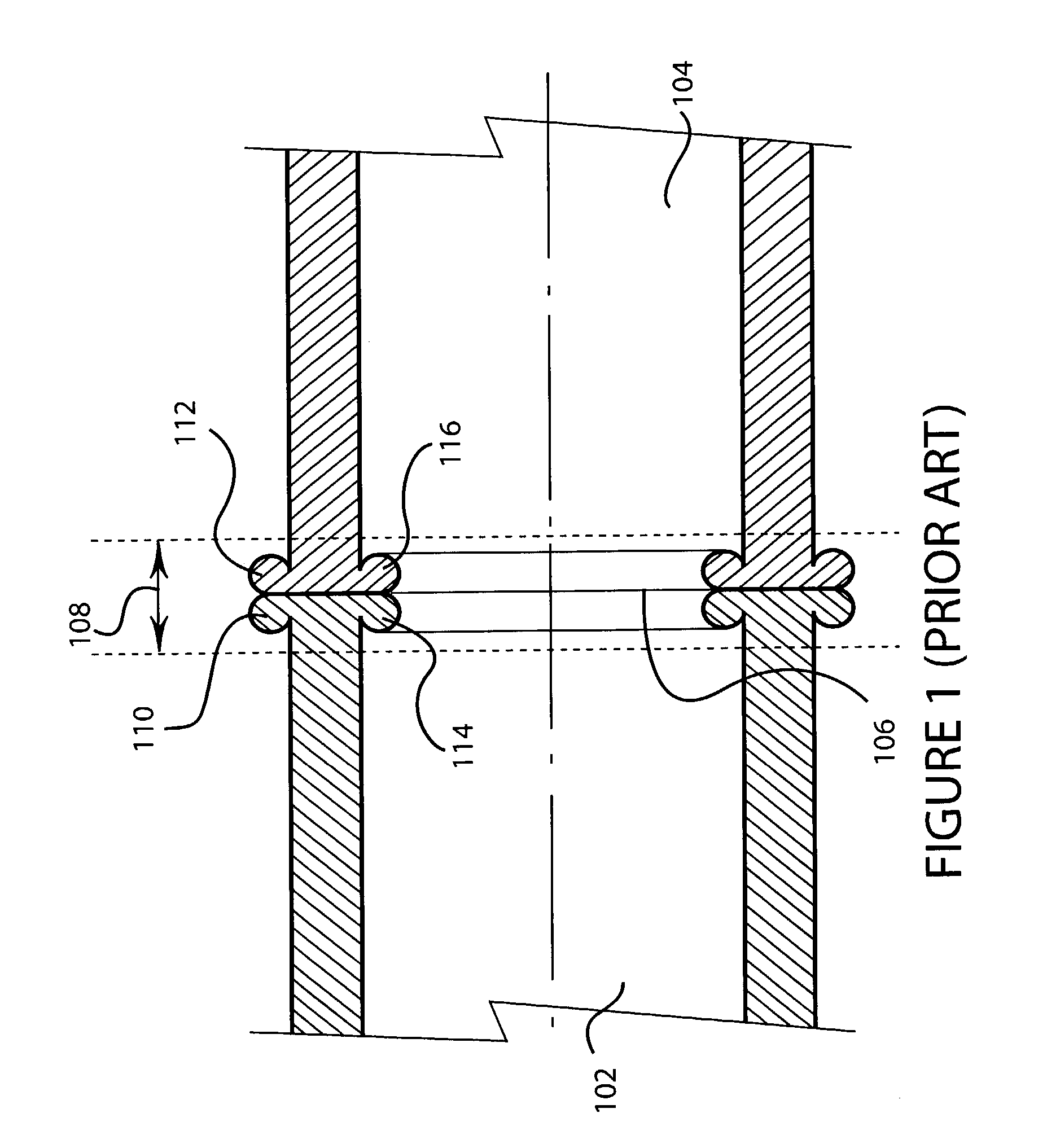

Beveled cutter

InactiveUS6994766B2Minimize external protrusionEliminate the effects ofButtonsMechanical working/deformationEngineeringFusion welding

Disclosed is a method, apparatus, and design of a fusion welded pipe wherein the effects of an inner bead of the fusion weld are minimized. The internal shape of the pipe prior to welding may be configured in several different shapes so that the beads or lips produced by the fusion welding process are unobtrusive and do not interfere with the function of the pipe. In a likewise manner, the outer shape of the pipe prior to welding may be configured so that the lips are unobtrusive on the external surface of the pipe.

Owner:FAST FUSION

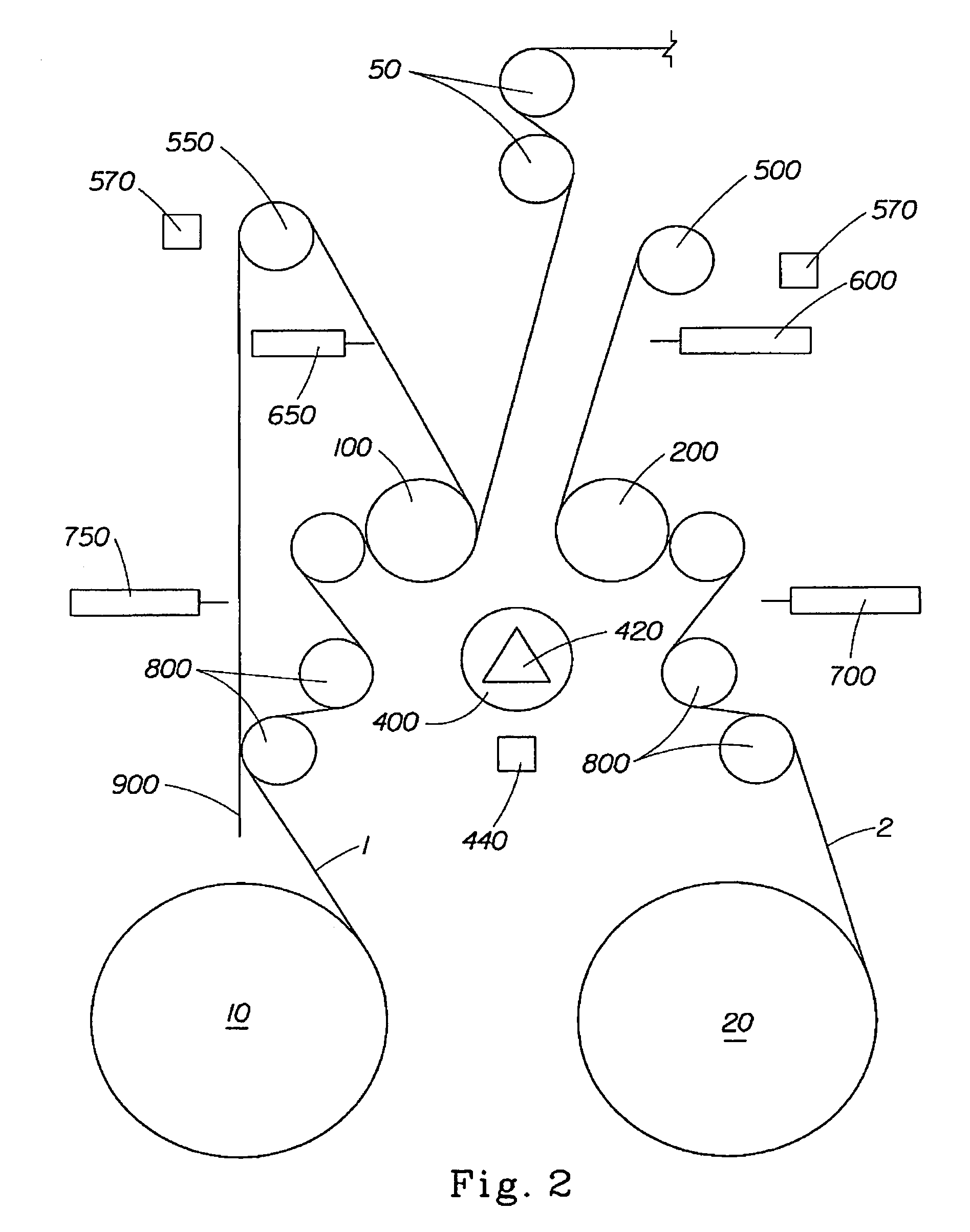

Method and apparatus for splicing a web material

An apparatus and method for splicing web materials. The apparatus comprises a first nip roller, a second nip roller and an adhesive roller. The apparatus further comprises a first wind up roller and a second wind up roller. The apparatus also comprises a pair of infeed web cutting elements, and a pair of outfeed web cutting elements. First and second webs are received from upstream web supplies. One web proceeds downstream and the other is wound on a wind up roller. Adhesive is applied to one web and the two webs together with the adhesive pass between the nip rollers. One web is separated between the upstream supply and the splice and the other is separated between the splice and the wind up roller. The splice may proceed downstream.

Owner:PROCTER & GAMBLE CO

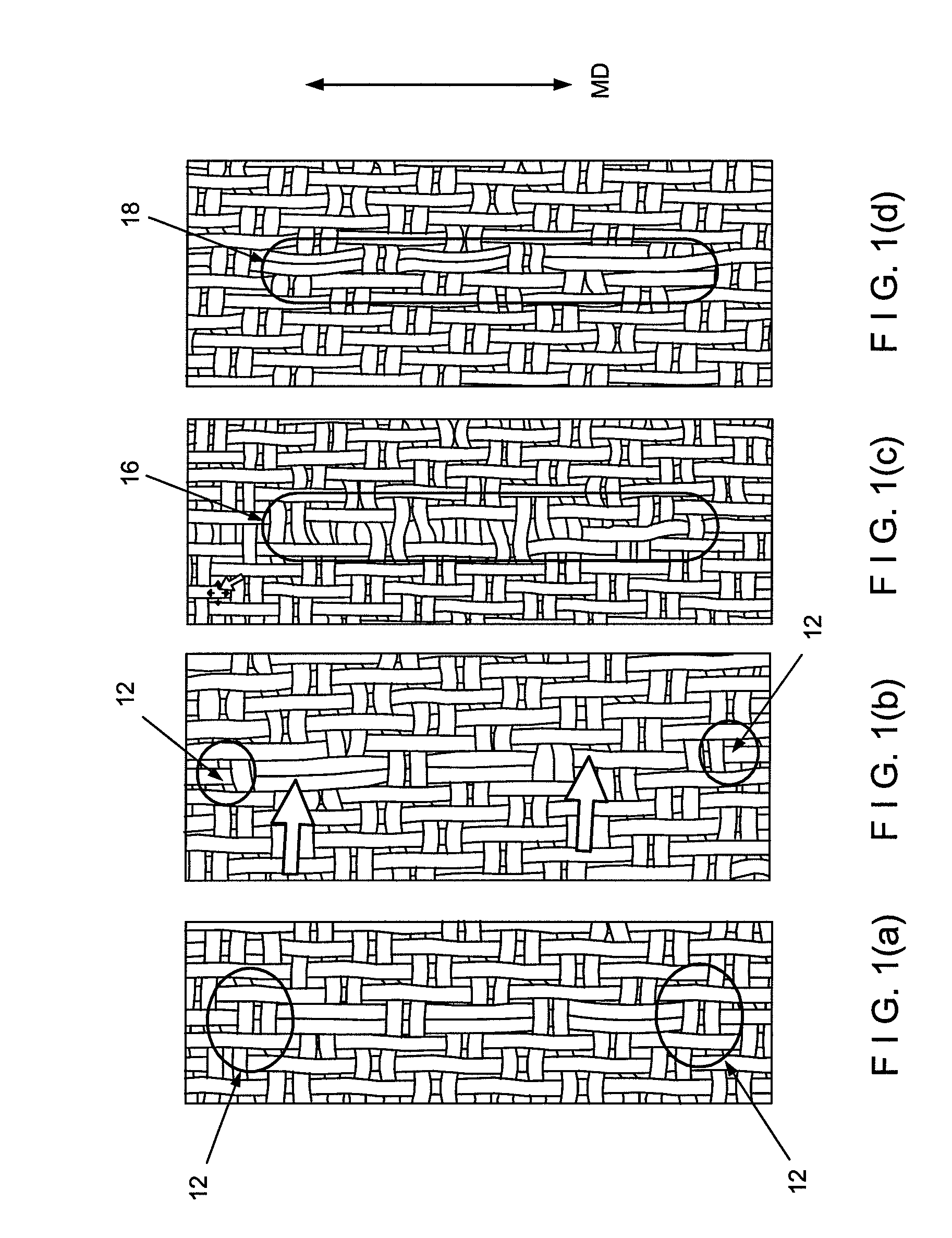

Formation of a fabric seam by ultrasonic gap welding of a flat woven fabric

ActiveUS7794555B2Enhance pin seams and inline spiral seamsPromote formationMechanical working/deformationLamination ancillary operationsYarnUltrasonic welding

The invention relates to ultrasonic gap welding of flat woven fabrics. Specifically, the invention relates to a method of ultrasonic welding the seam termination yarn ends of a fabric using a controlled gap. A mechanical stop may be employed to control the distance or gap between the horn and anvil to a predetermined level based on the depth of welding and amount of weld energy. By adding another degree of control, the ultrasonic gap welding technique of the present invention is able to achieve fabric seams that are stronger than conventional seams, and even those enhanced with gluing, and is conducive to formation of fabric seams by spot welding or along the termination yarn ends of the fabric.

Owner:ALBANY INT CORP

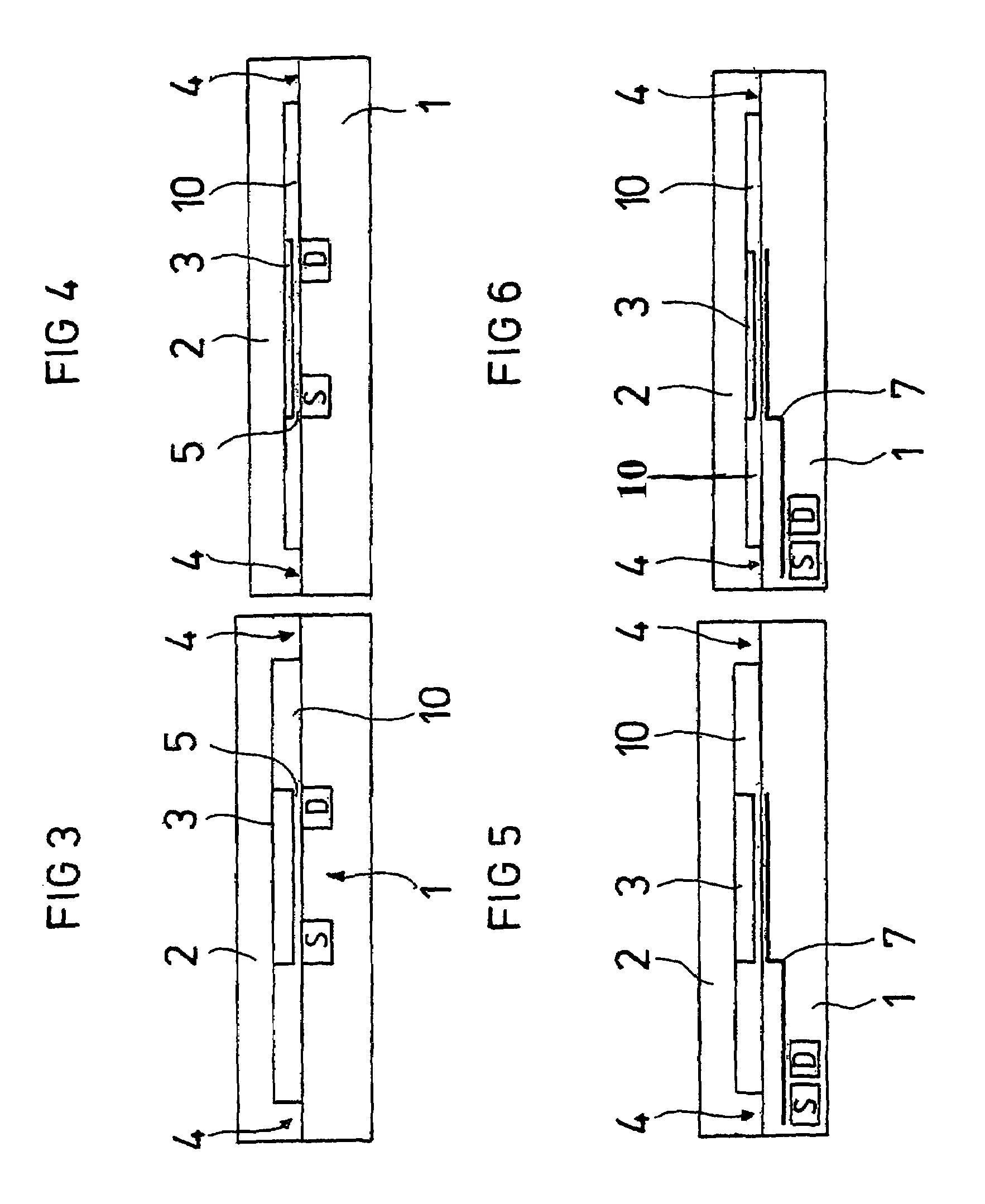

Gas-sensitive field-effect transistor with air gap

Owner:MICRONAS

Method of forming and adhesiveiy bonded seam

InactiveUS20050230026A1Mechanical working/deformationLamination ancillary operationsEngineeringSound pressure

The present invention provides a method of forming a stitchless, adhesively bonded seam for a garment. The method includes providing a first and second sheet of fabric with each sheet having an outside or facing surface, an inside or backing surface, and an edge. The outside surface and edge of the first sheet of fabric are positioned adjacent to the outside surface and edge of the second sheet of fabric, respectively. A first strip of adhesive tape, having first and second sides and an edge, is positioned between the first and second sheets of fabric such that the edge of the first strip of adhesive tape is adjacent to the edges of the first and second sheets of fabric, and the first and second sides of the first strip of adhesive tape are adjacent to the outside surfaces of the first and second sheets of fabric, respectively. A second strip of adhesive tape, having first and second sides and an edge, is positioned such that its edge and first side are adjacent to the edge of the second sheet of fabric and to a first portion of the inside surface of the second sheet of fabric, respectively. The second sheet of fabric is folded such that a second portion of the inside surface of the second sheet of fabric overlaps the second side of the second strip of adhesive tape. The adhesively bonded seam is formed by applying ultrasonic sound pressure to the first and second sheets of fabric and to the first and second strips of adhesive tape, causing the first strip of adhesive tape to join the outside surfaces of the first and second sheets of fabric and the second strip of adhesive tape to join the first and second portions of the inside surface of the second sheet of fabric.

Owner:MOUNTAIN HARDWEAR

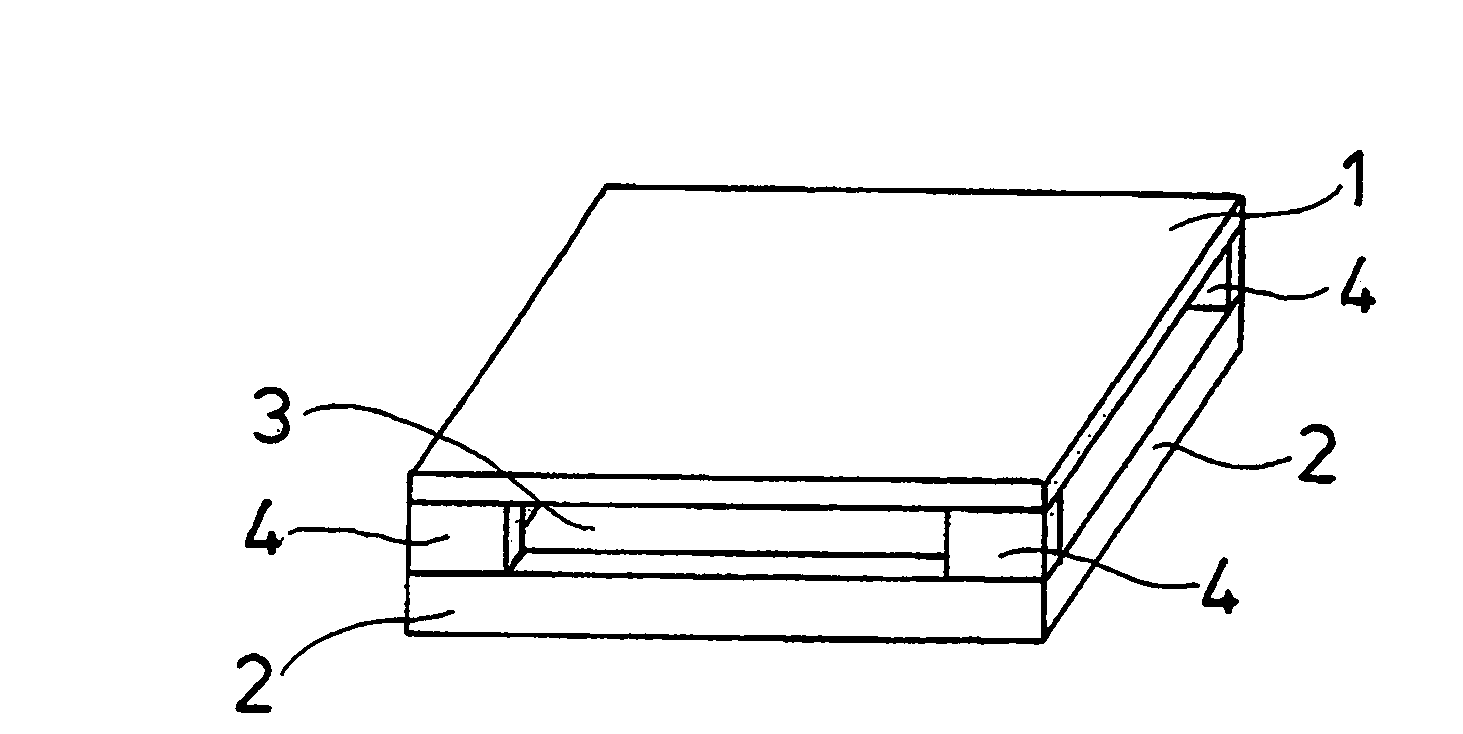

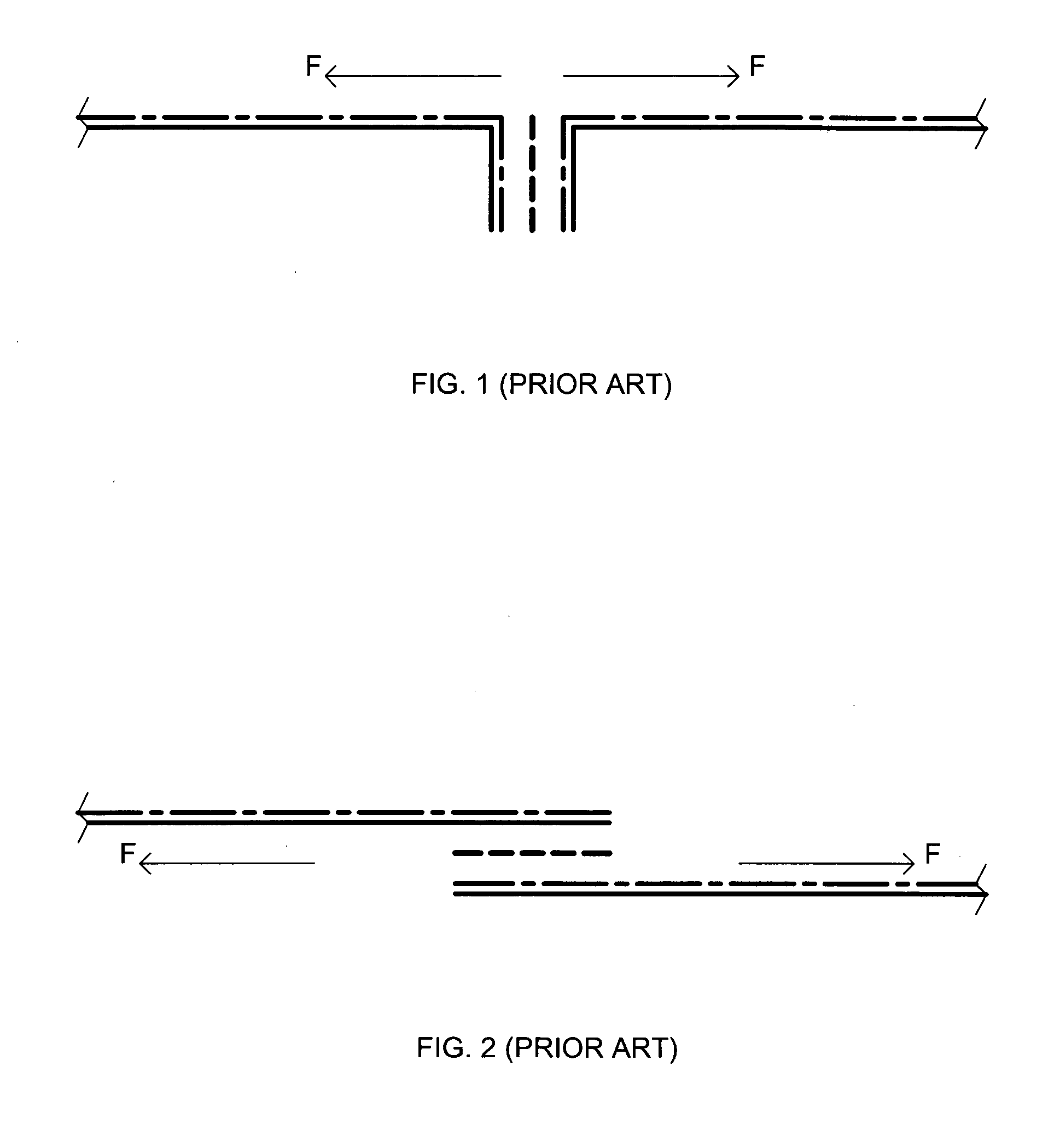

Method and apparatus for butt-jointing edges of elastic material sheet

InactiveUS20080017297A1High strengthMechanical working/deformationFilament handlingButt jointEngineering

Owner:SUMITOMO RUBBER IND LTD

Method for attaching web based polishing materials together on a polishing tool

InactiveUS20030022611A1Mechanical working/deformationFilament handlingEngineeringChemical-mechanical planarization

A method and apparatus for thermally attaching web-based polishing pads in a chemical-mechanical planarization (CMP) system. Specifically, one end of a first web-based polishing pad and an end of a second web-based polishing pad are inserted in a thermal sealing unit. The ends of the polishing pads are brought into contact with each other and secured in place within the thermal sealing unit. A heating element within thermal sealing unit is activated, thereby fusing the polishing pads.

Owner:MICRON TECH INC

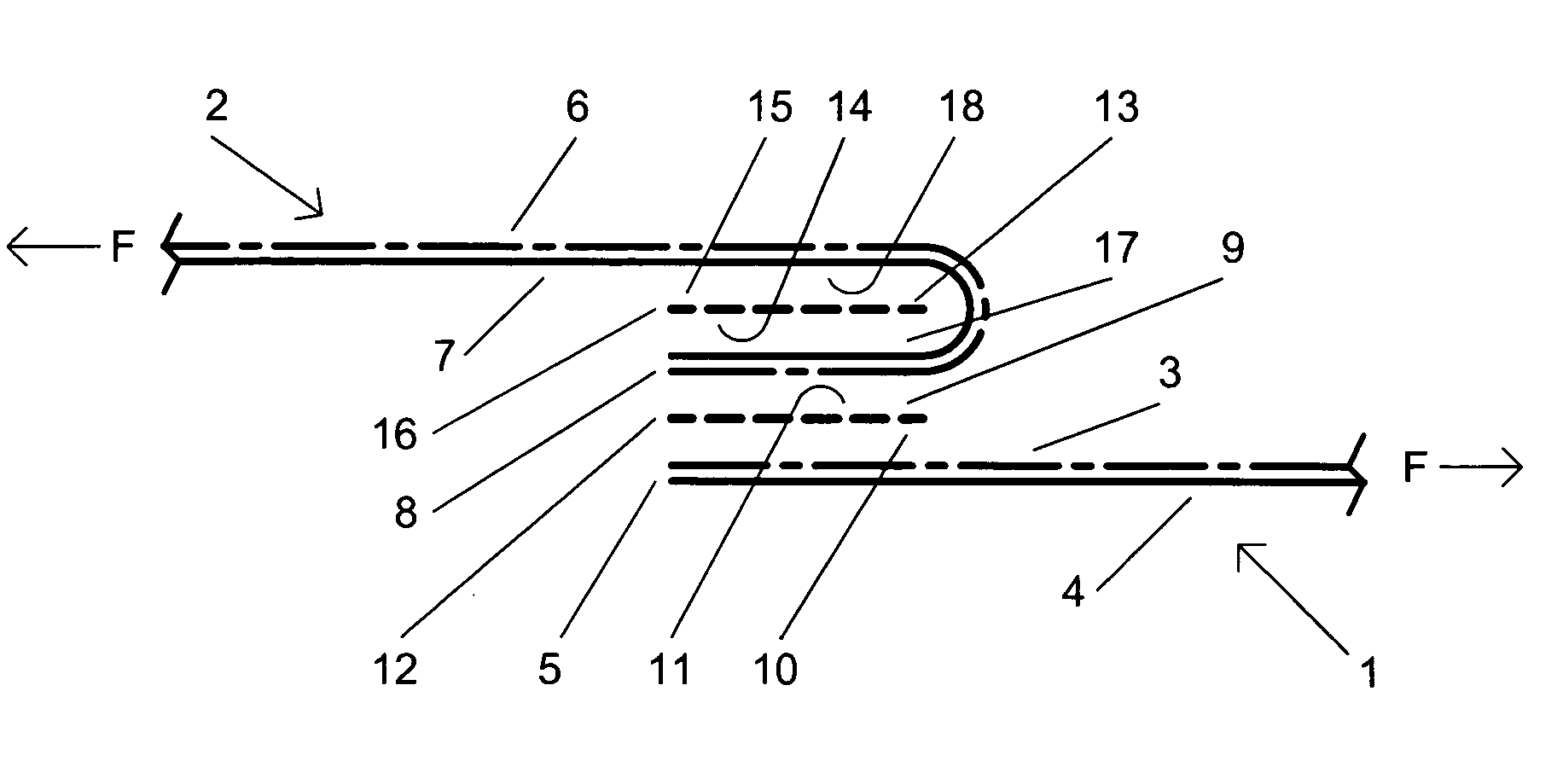

Tail for attaching the trailing edge of one roll of tape to the leading edge of another roll of tape and method of using same

InactiveUS6981537B2Easy to splitMechanical working/deformationControlling laminationLeading edgeMagnetic tape

A tape splicing mechanism joins the tail of one tape to the leading edge of another tape. A frame defines a passageway along which the tape passes. A pair of arms rotatably attached to the frame have projecting posts and rotate between a first position where the posts are closer to the pathway and a second position where they are further from the pathway. The arms are urged toward the first position and a catch mechanism holds them in the second position until released by a release mechanism when a release indicia in the first tape passes. The leading edge of the second tape is looped around the first tape to form a loose knot and is tied to the post on each side of the first tape. When the arms are released they move to the second position and tighten the knot.

Owner:FORBO ADHESIVES

Double-faced silicone adhesive tape and method of use thereof in splicing

InactiveUS20040219355A1Mechanical working/deformationFilament handlingSilicone adhesive tapeSilicone

A double-faced, non-woven supported silicone pressure sensitive adhesive splicing tape comprising a non-woven backing material having opposing porous surfaces, each said surfaces being coated with a pressure sensitive adhesive, with at least one of said surfaces being coated with a silicone pressure sensitive adhesive layer which is coated and cured on said surface. A method of using the double-faced, non-woven supported silicone pressure sensitive adhesive splicing tape to splice substrates having a low energy surface is also provided.

Owner:ADHESIVES RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com