Efficient photocatalyst for bismuth vanadate nanorod and preparation method of catalyst

A photocatalyst and nanorod technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high cost, achieve low equipment requirements, and reduce defects The effect of density, clear cost advantages and price/performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1: Dissolve 0.4mmol of bismuth nitrate pentahydrate in 20ml of deionized water, use the PTFE lining of the hydrothermal kettle as the container, stir for 30 minutes to form a uniform milky white cloudy liquid, then add 1.2mmol of sodium oleate, and stir for 60 minutes In order to obtain a stable milky white suspension, it is recorded as solution A;

[0031] Step 2: Take 0.4 mmol of ammonium metavanadate and dissolve it in 20 ml of deionized water, stir until it dissolves to form a light yellow transparent solution, which is recorded as solution B;

[0032] Step 3: Add solution B to solution A in the PTFE lining while stirring, and continue stirring for 2 hours to obtain a uniform light milky yellow mixture C;

[0033] Step 4: Transfer the uniformly mixed turbid liquid C to a high-temperature and high-pressure reactor, add a stirring magnet, react at 100°C for 24 hours, and naturally cool to room temperature;

[0034] Step 5: The obtained product was washed with de...

Embodiment 2

[0042] The preparation method in this embodiment is the same as that in Example 1, the difference is only that the conditions in the preparation process are different, in the step one and step two of the present embodiment, the amount of the substance of bismuth nitrate, ammonium metavanadate and sodium oleate and the implementation Compared with example 1, all were doubled, and the rest of the conditions were unchanged.

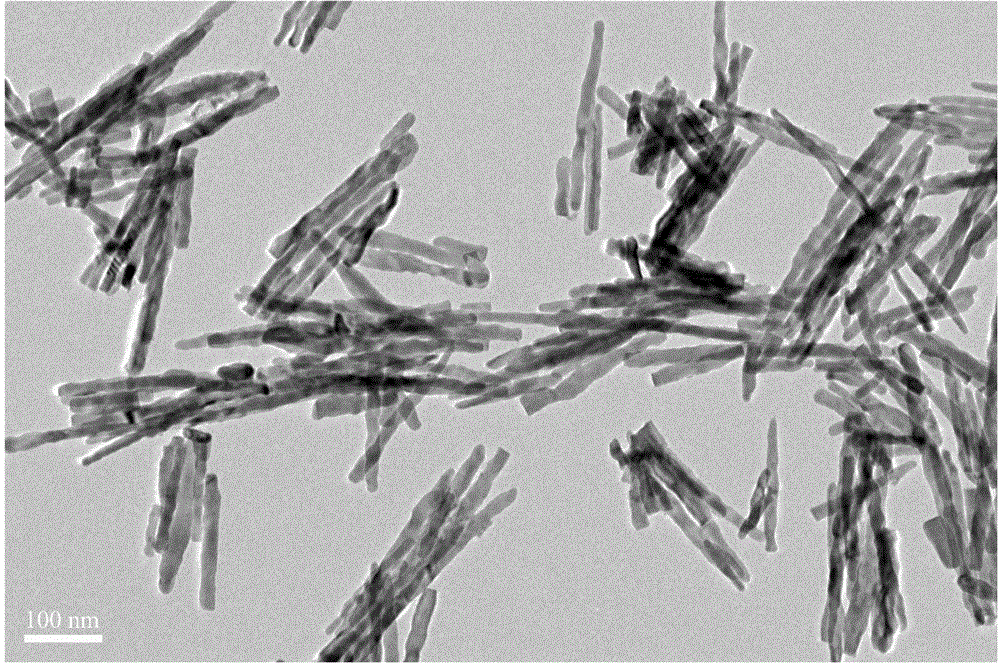

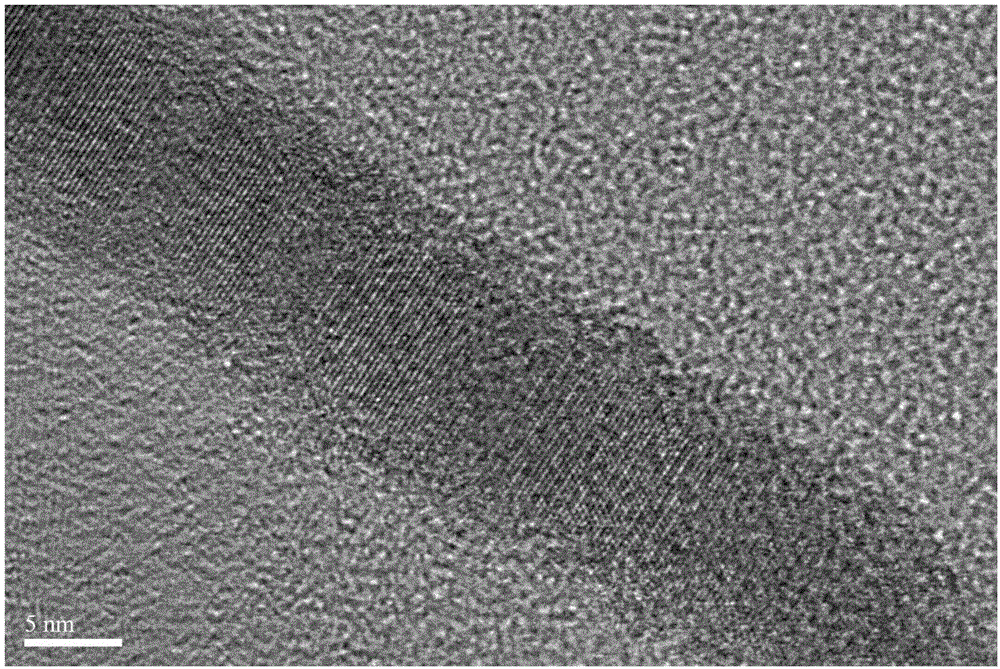

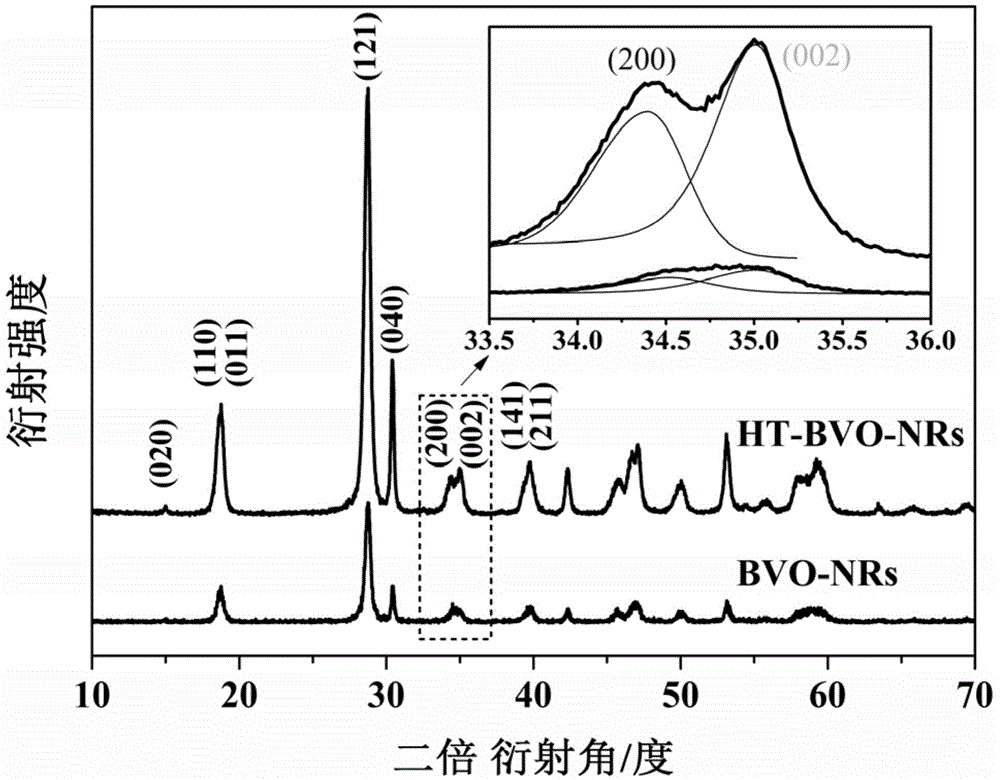

[0043] The bismuth vanadate photocatalyst prepared in Example 2 was characterized by transmission electron microscope, X-ray diffraction and other means. Transmission electron microscopy results show that the bismuth vanadate photocatalyst obtained in Example 2 is in the shape of nanorods, with good monodispersity, a diameter of about 25 nm, an aspect ratio of 10-35, and extending along the [010] direction. X-ray diffraction results show that the obtained bismuth vanadate nanorods are monoclinic scheelite phase.

Embodiment 3

[0045] The preparation method in this example is the same as that in Example 1, the only difference is that the conditions in the preparation process are different. The hydrothermal reaction time of Step 4 of this example is 48 hours, no magnetron is added, and the other conditions remain unchanged.

[0046] The bismuth vanadate photocatalyst prepared in Example 3 was characterized by transmission electron microscope, X-ray diffraction and other means. Transmission electron microscopy results show that the bismuth vanadate photocatalyst obtained in Example 3 is in the shape of nanorods, with good monodispersity, a diameter of about 20 nm, an aspect ratio of 10-40, and extending along the [010] direction. X-ray diffraction results show that the obtained bismuth vanadate nanorods are monoclinic scheelite phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com