Method of preparing titanium dioxide nanotube with assistance of cationic surface active agent

A surfactant and titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., to achieve high tube forming efficiency, increased tube length, and favorable application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

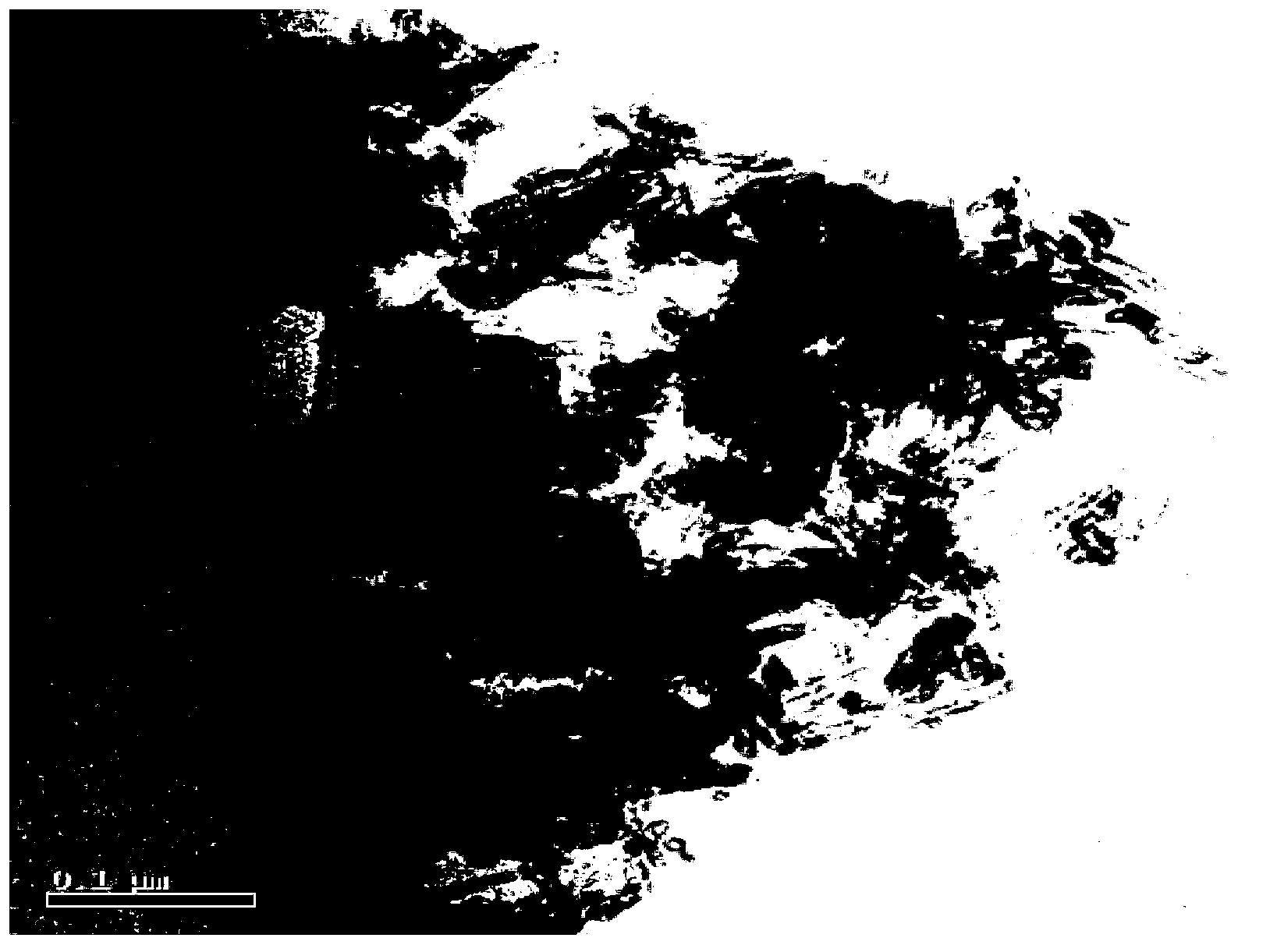

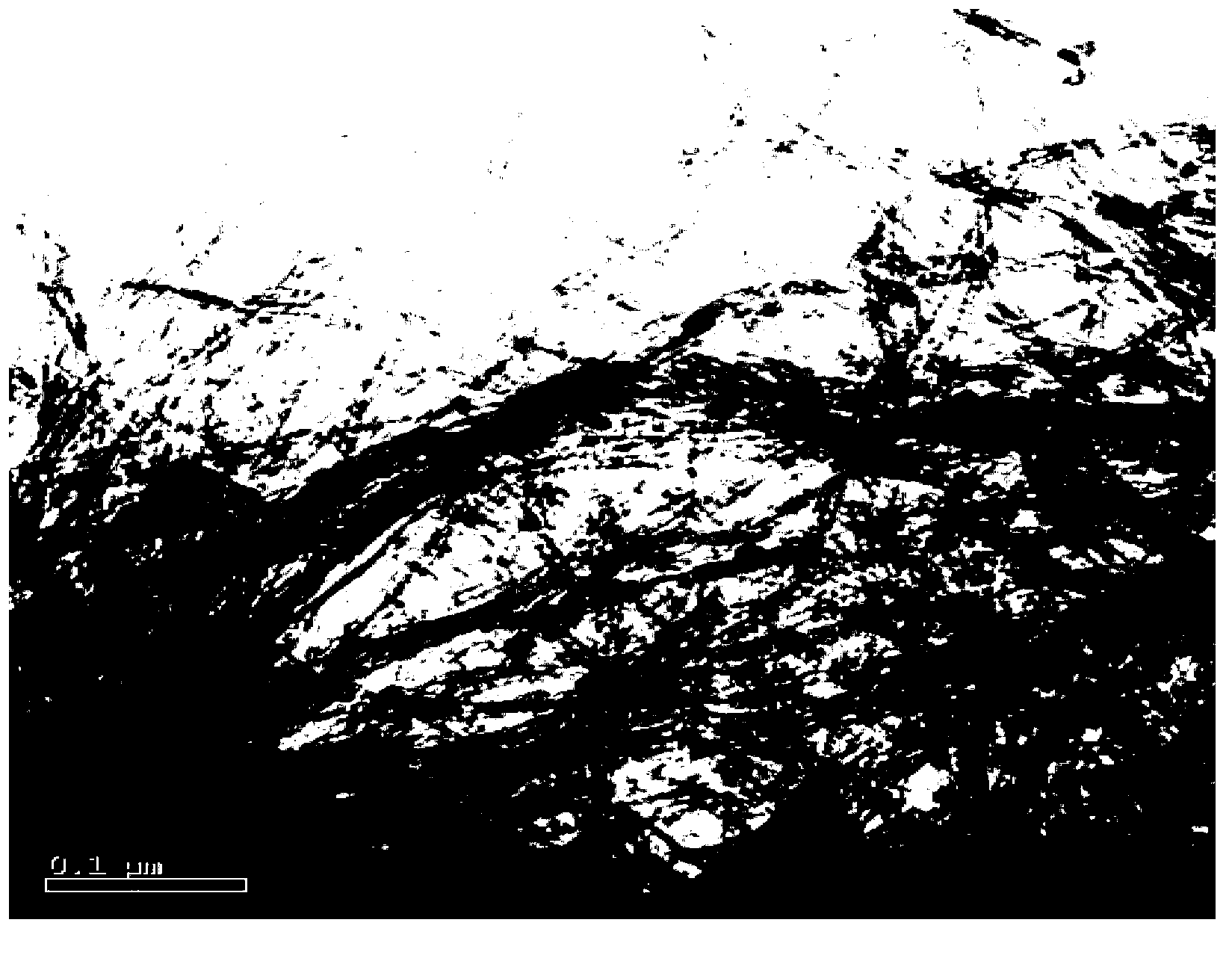

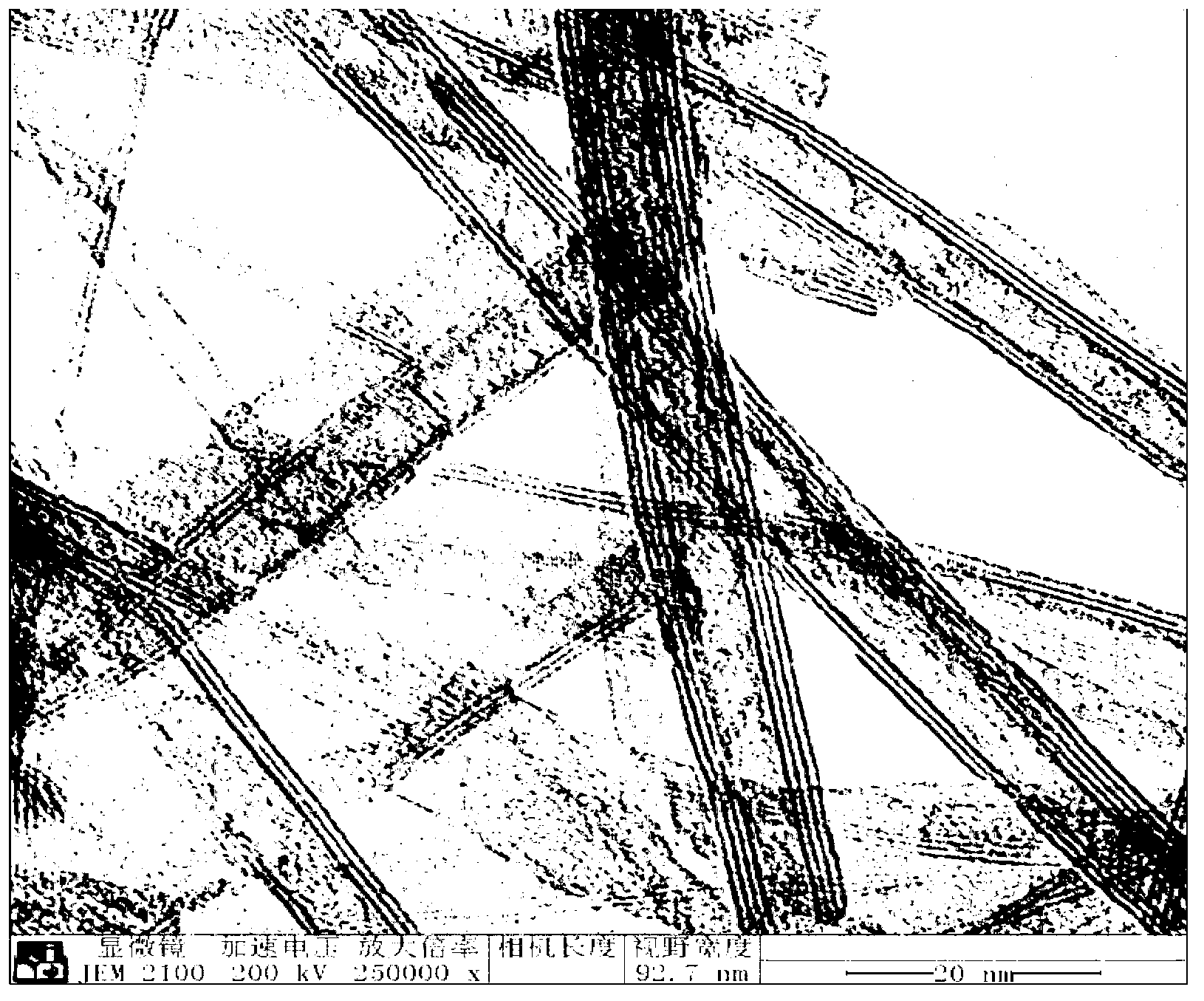

Image

Examples

specific Embodiment approach 1

[0022] Step 1: Prepare 10-50 mL of NaOH solution with a concentration of 8-15 mol / L and add it to the lining of the polytetrafluoroethylene reactor.

[0023] Step 2, weighing 0.1-10g of cetyltrimethylammonium bromide, 0.1-3g of titanium dioxide nanopowder with a particle size of 10-100nm and a crystal form of anatase phase, rutile phase or a mixture of the two, and adding Ultrasonic vibration in a good concentrated alkali solution to mix it evenly.

[0024] Step 3: Put the stainless steel reaction kettle into an oven for hydrothermal reaction at 100-200°C for 15-30h.

[0025] Step 4: After the hydrothermal reaction is completed, the supernatant is poured out, and the obtained solid powder is washed with water until neutral.

[0026] Step five, adding 0.1-1 mol / L nitric acid or hydrochloric acid to the obtained powder, and ultrasonicating at 50-100° C. for 1-3 hours.

[0027] In step six, the acid-treated sample is washed with water until it is nearly neutral.

[0028] Step ...

specific Embodiment approach 2

[0031] Configure 20mL NaOH solution with a concentration of 10mol / L and add it to the lining of the polytetrafluoroethylene reactor.

[0032] Weigh 0.5g of cetyltrimethylammonium bromide and 1g of anatase phase titanium dioxide powder with a particle size of 20nm, add it into the prepared concentrated alkali solution and ultrasonically oscillate to make them evenly mixed, and react in hydrothermal reaction at 120°C for 30h .

[0033] After the hydrothermal reaction is completed, the supernatant is poured out, and the obtained solid powder is washed with water until neutral.

[0034] Add 0.1 mol / L nitric acid to the obtained powder, and ultrasonicate at 60°C for 2h.

[0035] Wash the acid-treated powder with water until it is close to neutral, filter and fully dry.

[0036] The dried powder was ground and calcined at 400°C for 2h.

[0037] The titanium dioxide nanotubes can be efficiently prepared by using the above method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com