Macromolecule pipe wall pulse heating pipe

A pulsating heat pipe and polymer pipe technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as restricting the large-scale use of pulsating heat pipes, reduce the risk of surface scaling, increase preload, improve The effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Example

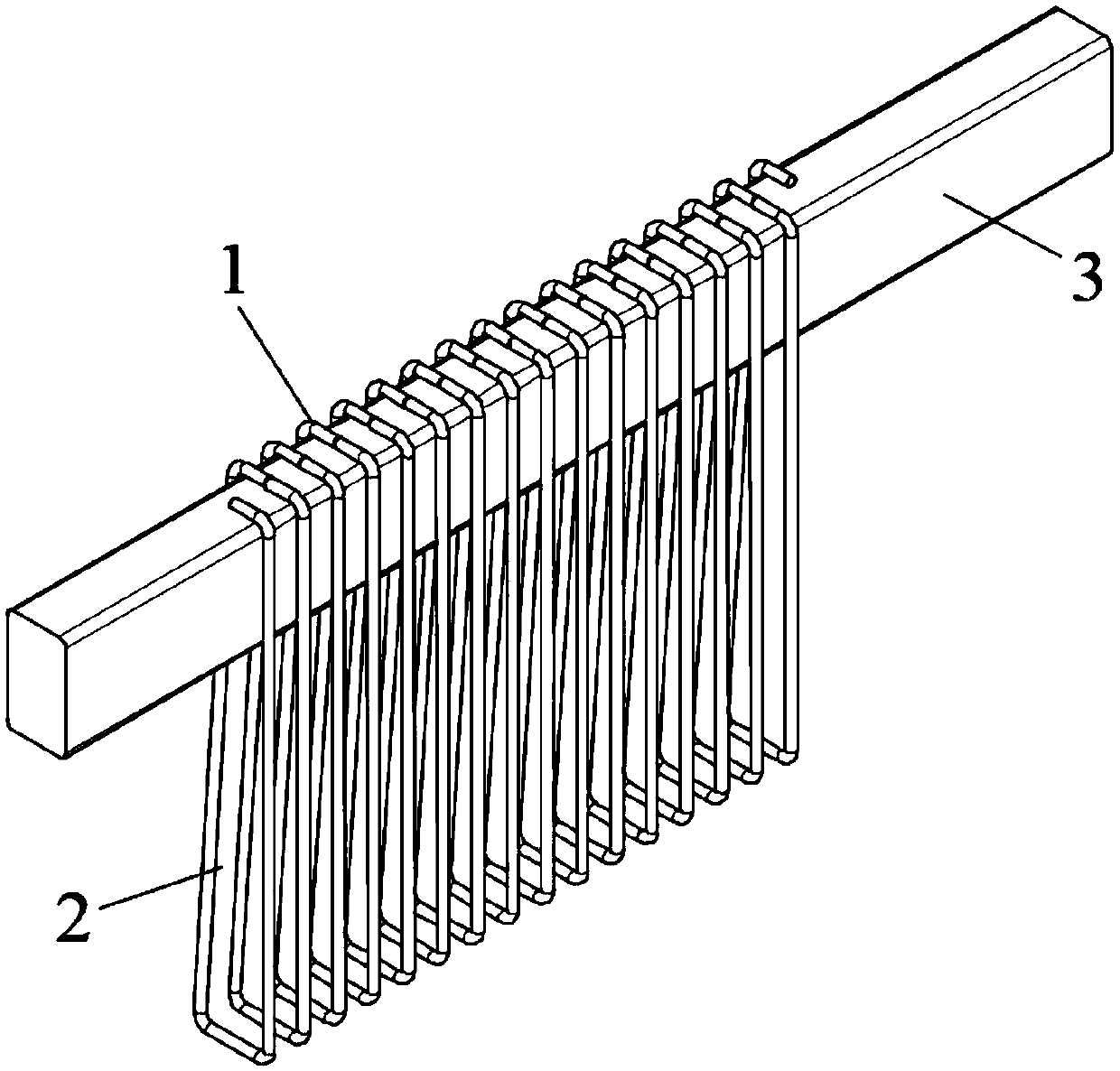

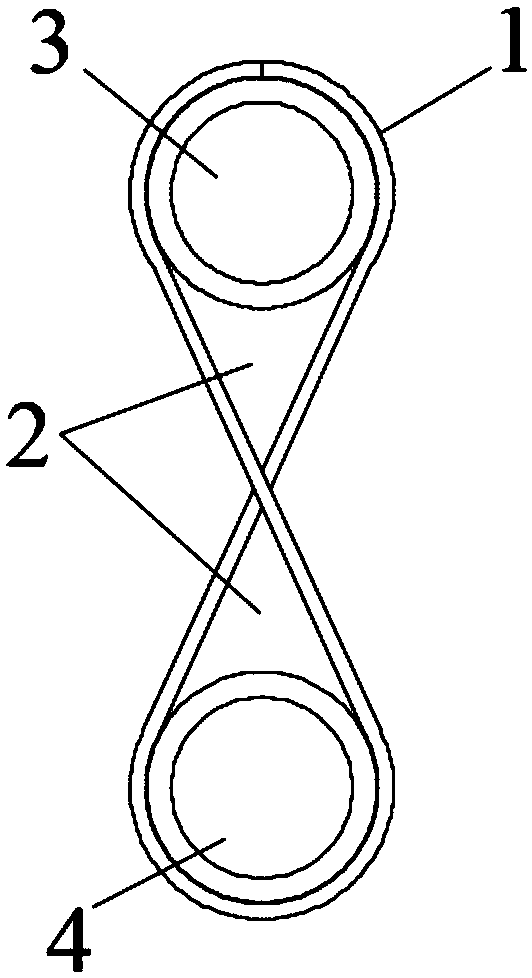

[0022] like figure 1 As shown, this embodiment provides a polymer tube wall pulsating heat pipe, which is a polytetrafluoroethylene tube body 1 with both ends closed. The tube body is a round tube with an inner diameter of 0.8mm and a wall thickness of 0.2mm. Medium fluorinated liquid Novec7100, the filling volume is 50% of the liquid volume capacity, the remaining space is Novec7100 saturated gas, the tube body is spirally wound into a rectangular cavity with a circular arc inside, and the tube body is partially wound on the outer periphery of the heat source for 16 turns , in close contact with the outer surface portion of the heat source 3 .

[0023] In the polymer tube wall pulsating heat pipe of this embodiment, as the temperature of the heat source rises, the heat of the heat source is transferred to the inside of the heat pipe to heat the internal working medium Novec7100, and the power generated by the violent gasification phase transition drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com