Applications of PHBV as novel natural antibacterial material in textile product preparation

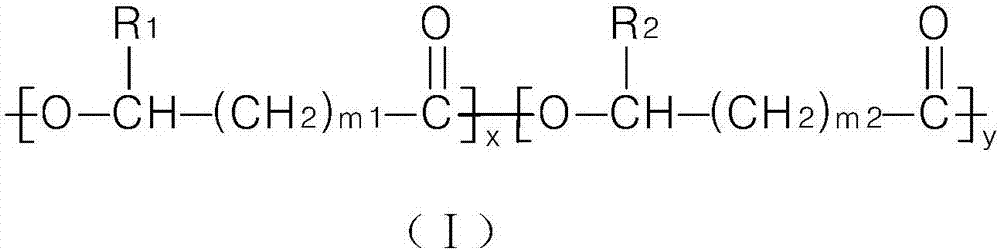

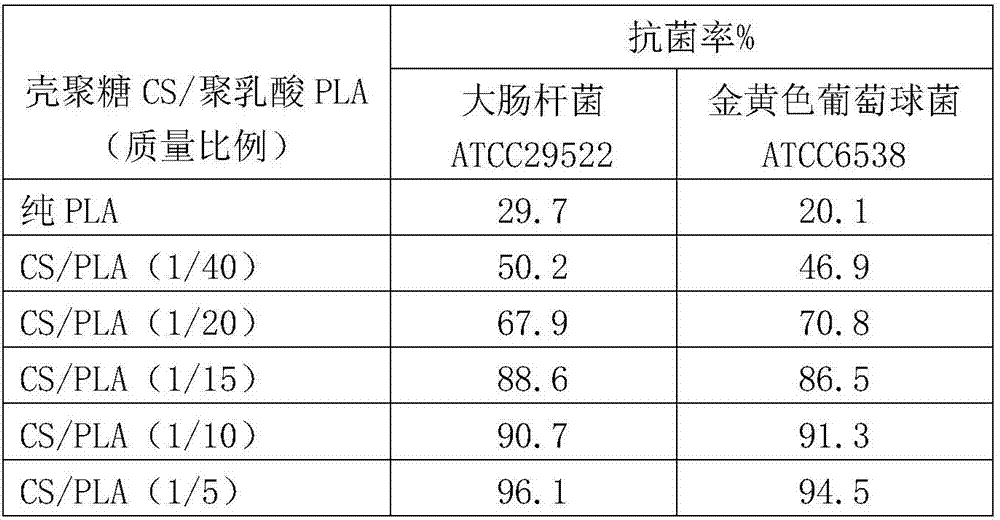

A natural antibacterial and textile technology, applied in the direction of single-component copolyester rayon, cellulose/protein conjugated rayon, conjugated synthetic polymer rayon, etc., can solve the problems that affect large-scale industrialization Problems such as application, high cost, and antibacterial effect have a huge impact on the content of antibacterial substances, and achieve the effect of low cost, good antibacterial effect, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: pure PHBV fiber, FDY filament

[0039] Get 1000 grams of PHBV (HV molar content 1%) sample, vacuum dry at 70°C, spin at 225°C, spin at a speed of 300m / min, melt-spin, and then double-draw to obtain FDY fibers, which are knitted into cloth. After cleaning the spinning oil, dry it, prepare samples, and test the antibacterial properties.

Embodiment 2

[0040] Embodiment 2: pure PHBV fiber, FDY filament

[0041] Get 1000 grams of PHBV samples (HV molar content 5%), vacuum-dry at 70°C, spin at 225°C, spin at a speed of 700m / min, melt-spin, and then draw 2.5 times to obtain FDY fibers, which are knitted into cloth. After cleaning the spinning oil, dry it, prepare samples, and test the antibacterial properties.

Embodiment 3

[0042] Embodiment 3: pure PHBV fiber, FDY filament

[0043] Get 1000 grams of PHBV samples (HV molar content 10%), vacuum dry at 70°C, spin at 215°C, spin at a speed of 1500m / min, melt spin, then draw 2.5 times to make FDY fibers, knitting cloth. After cleaning the spinning oil, dry it, prepare samples, and test the antibacterial properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com