Double perovskite type inorganic nano fiber and preparation method thereof

An inorganic nanofiber, double perovskite technology, applied in the direction of inorganic raw materials such as artificial filaments, can solve the problem of insufficient research on the properties of inorganic nanofibers, and achieve large aspect ratio, increase specific surface area, and high specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

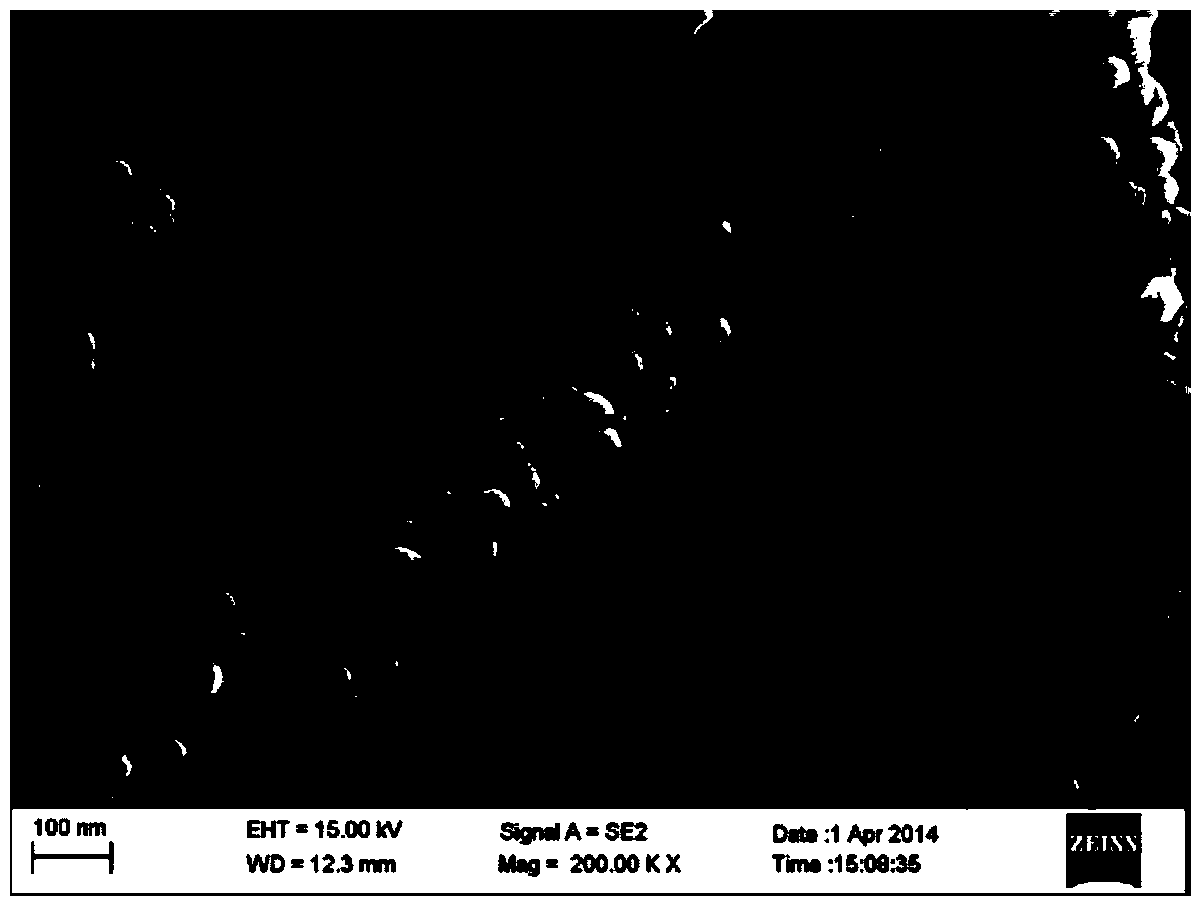

Embodiment 1

[0040] A double perovskite La 2 CaO 6 A preparation method for inorganic nanofibers, the preparation method comprising the steps of:

[0041] ①Dissolve 10% inorganic salt in 76% N,N-dimethylformamide by mass percentage and add 14% polyvinylpyrrolidone. The inorganic salt is a mixture of lanthanum nitrate, cobalt acetate and nickel acetate. The mol ratio of described lanthanum nitrate, cobalt acetate and nickel acetate is 2:1:1, obtains spinning precursor solution;

[0042] ② Electrospinning the spinning precursor solution, the electrospinning conditions are: the spinning voltage is 15kV, the curing distance from the nozzle to the receiving screen is 15cm, and the receiving time is 12h, to obtain composite nanofibers;

[0043] ③ pre-oxidize the composite nanofibers in air, the pre-oxidation conditions are: the pre-oxidation temperature is 220°C, the pre-oxidation time is 1h, the pre-oxidation heating rate is 1°C / min, and the pre-oxidation composite nanofibers are obtained;

...

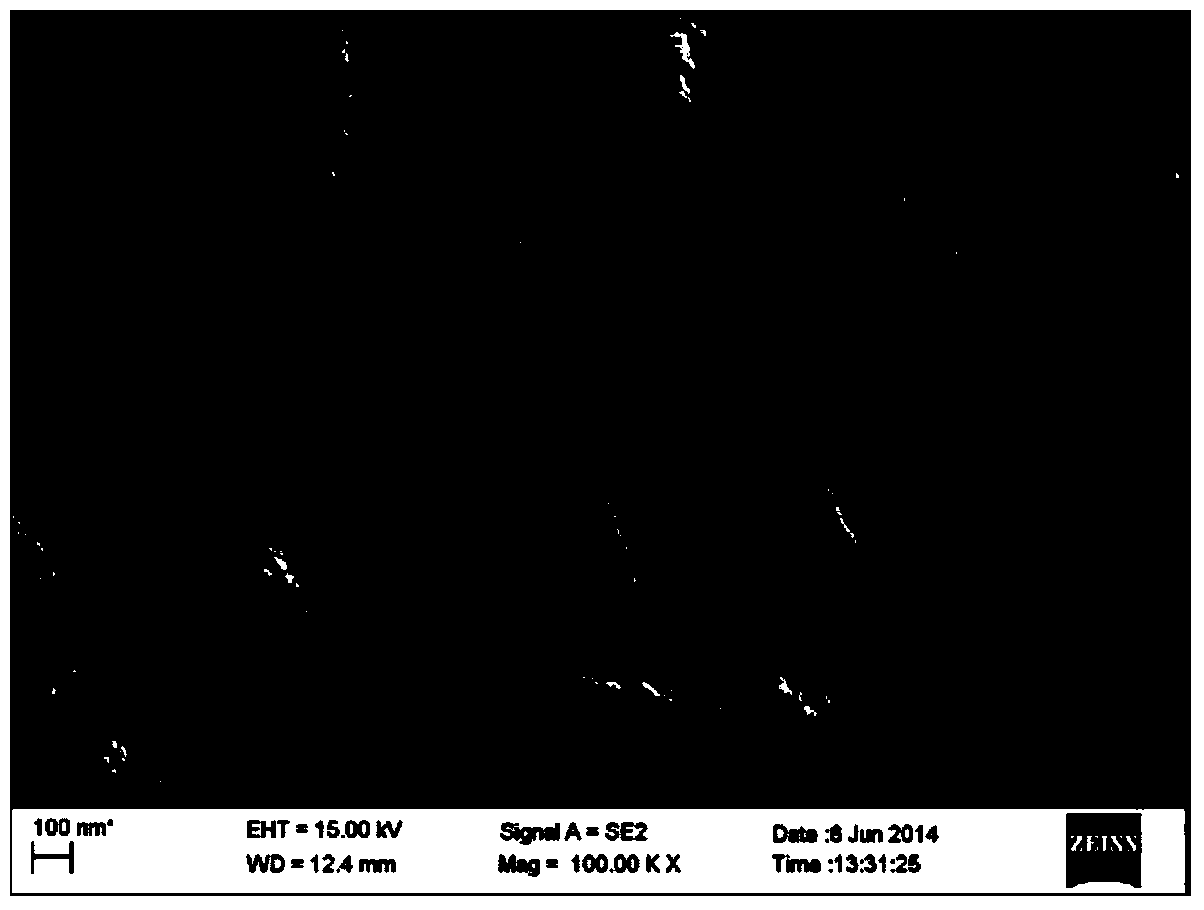

Embodiment 2

[0047] A double perovskite La 2 CoFeO 6 A preparation method for inorganic nanofibers, the preparation method comprising the steps of:

[0048] ①Dissolve 10% inorganic salt in 76% N,N-dimethylformamide by mass percentage and add 14% polyvinylpyrrolidone. The inorganic salt is a mixture of lanthanum nitrate, cobalt acetate and iron nitrate. The mol ratio of described lanthanum nitrate, cobalt acetate and nickel acetate is 2:1:1, obtains spinning precursor solution;

[0049] ② Electrospinning the spinning precursor solution, the electrospinning conditions are: the spinning voltage is 15kV, the curing distance from the nozzle to the receiving screen is 15cm, and the receiving time is 12h, to obtain composite nanofibers;

[0050] ③ pre-oxidize the composite nanofibers in air, the pre-oxidation conditions are: the pre-oxidation temperature is 220°C, the pre-oxidation time is 1h, the pre-oxidation heating rate is 1°C / min, and the pre-oxidation composite nanofibers are obtained;

...

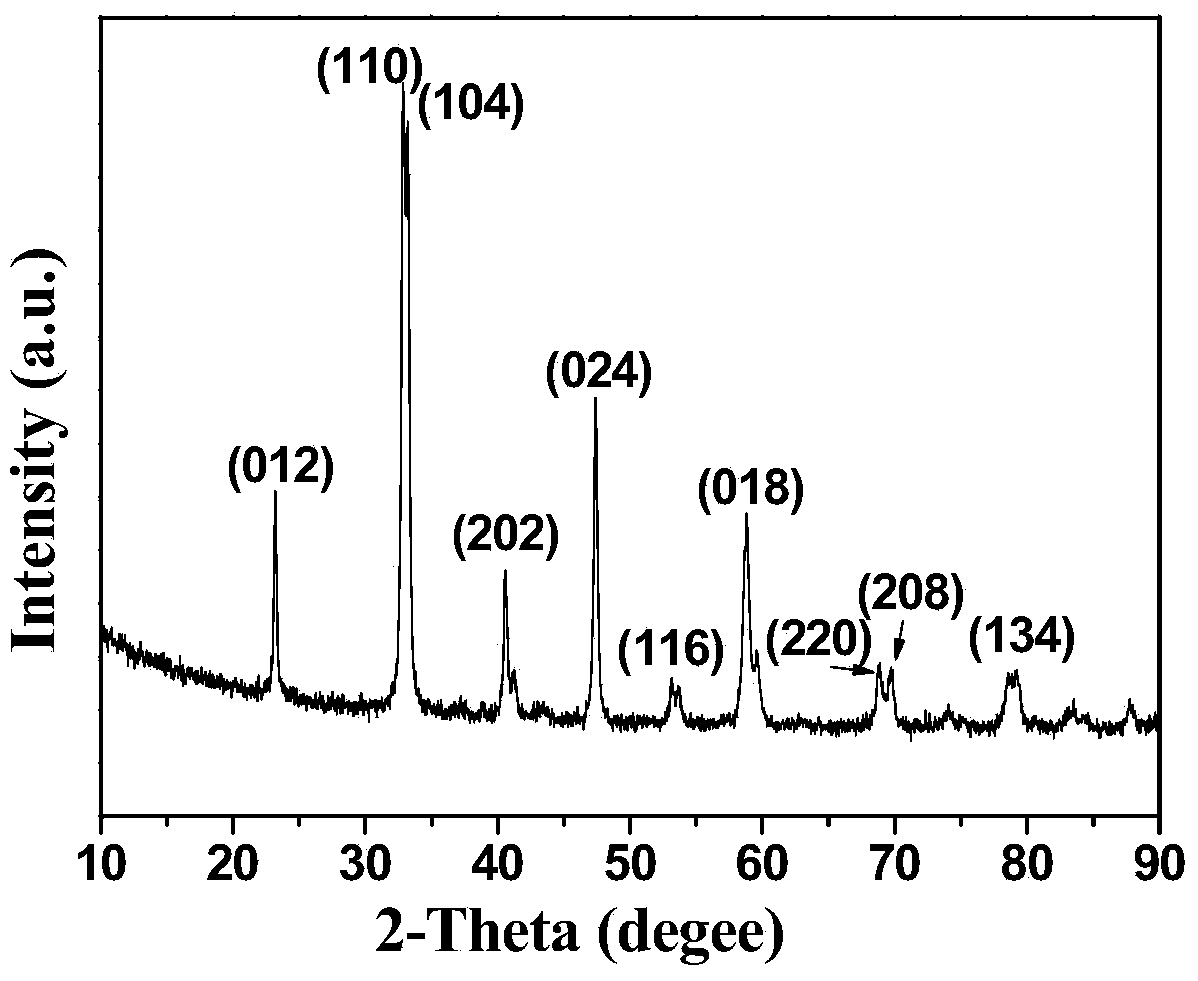

Embodiment 3

[0054] A double perovskite La 2 CoMnO 6 A preparation method for inorganic nanofibers, the preparation method comprising the steps of:

[0055] ①Dissolve 10% inorganic salt in 76% N,N-dimethylformamide by mass percentage and add 14% polyvinylpyrrolidone. The inorganic salt is a mixture of lanthanum nitrate, cobalt acetate and manganese acetate. The mol ratio of described lanthanum nitrate, cobalt acetate and manganese acetate is 2:1:1, obtains spinning precursor solution;

[0056] ② Electrospinning the spinning precursor solution, the electrospinning conditions are: the spinning voltage is 15kV, the curing distance from the nozzle to the receiving screen is 15cm, and the receiving time is 12h, to obtain composite nanofibers;

[0057] ③ pre-oxidize the composite nanofibers in the air, the pre-oxidation conditions are: the pre-oxidation temperature is 220°C, the pre-oxidation time is 1h, the pre-oxidation heating rate is 1°C / min, and the pre-oxidation composite nanofibers are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com