Method for preparing BaTiO3 nanowire through two-step salt melting method

A technology of nanowire and molten salt method, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effects of good repeatability, simple process flow and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

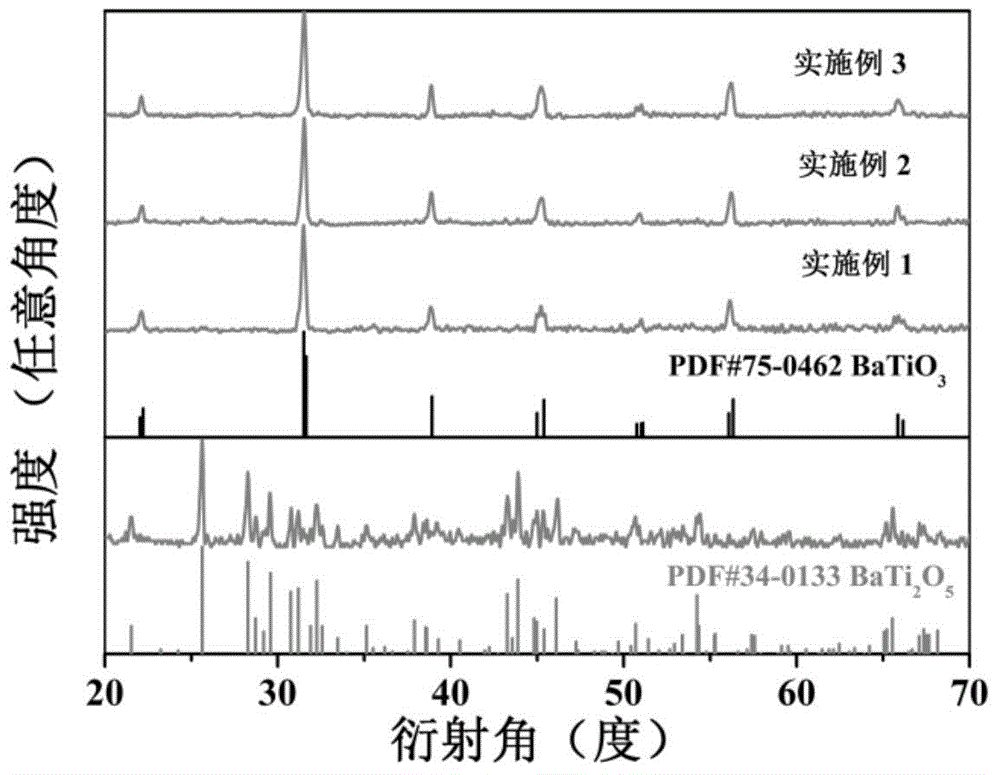

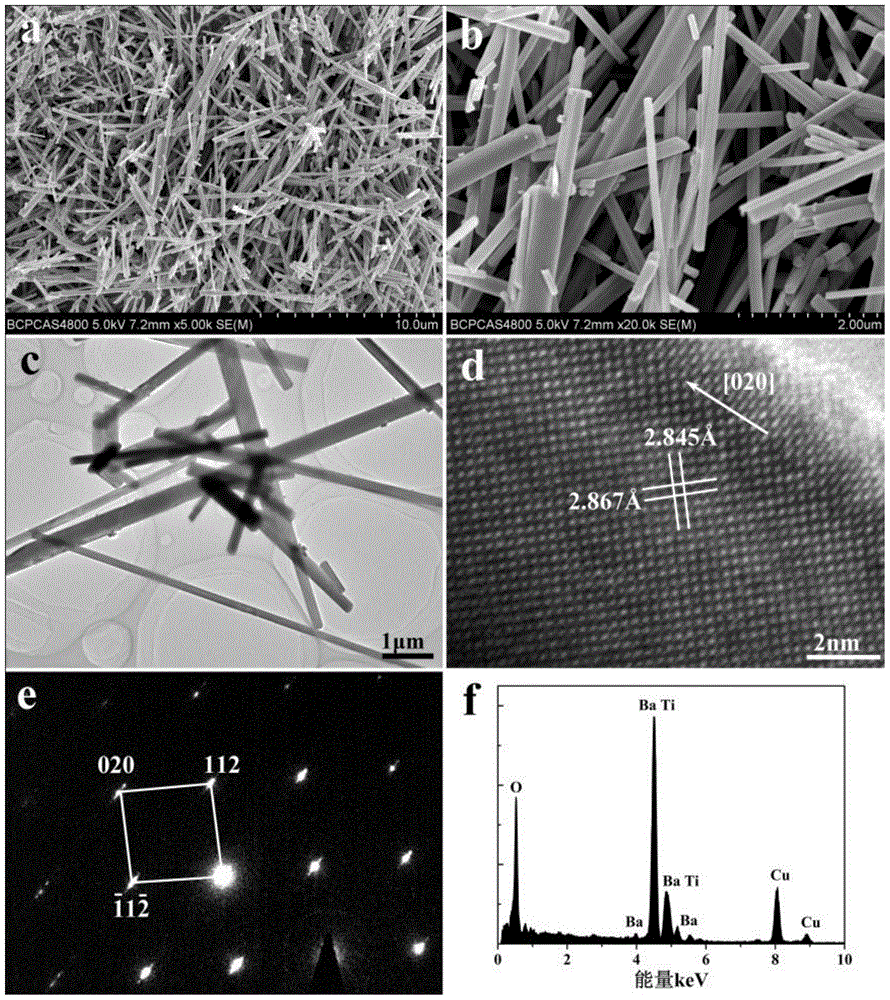

Embodiment 1

[0032] 1. Raw materials: Analytical pure barium carbonate, anatase phase titanium dioxide, sodium chloride, potassium chloride.

[0033] 2. Follow the steps below to prepare BaTiO 3 Nanowires

[0034] 1). The following four raw materials: ① barium carbonate, ② titanium dioxide (anatase phase), ③ sodium chloride, ④ potassium chloride, BaCO 3 : TiO 2 : NaCl: KCl is mixed in a molar ratio of 1:2:10:10, specifically: barium carbonate is 6.3032g, titanium dioxide is 5.1020g, sodium chloride is 18.6711g, potassium chloride is 23.8131g;

[0035] 2). Manually grind the mixture in step 1) for 30 minutes;

[0036] 3) Put the powder obtained in step 2) in a corundum crucible, and keep it in a muffle furnace at 875° C. for 5 hours;

[0037] 4) After the product of step 3) was cooled with the furnace, it was washed with deionized water several times, collected by centrifugation, and washed with 0.1mol / L AgNO 3 The solution was detected until Cl could not be found - ions, dried in an ...

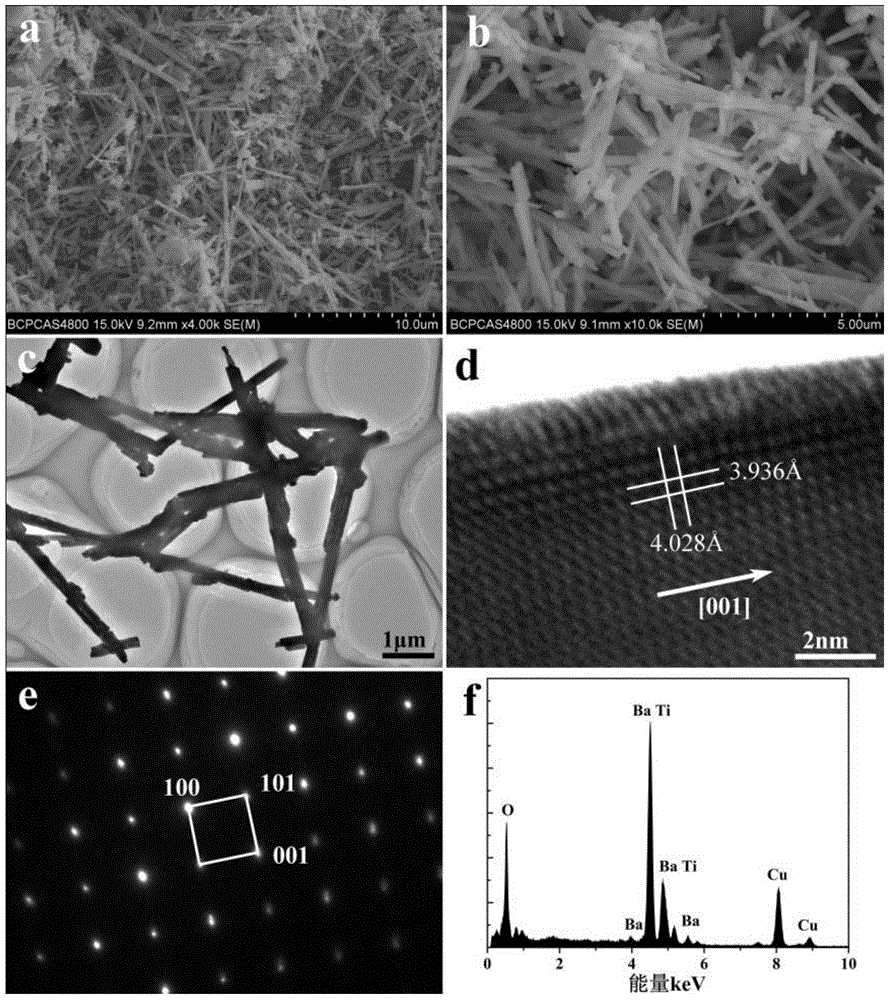

Embodiment 2

[0055] 1. Raw materials: Analytical pure barium carbonate, anatase phase titanium dioxide, sodium chloride, potassium chloride.

[0056] 2. Follow the steps below to prepare BaTiO 3 Nanowires

[0057] 1). The following four raw materials: ① barium carbonate, ② titanium dioxide (anatase phase), ③ sodium chloride, ④ potassium chloride, BaCO 3 : TiO 2 : NaCl: KCl is mixed in a molar ratio of 1:2:10:10, specifically: barium carbonate is 6.3032g, titanium dioxide is 5.1020g, sodium chloride is 18.6711g, potassium chloride is 23.8131g;

[0058] 2). Manually grind the mixture in step 1) for 30 minutes;

[0059] 3) Put the powder obtained in step 2) in a corundum crucible, and keep it in a muffle furnace at 875° C. for 5 hours;

[0060] 4) After the product of step 3) was cooled with the furnace, it was washed with deionized water several times, collected by centrifugation, and washed with 0.1mol / L AgNO 3 The solution was detected until Cl could not be found - ions, dried in an ...

Embodiment 3

[0067] 1. Raw materials: Analytical pure barium carbonate, anatase phase titanium dioxide, sodium chloride, potassium chloride.

[0068] 2. Follow the steps below to prepare BaTiO 3 Nanowires

[0069] 1). The following four raw materials: ① barium carbonate, ② titanium dioxide (anatase phase), ③ sodium chloride, ④ potassium chloride, BaCO 3 : TiO 2 : NaCl: KCl is mixed in a molar ratio of 1:2:10:10, specifically: barium carbonate is 6.3032g, titanium dioxide is 5.1020g, sodium chloride is 18.6711g, potassium chloride is 23.8131g;

[0070] 2). Manually grind the mixture in step 1) for 30 minutes;

[0071] 3) Put the powder obtained in step 2) in a corundum crucible, and keep it in a muffle furnace at 875° C. for 5 hours;

[0072] 4) After the product of step 3) was cooled with the furnace, it was washed with deionized water several times, collected by centrifugation, and washed with 0.1mol / L AgNO 3 The solution was detected until Cl could not be found - ions, dried in an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com